Green Chemistry

advertisement

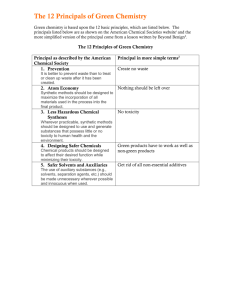

* Daniel Knapping 10 White * Green Chemistry is the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. Often referred to as a form of molecular- level pollution prevention, Green Chemistry relies on a set of 12 principles that can be used to design or re-design molecules, materials and chemical transformations to be safer for human health and the environment. The incorporation of Green Chemistry principles into the curriculum has fueled a fundamentally new approach to the teaching of chemistry and the GEMs database has been designed to be a rich and efficient resource for Green Chemistry education materials. * 1. Prevent Waste 2. Design safer chemicals 3. Find safer ways to make synthetic products 4. Maximise atom economy 5. Use safer products 6. Use renewable reactants 7. Maximise energy efficiency 8. Avoid chemical derivatives 9. Use catalysts whenever possible 10.Design biodegradable products 11.Use real-time analysis to prevent pollution 12.Minimise the potential for accidents * * Prevent Waste - It is better to prevent waste than to treat or clean up waste after it has been created * Design Safer Chemicals - Chemical products should be designed to effect their desired function while minimizing their toxicity. * Find safer ways to make synthetic products - Wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment. * Maximise atom economy - Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product. * Use safer products - The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made unnecessary wherever possible and innocuous when used. * Use renewable reactants - Energy requirements of chemical processes should be recognized for their environmental and economic impacts and should be minimized. If possible, synthetic methods should be conducted at ambient temperature and pressure. * Maximise energy efficiency - A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable. * Avoid chemical derivatives - Unnecessary derivatization (use of blocking groups, protection/ deprotection, temporary modification of physical/chemical processes) should be minimized or avoided if possible, because such steps require additional reagents and can generate waste. * Maximise energy efficiency - Catalytic reagents (as selective as possible) are superior to stoichiometric reagents. * Design biodegradable products - Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment. * Use real-time analysis to prevent pollution - Analytical methodologies need to be further developed to allow for real-time, in process monitoring and control prior to the formation of hazardous substances. * Minimise the potential for accidents - Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires. * By Daniel Knapping, 10 White * * The award that they received for this environmental breakthrough has been presented on behalf of the White House by the U.S. Environmental Protection Agency annually since 1996. It recognizes breakthrough technologies that transfer sustainability principles from the research lab into the real world to enable environmentally responsible and economically viable routes to commercial chemical manufacturing. It is the seventh Presidential Green Chemistry award for Dow and the fourth for BASF. The Dow-BASF innovation offers distinct economic and environmental benefits when compared to conventional PropyleneO(PO) process technologies. A joint study conducted by the two companies in 2007 using BASF’s Eco-Efficiency Analysis tool revealed the new HPPO process reduces waste water by 70 to 80 percent and energy use by approximately 35 percent, compared with existing PO Technology. HPPO Technology is also more environmentally friendly because no by-products are produced besides water. In addition, PO plants using the HPPO Technology require up to 25 percent less capital to build than conventional technologies, as they have reduced infrastructure, a smaller physical footprint and simpler raw materials integration. The two companies successfully started up the first commercial-scale HPPO production plant in 2008 at BASF’s Antwerp, Belgium, facility. SCG-Dow Group is building a second plant based on this technology, which is scheduled to begin production in Thailand, 2011. Bibliography http://www.dow.com/news/corporatxcv e/2010/20100622a.htm http://www.basf.com/group/corporate/en/sustainability/ecoefficiency-analysis/projects/press-releases/050621 http://greenchem.uoregon.edu/Pages/WhatIsGreenChemistry.php http://portal.acs.org/portal/acs/corg/content?_nfpb=true&_pageLabe l=PP_TRANSITIONMAIN&node_id=830&use_sec=false&sec_url_var=regio n1&__uuid=732a2c26-7f7a-44ea-8c30-56f66ebcb03f http://www.organic-chemistry.org/topics/green-chemistry.shtm http://www.greenchemistrynetwork.org/ http://greenoz2011.org/ http://www.greenplastics.com/ http://www.dtsc.ca.gov/PollutionPrevention/GreenChemistryInitiative /upload/FAQs_greenchem.pdf http://www.chempower.org/inaction.html Science Dimension 4 ( Text Book)