MFGT 124

Solid Design in Manufacturing

The Product Design Phase

Professor Joe Greene

CSU, CHICO

Reference: The Mechanical Process, 3rd Edition, David Ullman,

McGrall Hill New York (2003)

MFGT 124

Copyright 2003 Joseph Greene All Rights Reserved

1

Chap 9:Product Design Phase

• Topics

–

–

–

–

–

–

Introduction

Importance of Drawings

Drawings Produced during Design

Rapid Prototyping

Bill of Materials

Product Data Management

Copyright 2003 Joseph Greene All Rights Reserved

2

Summary

• The Product Design Phase

– Documentation measures progress in product development, and

many types of drawings are produced during the design phase.

– Drawings are the chief form of information communication during

product design.

– Layout drawings support the development of major components

and their relationships.

– Detailed drawings document the form of the individual

components.

– Assembly drawings show how the the components fit together.

– Solid models streamline the production of layout, detail and

assembly drawings.

– A bill of materials is a parts list- an index to the product.

– Rapid prototyping allows sample and even production components

to be made directly from solid models.

Copyright 2003 Joseph Greene All Rights Reserved

3

Introduction

• The Product Design Phase

– Knowledge gained from making the transformation from concept

to product often times involves iterations.

• Typically, it takes 3 iterations to take an idea from concept design to

production ready design.

• In the 1990s GM typically built 5 prototype design vehicles to finalize

design and to test system performance.

– Each prototype car would go through iterations of parts and systems to

make it function better.

– Goal is to reduce the number of prototype builds to 3 or less with the

use of digital (CAD and simulation).

• Documentation throughout the design phase is critical to the success of the

launch of the new vehicle.

– Concept to production gives shape to the idea.

– Figure 9.1 Product design phase

Copyright 2003 Joseph Greene All Rights Reserved

4

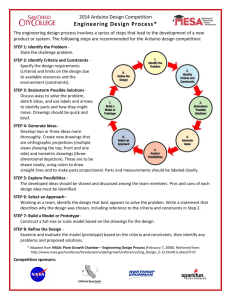

Introduction

• The Product Design Phase

– Figure 9.1 Product design phase

– Product Development

• Conceptual design

• Generate product

– Evaluate product

» Product Performance and robustness (low variation in product

performance after small changes in design)

» Cost: per piece cost, tooling cost, manufacturing cost, cycle time.

» Production requirements- assembly plant size and process flow (how

material flows in plant to produce part)

– Make product decision

– Document and communicate

» Drawings

» BOM

• Decision

– Release for production approval

– Sent back to development for refinement to reduce costs and improve quality.

– Cancel or suspend program

Copyright 2003 Joseph Greene All Rights Reserved

5

Importance of Drawings

• Importance of drawings

– Drawings are are the most essential part of a product.

• Beginning of design- usually a sketch on paper, napkin, envelope, or computer

sketch.

• Proof of concept prototype design- preliminary and incomplete because all of the

product requirements have not been put in the design, just the major requirements.

• Production release design- complete drawing with all product requirements

including, materials, tooling, GD&T, inspection, BOM (Bill of Material)

• Production design updates- changes to the parts are included with revisions to the

drawings for changes made during production to make the part less expensive and

higher quality.

– Drawings are used to:

•

•

•

•

•

•

Archive geometric form of the design.

Communicate ideas between design and manufacturing engineers.

Support analysis for engineering, manufacturing, production, and quality.

Simulate operation of product

Check completeness of drawing.

Act as synthesis tool to pull together design.

Copyright 2003 Joseph Greene All Rights Reserved

6

Drawings Produced

• Drawings produced during product design

– Layout drawings- Fig 9-2. Layout of a wheel and shock for bike.

•

•

•

•

•

•

Working document that changes during design process.

Made to scale.

Only important dimensions are shown.

Tolerances are not usually shown

Notes are used to explain a design feature or function of product

Becomes obsolete as detailed and assembly drawings are produced.

– Detailed drawings- Fig 9.3. Detailed drawing of Right Dropout.

• Major information piece for engineering, manufacturing, suppliers, quality.

• Used to define product for function and performance as well as

manufacturing cost and product quality.

• Parts and tools or molds are ordered from detailed drawings.

• All dimensions are toleranced

• Drawings standards for GD&T are followed.

• Drawing is signed by designers, checkers, and approval source.

Copyright 2003 Joseph Greene All Rights Reserved

7

Drawings Produced

• Drawings produced during product design

– Assembly drawings. Fig 9.4. Link Assembly exploded view

•

•

•

•

Used to show how components fit together.

Useful for assemblies of parts that need to fit together.

Used to calculate manufacturing costs of assemblies.

Each component is identified with a number or letter keyed to the bill of

materials (BOM).

• References are made to other drawings and specific assembly instructions,

especially the order of build.

– Order of build specified the function of a welding cell for an

automotive component, e.g., door system with inner, outer door panel,

hardware, glass, hinges, bolts, rub strips, etc.

• Necessary detailed views are included to convey information not clear in

major views.

• As with detailed drawings, assembly drawings require a signature block.

Copyright 2003 Joseph Greene All Rights Reserved

8

Solids Modeling

• Most designs today on large parts are produced with Solids

modeling CAD.

– Solid geometry is native and live.

– 2-D representations through layouts and drawings are dependent

upon the native solids model geometry.

• Changes to the part design must be made to the solid model and then to the

drawings.

– Ignore the book’s ideas on drawbacks to Solids CAD.

– Solids modeling helps sketching because sketches can quickly turn

into a 3-D representation with solids modeling.

– Most designs in big companies have automated CAD C-programs

that help the designer design the parts to company standards.

– CAD packages are a lot easier now with SolidWorks.

• ProE, Catia, Unigraphics, SDRC Ideas can take 6 months to learn.

Copyright 2003 Joseph Greene All Rights Reserved

9

Rapid Prototyping

• Rapid Prototype Methods

–

–

–

–

–

Stereolithography

Selective Laser Sintering

Laminated Object Manufacturing

Z-Printing

Fused Deposition Modeling (FDM)

• Stratasys FDM at CSU Chico

• Case Study- Frisbee Golf Driver

Copyright 2003 Joseph Greene All Rights Reserved

10

Rapid Prototype Methods

• Rapid prototypying is a process of building objects

during the design phase to have a 3-D object to check

for fit, form, and function

• The rapid prototype will help you visualize the

dimensions of the part and see if 3-D object is desired.

• The object is made from the solid model geometry in a

stereolithography file.

– Stereolithography represents the 3-D object as a shell of the

part that is broken into triangles.

• Rapid prototype process can bring a design on the

computer to 3-D shape in a matter of minutes to hours.

Copyright 2003 Joseph Greene All Rights Reserved

11

Rapid Prototype Process

• Process involves CAD system to digitizer to rapid part

Computer Aided Design

(CAD)

Rapid Prototyping Device

Copyright 2003 Joseph Greene All Rights Reserved

3-D Object

12

Stereolithography

• 3D Systems of Valencia, CA (www.3dsystems.com)

• Founded in 1987 currently offers

• SLA® (stereolithography) systems ($799,000),

• ThermoJet® solid object printer ($49,995), and

• SLS® (selective laser sintering)

• SLA 7000, 5000, 3500, 250 series systems

– Used for Limited production runs, Rapid tooling, Prototyping,

Master patterns for investment casting

• Licenses the complementary 3D Keltool®

• Method to produce steel mold inserts.

Copyright 2003 Joseph Greene All Rights Reserved

13

Stereolithography Process

• Process

– UV laser cure of epoxy resin in a vat of liquid

• Layer of resin above an elevator platform is illuminated with laser and

adheres to top of platform.

• Platform moves down and next layer drawn onto surface, etc.

• Uncured resin is washed with solvent.

• Part is post cured.

– Specs

•

•

•

•

•

•

Laser: 354.7 wavelength

Build layer: 0.076 mm

Vat volume: 253.6 L

Size: W2.1 x D1.55 x H2.36 m

Weight 1455 kg

Not for office use.

Copyright 2003 Joseph Greene All Rights Reserved

14

Solid Object Printer

• ThermoJet® solid object printer

– Builds material yields superior model quality and surface

finish that's perfect for most models and investment casting

and RTV molding patterns.

• Process

– Multi Jet Modeling (MJM)

Printing of plastic resin

– Specs

•

•

•

•

Resolution: 300 x 400 x 600 DPI (XYZ)

Color: Neutral, gray, or black

Size: 250 x 190 x 200 mm (10 x 7.5 x 8 in) (XYZ)

Ready for office use.

Copyright 2003 Joseph Greene All Rights Reserved

15

Selective Layer Sintering

• The SLS Vanguard Process

– Create durable, metal, plastic, or rubber-like parts directly

from any solid CAD model in one day

• Process

– Fuses thermoplastic powder

– Specs

•

•

•

•

•

•

Laser: 25 or 100 Watt CO2

Build layer: 0.076 mm

Vat volume: 253.6 L

Size: W370 x D320 x H445 mm (W14.5 x D12.5 x H17.5”)

Weight 1455 kg

Not for office use.

Copyright 2003 Joseph Greene All Rights Reserved

16

Selective Layer Sintering (SLS)

• SLS System Process

– 1. Start with an STL file of your 3-D CAD data.

– 2. Enter the data into a Vanguard HS si2™ SLS® system.

– 3. Spread a layer of powdered material. As the process begins, a precision

roller mechanism automatically spreads a thin layer of powdered SLS

material across the build platform.

– 4. Sinter a cross-section of the CAD file. Using data from the STL file, a

CO2 laser selectively draws a cross section of the object on the layer of

powder. As the laser draws the cross section, it selectively "sinters" (heats

and fuses) the powder creating a solid mass that represents one cross

section of the part.

– 5. Repeat. The system spreads and sinters layer after layer until the object

is complete.

– 6. Remove the part. Once the part is complete, remove it from the part

build chamber and blow away any loose powder.

– 7. Finish as desired. Use the part as is—or sand, anneal, coat, or paint it

beforeusing it for its intended application.

Copyright 2003 Joseph Greene All Rights Reserved

17

Laminated Object Manufacturing

• LOM process laminates adhesive-backed part materials

together to form prototypes.

– Created by Helisys Corporation

• Specs

•

•

•

•

•

•

Laser: 25 or 100 Watt CO2

Build layer: 0.076 mm

Vat volume: 253.6 L

Size: W370 x D320 x H445 mm (W14.5 x D12.5 x H17.5”)

Weight 1455 kg

Not for office use.

Copyright 2003 Joseph Greene All Rights Reserved

18

Laminated Object Manufacturing

• LOM process laminates adhesive-backed part materials

together to form prototypes.

– Created by Helisys Corporation

• Process

–

–

–

–

–

–

–

Part material enters the machine as a roll of adhesive-coated sheet.

Sheet is pulled through the machine and over build area.

Heated platen rolls laminate the new layer over previous layers.

Laser outlines the boundary of the desired cross section of the part.

Material outside the boundary area of the part is crosshatched.

Process continues as additional layers are added until part is done.

Crosshatched part material serves as a support for undercut features

on higher layers within the part.

– Manual “debugging”step is required to remove all of the small

cubes of crosshatched .

– Polymer material is used

19

Copyright 2003 Joseph Greene All Rights Reserved

Z Corporation 3-D Printing

• Z Corporation (www.zcorp.com/)

– Licensee of 3-D Printing process from MIT

– Products include Z400, Z810 Systems

• Process

– Smooth bed of starch and cellulose powder.

– Liquid binder (water based) is deposited over certain regions of the

bed and bound together.

– When the cross-section is complete, the build piston is lowered

slightly, and a new layer of powder is spread over its surface.

– The process is repeated until the build is complete.

– The build piston is raised and the loose powder is vacuumed away,

revealing the completed part.

– Porous surface is closed with heat or with

• wax for office environment, or

• cyanocrylate resin for stronger part.

Copyright 2003 Joseph Greene All Rights Reserved

20

Z Corporation 3-D Printing

• Z Corporation

– Licensee of 3-D Printing process from MIT

• Specs

• Build thickness: 0.003"-0.010"(.076-.254 mm)

• Build volume: 20" x 24" x 16" (500 x 600 x 400 mm)

• Not for office use.

Full Scale Engine Block

(18"x19"x13")

Copyright

2003 Joseph Greene All Rights Reserved

21

Fused Deposition Modeling

• Stratasys Corporation (www.stratasys.com)

– The first product in 1992.

– Models

• 3-D Printing Genysis

• FDM3000, FDM 8000, Titan

• Process

–

–

–

–

Extrudes plastic bead through nozzle onto heated table.

Builds layers of plastic part.

Plastic can be ABS, Polycarbonate, Polyester, Polysulfone

Removable support structure is built under part for support.

Copyright 2003 Joseph Greene All Rights Reserved

22

Fused Deposition Modeling

• Stratasys Corporation

• FDM Maxum uses two extrusion heads

– One for building the designated model.

– The second head deposits the support material.

– Models are uniformly smooth, details sharp, and accuracies held to

the most exacting specifications.

• Specs

• Size: 600 x 500 x 600 mm

• Accuracy of ± .127 mm (± .005 in) for parts up to 127mm (5 in.). Accuracy

on models greater than 127 mm (5 in) is ± .0015 mm per millimeter (± .0015

in/in)

• Build layer: widths between .305 to .965 mm (.012 to .038 in) and thickness

from .178 to .250mm (.007 to .010 in)

• Ready for office use.

Copyright 2003 Joseph Greene All Rights Reserved

23

Rapid Prototype Technical Reference

Copyright 2003 Joseph Greene All Rights Reserved

24

Rapid Prototype Material Properties

Copyright 2003 Joseph Greene All Rights Reserved

25

Rapid Prototype at CSU Chico

• CSU Chico wanted to use rapid prototyping techniques

for classes and student projects.

– Rapid prototype selection requirements

•

•

•

•

•

•

•

•

Safe and easy to use for students.

Non-toxic materials.

Ready for classroom setting and quiet.

Relatively inexpensive and low maintenance costs.

Compatible with CAD packages.

Relatively fast production rates. Parts made in < 1 hour.

Reasonable size build size.

Well known in industry.

Copyright 2003 Joseph Greene All Rights Reserved

26

Rapid Prototype at CSU Chico

• CSU Chico selected:

– Genisys XS 3-D Printer

•

•

•

•

•

•

•

•

Polyester material.

$65K new; $45K reconditioned educational discount.

Material cost is $6 per hour of build.

Build rate size is 16g per hour.

Maximum build size is 8” x 10” x 4”

Number of parts built: 30 in 6 months

Maintenance contract is $6,000 per year. (We declined)

Genisys XS is smaller version of Stratasys FDM with ABS

Copyright 2003 Joseph Greene All Rights Reserved

27

Rapid Prototype at CSU Chico

• Design Requirements

–

–

–

–

Customer is Chico State Alumni.

Event is baseball game free gift for 500 souvenirs.

Delivery date: April 24, 2002 (6 weeks).

Design

Copyright 2003 Joseph Greene All Rights Reserved

28

SolidWorks CAD

Copyright 2003 Joseph Greene All Rights Reserved

29

SolidWorks CAD

Copyright 2003 Joseph Greene All Rights Reserved

30

Rapid Prototype at CSU Chico

• Moldflow Mold Advisor

Copyright 2003 Joseph Greene All Rights Reserved

31

Rapid Prototype at CSU Chico

• Stratasys Rapid Prototype Parts

– Produced at 85% of full scale since the part diameter is 9

inches and the max build dimension is 8 inches.

Copyright 2003 Joseph Greene All Rights Reserved

32

Project Status

•

•

•

•

•

•

•

•

•

Prototype part design was accepted.

SolidWorks 3-D design complete.

Moldflow analysis complete.

Surfcam and CNC underway.

Screen printing design underway.

First article date of April 4, 2002.

Projected production date is April 11, 2002.

Plastic parts printing complete April 18, 2002.

Anticipated delivery of 500 Frisbee golf drivers April

21, 2002

Copyright 2003 Joseph Greene All Rights Reserved

33

Rapid Prototype Conclusions

• Stratasys 3-D Printing

– Very effective teaching tool to demonstrate the link between design

and 3-D shapes.

– Very effective learning tool for students who build projects and

check for manufacturability before machining.

– Clean, non-toxic, quiet way to produce prototype parts.

– Maintenance record is marginal with replacement of pump, tip, and

control board.

– Dimensional accuracy is marginal at +/- 0.010 in.

– Orientation of part during build state affects accuracy.

– Future work will study orientation and dimensional accuracy.

Copyright 2003 Joseph Greene All Rights Reserved

34

• BOM

Bill of Materials (BOM)

– Similar to an index of the product.

– Good practice to generate a BOM as the product evolves.

• Spreadsheets are commonly used.

– Typical BOM is listed below:

Item

1

2

3

4

5

Part #

63172-2

94563-1

12345-5

56985-3

87965-1

Quantity

1

5

1

4

3

Name

Material

Source

Outer tube 1018 Carbon steel Coyote Steel 412-888-1234

Roller bearing4420 steel

Bearings Inc. 212-789-1238

Shaft

305 Stainless SteelCoyote Steel 412-888-1234

Link rubber Natural rubber

Press Rubbers 807-123-4221

Sleeve

Santoprene

R&D Dept. Dr. Greene 313-332-4321

– Separate lists are kept for each assembly.

– Minimum 6 pieces of information on a BOM

•

•

•

•

•

•

Item number or letter

Part number

Quantity needed.

Name or description of component

Material from which component is made from.

Source of the component.

– Purchased components include name of company and parts number and

purchase order number

– In-house manufactured component then this item can be left blank or

Manufacturing department and contact name is given.

Copyright 2003 Joseph Greene All Rights Reserved

35

Product Data Management (PDM)

• PDM

– Management of design information is a major undertaking.

• Intellectual property is one of the company’s most valuable assets.

• Long ago drawings were stored in vaults that large rotating retrieval systems or

microfiche.

– At GM you requested a print from the mylar (plastic) drawing. After several

days, the operator would retrieve the drawing and then make a copy of it (blue

print or brown print).

• Indexing and finding information was very difficult and required a long time to find

a dimension or feature on an archived document.

– Problem: If you found the document it might not be up to date with production

since changes are made during production and not pur back on the drawing.

– Today

• Computer drawings are kept in computer files and can be retrieved very easily.

– Information is usually up-to-date since changes are made to the computer CAD

file (math data).

– Math data is master and drawings are slaves.

• Companies are sent computer files and not paper to quote jobs and produce parts.

Copyright 2003 Joseph Greene All Rights Reserved

36

Product Data Management (PDM)

• PDM

– Management of design information is a major undertaking.

• Files are sent and not paper to companies so that they can quote jobs and

produce parts.

– The data on the computer CAD files are managed so that they are

kept up to date with the latest changes and product features.

• So that the most up-to-date information can be given to:

– Companies for more accurate quotes.

– Engineers who have parts that attached to design.

– Designers who are working with related parts and assemblies.

– Team of designers that are designing related parts.

– PDM systems are database programs used to support management

of documents and files, product structure, and processes.

Copyright 2003 Joseph Greene All Rights Reserved

37

Product Data Management (PDM)

• PDM is a database program.

– Document files and records generated during generation of product.

•

•

•

•

•

•

•

CAD files and geometry

Text documents of meeting notes

Spreadsheets for QFD, decision matrices

Database reports

Parts libraries

Vendor data

Engineering change orders (ECOs)

– PDM can be used to search for all information related to a part number.

• Which components are in an assembly and what material is it made out and by

which supplier.

– Biggest use of PDM is to manage all of the changes that occur during the

development of a part.

• For automotive parts, there can be hundreds of changes made during the

development cycle. The changes have to be managed so that everyone gets the same

model geometry at the appropriate time.

Copyright 2003 Joseph Greene All Rights Reserved

38

Product Data Management (PDM)

• PDM is a database program.

– Change control

• Designs are checked out by designer or engineer to make changes.

• Example,

– If one engineer is working on one component and makes some changes, how

does another engineer get information about the product.

• Solution,

– CAD files are checked out by designers or engineers to make changes during

design.

– When another engineer asks about the part information, the PDM manager

gives notice to the second engineer that the file is checked out and is being

modifed.

– The second engineer places a request for the file to be e-mail to the engineer

after the part is checked in OR the engineer can take and older version.

– When the first engineer checks in the part file,

» The PDM automatically lists the changes that were made and colors them

a different color than the previous design colors.

» The other engineers and designers on the team are notified that changes

were made to the part and to request the newest version.

– PDM supports task schedule to develop Gantt charts and flow charts to track

project progress.

Copyright 2003 Joseph Greene All Rights Reserved

39

![Title of the Presentation Line 1 [36pt Calibri bold blue] Title of the](http://s2.studylib.net/store/data/005409852_1-2c69abc1cad256ea71f53622460b4508-300x300.png)