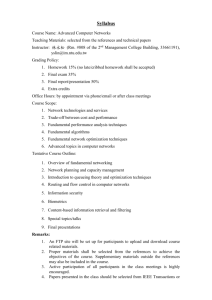

Workbench Simulation - Structural Nonlinearities

Nonlinear Diagnostics

General Troubleshooting

Nonlinear Diagnostics – Goal and Description

•

Goal

– In this workshop, our goal is to use the nonlinear diagnostics tools available in Solution

Information branch to troubleshoot an advanced nonlinear application.

•

Model Description

3D large deflection of spring plate using a frictionless contact pair:

–

Spring plate

– Flat rigid plate

– One frictionless contact pair

Loads and Boundary Conditions:

– Fixed support

– Displacement of flat surface into Spring 8mm

Nonlinear Diagnostics – Start Analysis

Steps to Follow:

• Start an ANSYS Workbench session. Browse for and open “Spring_ws06A.wbdb” project file.

– This project contains a Design Modeler (DM) geometry file “Spring_ws06A.agdb” and a

Simulation (S) file “Spring_ws06A.dsdb”.

• Highlight the Model, Spring_ws06A.dsdb file and open a Simulation Session.

Nonlinear Diagnostics – Setup

• Insert a manual contact region (RMB on Contact folder) between curved surface of spring and adjacent flat plate.

• In Details of Contact Region Window, defining Contact and Target surfaces, choose Frictionless type, Asymmetric behavior and Augmented Lagrange algorithm.

• Interface Treatment: Add Offset, Ramped Effects.

• Take the defaults for all other options.

Nonlinear Diagnostics – Setup

• Highlight Analysis Settings:

– Turn off Weak Springs option

– Activate Large Deflection.

• Highlight Solution Branch:

– RMB to Insert Contact Tool Folder

– Add Pressure Result to Contact Tool

Nonlinear Diagnostics – Setup

• Highlight Solution Information branch and insert

– Request Newton-Raphson Residual feedback on the last three iterations of the run

Nonlinear Diagnostics – Setup

• Highlight Solution Information branch and insert

Results Tracker for Contact

• In Details Window for Results Tracker:

– Contact Region: Frictionless

– Solid to Solid

– Type: “Number Contacting”

– RMB “Rename Based on Definition”

• Repeat above steps for “Penetration”

Nonlinear Diagnostics – Solution

• Execute Solve

• The run converges without error. A plot of Total

Deformation, however, indicates that results are not correct.

• Review Solution Output Information

– Plot Displacement

• Review Contact Results

– Number Contacting

– Penetration

• The Contact has obviously failed to engage, but why?

Nonlinear Diagnostics

• The run converged in one iteration!.

The calculated force convergence value was essentially zero.

The maximum DOF increment equals the full displacement applied under “Given

Displacement” branch

Nonlinear Diagnostics

• Return to the Solution Information worksheet and examine the contact specifications closely.

The most useful feedback in this output is the note about an initial gap existing between the contact and target elements.

The contact is initially “Open”

Scrolling up the worksheet further, notice that the initial substep size is

“1”, maximum of “10”. This means that the total displacement (8mm) of the flat plate is applied at the first substep!

With the initially open contact status and this large initial displacement, the contact jumps over the target from the start and is never detected.

Nonlinear Diagnostics

• Return to the Details of Frictionless Contact Region window and specify the Interface Treatment to

“Adjust to Touch”. This option is very useful for small adjustments to close gaps and force a closed contact status at the start of the analysis.

• Without changing any other specifications, execute another SOLVE.

• Solution now begins a long iteration process. Notice in the updated Solution Information

Worksheet that the initial contact adjustment was made to close the gap as expected.

Nonlinear Diagnostics

• After numerous iterations which include three bisections to try to overcome converge difficulties, the solution ultimately fails to converge.

The feedback from this output indicates a very high calculated

Force residual as compared with criteria.

IN THE INTEREST OF TIME, YOU

CAN STOP THE SOLUTION PRIOR

TO REACHING THE POINT OF

CONVERGENCE FAILURE

Nonlinear Diagnostics

• In order to achieve a successful convergence, it is necessary to determine the cause of the high residual. One troubleshooting technique that can be useful (especially in very complex models with multiple sources of nonlinearities) is a plot of the Newton-Raphson residual data. In this case, we saved the last three iterations.

This plot indicates that the highest

Newton-Raphson residual is located at the contact interface.

The cause of the convergence difficulty is a contact normal stiffness which is excessive relative to the stiffness of the underlying geometry. This makes the model too sensitive to changes in contact status at this location.

A smaller factor on contact (FKN) stiffness combined with a refined

timestep size will prove to be very helpful in reducing this residual force and thereby enhancing convergence.

Nonlinear Diagnostics

• Return to the Details of Contact window and set:

– Normal stiffness = Manual

–

Normal Stiffness Factor = 1e-004

– Update Stiffness = Each Equilibrium Iteration

• In Details of “Analysis Settings”, turn Auto Time

Stepping ON and set initial, min and max substep specifications to 10,5, and 25 respectively .

Nonlinear Diagnostics

• Furthermore, a closer inspection of this region indicates that contact may only be engaging at a relatively few gauss points, aggravating convergence and, if nonlinear materials were active, causing excessive element distortion errors in this location.

Nonlinear Diagnostics

• To address this, insert strategic mesh sizing of 0.5mm to the curved surfaces associated with the contact region , six faces total, 3 on each side of plate. The localized mesh refinement adds more contact gauss point in this critical area thereby reducing the iterations to convergence. It also enhances quality of results.

• After making these changes, reexecute SOLVE …

Nonlinear Diagnostics

• Solution now converges in under 40 iterations without error and without any bisections.

Nonlinear Diagnostics

• Post process results ...

Nonlinear Diagnostics

• Note: Had we not refined the mesh and not included stiffness updating between iterations, the solution would still have converged, but it would have taken many more iterations and required bisections toward the end of the given displacement.

• Also, because of the crude mesh, results at the contacting surface would not have been as accurate.

Hence, even for models that have successfully converged, it is always good practice to review the solution output and look for opportunities to enhance performance

(minimize run time) in future.