File

Burgoyne Hughes

“(E)-Bromeneation”: Bromination of (E)-Stilbene

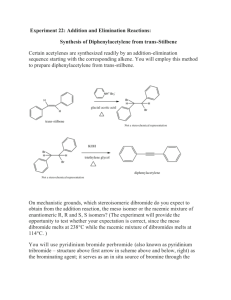

The goal of this experiment is to carry out the bromination of (E)-stilbene while demonstrating the stereospecific nature of adding bromine to alkenes. Observing this reaction will demonstrate a stereospecific reaction as only one possible diastereomer, mesostilbene dibromide, will be formed as a product. This is an important concept as stereochemistry has a large impact on chemical properties of a molecule. For this reason a specific reaction must be chosen to acquire the appropriate product. Using this reaction guarantees the formation of the target structure of the product, which will assure it has the appropriate chemical properties for later experiments. This is a two stage reaction. The first step forms an intermediate cyclic bromonium ion. The second stage involves a nucleophilic bromide ion attacking the intermediate bromonium ion. Due to the path taken by the bromide ion, the carbon atom being attacked will undergo an inversion of its stereochemistry. This aspect of the reaction is what causes the stereospecific nature of the process. See the attached sheet to see this reaction drawn out. The product will be tested in two ways, one will be a chemical test to assure the presence of bromine, and the other will be a melting point test. The chemical test will prove there is bromine present in the product which would show the bromination was successful, while a melting point will be taken to assure that the correct diastereomer was formed. The target product, meso -stilbene dibromide has a melting point of ~241̊C, while another diastereomer of stilbene bromide has a melting point of ~110̊C.

Procedure

1.

300mg (E)-stilbene was combined with 6mL acetic acid in a 10mL round-bottom flask equipped with a water condenser.

2.

The mixture was heated and stirred in a sand bath until most of the solid dissolved.

3.

The flask was removed from the sand bath to add 600mg pyridinium bromide perbromide.

4.

A small dab of greases was added to the joint of the flask and condenser to prevent sticking or fusing.

5.

The mixture was placed in the sand bath and the water condenser was set up. The mixture was then boiled for 15 minutes.

6.

After 15 minutes the flask was removed from the sand bath. The flask was placed in a beaker for approximately 2 minutes to cool; the flask was then placed in an ice bath for about 5 minutes.

7.

6mL of water was added to the mixture before returning it to the ice bath for about 5 minutes.

8.

The mixture was filtered with a large syringe vacuum and rinsed with cold water and acetone. Once a solid was recovered the filter paper was left to dry in a drawer for a week.

9.

A mass of the dry solid was acquired.

10.

To create a test for the presence of alkyl bromides 5 drops of ethanolic silver nitrate was added to about 2mg of product in a test tube.

11.

About 1mL of 95% ethanol was added to the test solution.

12.

The solution was boiled in a sand bath for about 5 minutes.

13.

The mixture was removed from the sand bath and observed. A precipitate gray in color under light was observed, confirming the presence of alkyl bromides.

14.

The melting point range of the product was taken.

Mass of Product (g) Percent Yield

Results

Melting Point Range

(̊C)

228-234

Actual Melting Point

Range (̊C)

241-243 .423 74.7%

Theoretical Yield

300𝑚𝑔 (𝐸) − 𝑠𝑡𝑖𝑙𝑏𝑒𝑛𝑒 ∗

1 𝑚𝑚𝑜𝑙 (𝐸) − 𝑠𝑡𝑖𝑙𝑏𝑒𝑛𝑒

∗

180.25𝑚𝑔

1𝑚𝑚𝑜𝑙 𝑠𝑡𝑖𝑙𝑏𝑒𝑛𝑒 𝑑𝑖𝑏𝑟𝑜𝑚𝑖𝑑𝑒

1𝑚𝑚𝑜𝑙 (𝐸) − 𝑠𝑡𝑖𝑙𝑏𝑒𝑛𝑒

340.05𝑚𝑔

∗

1 𝑚𝑚𝑜𝑙 𝑠𝑡𝑖𝑙𝑏𝑒𝑛𝑒 𝑑𝑖𝑏𝑟𝑜𝑚𝑖𝑑𝑒

= 566𝑚𝑔

Percent Yield

423𝑚𝑔 𝑠𝑡𝑖𝑙𝑏𝑒𝑛𝑒 𝑑𝑖𝑏𝑟𝑜𝑚𝑖𝑑𝑒 𝑟𝑒𝑐𝑜𝑣𝑒𝑟𝑒𝑑

566𝑚𝑔 𝑠𝑡𝑖𝑙𝑙𝑏𝑒𝑛𝑒 𝑑𝑖𝑏𝑟𝑜𝑚𝑖𝑑𝑒 𝑡ℎ𝑒𝑜𝑟𝑒𝑡𝑖𝑐𝑎𝑙

= .747 = 74.7% 𝑌𝑖𝑒𝑙𝑑

(E)-stilbene is a white solid with large grains with an appearance similar to sugar.

Pyridinium bromide perbromide is a solid with bright orange-red flakes. When the mixture of these two solids was boiled it boiled bright orange in color. The final product after filtration, mesostilbene dibromide, is a soft white powder. The chemical test to identify the presence of alkyl bromides positively identified alkyl bromides in the product. The melting point range taken, though flawed, further confirms the identity of the product as mesodibromide.

Discussion

Based on the data acquired from the alkyl bromide test and the melting point range measurement it can safely be said that the product acquired was mesostilbene dibromide. The silver nitrate test confirmed the presence of alkyl bromides, meaning the product that was produced contained bromine-carbon bonds. This does not explicitly state what product was recovered but it does

confirm that the bromination aspect of the experiment was successful and bromine was allowed to react with carbon. Knowing that the product is at the very least, structurally similar to the target, the melting point can be tested to narrow down exactly what product was recovered. The melting point was similar to literature values of mesostilbene dibromide, proving that the target product was produced. The meso compound is formed when the chiral centers on the stilbene dibromide molecule are opposed, as in one center is S while the other is R. When the chiral centers are aligned in this way a plane of symmetry is created for the molecule. If the reaction mechanism was changed slightly so that a stilbene dibromide was formed in which the chiral centers were both R or S the molecule would no longer have symmetry and would become chiral and have different chemical properties. Looking at the structure of mesostilbene dibromide, it should be noted that the bromine atoms are trans to one another, thus the reaction mechanism must be carried out in such a way that the bromine atoms become trans to one another during the reaction. This happens when bromide ion attacks either carbon in the intermediate bromodium ion from the bottom, or on the opposite side of the bromine in the brominium ion. See the attached sheet for a drawing of this mechanism.

The theoretical yield of the reaction was about 566mg, while 423mg was recovered for a percent yield of 74.7%. This percent yield shows a very large amount of solid was recovered, meaning that the procedure was carried out properly and few mistakes were made. A possible mistake that was made during the procedure that could have caused some product to be lost was the water and acetone used to rinse the product during filtration were not very cold at all by the time they were added as the ice bath they were placed in had nearly melted away quite a while before they were used. This could have possibly not dropped the temperature enough to cause precipitation of the product, meaning small traces of solid could have stayed dissolved, easily

slipping through even the smallest tear in the filter paper. When comparing percent yield to others in the lab, mine was slightly higher than those whom I spoke with. However, the next measure of accuracy, melting point range, did not give quite as favorable results and was lower than that of anyone I spoke with. The experimental melting point range recorded was 228-234̊C.

This is rather far below the literature value of 241-243̊C, meaning impurities must have been present. There are quite a few ways that impurities could have entered the product. The main instance at which this could have occurred was during the drying process. While the product was drying in the drawer, it was simply folded in a piece of weigh paper in a makeshift envelope.

This is far from an airtight seal and could have allowed any sort of airborne contaminant to enter the product. These small issues however were essentially the only problems faced during the procedure as everything went extremely well. This lab runs very smoothly, however there are a few changes that may help in the future. The silver nitrate test feels unnecessary and almost by itself turns the lab into a two week lab. Without the silver nitrate test the product could dry for a few days and the mass and melting point could be recorded on the students’ own time, allowing an open week for another lab. The silver nitrate tests’ purpose is clear but its scope is too simple as it would be rather difficult to fail to create an alkyl bromide in the first section of the procedure. Another small suggestion is to acquire a better system for filtration as the large syringe vacuum system is slow and prone to error as creating too much suction can tear the filter paper by ripping solid through it with the vacuum force.

Works Cited

Mayo, D., & Pike, R. (n.d.). Microscale organic laboratory: With multistep and multiscale syntheses (Sixth ed., pp. 452-456).