ERMSAR2012-1.05 slides

advertisement

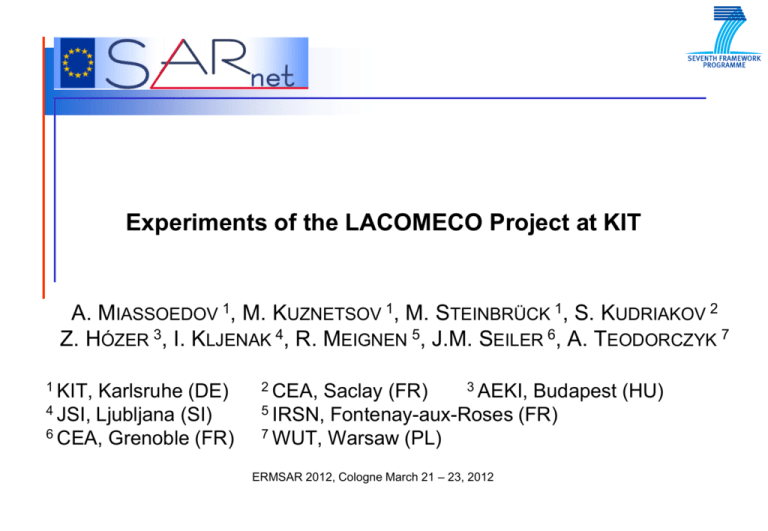

Experiments of the LACOMECO Project at KIT A. MIASSOEDOV 1, M. KUZNETSOV 1, M. STEINBRÜCK 1, S. KUDRIAKOV 2 Z. HÓZER 3, I. KLJENAK 4, R. MEIGNEN 5, J.M. SEILER 6, A. TEODORCZYK 7 1 KIT, Karlsruhe (DE) 4 JSI, Ljubljana (SI) 6 CEA, Grenoble (FR) 2 CEA, 3 AEKI, Budapest (HU) Saclay (FR) 5 IRSN, Fontenay-aux-Roses (FR) 7 WUT, Warsaw (PL) ERMSAR 2012, Cologne March 21 – 23, 2012 Background Four KIT large-scale experimental facilities QUENCH, LIVE, DISCO, and HYKA are offered to EU partners through the Transnational Access to Large Research Infrastructures (TALI) Project of the 7th EU FWP: 1 experiment in QUENCH 1 experiment in LIVE 1 experiment in DISCO 3 experiments in HYKA Investigation of accident scenarios from core degradation to melt formation and relocation in the vessel, melt dispersion to the reactor cavity, and hydrogen related phenomena in severe accidents LACOMECO activities are strongly coupled to SARNET2 ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 2 Selected LACOMECO experiments QUENCH: QUENCH-16: Slow oxidation of fuel rod bundles in air atmosphere (KFKI / AEKI, Budapest, Hungary together with INRNE Sofia, Bulgaria) LIVE: LIVE-CERAM: Dissolution kinetics of a pure KNO3 crust by a KNO3/NaNO3 melt (CEA, Grenoble, France) DISCO: DISCO-FCI: Ex-vessel fuel coolant interaction experiment in the DISCO facility (IRSN, Fontenay-aux-Roses, France) HYKA: • UFPE: Upward flame propagation experiment in air-steamhydrogen atmosphere (JSI, Ljubljana, Slovenia) • DETHYD: Detonations in partially confined layers of hydrogen-air mixtures (WUT, Warsaw, Poland) • HYGRADE: Hydrogen concentration gradients effects understanding and modelling with data from experiments at HYKA (CEA, Saclay, France) ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 3 QUENCH facility Bundle with 21-31 fuel rod simulators of ~2.5 m length Electrically heated length: ~1 m; max. power ~70 kW Fuel simulated by ZrO2 pellets Quenching (from the bottom) with water or saturated steam Gas analysis by mass spectrometry (H2, steam …) Fully instrumented to measure T, p, flow rates, water level, etc. Corner rods removable during tests ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 4 QUENCH-16 bundle test on air ingress Consequences of possible air ingress into overheated fuel assembly after damaging of RPV or spent fuel container: Objectives of the QUENCH-16 test acceleration in the cladding oxidation • • fuel rod degradation the release of some fission products, most notable ruthenium • • air oxidation after moderate preoxidation in steam slow transition in high temperature air with following temperature excursion role of nitrogen under oxygen-starved conditions hydrogen and nitrogen production during reflood Previous integral air ingress experiments: CODEX-AIT-1 and CODEX-AIT-2 tests were performed at AEKI in 1998 and 1999 with small bundles QUENCH-10 performed 2004 at KIT: strong pre-oxidised bundle PARAMETER SF4 performed 2009 at LUCH/Podolsk: very high temperatures on reflood initiation ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 5 QUENCH-16: gas consumption during air ingress and gas release during reflood reflood N2 consumption air ingress O2 starvation ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 6 QUENCH-16 summary Compared to QUENCH-10, the QUENCH-16 test was performed with lower pre-oxidation, longer oxygen starvation during air ingress and reflood initiation at lower temperatures Maximal clad oxide thickness before air ingression 130 µm Oxygen starvation duration 835 s on the end of air ingress Temperature escalation from 1800 K to 2420 K upon reflood initiation Release of 24 g nitrogen during reflood compared to 29 g consumed during oxygen starvation period Significant hydrogen release during reflood: 128 g Solidified partially oxidised melt between 300 and 500 mm, relocated from upper elevations 500 – 800 mm ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 7 LIVE facility 1:5 scaled RPV, Ø1 m, wall thickness ~30 mm cooling vessel to allow cooling by water or air heating furnace of ~220 l volume volumetric heating system maximum temperatures of up to 1100 °C central and non-central melt relocation Pouring spouts Instrumentation thermocouples boundary layer temperature measurements video (optical and IR) cameras recording of the power input extraction of melt sample ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 8 Background and objectives of LIVE-CERAM experiment Background Design of refractory liners for core catchers and for protection of concrete walls (applications for LWRs and for LMFBRs). Development of model calculations for corium – refractory material interaction Few data on corium-refractory material interaction No detailed transient data available for the corium-refractory material interaction for 2D geometry The objective is to simulate ablation process of a high-melting temperature refractory material by low-melting temperature corium KNO3 as refractory material (melting temperature ~334 °C) and a KNO3+NaNO3 melt at, initially, the eutectic composition (melting temperature ~220 °C) as corium Provide data for transient corium-refractory material interaction – Evolution of boundary layer temperature during ablation transient – Evolution of melt pool temperature during ablation transient ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 9 Crust thickness profile evolution in LIVE-CERAM 8 cm thick KNO3 refractory wall was created by Crust thickness, mm before ablation 120 Ablation 1, 7 kW 100 Ablation 2, 15 kW 80 60 40 20 0 0 10 20 30 40 50 Polar angle, ° 60 70 80 lifting the heating coils 63 mm higher power density in the lower part of the vessel Ablation phase 1: 7 kW dissolved KNO3: 39 kg KNO3 in melt: – original melt: 51% – final melt: 60% 160 140 90 Ablation phase 2: 15 kW dissolved KNO3: 24 kg KNO3 in melt: – original melt: 58.2% – final melt: 62% ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 10 LIVE-CERAM: progression of melt temperatures and interface temperatures Ablation phase 1 Ablation phase 2 max. melt temp 340 340 max. melt temp 320 Interface temp Temperature, °C Temperature, °C 320 300 280 260 300 280 260 240 240 220 220 200 200 0 20000 40000 60000 80000 100000 Interface temp 120000 0 20000 Time, s ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 40000 60000 80000 100000 Time, s 11 120000 DISCO-FCI background and objectives Experiment similar to those made for DCH, but with water in the pit data for the validation of the codes in geometrical situation closer to the reactor ones than all other available data – Bridges the gap between DCH and ex-vessel FCI issues Valuable information for several SARNET2 WPs – Melt fragmentation processes for high velocity melt jets obtained by a precise analysis of the size of the debris found (WP7.1, WP5.3) – Pressurization of the pit and containment during the mixing (WP7.1) – Debris bed characteristics important for coolability: shape, porosity, debris size distribution (WP5.3) – Melt and water dispersion out of the pit during the process: initial conditions for MCCI (WP6) – Oxidation of the iron to be compared with cases without water: impact of water on DCH (WP7.1) – Hydrogen production and potential impact of water for combustion (WP7.2) ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 12 Design of the DISCO-FCI experiment Vmelt = 0.0026 m³ Vwater = 0.125 m³ Vw/Vm ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 = 48 13 DISCO-FCI: Main results Particle size distribution Pressures in the cavity Containment temperatures MC3D analysis at IRSN ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 14 HYKA facilities for hydrogen research A3 Analysis of H2 distribution and combustion processes in severe PWR accidents and BWR incidents Provision of an adequate scientific basis for reliable hydrogen risk reduction in NPPs A1 Parameters of the test vessels A1: 110 m3, 100 bar A3: 30 m3, 60 bar A6: 23 m3, 40 bar ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 A6 15 UFPE: Upward flame propagation experiment in hydrogen-air-steam atmosphere Objectives: Scaling of H2 combustion in NPP containments for code validations Method: To compare dynamics of the combustion process with similar THAI tests Objects for scaling: PWR HYKA-A2 THAI Blind numerical calculations will be performed within SARNET2 Volume: 125000 m3 (SF=2100) Diameter: 50 m (SF=16) Height: 63 m (SF=7) H/D: 1.3 PWR 220 m3 (SF=3.7) 6m (SF=1.9) 9.1 m (SF=1) 1.5 HYKA-A2 ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 60 m3 (SF=1) 3.2 m (SF=1) Scaling Factor (SF) 9 m (SF=1) 2.8 Aspect Ratio THAI 16 UFPE: Upward flame propagation experiment in hydrogen-air-steam atmosphere Initial conditions: pressure temperature steam concentration hydrogen concentration p = 1.5 bar t = 90 oC 25 vol. % 10 vol. % Integral characteristics to be compared: Max. pressure: pmax = 5 bar Max. temperature: tmax = 900 oC Time of combustion: tc = 4.5 s THAI hidden before blind ??? calculations will be finished ??? ??? HYKA-A2 Scientific questions: (1) if two experiments are performed in similar facilities of different volumes, with similar experimental conditions, what are the observed qualitative and quantitative differences? (2) how can experimental results obtained in scaled-down experimental facilities be extrapolated to NPP containments ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 17 HYGRADE: Hydrogen concentration gradients effects Objectives: (1) Flame acceleration and quenching experiments with concentration gradients in obstructed geometry in large scale offered by HYKA-A3 vessel (2) To provide high quality experimental data on overpressures and flame propagation velocities required for numerical code validations Method: to register dynamics of the combustion process, to measure energy (heat) losses (by pressure measurements) Facility: HYKA-A3 (V=33 m3, H=8 m, D=2.35 m) Ignition A3 vessel Internal obstacles ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 Hydrogen injection systen 18 HYGRADE: Hydrogen concentration gradients effects Current state: (1) Ten combustion experiments were performed (2) Data processing is in progress (3) Numerical simulations to be started Main results: (1) Hydrogen distribution experiments were performed in order to create a relatively stable vertical hydrogen concentration gradients from 4 to 13%H2 and from 13 to 4% H2 (2) Flame propagation experiments for upper and lower ignitions with positive and negative hydrogen concentration gradients showed that no quenching phenomena in large scale occurred H2-concentration gradients Pressure and temperature records 09.01.2012 + 10.01.2012H2 7000 6000 h / mm 5000 4000 3000 2000 positive 1000 0 4 5 6 7 8 9 10 11 12 13 H2+13.01.2012 /% 12.01.2012 (2) H2 7000 6000 h / mm 5000 h, m 7.5 7 6.5 6 5.5 5 4.5 4 3.5 3 negative gradient 12 – 6 % Flame trajectory 2.5 4000 2 1.5 3000 2000 negative 1000 0 4 5 6 7 8 9 10 11 12 13 Ignition 1 0.5 t, s H2 / % ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 19 DETHYD: Detonation in partially confined layers of hydrogen-air mixtures Objectives: To find experimentally the critical conditions for DDT and detonation propagation in partially confined layers of hydrogen-air mixtures To provide high quality experimental data on overpressures and flame propagation velocities required for numerical code validations Method: To register dynamics of the detonation process, records of soot tracks (l), max. pressure (PCJ) Facility: HYKA-A1 (V=100 m3, L=12 m, D=3.3 m) in a box of 9x3x0.6 m Experimental set-up: Test layer 30 cm Uniform mixture (30%H2-air) Stratified mixtures (20-35%H2 at the top and 0- 4%H2 in air at the bottom) ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 20 DETHYD: Detonation in partially confined layers of hydrogen-air mixtures Current state: (1) Ten detonation experiments are performed (2) Data processing is completed and report is issued Main results: The critical layer thickness for detonation propagation in a semi-open, uniform, stoichiometric hydrogen-air mixture is greater than approximately h* > 3 cm. This critical value corresponds to the ratio do detonation cell size λ as h* ≈ 3λ. The critical hydrogen concentration for steady-state detonation propagation in a stratified layer of H2-air mixture was measured of about 16.6 %. It also requires h*=8.5-14 cm of layer thickness or ~3-4 detonation cells across the layer. High speed movie Pressure-time history H2-concentration gradient Maximum pressure vs. distance 60 Maxim um hydrogen concentration 31%H2 Overpressure D p [bar] 50 27%H2 26%H2 25%H2 40 30 20 10 0 Detonation cell structure Uniform mixture (30%H2-air) 0 2 4 6 8 x [m] 10 Detonation cell structure Stratified mixtures (20-35%H2 at the top and 0- 4%H2 in air at the bottom) ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 21 Acknowledgements The authors gratefully acknowledge funding by Euratom to support the work within LACOMECO project ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 22 … and finally Thank you for your attention! ERMSAR 2012, Cologne, Germany, March 21 – 23, 2012 23