green chem

advertisement

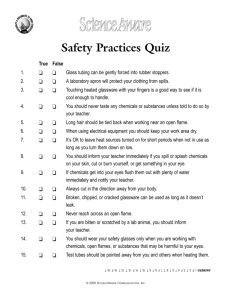

Lecture Topic 6: Safety and Waste Issues Ref: “Introduction to Green Chemistry”, by A. S. Matlock; “Industrial Organic Chemistry”, by K. Weissermel and H.-J. Arpe; “Inorganic Chemistry: An Industrial and Environmental Perspective”, by T. W. Swaddle. Premise: The chemical industry must consider the health and safety of the workers, community and environment. Goal: Students should be able to 1) discuss the concept of “toxicity” and give examples of known toxins 2) give a brief explanation of why accidents occur, using examples 3) define “green chemistry”, with examples 4) discuss waste issues and give examples of current recycling techniques Toxicity of Chemicals in the Environment • The public’s perception of toxicity and risk often differs from that found by scientific testing. • The idea that “natural” is better than “chemical” is overly simplistic. • Many chemicals found in nature are extremely potent biologically. COOH O HO O N CH 3 H O O OH O O HN H N HN O OH O HO O OCH 3 Aflatoxin B1 HN Lysergic Acid OH Tetrodotoxin OH Safrole Toxicity of Chemicals in the Environment The U.S. Congress added the Delaney clause to the Food, Drug and Cosmetic Act in 1958. “No additive shall be deemed to be safe if it is found to induce cancer when ingested by man or animal, or if it is found, after tests which are appropriate for the evaluation of the safety of food additives, to induce cancer in man or animal.” NH 2 O NH 2 N NH S O O Saccharin (o-benzoic sulfimide) H3C N N N N CH 3 N CH 3 N typical heterocyclic amine mutaagens occuring in fried beef and broiled fish Toxicity of Chemicals in the Environment • Chemical safety is an international challenge. • Complete health effects data are available for only about 7% of the chemicals produced in > 106 lb annually. • It is not always easy to determine the relative toxicity of chemicals. • Toxicity can vary with age, gender and species of the animal. • Toxicity can also vary with the manner of application. Toxicity of Chemicals in the Environment •LD50 data on chemicals generally does not determine the longterm effects caused by bioaccumulation. • Populations of animals can also be decimated by chemical effects that do not kill the animals. e.g., Cl Cl Cl Cl Cl DDT dichlorodiphenyltrichloroethane [1,1-bis(4-chlorophenyl)-2,2,2-trichloroethane] • causes eggshell thinning and nesting failure in peregrine falcons, bald eagles, osprey and brown pelicans. Safety in the Workplace Toxic chemicals e.g., HCN average fatal dose for a human: 50-60 mg !! Explosives e.g., ammonium nitrate … used as “34-0-0” fertilizer NH4NO3 gentle heat to 170 C N2O + 2 H2O Flammable Materials e.g., carbon disulfide CS2 NH 4NO 3 N2 + 2 H2O + 1/2O2 >250 C or shock b.p. 46°C flashpoint -33.9°C autoignition 100°C Non-flammable gasses e.g., nitrogen gas or liquid nitrogen Accidents with Chemicals Chemistry is a relatively safe occupation. • In 1996, in the U.S., the nonfatal injury rate for chemical manufacturing was 4.8% for full-time workers….compared to 10.6% for all manufacturing. • There were 34 deaths in the chemical industry, about 5% of those for all manufacturing. However… • About 60, 000 chemical accidents are reported annually in the U.S. • In the past decade, these accidents caused an average of 226 deaths and 2000 injuries. Bhopal, India. Dec.3, 1984 • 40 tons of methyl isocyanate escaped from a pesticide plant into a densely populated area. • 3500 deaths and 150,000 injuries • At the time of the accident, a refrigeration system, a temperature indicator, and a flare tower were not functioning. • According to reviews, the accident … “… was the ultimate outcome of faulty technological design, years of poor management of an unprofitable and highly dangerous facility, years of ignoring an outrageously bad safety record on the part of both the parent company and the Indian government, inadequate education and training of the work force, uncontrolled growth of an industrial population center, a nonexistent emergency response system and the community’s ignorance about the dangers in its midst.” More Accidents with Chemicals • In 1994, failure of a storage tank at Occidental Chemical in Delaware allowed as much as 500 lb of Cl2 to escape. • In 1998, an explosion at a Sierra Chemical explosives plant in Nevada killed 4 and injured 3. The explosion occurred when an operator turned on a mixing pot motor causing detonation of explosives that had solidified on standing overnight. • An explosion and fire at Shell Chemical’s Belpre, Ohio, thermoplastic elastomer plant revealed that… “… roughly 7 times the normal amount of butadiene had inadvertently been added to the reactor. Alarms indicated that the reactor had been overcharged, but interlocks were manually overridden to initiate the transfer of raw materials into the reactor vessel, contrary to established procedures.” Accident Prevention • Engineering steps may be taken to produce a fail-safe system: e.g., additional alarms, interlocks, automatic shut-offs etc. • Written safe operation procedures. • Adequate formal training (NOT informal “on-the-job” training!) • Highly qualified personnel. • The use of less dangerous chemicals! … “green chemistry” What is “green chemistry”? Green Chemistry is the choice to use less toxic materials over more toxic ones and to try to minimize the use of flammable, explosive, or highly reactive materials. NOTE: It is not always easy to figure out which is the least toxic chemical. RECALL: • Long term effects caused by bioaccumulation are difficult to test. • Effects other than toxicity may not be anticipated. O N O NH O O Thalidomide CFCs chlorofluorocarbons Pb(Et)4 tetraethyllead A “Green” Approach: Examples • Nuclear reactor accidents (e.g., Chornobyl) can be avoided by using alternative electrical power generation techniques: ….wind, wave power, geothermal and solar energy • The explosion at a BASF plant in Ludwigshafen, Germany could have been avoided by using nitrogen or carbon dioxide to blow polystyrene instead of pentane. • A hydrogen cyanide leak at a Rohm&Haas plant in Texas sent 32 workers to hospital. HCN was being used in the synthesis of methyl methacrylate. An alternative route, using isobutylene, is known. Catalysis: the “key” to green chemistry It has been suggested that the “key” to reducing the incidence and severity of accidents, waste, toxicity of chemicals, and amount of energy used is the development of more sophisticated catalysts. • enantioselective catalysts - to prepare bioactive optical isomer only • biocatalysts - to run reactions at low temperatures in aqueous media • oxidation with air or H2O2 instead of heavy metal-containing oxidants • solid acids rather than HF or H2SO4 in alkylation reactions A Word on Waste Waste is not waste if it can be reused! Examples: • Calcium sulfate from flue gas desulfurization ends up in dry wall for houses in Denmark and Japan. • DuPont markets a number of intermediates from its manufacturing of fibers. • Rhone-Poulenc-Ruhrchemie uses a water-soluble rhodium phosphine complex to catalyze the hydroformylation of propene to butyraldehyde. In 10 years, 2 x 106 tonnes of butyraldehyde were manufactured with the loss of only 2 kg of rhodium! Recycling Used Plastics: Most proposals for chemical recycling of used plastics are based on synthesis gas recovery (CO / H2) from used plastics by the addition of acid and water. Used PVC: Discarded PVC can be recycled by pyrolysis at 1200°C in a rotary kiln to generate HCl (chlorine recycling). Unwanted CFCs: Hoechst has developed a process for the disposal of CFCs by thermal cleavage in an O2 / H2 flame at 2100°C in an acidresistant graphite reactor. This thermal cracking of CFCs yields a mixture of HCl, HF, CO2, H2O and Cl2 (> 99.99% conversion!) Recycling Chlorine-containing residues: • Chlorination of methane • Manufacture of vinyl chloride • Manufacture of allyl chloride • Manufacture of chlorobenzene • Manufacture of propylene oxide via chlorohydrin Generate residues with high chlorine content Gas-phase cracking of these chlorinated hydrocarbon residues, with simultaneous chlorination, yields either mixtures of CCl4, Cl2C=CCl2, and Cl2C=CHCl or only CCl4. Process variables such as pressure, temperature, residence time, and Cl2/hydrocarbon ratio determine the selectivity of the chlorinolysis. Recycling Waste paper: The processing of scrap paper does not require delignification with sulfur chemicals, since lignin was removed in the manufacture of the of the new paper. If scrap paper is to be used for packing materials and chipboard, the colour is unimportant and deinking is unnecessary. About 20% of recycled paper is used for printing paper. Deinking is achieved by either ink washing or ink flotation. Recycling Scrap iron and steel: Typically, iron is produced by reducing iron ore (Fe2O3) in a blast furnace. Iron and steel can also be produced from recycled scrap which, of course, does not need to be reduced and can be melted down directly in an electric arc furnace. The main problem is the presence of other metal impurities (particularly Sn with S) called “tramps” brittle product. Reprocessed scrap usually must be mixed with new steel to ensure tramps < 0.13%...good enough for new automobile bodies.