I & II sem IC - Sahyadri Science College

advertisement

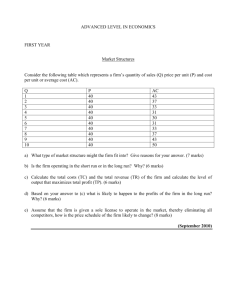

KUVEMPU UNIVERSITY DEPARTMENT OF INDUSTRIAL CHEMISTRY SAHYADRI SCIENCE COLLEGE (AUTONOMUS) SHIMOGA – 577 451 I SEMESTER B.SC COURSE DRAFT SYLLABUS -2013 Hr/week:4 hr Total Hours: 60 INDUSTRIAL ASPECTS OF ORGANIC CHEMISTRY IC.101: Nomenclature, Generic names, Trade names - No. of hours: 20 3 hr (4 marks weightage) IC.102: Raw materials for organic compounds, petroleum, natural gas, fractionation of crude oil, cracking, reforming, hydro forming, isomerisation. – 5 hr (6.5 marks weightage) IC.103: Fuels: types, definition, calorific value(GCV-NCV).Determination of CV(Bomb colorimeter).Coal types, structure, properties, distillation of coal tar.- 5hr (6.5 marks weigtage) IC.104: Renewable natural resources. Cellulose, starch, properties, modifications, important industrial chemicals derived from them. Achohol and alcohol based chemicals, oxalic acid, and furfural. - 7hr ( 9 marks weigtage) BOOKS: 1. Coal convertion,E J Hoffimann. 2. Introduction to petroleum chemicals, H. Steiner, Pengamon Press. 3. From agrocarbons to petrochemicals, L.F. Hatch and S. Matram, Gulf publishing Co., Houston 4. Cotton-Cellulose: Its chemistry and tehnology, Hall.H.G 5. Methods of carbohydrate chemistry, Vol.3 Cellulose, whister.R.L. 6. Chemistry of cellulose Heuser E. 7. Chemistry and industry of starch Kerr.R. W. 8. Modified starches: Properties and uses, Wurzburg.O. INDUSTRIAL ASPECTS OF INORGANIC CHEMISTRY No. of hours: 20 IC.105: Basic metallurgical operations- Pulverisation, Calcination, Rosting and Refining. - 5 hr (6.5 marks weigtage) IC.106: Physcio-chemical principles of extraction of copper, lead, silver, zinc, chromium and Magnessium..-10hr ( 13 marks weigtage) IC.107: Inorganic materials of industrial importance: Their availability, forms, structures and modification, silica, siliates, clays, mica and zeolites. -5hr (6.5 marks weigtage) BOOKS: 1. Principles of extractive metarllurgy, Herbasha, Vol. 1,2 2. Theory of metallurgical process, 3. Text book of metallurgy Baiky A. R. 4. Clays, H. Ries, John Willeys and sons 5. Theory of metarllurgial process, Fillipov, Mir publications 6. Unit process of extractive metallurgy, Pehlke, Elsevier publications. 7. Industrial Chemistry, Riegel, Reinhold publications. INDUSTRIAL ASPECTS OF PHYSICAL CHEMISTRY No. of hours : 20 IC.108: Surface chemistry and interfacial phenomenon: Adsorption, isotherm, sols, gels, emulsions, micelles, aerosols, effect of surfactants, hydrotropes.- 8hr (10.5 marks weigtage) IC.109: Catalysis: Introduction, types homogeneous and heterogeneous, basic principles, mechanisms, factors affecting the performance, introduction to phase transfer catalysis, enzyme catalysed reactions-rate model, industrially important catalytic reactions.- 12 hr (15.5 marks weightage) BOOKS 1. Aerosol Science and Technology, Shepherd,H.R. 2. Catalysis: Heterogeneous and homogeneous, Delmon.B. Janner.G. 3. Catalysis: Science and Technology, Anderson.J. 4. Catalysis in micellar and macromolecular systems, Fendler.J. Fendler.E 5. Catalysis in theory and practice, Rideal.E.K and Taylor H.S. 6. Phase transfer catalysis, Principles and Tehniques Starles.C. 7. Surface Chemistry, J.J Bikermann, Academis press. 8. Physical Chemistry of Surfaces, A. W. Adamson 9. Catalysis: Heterogeneous. Delmon Elsevier Science Publisher. Scheme for practicals Practical: 20 marks Viva: 5 marks Record: 5 marks PRATICALS: 1. Estimation of sodium hydroxide using hydrochloric acid 2. Estimation of Mohr’s salt using Potassium permanganate 3. Estimation of Mohr’s salt using Potassium dichromate 4. Estimation of Ceric ammonium sulphate using Mohr’s salt solution 5. Determination of sodium hydroxide and sodium bicarbonate together using hydrochloric acid 6. Estimation of ammonia 7. Standardization of EDTA using magnesium sulphate solution 8. Analysis of sodium nitrite 9. Estimation of sulphuric acid using potassium biphthalate 10. Estimation of copper by iodometric method KUVEMPU UNIVERSITY DEPARTMENT OF INDUSTRIAL CHEMISTRY SAHYADRI SCIENCE COLLEGE (AUTONOMUS), SHIMOGA – 577 451 II SEMESTER B.SC COURSE DRAFT SYLLABUS -2013 Hr/week: 4hr 1. OILS FATS WAXES AND SOAPS Total Hours: 60 10 Hours( 13 marks weightage ) Distinction between oils and fats, properties, classification. Vegetables oils, manufature of cotton seed oil by expression and solvent extraction. Manufacture of soyabean by solvent extraction. Refining of crude vegetable oils. Animal oils and fats, their processing, Mineral oils. Differences between vegetable, animal and mineral oils. Essential oil isolation. Analysis of oils and waxes: saponification value, iodine value, acid value,Wijis method. Hydrogenation of oil. Manufacture of candles. Soap and its manufacture, toilet and transparent soaps and other special soaps. Oils to be used for soaps. Cleansing action of soap and recovery of glycerin. 2. DETERGENTS 4 Hours( 5 marks weightage) Classification of surface active agents, Synthetic detergents: Anionic, Cationic, Non-ionic and amphoteric detergents. Bio-degradability of detergents, Builders and additives in detergents formulation, Manufacture of shampoos 3. NANOTECHNOLOGY 6 Hours( 8 marks weightage) Introduction, Size and surface area, size dependent properties, geometric and electronic structure, stability, synthesies-up-down(laser ablation) and bottom up approach(metal ion reduction) carbon based nanoparticle and applications (fullerens, carbon nanotubes and graphene) 4. PULP AND PAPER TECHNOLOGY 6 Hours( 8 marks weightage) Methods of production of pulp-Kraft process, Soft and sulfite process, beating, sizing, coloring, Manufacture of paper, paper and paper products. Paper industries in India. 5. ADHESIVES 4 Hours (5 marks weigtage) Process of bonding, classification: solvent responsive, heat sealing, pressuresensitive, chemically reactive adhesives. Preparation of adhesives. Animal glue-uses other Protein adhesives, starch adhesives, Synthetic resin adhesives, Rubber based, cellulose and silicate adhesives uses. 6. EXPLOSIVES 6 Hours (8 marks weightage) Classification, characteristics, Deflagrating or low explosives, Nitrocellulose, PETN, Dinitrobenzene (DNB), TNB, Trinitrotoluene (TNT), Picric acid, Ammonium picrate, Nitroglycerine and dynamite, Gun powder, RDX or cyclonite, Tetryl. Toxic chemical weapons, screening smokes, incendiaries. Pyrotechniques,Explosives Industries in India. 7. ALLOYS 10 Hours( 13 marks weightage) Purpose of making alloys Types of alloys. Ferrous alloys, special steels, light alloys, cast alloys, non-ferrous alloys. Alloys of Nickel, Ni-Fe, Ni-Cr, Lead and super alloys, bearing alloys,heat treatment of alloys.Manufacture of alloys(powder metallurgy) 8. COROSSION 8 Hours(10.5 marks weightage) Economics aspects, types, Dry and wet corrosion, Chemical corrosion-factors affecting theories of wet corrosion. Galvanic corrosion, Atmospheric corrosion, soil corrosion, dezincification corrosion agents, Prevention of corrosion: based on treatment of metals, medium and external influence. 9. MECHANICAL PROPERTIES OF METALS 3 Hours( 4 mrks weightage) Introduction, elasticity, plasticity, toughness, resilience, tensile and impact strength, ductility, malleability, brightness, creep, fatigue and wear resistance. Factors affecting mechanical properties, High temperature and low temperature effects 10. COMPOSITE MATERIALS 3 Hours(4 marks weightage) Introduction Classification-Particle reinforced composites. Fibre reinforced composites, Structural composites. BOOKS. 1. 2. 3. 4. 5. 6. 7. 8. 9. Industrial Chemistry by B.K Sharma Test book of Chemical Enginerring by Koria Cose and Raja Ram Text book of Chemical Technology by Anand Rao Industrial Chemistry by S.S.Dara Surface Chemistry, J.J Bikermann, Academis press. Physical Chemistry of Surfaces, A. W. Adamson Principles of extractive metallurgy, Herbasha, Vol. 1,2 Unit process of extractive metallurgy, Pehlke, Elsevier publications Introduction to nanotechnology by Scheme for practicals Practical: 20 marks Viva: 5 marks Record: 5 marks PRACTICALS 1. Determination of saponification value of oil 2. Determination of acid value of acid 3. Determination of iodine value of oil 4. Determination of ester value of oil 5. Determination of density of an oil 6. Determination of viscosity of oil 7. Determination of surface tension of oil 8. Calibration of thermometer 9. Partition coefficient of iodine between water and carbon tetrachloride 10. Partition coefficient of benzoic acid 11. Manufacture of soap. 12. descaling of rust. THIRD SEMESTER (60 Hours) Nitration: Introduction, nitrating agents, kinetics and mechanism of nitration process such as nitration of i) ii) iii) iv) v) Paraffinic hydrocarbons Benzene to nitrobenzene and m-dinitrobenzene Chlorobenzene to o- and p-nitrochlorobenzene Acetanilide to p-nitro acetanilide Toluene Continuous V/S batch nitration. Halogenations: Introduction, kinetics of halogenations reaction, reagents for halogenations, halogenations of aromatic side chain and nuclear halogenations, commercial manufacture of chlorobenzens, chloral, monochloroacetic acid and chloromethane, dichlorofluromethanes. Sulphonation: Introduction, sulphonating agents, chemical and physical factors in sulphonation. Kinetics and mechanism of sulphonation reaction. Commercial sulphonation benzene, naphthalene, alkyl benzene. Batch V/S continuous sulphonation. Oxidation: Introduction, types of oxidation reaction, oxidizing agents, kinetics and mechanism of oxidation of organic compounds. Liquid phase oxidation, vapor phase oxidation, commercial manufacture of benzoic acid, maleic anhydride, phthalic anhydride, acrolein, acetaldehyde, acetic acid. Hydrogenation: Introduction, kinetics and mechanism of hydrogenation reactions. Hydrogen ation of vegetable oils, manufacture of methanol from carbon monoxide and hydrogen, hydrogenation of acids and esters to alcohol, catalytic reforming. Alkylation: Introduction, types of alkylation, alkylating agents, thermodynamic and mechanism of alkylation reaction, manufacture of alkyl benzenes (for detergent manufacture) , ethyl benzene, phenyl ethyl alcohol, N-alkyl anilines(mono and dimethyl and ethyl anilines). Esterification: Introduction, hydrodynamics and kinetics of esterification reaction. Esterification by organic acids by addition of unsaturated compounds, esterification of carboxy acid derivatives, commercial manufacture of ethyl acetate, dioctyl phthalate, vinyl acetate, cellulose acetate. Process instrumentation: Concept of measurement and accuracy Principles, construction and working of following measuring instruments, Temperature: glass thermometer, bimetallic thermometer, pressure spring thermometer, vapor filled thermometer, resistant thermometer, radiation pyrometer. Pressure: manometers, barometers, bourdon pressure gauge, LVDT, dead weight piston gauge. Direct Liquid level measurement: point contact method, bob and tape method, hook gauge method, buoyancy method, float and tape gauge. Indirect liquid level measurement: radiation method, hydrostatic method, ultrasonic level gauges, bubbler method. References: 1) Unit processes in organic synthesis, P.H.Groggins, McGraw-hill book Co. New York. 2) Process instrumentation and control, A.P.Kulkarni. 3) Industrial instrument, D.P.Eckman, John-wileys and sons. 4) Applied instrumentation in process industries, Vol. I, II and III W.G. Andrews, Gulf publications. 5) Instrumentation and control for the process industries. S.Barer, Elsevier, Applied science publishers. 6) Chemical Engineers hand book. J.H.Perry and D.Greenb. McGraw-Hill publishing Co. New York. 7) Principles of process controls. Patranabis, McGraw-Hill publishing Co. New York. 8) Process control. Harriot. McGraw-Hill publishing Co. New York. 9) Chemical reaction engineering. Mrs. Joshi. 10) Introduction to chemical engineering, Ghosal. Practicals: 1) 2) 3) 4) 5) 6) 7) 8) Determination of hardness Determination of acidity Determination of alkalinity Determination of dissolved oxygen Determination of BOD Determination of COD Determination of PH Determination of iron by colorimetry 9) Determination of free chlorine. FOURTH SEMESTER (60 Hours) STIOCHIOMETRY AND UNIT OPERATION Dimensions and units: Basic chemical calculations, atomic weight, molecular weight, mole fraction, method of expressing the composition of gas mixture. Material balance without chemical reaction: Flow diagram for material balance, simple material balance with or without recycle or by-pass for chemical engineering operation such as distillation, absorption, crystallization, evaporation, extraction etc. Material balance involving chemical reaction: Concept of limiting reagent conversion yield liquid phase reaction, gas phase reaction, with or without recycle or by-pass. Distillation: Introduction, batch and continuous distillation plate columns and packed columns. Absorption: Introduction, equipment packed columns, spray columns, bubble columns, packed bubble column, mechanically agitated contractors. Evaporation: Introduction, equipments, short tube evaporator, forced circulation evaporator, falling film evaporators, climbing(upper) film evaporators, wiped (agitated) film evaporator. Filtration: Introduction, filter media and fitter aides, equipments plate and frame filters, press nutch filter, rotary drum filter, sparkler filter, candle filter, back filter, centrifuge. Drying: Introduction, free moisture, bound moisture, drying curve, equipments, tray drier, rotary drier, flash drier, fluid bed drier, spray drier. Crystallization: Introduction, solubility, super saturation, nucleation crystal growth, equipment, tank crystallizer, agitated crystallizer, evaporator crystallizer. Heat transfer: Heat exchangers, shell and tube type, fined tube heat exchangers, plate heat exchangers, refrigeration cycles. Extraction: Introduction, selection of solvent, equipments, spray column, packed column, rotating dick column, mixer-settler, triangular diagram. Mixing: Introduction, mixing of liquid-liquid, solid-solid, and liquid-solid systems. References: 1. Introduction to chemical engineering W. L. badger and J. T. BancheroMcGrawHill Book Co. New York. 2. Unit operation chemical engineering W. L. McCabe and J. C. Smith McGraw-Hill Book Co. New York. 3. Chemical engineering Hand Book J. H. Perry, McGraw-Hill Book Co. New York. 4. Unit operation and II Kale. Pune Vidyarathi Griha Prakashan, pune. 5. Standard Hand book of plant engineering Editors: R. C. Rosaler and J. O. Rice McGraw –Hill Co. New York. 6. Introduction to stoichiometry, K. A. Gavhane. 7. Fundamentals of stoichimetry, Bhat & Vora. 8. Unit operations K. A. Gavhane. 9. Unit operations Majudar & Dixit. Practicals: 13. Preparation of p-Nitoacetanilide 14. Preparation of p-Bromoacetanilide 15. Preparation of phenylazo-β-Naphthol 16. Preparation of Diazoaminobenzene 17. Preparation of sulphanilic acid 18. Estimation of ascorbic acid 19. Estimation of hydrogen peroxide 20. Estimation of saponification value of oil 21. Estimation of acid value of acid 22. Estimation of iodine value of oil.