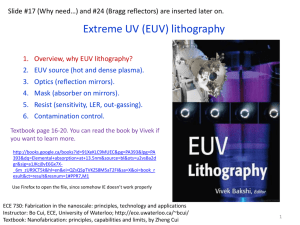

Laser-produced plasma for EUV lithography UCLA MAE Department

advertisement

page 1 of 27 Laser-produced plasma for EUV lithography M. S. Tillack UCLA MAE Department Thermo/Fluids Research Seminar Series 29 June 2007 page 2 of 27 The end is in sight for semiconductor lithography based on direct laser exposure Current technology (www.intel.com/technology/silicon/lithography.htm) Efforts to drop the wavelength to 157 nm ended unsuccessfully Innovations such as immersion (high n) or phase-shift masks (interference) have pushed the limits of feature size at a given wavelength page 3 of 27 EUV lithography has become the frontrunner “next generation” technology Discharge (DPP) and laser (LPP) alpha tools have been built LPP has several advantages: higher collection efficiency, more manageable thermal loads and debris, more scalable to HVM mask EUV source laser wafer page 4 of 27 At UCSD we are developing technologies for a LPP light source using Sn targets Why 13.5 nm? Why Sn? Key challenges: Maximize in-band emissions, Minimize debris damage Research at UCSD: * Low-density and mass-limited targets * Wavelength and pulse length optimization * Double-pulse irradiation * Gas and magnetic mitigation UCSD Laser Plasma & Laser-Matter Interactions Lab page 5 of 27 13.5 nm is a large, but credible next step Transition to reflective system results in smaller NA (0.15 vs. 1), requiring much smaller wavelength for increased resolution (NA~1/2f) Multilayer mirrors as low as 13.5 nm are commercially available Mo/Si, 6.9 nm period http://www-cxro.lbl.gov/optical_constants/multi2.html QuickTime™ and a TIFF (Uncompressed) decompressor are needed to see this picture. 32 cm diameter ~70% reflectivity Yulin et al, Microelectronic Engineering, vol. 83, Issue 4-9, (2006) 692-694. page 6 of 27 The UTA of Sn is an efficient source at 13.5 nm Sn Gerry O’Sullivan, University College Dublin Sb Sn+8 Te Sn+7 I Sn+6 Xe Konstantin Koshelev, Troitsk Institute of Spectroscopy Light comes from transitions in Sn+6 to Sn+14, between 4p64dn and 4p54dn+1 or 4dn-1(4f,5p) Lighting up these transitions, and only these transitions requires exquisite control of laser plasma page 7 of 27 Optimum conditions for EUV light generation: a plasma temperature of ~35 eV, … … and laser heating where EUV light can escape Region of EUV emission Calculation of non-LTE ionization balance using Cretin Interferometry data 840 ns after pre-pulse Good News: These conditions can be achieved using relatively “ordinary” Joule-class pulsed (10 ns) lasers page 8 of 27 Laser plasma is notoriously difficult to control Steep spatial gradients Strong time dependence T (eV) Hyades: double-sided illumination of foam t (ns) ne 20 (10 /cm3) t (ns) Intimate dependence on temperature Non-LTE behavior (rate-dependent R (cm) atomic populations) t (ns) page 9 of 27 … and difficult to measure Nomarski interferometer Transmission grating EUV spectrometer In-band energy monitor Faraday cup 2 ns visible imaging Spatially-resolved visible spectroscopy (2 ns) EUV imaging at 13.5 nm page 10 of 27 Challenge #1: Maximize conversion of laser light to in-band EUV output Maximum in-band emission with minimum out-of-band saves $$ on the laser and cost of ownership, and reduces optic damage. Intel’s EUV MicroExposure Tool Our work: Techniques to narrow the UTA Optimized pulse length & wavelength Avoidance of reabsorption Cymer’s HVM EUVL source concept page 11 of 27 Low density targets produce a narrower UTA Targets provided by Reny Paguio, General Atomics • • • 100 mg/cc RF foam 0.1-1% solid density Sn e.g., 0.5%Sn = Sn1.8O17.2C27H54 We attempted to reduce debris by reducing the target density. The optical depth at 13.5 nm is only ~7 nm of full density Sn. Beyond that, light is reabsorbed. An unexpected advantage is a narrower spectrum. page 12 of 27 Conversion efficiency can be optimized by choosing the laser pulse length & wavelength 2.5 Conversion efficiency is higher at longer wavelengths 2.0 CE 1.5 Sequoia 1.0 Ando 0.5 0.0 0 5 10 15 20 Pulse Duration (ns) 2 ns gives better CE, but longer pulses may be more cost-effective 2.5 2 CE 1.5 1 7 ns 15 ns Ando 2.3 ns Ando 5.6 ns Ando 8.5 ns 0.5 0 10 10.5 11 11.5 2 Intensity (Log10 W/cm ) 12 Laser absorption occurs at a lower density, allowing the EUV light to escape more efficiently. page 13 of 27 A spectral dip can occur due to reabsorption, degrading the conversion efficiency e.g., spot size is one of several factors that contribute to opacity control Emission spectrum (I=21011W/cm2 ) CE vs. laser intensity CE depends on a balance between emissivity and opacity In a smaller spot: Lateral expansion wastes laser energy less emissivity Lateral expansion reduces plasma scale length less opacity page 14 of 27 Challenge #2: Minimize optic damage from high-energy particles Laser-produced plasma generates debris and energetic ions Optic lifetime must be >30,000 hours Debris can be cleaned, but… Energetic ions damage multilayer mirrors Our work: Gas stopping Magnetic stopping Gas plus magnets Double-pulsing Full density Mass-limited Mass-limited plus gas page 15 of 27 Gas stops ions, but also stops EUV photons Ion yield at 10˚, 15 cm Faraday cup vs. SRIM estimate Conversion efficiency at 45˚, 78 cm E-mon vs. attenuation calculation Calculated Hydrogen is best, but not good enough (and nasty) Collisionality in plumes also affects their range page 16 of 27 Magnetic diversion is partially effective, but not sufficient 5 GW/cm2 aluminum free expansion velocity v=6x106 cm/s page 17 of 27 A magnetic field produces a synergistic effect in combination with background gas Faraday cup time-of-flight measurements at 10˚, 15 cm from target photoionization peak appears when gas is present 100% dense page 18 of 27 We recently discovered a technique that dramatically reduces the ion emission energy Low-energy short pre-pulse forms target; main pulse interacts with pre-plasma. Degrees of freedom to control performance. Pre-pulse: Wavelength Pulse length Energy Intensity Spot size Main pulse: Wavelength Pulse length Energy Intensity Spot size 532, 1064 nm 130 ps 2 mJ ~1010 W/cm2 300 µm 1064 nm 7 ns 150 mJ 21011 W/cm2 100 µm 2 mm Sn slab Camera gate page 19 of 27 Ion energy was reduced by a factor of 30! Energy spectra of ions vs. time delay 5.2 keV v=L/t, E=1/2 mv2 page 20 of 27 The main pulse interacts with a pre-formed gas target on a gentle density gradient Pre-plume density profile 840 ns after the pre-pulse Thermal plasma 500 m cold plume 10 ns 440 ns 840 ns 1840 ns 130 ps pre-pulse, 2 mJ, 532 nm page 21 of 27 The location of absorption of the main pulse is clearly displaced away from the surface single pulse double pulse Region of EUV generation lasers pre-plasma main plasma Nomarski interferometer page 22 of 27 At the optimum delay time, no loss of conversion efficiency is observed CE Particle energy reduction factor Delay (ns) page 23 of 27 Gas is more effective at stopping ions that already have their energy degraded 300 mTorr Hydrogen TOF spectrum 10 mTorr Argon TOF spectrum In both cases, the predicted transmission of 13.5 nm light is >95% page 24 of 27 “Mass-limited” targets should reduce the debris loading, without loss of light output Thin films were fabricated using e-beam evaporative coating of Sn on plastic and glass Film thicknesses from 20 to 100 nm, as well as foils from 1 to 10 µm were tested page 25 of 27 Unlike single-pulse results, ion energy was reduced using a pre-pulse on thin coatings Acceleration with single pulse likely due to low-Z substrate Double-pulse pump beam never reaches the substrate page 26 of 27 Pre-pulse + gas + mass-limited target could satisfy requirements of a practical EUVL source We need better diagnostics to measure vanishingly small yields MCP page 27 of 27 Acknowledgements Contributors: Yezheng Tao, S. S. Harilal, Kevin Sequoia Financial support: General Atomics, William J. von Liebig Foundation, Cymer Inc., LLNL and the US Department of Energy http://cer.ucsd.edu/LMI page 28 of 27 Laser-matter interactions at UC San Diego Laser plasmas: • • EUV lithography HED studies (XUV, electron transport) Relativistic laser plasma (fast ignition) Thermal, mechanical and phase change behavior Laser ablation plume dynamics, LIBS, micromachining optics damage Center for Energy Research