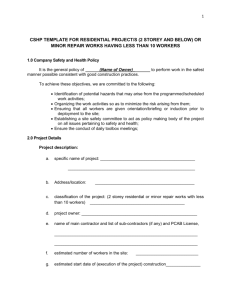

Toolbox Talks Suite: Safety Guidance for Construction

advertisement