Process Mapping

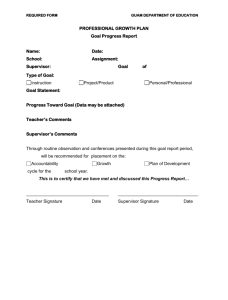

advertisement

DEWITT ARMY HOSPITAL Fort Belvoir, VA OUTLINE • • • • • • • • Definition of Process Mapping Parts of Process Mapping Steps of Process Mapping Tools for Process Mapping Final Checking of Process Mapping Examples of Process Mapping How Process Mapping fits into the QSEs Common Mistakes in Process Mapping Process Mapping • Is a graphical representation from start to finish. • Flow chart Oval: Show the input to start the process Arrows show direction or the flow of the process Box or Rectangle: Show a task or activity performed in the process T E M P L A T E Flow Chart Diamond: Shows where a Yes/No question is asked or a decision is required No Yes Usually only one arrow out of an activity box. If more than one arrow, you may need a decision diamond. Oval: Show the output at the end of the process Make sure every feedback loop is closed, Every path takes you either back or forward to another step Tools for Process Mapping • Pen and paper • Post-It notes • Software: PowerPoint, Visio, etc. Start …………………….End Links to another process or flow chart Arrow Steps (Procedure) Questions ??? Feedback loop Quality System Essentials Organization QUALITY SYSTEM ESSENTIAL Organization DeWitt Army Community Hospital Department of Pathology DCCS Chief, Pathology Quality Management NCOIC Lab Manager Administrative Support Soldiers Assistant Lab Manager MLT Phase II Safety Anatomical Pathology Histology Clinical Pathology Decentralized Labs Client Services Chemistry Central Processing POCT Blood Bank Phlebotomy Rader Microbiology Shipping Woodbridge Hematology Organizational Chart 6/28/2007 Fairfax Quality System Essentials Safety NEEDLESTICK Or other blood borne pathogen exposure APPLY FIRST AID !!! OR REPORT TO ER IMMEDIATELY ATTENDING MD SF 558 or progress notes. Give to injured employee Consent FORMS for HIV on both source & injured employee Order & draw lab tests STAT: “NEEDLE SOURCE” (order set name) Tubes: 1 red, 1 purple, & 1 HIV Tests: Rapid HIV-1; HIV; Hepatitis B Surface AG; Hepatitis C Antibody “NEEDLE EMPLOYEE”(order set name) Tubes: 2 red, 1 purple, & 1 HIV Tests: HIV, Hepatitis B Surface Antibody, Hepatitis C Antibody; CBC, CMP, HCG (female childbearing age) Decide on Tetanus shot If necessary, consult Community Health Nurse for psychological assistance Decide on PEP (post exposure prophylaxis) therapy • If YES, contact WRAMC Infectious Disease for follow up 202-782-1663 SUPERVISOR NOTIFY SUPERVISOR Supervisor/ employee complete the assigned forms What is the status of the employee? Military DA 4106 DD 689 FM 879 GS Civilian DA 4106, FM 879, DD 689 CA-1 & CA-17* *when applicable Patient, Contract , Student, Volunteer, Visitor DA 4106 Report to ER for emergent care Report to ER for emergent care • Ensure paperwork is properly filled out • Forward Paperwork to designated area. REFER TO BACK PAGE. •Report event to Infection Control Report to ER for emergent care Report to Occupational Health within 72 hours of injury for follow-up care, (bring SF 558) CA-1 should be submitted to Safety Manager within 5 workdays of the injury END Report to your respective Contract Representative Office or Primary Provider for follow- up care UPDATED 11-23-2004 Phone #s: ER (805-0518); Occ Health (805-0443); Infection Control (805-0044); Safety Manager (805-0157); Patient Safety (805-8048);CPAC (703-704-2743) ACCIDENT/INJURY REPORTING FIRST AID FIRST!!! IF UNCLEAR, REPORT TO ER IMMEDIATELY DD 689 – Individual Sick Slip Form – Supervisor will give a signed form to injured employee to seek medical attention at ETR or Occupational Health DA4106 – Quality Assurance/Risk Management Form – On duty injuries must be reported to Patient Safety MEDDAC FM 879 – DeWitt Army Hospital Supervisor Mishap Report – Required to be submitted to Safety Management Office within 5 days of injury/accident. DA 285-A-B-R may be substituted to report POV incidents for military. CA1 – Federal Employee’s Notice of Traumatic Injury and Claim for Continuation of Pay/Compensation – Supervisors are required to fill out form and bring it to Safety Management Office to be submitted to Department of Labor. Form is required to be submitted within 3 days of injury/accident. CA17 – Duty Status Report – Supervisor will fill out column A of form and give to injured employee if limited duty is applicable. Employee will provide form to provider and return to supervisor. NOTIFY SUPERVISOR Supervisor/ employee complete the assigned forms What is the status of the employee? SUPERVISOR Military DA 4106 DD 689 FM 879 (Both On and Off Duty accidents must be reported) Report to ETR for emergent care and OH for first aid (DD 689 required) GS/WG Civilian DA 4106, FM 879, DD 689 CA-1 & CA-17* Contract , Student, Volunteer, Visitor DA 4106 *when applicable Report to ETR for emergent care and OH for first aid (DD 689 required) Report to Occupational Health within 72 hours of injury for follow-up care and bring DD 689 and ETR Report (SF558) if seen at DACH ETR. For GS/WG civilians, medical documentation is required. • Ensure paperwork is properly filled out • Forward Paperwork to designated area. REFER TO BACK PAGE. •Report event to Safety Management Office at 703805-0157 Report to ETR for emergent care Report to your respective Contract Representative Office or Primary Provider for follow- up care END Phone #s: Safety Manager (805-0157); Occupational Health (805-0443); Infection Control (805-0044); Patient Safety (805-8048);CPAC (703-704-2743) UPDATED 02-04-2005 DA 4106 SAFETY MANAGER FM 879 (Incident Report) (Dewitt Army Community Hospital Supervisor’s Mishap Report) COPY ORIGINAL CA-1 (Federal Employee’s Notice of Traumatic Injury and Claim for Continuation of Pay/Compensation) COPY COPY CA-17 SF 558 (Duty Status Report) (Emergency Care and Treatment- Dewitt ACH) COPY COPY (Electronically submitted) OCCUP HEALTH PATIENT SAFETY DD 689 (Individual Sick Slip) COPY COPY COPY COPY ORIGINAL ORIGINAL ORIGINAL COPY COPY COPY COPY COPY COPY ORIGINAL *CPAC (Civilian only) EMPLOYEE FILE LAB PI COPY COPY COPY COPY COPY COPY # OF COPIES 2 2 4 4 4 5 Quality System Essentials Occurrence Management NOTIFICATION / DOCUMENTATION CRITICAL VALUES *** START*** Confirmed CRITICAL VALUE Outpatient, ER and Outlying Clinics (Fairfax+ Woodbridge) Inpatient (Wards ) Patient’s location? Ask for : Normal duty hour? (Refer to Clinic hours) 1st: ORDERING PROVIDER 2nd: RN in charge of patient or charge nurse YES Call clinic and ask for ORDERING PROVIDER Successful Reporting ? NO Page ORDERING PROVIDER YES HOW TO DOCUMENT IN CHCS: (Example) “Critical read back by Dr. Jane Doe, ER, 7/06/06@0800 GHY” Note: Have Health Care Provider read back critical lab results with patient’s name NO Document in CHCS *** END *** CALL MOD ( after minimum of 2 attempts ) YES Normal duty hr: -Inform supervisor, lab manager, QI, or pathologist Successful Reporting? NO Off duty hr: -Call pathologiston call QSE: Purchasing and Inventory & Process Control QUALITY SYSTEM ESSENTIALS PURCHASING AND INVENTORY PROCESS IN EVALUATING CRITICAL MATERIALS/ SERVICES REQUEST FOR CRITICAL EQUIPMENT/SUPPLIER/SERVICES DOCUMENT QUALIFIERS REQUIREMENTS (REFER TO PROCESS VALIDATION FORM) REMOVE FROM LIST NO Deliver to the section SECTION CHECKS/ DOCUMENTS: -supplies: lot #, expiration dates, temperature, qc -equipment: calibration, scheduled qc Meets requirements? YES NO CHECKS WITHIN ACCEPTABLE LIMITS? For equipment/ services: For supplies: BACK TO MAINTENANCE OR SUPPLY OFFICER APPROVED BY LAB MANAGER YES 1. Request for 3953 (Purchase request and commitment) 2. Accounted by property book (check annually) 3. Med Maint will do functional, preventive checks 4. Provide ER 24-7 DMLSS (common use, not in contract) CONTRACT (request for 3953, yearly) 1. Received by authorized or designated personnel (supply officer) 2. If high priority, will notify telephonically CREDIT CARD (for emergency request) READY FOR USE Page 1 QSE: Process Improvement Urine Collection Process in the Outpatient Phlebotomy Area Start Ship to reference lab? Print & Verify Labels No Patient Arrive Yes Label samples Log in CHCS Met Requirements ? No Patient Collect Sample Specimen transport to UA section Yes Patient turn in sample Give instructions to patient Transport to Shipping dept INPUT STEPS (Adjustable, Specifications?) OUTPUT (Valuable, Measurable?) BEGIN END IMPROVE CUSTOMER SERVICE IN THE PHLEBOTOMY ROOM INPUT PROCESS (Adjustable, Specs?) Greet patient with a smile (Valuable, Measurable?) Patient arrive A Phlebotomist Available Log in CHCS Request for at least 2 IDs (DOB and name) Labels ; printer Verify Labels Labeled cups Verbal instruction “script” A Instruction sheet A Sterile cups with wipes (not expired) Who will deliver ? A Time to deliver (within 1hr) A Back-up plan when busy A OUTPUT Collect samples Transport to lab Patient Satisfaction Survey V,M Patient Waiting Time V,M Patient Identification V Verification of the printed label V Eliminate mislabeled sample V,M Patient recall V,M Repeat Testing Delivered in a timely manner V,M Example of Measurable Output CUSTOMER SERVICE ( Patient Satisfaction Survey 2007) Example of Measurable Output CUSTOMER SERVICE COMPLAINTS 25 20 1st Q 15 2nd Q 3rd Q 10 4th Q 5 0 Access Policy Staff Behavior Quality of Care Misc QUALITY SYSTEM ESSENTIALS ASSESSMENTS PHLEBOTOMY WAITING TIME Percent Served <= 15 Minutes (Threshold: 90%) 100% 95% 90% 85% 80% 75% 2006 70% 2007 65% 60% 1 2 3 4 5 6 7 8 9 10 11 12 QUALITY SYSTEM ESSENTIALS ASSESSMENTS 2007 PATIENT RECALL (Threshold: < 1%) # of patient seen % of pateint recalled 4500 2.0% 4000 1.8% 3500 1.6% 1.4% 3000 1.2% 2500 1.0% 2000 0.8% 1500 0.6% 1000 0.4% 500 0.2% 0 0.0% JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC Example of Measurable OUTPUT % Urine Contam ination 50% 40% 30% 20% 10% 0% previous current peers Your lab 16% 84% 25% male male female female 75% Steps of Process Mapping • First identify the PROCESS • Provide OUTPUT variables for each step before the INPUT variables • OUTPUT : Valuable or measurable • INPUT: Controllable and enter specifications – P and 5 M (People, Machine, Materials, Method, Mother Nature, Measure) Improve Customer Service In The Phlebotomy Room INPUT PROCESS (Adjustable, Specs?) Greet patient with a smile (Valuable, Measurable?) Patient arrive A Phlebotomist Available Log in CHCS Request for at least 2 IDs (DOB and name) Labels ; printer Verify Labels Labeled cups Verbal instruction “script” A Instruction sheet A Sterile cups with wipes (not expired) Who will deliver ? A Time to deliver (within 1hr) A Back-up plan when busy A OUTPUT Collect samples Transport to lab Patient Satisfaction Survey V,M Patient Waiting Time V,M Patient Identification V Verification of the printed label V Eliminate mislabeled sample V,M Patient recall V,M Repeat Testing Delivered in a timely manner V,M Finalizing the Process Mapping • Review the process, by observing or asking the operator • Are the operators following the process as charted? • Do you have a consensus? • Do you need to add or remove steps? Process Mapping Mistakes •Map is too detailed, too much information and does not emphasize the importance. Process Mapping Mistakes • Process is not focused on your main goal i.e. create value for your customer (customer satisfaction) • Map the process without showing how the results will be measured QUESTIONS