MICROBES CAN MAKE USEFUL PRODUCTS

advertisement

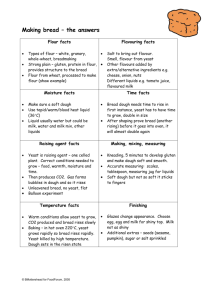

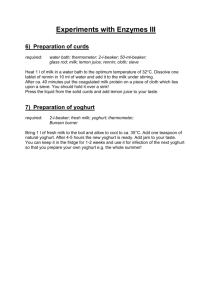

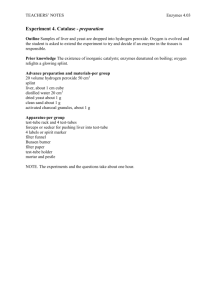

MICROBES CAN MAKE USEFUL PRODUCTS WJEC Biology Module 3 You will learn: • What products are made by microbes? • What are the advantages of using microbes? • How is commercial production carried out? Learning outcomes • To discuss the advantages of using microbes in food production. Time to Think • how do we make use of microbes in food production? • gives examples of microbes used • can you think of any advantages in using micro-organisms in food production? Microbes in Food production • Advantages of using microbes in food production – rapid growth – contained growth so minimum space is used – predictable product is made under controlled conditions – they may grow on waste materials from other processes. Learning outcomes • To understand how bacteria are used in yoghurt production Yoghurt Production • Yoghurt is a thickened milk product with a sour taste • The sour taste is produced by bacteria introduced into the milk which breakdown lactose (milk sugar) to lactic acid. • The low pH of lactic acid prevents other microbes from growing in the milk. • Yoghurt production is a batch process. Yoghurt production • 5 stages – Pasteurisation • Raw milk is pasteurised by heating the milk to 93oC, this kills unwanted bacteria – Cooling – Incubation • Bacterial culture is added to the cooled milk – Chilling • Temperature reduced to 5oC, reducing bacterial enzyme activity – Packaging • Into sterile yoghurt pots, which are sealed and stored below 4oC. Incubation • Streptococcus thermophilus and Lactobacillus bulgaricus bacteria convert milk sugar (lactose) into lactic acid • Optimum temperature 42oC • The lactic acid produced lowers the pH • Milk protein coagulates (thickens) • Process takes 4 – 6 hours Flow diagram for the manufacture of yoghurt Bulk raw milk Cool Storage 4oC pasteurisation cooler Packaging Chiller 5oC Incubation at 42oC for 6 – 8 hours Quick Questions on Yoghurt production • At what temperature is the raw milk pasteurised for yoghurt manufacture? • If pasteurisation were not carried out, what could happen to the yoghurt? • Write a word equation for the chemical reaction that causes the pH of yoghurt to drop. • Why should you remember Pasteur when you drink milk or eat yoghurt? Learning outcomes • To understand how yeast is used in baking Yeast in Bread Making • “strong flour” (flour with a high gluten content) is used as this provides a more stable loaf with even air pockets. • Stages in bread production – – – – – Activation Kneading Proving Leavening Baking Activation • Yeast is activated by adding warm water and a little sugar • Yeast respires aerobically and bubbles of carbon dioxide form Kneading • Activated yeast is added to “strong flour” to make dough. • Dough is kneaded to – distribute yeast evenly through the dough – Remove most of the carbon dioxide Proving • Dough is put in a warm place • Yeast respires anaerobically and different enzymes in the yeast speed up the breakdown of sugars to form alcohol and carbon dioxide • CO2 causes the volume to increase. Reactions in Proving yeast enzymes Sugar + water glucose + fructose yeast enzymes glucose + fructose alcohol + carbon dioxide Leavening • Dough is kneaded for a second time • Carbon dioxide produced is trapped in the dough in small bubbles • When the bubbles expand the volume of the dough is increased. • This gives the bread its light texture Baking • When the dough has doubled in volume again, it is baked in a hot oven. • The high temperature denatures the yeast enzymes stopping further reactions. • Alcohol evaporates and the carbon dioxide bubbles expand. Baking Questions • What is the source of enzymes for bread making? • If a thermostat failure caused the proving temperature to rise to 65oC in a bakery, would you expect to get “super-sized” loaves? Explain your answer. • What is the role of gluten protein in the bread-making process? Watching Dough rise • Online resource Learning outcomes • to investigate factors affecting fermentation in yeast • to represent data collected in appropriate tabular and graphic form Fermentation in Yeast • Yeast is a single-celled fungus • Is reproduces asexually by budding • Yeast can respire aerobically Sugar + Oxygen carbon dioxide + water • Yeast can also respire anaerobically Sugar ethanol + carbon dioxide • Anaerobic respiration produces less cellular energy than aerobic. Factors affecting fermentation in yeast • Sugar concentration • Temperature • pH • Type of yeast Learning outcomes • To discuss the commercial production of anti-biotics Antibiotic Production • Penicillin is a widely used anti-biotic, first discovered by Alexander Fleming in 1928. • Large-scale production of penicillin requires – – – – sterile conditions Fermenter Nutrient medium Aeration with sterile air Batch process in several stages 1. A sterile sample of Penicillium is added to the culture medium – The sterile culture medium contains the substances necessary for rapid growth of the mould • • • • – Lactose Amino acids Mineral ions Vitamins pH and temperature are set at optimum levels 2. When Penicillium has used up the nutrients it starts to produce penicillin as a secondary product. • The temperature is changed for this stage 3. After about a week, the maximum antibiotic concentration is reached • Mould is filtered from the fermentation liquid • Antibiotic is separated from the liquid, purified and crystalised 4. Antibiotic is processed into a form where it is sold and used. • All processes must take place under sterile conditions • Temperature must be controlled throughout as penicillin can be easily damaged by heat. Fermenter • A fermenter is a large steel vessel used for biochemical reactions. • Sensors monitor the conditions inside • The sensors send information to a computer, which then controls input valves to maintain temperature, pH, nutrient and oxygen levels at the optimum value. Learning outcomes • To revise knowledge of enzyme action • To understand the use of enzymes in food production. Industrial productions and the use of enzymes • Industrial application of enzymes includes – – – – – Food, wine and beer production Making fructose sweeteners for soft drinks Laundry detergents Producing “stone washed” jeans Manufacturing pharmaceuticals Enzymes • Enzymes are used in industry as they bring about reactions at normal temperatures and pressures which would otherwise require expensive, energy demanding equipment • All enzyme reactions also give a pure and reliable product. • To produce enzymes, micro organisms are cultured in a fermentation process Enzymes in food production • Early uses of enzymes in the food industry include the production of sweet syrups by breaking down starch. – Carbohydrase and isomerase enzymes are commonly used Uses of enzymes in food production • Baby food – Some baby food is pre-digested using proteases so that the baby can use amino acids without digestion – Baby-milk powders are manufactured from cows’ milk and are treated with enzymes to break down the proteins • This reduces the risk of allergic reactions Fruit Juice production • pectinases are used for extracting fruit juice. – Pectin in fruit holds the cellulose fibres in the cell wall together – The enzyme pectinase breaks down the pectin and cell walls releasing the juice. Pupil Activity • Answer the exam question on pectinase • Complete the activity worksheet analysing an experiment looking at the effect of temperature on pectinase action. Learning outcomes • to carry out at GCSE practical examination on the extraction of fruit juice using pectinase Learning Outcomes • To understand how biological washing powders help to remove stains Biological Washing Powders • Modern biological washing powders use enzymes that function efficiently at low temperatures, this reduces fuel costs. • Food or biological stains include – Fats and oils from fried items, butter or oily dressings – Protein from eggs, grass or blood – Starches from sauces made with flour Biological washing powders • Biological washing powders have the following enzymes added – Lipase to breakdown fats – Proteases to digest proteins – Carbohydrases to remove starch stains Biological powder advantages • Improve stain removal • Reduce costs • Environmentally – Biodegradable • Enzymes are proteins and break down naturally in the environment – Energy efficiency – Water efficiency Pupil Activity • The instructions on the box state that biological washing powders are not effective when used at temperatures above 40oC – Explain why this is so. – If you had dropped fruit and cream down the front of your best silk shirt, what would be the advantage of using biological washing powder? Pupil Activity • In the table write in whether you think the benefits are for the – Customer – Environment • Read through the handout and answer the questions on Stone washed jeans.