Split plot designs

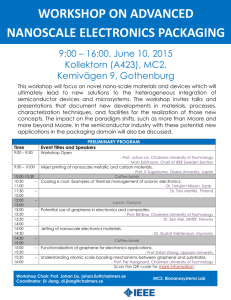

advertisement

Chalmers University of Technology Split-plot designs Martin Arvidsson Chalmers University of Technology Improvement work performed at Cochlear BAS Chalmers University of Technology Two important inventions contribute to the successfulness of the hearing aid device The titanium implant The vibrator Chalmers University of Technology A simple test performed at Cochlear BAS to evaluate a new supplier of components • The objective of the test was to evaluate whether washers from a new supplier could be used • Altogether 120 vibrators where produced, 60 with washers ordinary used and 60 with washers from a new potential supplier • The order in which the 120 vibrators was produced was randomised Chalmers University of Technology Details of the improvement work The objective of the project is to improve the production yield of the vibrators • The vibrator is made up by a rather large number of components • The assembly process of vibrators include a rather large number of operations • The assembly process requires that measurement equipment work satisfactory Chalmers University of Technology Individual value plot Individual Value Plot 1200 1100 1000 900 800 700 Ordinary used Washer from new supplier Type of washer Chalmers University of Technology Individual value plot – two outliers removed Individual Value Plot 800 790 780 770 760 750 740 Ordinary used Washer from new supplier Type of washer Chalmers University of Technology Time series plot to investigate whether the process was stable during the test Time Series Plot 800 790 780 770 760 750 740 1 12 24 36 48 60 Index 72 84 96 108 Chalmers University of Technology Histogram of the”populations” Histogram Normal Ty pe of washer Ordinary used Washer from new supplier 0,04 Mean StDev N 760,1 9,643 59 769,9 11,82 59 Density 0,03 0,02 0,01 0,00 740 750 760 770 780 790 Chalmers University of Technology Complete randomisation • Randomisation of run order • Resetting of all factor levels between each experiment Chalmers University of Technology Randomizing • Problem: Systematic dependence between the experiments. • Solution: Make the experiments in random order Exp. A B C Y order. nr 8 1 - - - 53.8 5 2 + - - 51.8 1 3 - + - 47.4 2 4 + + - 47.8 4 5 - - + 50.6 7 6 + - + 51.8 6 7 - + + 48.2 3 8 + + + 48.6 Chalmers University of Technology Resetting of factor levels Exp. 1 2 3 4 5 6 7 8 A + + + + 8 contrasts i 1 4 i B + + + + C + + + + y 53.8 51.8 47.4 47.8 50.6 51.8 48.2 48.6 ε εA1+εB1+εC1+ε1 εA2+εB2+εC2+ε2 εA3+εB3+εC3+ε3 εA4+εB4+εC4+ε4 εA5+εB5+εC5+ε5 εA6+εB6+εC6+ε6 εA7+εB7+εC7+ε7 εA8+εB8+εC8+ε8 8 i 2 i 1 Var (contrasts) Var 4 2 Chalmers University of Technology Exp. 1 2 3 4 5 6 7 8 A + + + + 8 contrast A 8 contrastC i 1 i 1 Ai B + + + + C + + + + y 53.8 51.8 47.4 47.8 50.6 51.8 48.2 48.6 Bi i 4 2 Ai Bi i 4 Cj j 1 4 ε εA1+εB1+εC1+ε1 εA2+εB2+εC1+ε2 εA3+εB3+εC1+ε3 εA4+εB4+εC1+ε4 εA5+εB5+εC2+ε5 εA6+εB6+εC2+ε6 εA7+εB7+εC2+ε7 εA8+εB8+εC2+ε8 Responses are not independent! Var contrast A A2 B2 2 2 A2 B2 2 Varcontrast C 2 C2 2 If factors are not reset between each experiment, contrasts will have unequal variance! Chalmers University of Technology Split-plot designs: A Composite Material Example Manufacturing process of composite material y – bending strength response variable A – curing temperature B – pressure C – holding time control factors (process variables) D – proportion of hardener E – thermo-plastic content F – proportion of epoxy G – material ageing H – process type • • noise factors Four different process conditions Eight batches of raw material ? y = f (A,B,C,D,E,F,G,H) Chalmers University of Technology Experimental design Product D E F G H Process variables (control factors) A Curing temperature B Pressure C Holding time Incoming material (noise factors) D E F G H Proportion of hardener Thermo-plastic content Proportion of epoxy Material aging Type of process Process A B C -1 1 -1 1 -1 -1 1 1 1 -1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 -1 1 -1 -1 1 -1 1 1 -1 1 2075 2117 2221 2227 2201 2179 1988 1858 1829 1978 2111 2205 2127 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 -1 -1 1 -1 1 1 -1 1 -1 -1 1 -1 1 1 -1 1 -1 -1 1 2106 1870 1879 2245 2242 2245 2258 2206 2207 2053 2188 2219 2145 2174 2265 2241 2187 2208 2181 Chalmers University of Technology Confounding pattern 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 I A B D E F AB AD AE AF BD BE BF DE DF EF ABD ABE ABF ADE ADF AEF BDE BDF BEF DEF ABDE ABDF ABEF ADEF BDEF ABDEF EFG AEFG BEFG DEFG FG EG ABEFG ADEFG AFG AEG BDEFG BFG BEG DFG DEG G ABDEFG ABFG ABEG ADFG ADEG AG BDFG BDEG BG DG ABDFG ABDEG ABG ADG BDG ABDG DEFH ADEFH BDEFH EFH DFH DEH ABDEFH AEFH ADFH ADEH BEFH BDFH BDEH FH EH DH ABEFH ABDFH ABDEH AFH AEH ADH BFH BEH BDH H ABFH ABEH ABDH AH BH ABH ABC BC AC ABCD ABCE ABCF C BCD BCE BCF ACD ACE ACF ABCDE ABCDF ABCEF CD CE CF BCDE BCDF BCEF ACDE ACDF ACEF ABCDEF CDE CDF CEF BCDEF ACDEF CDEF ABCEFG BCEFG ACEFG ABCDEFG ABCFG ABCEG CEFG BCDEFG BCFG BCEG ACDEFG ACFG ACEG ABCDFG ABCDEG ABCG CDEFG CFG CEG BCDFG BCDEG BCG ACDFG ACDEG ACG ABCDG CDFG CDEG CG BCDG ACDG CDG ABCDEFH BCDEFH ACDEFH ABCEFH ABCDFH ABCDEH CDEFH BCEFH BCDFH BCDEH ACEFH ACDFH ACDEH ABCFH ABCEH ABCDH CEFH CDFH CDEH BCFH BCEH BCDH ACFH ACEH ACDH ABCH CFH CEH CDH BCH ACH CH ABCDGH BCDGH ACDGH ABCGH ABCDEGH ABCDFGH CDGH BCGH BCDEGH BCDFGH ACGH ACDEGH ACDFGH ABCEGH ABCFGH ABCDEFGH CGH CDEGH CDFGH BCEGH BCFGH BCDEFGH ACEGH ACFGH ACDEFGH ABCEFGH CEGH CFGH CDEFGH BCEFGH ACEFGH CEFGH DGH ADGH BDGH GH DEGH DFGH ABDGH AGH ADEGH ADFGH BGH BDEGH BDGH EGH FGH DEFGH ABGH ABDEGH ABDFGH AEGH AFGH ADEFGH BEGH BFGH BDEFGH EFGH ABEGH ABFGH ABDEFGH AEFGH BEFGH ABFEGH Chalmers University of Technology 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 I A B D E F AB AD AE AF BD BE BF DE DF EF ABD ABE ABF ADE ADF AEF BDE BDF BEF DEF ABDE ABDF ABEF ADEF BDEF ABDEF -49,0625 143,3125 46,0625 13,0625 -23,3125 -54,8125 -130,313 -0,4375 10,8125 -26,6875 7,8125 30,9375 38,9375 -2,8125 8,3125 14,5625 -34,0625 -6,9375 4,8125 10,0625 -17,4375 -8,0625 31,9375 30,1875 92,5625 -4,8125 -10,5625 17,3125 -6,1875 -2,0625 -25,8125 Contrasts! Chalmers University of Technology Analysis of the experiment 3 B 2 BG 1 0 -150 -100 -50 0 50 -1 G -2 -3 contrasts 100 150 200 Chalmers University of Technology Confounding pattern 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 I A B D E F AB AD AE AF BD BE BF DE DF EF ABD ABE ABF ADE ADF AEF BDE BDF BEF DEF ABDE ABDF ABEF ADEF BDEF ABDEF EFG AEFG BEFG DEFG FG EG ABEFG ADEFG AFG AEG BDEFG BFG BEG DFG DEG G ABDEFG ABFG ABEG ADFG ADEG AG BDFG BDEG BG DG ABDFG ABDEG ABG ADG BDG ABDG DEFH ADEFH BDEFH EFH DFH DEH ABDEFH AEFH ADFH ADEH BEFH BDFH BDEH FH EH DH ABEFH ABDFH ABDEH AFH AEH ADH BFH BEH BDH H ABFH ABEH ABDH AH BH ABH ABC BC AC ABCD ABCE ABCF C BCD BCE BCF ACD ACE ACF ABCDE ABCDF ABCEF CD CE CF BCDE BCDF BCEF ACDE ACDF ACEF ABCDEF CDE CDF CEF BCDEF ACDEF CDEF ABCEFG BCEFG ACEFG ABCDEFG ABCFG ABCEG CEFG BCDEFG BCFG BCEG ACDEFG ACFG ACEG ABCDFG ABCDEG ABCG CDEFG CFG CEG BCDFG BCDEG BCG ACDFG ACDEG ACG ABCDG CDFG CDEG CG BCDG ACDG CDG ABCDEFH BCDEFH ACDEFH ABCEFH ABCDFH ABCDEH CDEFH BCEFH BCDFH BCDEH ACEFH ACDFH ACDEH ABCFH ABCEH ABCDH CEFH CDFH CDEH BCFH BCEH BCDH ACFH ACEH ACDH ABCH CFH CEH CDH BCH ACH CH ABCDGH BCDGH ACDGH ABCGH ABCDEGH ABCDFGH CDGH BCGH BCDEGH BCDFGH ACGH ACDEGH ACDFGH ABCEGH ABCFGH ABCDEFGH CGH CDEGH CDFGH BCEGH BCFGH BCDEFGH ACEGH ACFGH ACDEFGH ABCEFGH CEGH CFGH CDEFGH BCEFGH ACEFGH CEFGH DGH ADGH BDGH GH DEGH DFGH ABDGH AGH ADEGH ADFGH BGH BDEGH BDGH EGH FGH DEFGH ABGH ABDEGH ABDFGH AEGH AFGH ADEFGH BEGH BFGH BDEFGH EFGH ABEGH ABFGH ABDEFGH AEFGH BEFGH ABFEGH Chalmers University of Technology Error structure of a Strip-Block Experiment D E F G H A B C -1 1 -1 1 -1 -1 1 1 1 -1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 -1 1 -1 -1 1 -1 1 1 -1 1 2075 2117 2221 2227 2201 2179 1988 1858 1829 1978 2111 2205 2127 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 -1 -1 1 -1 1 1 -1 1 -1 -1 1 -1 1 1 -1 1 -1 -1 1 2106 1870 1879 2245 2242 2245 2258 2206 2207 2053 2188 2219 2145 2174 2265 2241 2187 2208 2181 εs1 εs εw ε ε1 εw1 εs2 εw2 εw3 εw4 ε32 Chalmers University of Technology A -1 -1 -1 -1 -1 -1 -1 -1 1 1 1 1 1 1 1 1 -1 -1 -1 -1 -1 -1 -1 -1 1 1 1 1 1 1 1 1 B -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 D -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 AD 1 -1 1 -1 1 -1 1 -1 -1 1 -1 1 -1 1 -1 1 1 -1 1 -1 1 -1 1 -1 -1 1 -1 1 -1 1 -1 1 error εw1+ εs1+ ε1 εw1+ εs2+ ε2 εw1+ εs3+ ε3 εw1+ εs4+ ε4 εw1+ εs5+ ε5 εw1+ εs6+ ε6 εw1+ εs7+ ε7 εw1+ εs8+ ε8 εw2+ εs1+ ε9 εw2+ εs2+ ε10 εw2+ εs3+ ε11 εw2+ εs4+ ε12 εw2+ εs5+ ε13 εw2+ εs6+ ε14 εw2+ εs7+ ε15 εw2+ εs8+ ε16 εw3+ εs1+ ε17 εw3+ εs2+ ε18 εw3+ εs3+ ε19 εw3+ εs4+ ε20 εw3+ εs5+ ε21 εw3+ εs6+ ε22 εw3+ εs7+ ε23 εw3+ εs8+ ε24 εw4+ εs1+ ε25 εw4+ εs2+ ε26 εw4+ εs3+ ε27 εw4+ εs4+ ε28 εw4+ εs5+ ε29 εw4+ εs6+ ε30 εw4+ εs7+ ε31 εw4+ εs8+ ε32 Chalmers University of Technology Variances of the contrasts contrasts process materialinteractions 1 32 i 16 i 1 4 1 32 contrasts process factors i 8 wi 16 j 1 i 1 8 1 32 contrastsmaterial factors i 4 si 16 j 1 i 1 1 Var contrasts process materialinteractions 2 8 1 Var contrasts process factors w2 2 8 1 1 Var contrastsmaterial factors s2 2 2 8 Chalmers University of Technology Identification of location effects 2 2 B Standard deviation 1 -1 5 0 0 -1 0 0 -5 0 0 50 -1 -2 100 150 3 2 1 0 -1 5 0 -1 0 0 -5 0 0 50 100 150 -1 G Standard deviation 3 Standard deviation 3 -1 5 0 BG 1 0 -1 0 0 -5 0 0 50 100 150 1 -2 2 -3 3 -3 Contrasts Process factors Contrasts Factors and interactions associated with incoming material Contrasts Interactions between ”process factors” and ”incoming material factors” •B, G and BG was determined to be active based on engineering knowledge and the normal plots Chalmers University of Technology Model yˆ ( B, G) 2132 72 B 65G 46 BG 2132 72 B 46 B 65 G B ≈ 1.4 Chalmers University of Technology Conclusions • The storage time of the incoming material (G) is causing variation in the bending strength of the composite material. • If the pressure (B) is set at high level the bending strength is made insensitive to the storage time. Chalmers University of Technology Randomisation and split-plot • View randomisation as an insurance against unknown factors - buy as much as you can afford • It is not always advisable to reset all factor levels between each experiment! – Can be very time consuming and expensive – Split-plot designs allow some contrasts of interest to be estimated with great precision. This characteristic can, for example, be useful in robust design experiments