PowerPoint-Präsentation

advertisement

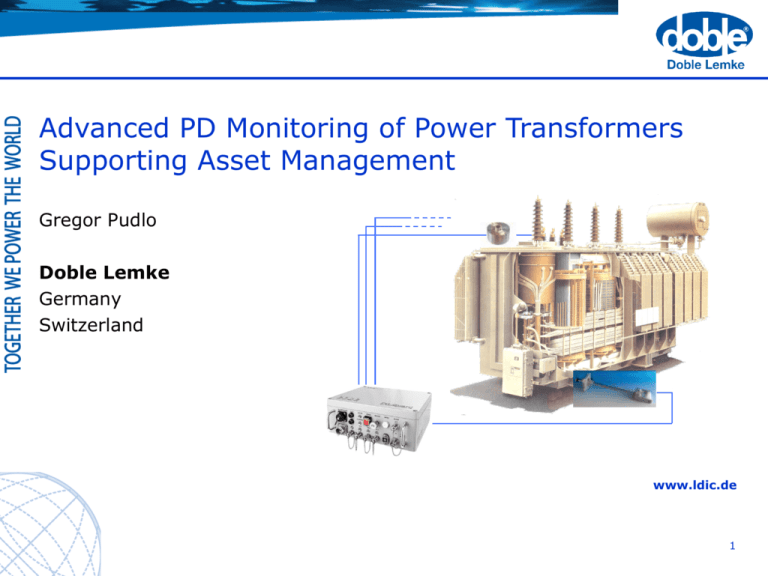

Advanced PD Monitoring of Power Transformers Supporting Asset Management Gregor Pudlo Doble Lemke Germany Switzerland www.ldic.de 1 Abstract • Reasons for (PD) monitoring of transformers • Partial Discharge Detection principles • Electrical PD diagnostic techniques • PD measuring circuits according to IEC 60270 • Advanced tools for PD monitoring • Acoustic and electromagnetic PD measuring principle • Cone-shaped drain valve UHF-sensors / Performance Check • Case studies – UHF PD measurements 2 Reasons: PD Monitoring of Power Transformers • Power transformers are the most important and expensive pieces of equipment in substations. • A new power transformer costs millions of dollars. • Unplanned outage and repair costs, penalties, etc. sum up • Transformers design life is 20-35 years. • With proper maintenance they can remain in service for 60 years. • As transformers age, their internal conditions degrade which increases the risk of failures. • Time-based maintenance changes to condition-based maintenance approaches 3 Partial Discharge Detection Principles Macroscopic-Physical Effects HV Detection Methods Optical Effects (Light) Optical Pressure Wave (Sound) Mechanical Discharge Effects Dielectric Losses High Frequency Waves Acoustic Opto-acoustic Draft IEC 62 478 Electrical IEC 60270 HF/VHF/UHF Chemical Effects Chemical Heat 5 Electrical PD diagnostic techniques PD measuring circuits according to IEC 60270 often applied in on-site/online PD investigations frequently used circuit in test laboratories [König, 1993] a) coupling device in series with the coupling capacitor b) measurement at a bushing tap Components: AC voltage source U, optional blocking impedance Z, coupling capacitor CK, measuring impedance Zm, a measuring instrument M and generalized test object Ca. 6 Electrical PD diagnostic techniques PD Measuring Impedance for Bushing Tap Installation • Decoupling of PD signals from the bushing tap • in a wide frequency range up to 30 MHz • Lower cut-off frequency < 60 kHz • Additional voltage signal for phase-resolved measurements 500 kV Transformer Bushing • Superimposed PD and test voltage signal • Very fast and safe over-voltage protection • TNC-socket for signal output • Dimensions: diameter 125 mm, length 120 mm; Weight: 2 kg • Special feature for continuous PD monitoring (IP 68) 7 IEC 62478 - Draft level "Non-conventional PD-measurements“: • Electromagnetic PD Detection in the (HF/VHF/UHF) - range • Acoustic PD measurements • Mixed acoustic and electromagnetic method -> PD location in Power Transformers and Reactors 9 Advanced tools for PD monitoring – Electromagn. PD Tests Cone-shaped active drain valve UHF-sensors • for the decoupling of electromagnetic PD signals from the inner of an oil-paper-insulated transformer • PD-signals in the UHF frequency range (mainly 300 MHz – 1 GHz) • sensors support „Performance/Sensitivity Check“ (high-frequency test impulses can be injected with additionally integrated electrode) • sensor head is grounded (for lower frequencies) • sensor application at oil valves, which are available e.g. for oil filling or draining (liquid tightness is tested for 120°C warm oil with 5 bar compression) View from inside the transformer 10 Performance Check grounded probe Performance Check output path input path normalized amplitude 1,0 0,8 0,6 0,4 0,2 0,0 0,00 0,25 0,50 0,75 1,00 1,25 frequency / GHz Cone-shaped active UHF-sensor (DN 50/80 oil gate-valve) UHF PD spectra for grounded and ungrounded sensor head • Functional check of the whole measuring path including sensors and partial discharge (PD) acquisition system through injection of high-frequency test impulses • „single-port“ solutions are possible • the Performance Check „controls“ e.g. the effect of a contact to grounded elements within the oil valve. 12 Performance Check Performance check at 750 MHz Phase-resolved view in UHF PD device LDS-6/UHF Drain valve Output Pre-amplifier UHF PD probe DN80 High-pass filter Input Transformer 14 Advanced tools for PD monitoring – Electromagn. PD Tests Case study B - on-line UHF PD measur. of a 200 MVA single-phase transformer 40 30 UHF pulse recorded on-line amplitude (V) 380/220kV, 200 MVA singlephase transformer and position of the gate-valve UHF-sensor 20 10 0 -10 -20 -30 0 50 100 150 200 time (ns) 0.6 corresponding UHF PD spectrum up to 1.5 GHz Application benefit: amplitude (Vs) 0.5 0.4 0.3 0.2 0.1 0.0 0.00 • customer wanted to verify the hydrogen measurements and locate potential PD • full in-service sensor application and measurement • UHF PD signal could be used to enhance acoustic PD measurements 0.25 0.50 0.75 1.00 1.25 frequency (GHz) 17 1.50 Advanced tools for PD monitoring – Electromagn. PD Tests Case study C - on-line UHF PD measur. of a 3-phase power transformer 600 MVA 150 100 UHF pulse recorded on-line amplitude (mV) gate-valve UHF-sensor used at the 3-phase power transformer 600 MVA, 21/380kV 50 0 -50 -100 -150 -500 -250 0 250 500 750 1000 time (ns) Application benefit: 12 10 amplitude (Vs) corresponding UHF PD spectrum up to 1.0 GHz 8 6 4 2 0 0.00 0.25 • gas-in-oil hydrogen indication „useless“ due to active hot spot • customer wanted to test for PD and check a potential load dependency of PD • full in-service sensor application and measurement • Inception and extinction voltage could be identified, load dependency excluded 0.50 0.75 1.00 frequency (GHz) 18 UHF PD Measurements and delivered UHF PD Probe DN50/80 Taiwan Taipeh China Shangai Philippines Manila Belgium Linkebeek Saudi Arabia Jeddah Jizan Germany Berlin Heidenau Riesa UAE Dubai Ireland & UK Ardnacrusha Cashla Dublin Louth Egypt Kairo Colombia Bogota 19 UHF PD measurements in Ireland 21 UHF PD measurements in Ireland Locations: • Louth • Dublin • Ardnacrusha • Cashla Application benefit: • Tested measurements have been performed using non-conventional decoupling methods taking advantage of electromagnetic field coupling • PD measurements on the power transformers have been functioned on the drain valves of the 3- phase 110/225kV power transformers with the help of the UHF probe DN 50 • Three transformers found with minor PD activity, one transformer with clear PD 22 UHF PD measurements in Ireland Measuring Instrument: • • • • PD Measuring System LDS-6/UHF UHF Probe DN50 (with Adapter DN50/DN80) UHF Calibrator LDC-6/UHF Pre Amplifier LDA-5/GIS Drain Valve Applied UHF Drain Valve Sensor Measuring System LDS-6/UHF Mounting of the UHF Probe DN50 (with Adapter DN50/DN80) 23 UHF PD measurement in Louth, Dublin, Ardnacrusha, Cashla (Ireland) Left drain valve Louth Right drain valve The measurements on both valves showed PD activity from inside the transformer. V ≈ 550 mV at measuring frequency 560 MHz V ≈ 238 mV at measuring frequency 560 MHz Left drain valve T2xxx Right drain valve Not any critical PD levels above the detection sensitivity have been measured in Dublin, Ardnacrusha and Cashla. V ≈ 139 mV at measuring frequency 560 MHz V ≈ 128 mV at measuring frequency 520 MHz 24 UHF PD measurements in Jizan, Saudi Arabia 25 UHF PD measurements in Jizan, Saudi Arabia on 33/13,8 KV Power Transformers “A” and “B” Measuring Instrument: • UHF Probe DN50 • Calibrator LDC-6/UHF • PD measurement instrument LDS-6/UHF Drain Valve Power Transformer 26 UHF PD measurements in Jizan, Saudi Arabia “A” “B” Not any critical PD levels above the detection sensitivity have been measured. PRPD Pattern at the measuring frequency of 400 MHz V = 177 mV PRPD Pattern at the measuring frequency of 400 MHz V = 288 mV Application benefit: • For examination and diagnostics of the insulation quality of high voltage apparatus the measurement of PD is accomplished by sensitive UHF method on-site • UHF probe applied in full operation of transformer, no outage needed 27 Conclusion • sensitive UHF PD measurement with UHF probes applicable in service provide advantageous robust and easy PD decoupling • PD location - especially in transformers of great importance is possible in mixed and all-acoustic way • significant diagnostic information are derived from advanced tools for PD monitoring • valuable application benefits e.g. on-line quick start of PD monitoring, enabling time-based maintenance, “diagnostic double checks”, etc. are at hand Doble Lemke GmbH Kesselsdorf/Dresden,Germany Tel.: +49 35204 3900 0 www.ldic.de Doble Lemke AG Rheinfelden, Switzerland Tel.: +41 61 836 8000 www.ldic.ch 33