exp1_0903489 - Faculty of Engineering and Technology

advertisement

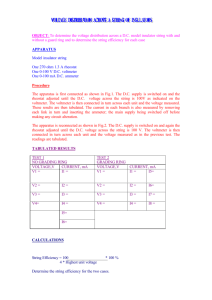

University of Jordan Faculty of Engineering & Technology Electrical Engineering Department Power Lab. EE 489 Experiment #1 A: Voltage Distribution Over A String Of Suspension Insulators ----------------------------------------------------------------------------------Objective: 1. To study the potential distribution over a string of suspension insulators. 2. To determine the string efficiency. 3. To investigate how the potential distribution can be equalized. Introduction: Overhead line conductors are not insulated and therefore, insulators mounted on crossarms are used to provide the necessary clearances required between the conductors and between conductors and earth under all operating conditions. The most common materials of insulators are porcelain and toughened glass. Their basic types are: 1. Pin type insulators. 2. Post insulators. 3. Suspension insulators. A Typical pin type insulator is shown in Fig. 1. It gets its name from the fact that it is made of one or two or more insulator sheds supported on a pin. They are simple in construction, cheap and seldom used on transmission lines above 44 kv because their cost increases very rapidly as the working voltage is increased. The post-type insulators are a modified version of the pin-type insulators, 1 but frequently have a metal cap so that more than one unit can be mounted in series. The creepage distance is made large by using many identical sheds. They are used up to the highest voltage levels and constructed for vertical or horizontal mounting. Fig.2 shows a typical post-type insulator. Suspension insulators consist of a single shed of insulator ( porcelain or glass ) with several skirts underneath , the number and creepage distance of the skirt increases for units to be used in heavily polluted and fog areas. Each insulator is cemented into a metal cap and a metal ball below, such that several identical units can be joined together in ball and socket joints to form an insulator string . Each insulator is designed for a comparatively low working voltage, (about 11 kv) and the insulator for any required line voltage can be obtained by the choice of the proper number of insulators. A typical suspension insulator is shown in Fig. 3. In the event of an insulator failure of one unit, that unit instead of the whole string has to be replaced. In the event of an increase in the operating voltage of the line additional units can be added instead of replacing all insulators. However, the main disadvantage is that the voltage distribution over each unit in the string will not be uniform and this is the subject of our experiment. Theory : Fig.4 shows a string of suspension insulators with the equivalent circuit capacitances. C = capacitance of each unit. mC= capacitance to ground . The student is asked to prove that the relations between voltages across the units are as follows: V2 =V1(l + m).......................................... ...........(1) V3 = V1(l+3m+m2)....................... ......................(2) V4 = V1 (l+6m+5m2 +m3)..................................(3) 2 Also, we have: V=V1+V2+V3+V4 ……………………………………(4) Where V is the total voltage across the string (transmission line voltage) and Vl,V2,V3 &V4 are the voltages across the subsequent units starting from the ground end . From (1),(2),(3) and (4) we can prove that: V1 = V/(4 + 10m + 6m2 + m3)............................................... (5) V2 = V(l + m)/(4 + 10m + 6m2 + m3)............................... .....(6) V3 = V(l + 3m + m2) / (4 + 10m + 6m2 + mJ)....................... (7) V4 = V(l + 6m + 5m2 +m3)/(4 + 10m + 6m2 +m3)................(8) It is quite clear that the voltages V1, V2, V3 &V4 are not equal and therefore the voltage is not equally distributed over the units of the string. Procedure(l) : Determination of Voltage Distribution 1. Connect the condensers as shown inFig.4 , to represent the insulators string and its capacitance to earth . Take C=Capacitance of each unit =2.2uf. Take mC=Capacitance to ground = 0.22uf. 2. Connect a 110 V through an ammeter across the string ,and measure the voltage across each unit. “Any noticeable ammeter reading means that the system is a fulty”. 3. Repeat the above procedure for values of mC = 0,0.47, 0.69 uf. 4. Plot on the same graph a set of curves for the voltage distribution across the condensers for each value of mC . 5. Compare the results obtained experimentally with those calculated using equations (5) to (8) 3 6. Calculate the string efficiency for each mC value as follows: String efficiency = Voltage across the string /(N * Voltage across the unit adjacent to the line conductor) ; Where N=Number of units. -The student is asked to prove that the string efficiency is given by : 4 10m 6m2 m3 4 1 6m 5m2 m3 ……………………..(9) -Check the correlation between efficiencies obtained from the measured and theoretical (calculated) values. It is thus seen that the voltage distribution is not uniform; however it can be theoretically controlled by two methods: Equalization Of Voltage Distribution a-Grading of the units : With reference to Fig. 4, it is readily evident that if we can use different types of units; i.e. C4 > C3 > C2 > C1 , the voltage across the lower units will be reduced while the voltage on the top units will be increased . The student is asked to prove that perfect grading; i.e. V1=V2=V3=V4 is achieved if Cn = Cn-1+(n-l) mC ...................................................(10) Where : Cn = the capacitance of the nth unit . Cn-1= capacitance of the lower unit . mC = capacitance to ground . This method necessitates the use of different types of units and therefore it is completely impractical and has never been used . 4 However to confirm these results, connect the circuit as shown in Fig.4, but with the new values of capacitance as determined from equation (10). Measure V1, V2, V3 & V4 and comment on the results. (Take mC = 0.22uf and C1 = 2.2 uf ) . b-Static Shielding: In this method voltage distribution is controlled by employing a grading or guard ring which usually takes the form of a large metal ring surrounding the bottom unit and connected to the line. This ring has the effect of increasing the capacitance between the metal work and the line. The student is asked to prove that if V1=V2=V3=V4 then : C1= mC/( N-l), C2= 2mC/( N-2), C3= 3mC/( N-3 ) .....................................................(11) Where : N = Number of units . Procedure (2) : Voltage Control using static shielding 1-Take mC= 0.47uf, and C= 2.2uf as shown in Fig. 5 . 2-Connect condenses to represent the guard ring effect, adjusting the values of condensers C1 , C2 , C3 as near as possible to the values calculated according to equation(l1). 3-Connect a 110 V through an ammeter across the string and measure V1, V2, and V3 &V4. 4-Comment on the results obtained. 5 Fig.1: Pin Type Insulator Fig.2: Post Type Insulator Fig.3: Suspension Insulator 6 Fig. 4: Equivalent Circuit of 4 Suspension Insulators Fig. 5: Equivalent Circuit of 4 Suspension Insulators with Guard Ring. 7 University of Jordan Faculty of Engineering & Technology Electrical Engineering Department Power Lab. EE 489 Experiment #1 B: 1-t Charachteristics of a Wire Fuse in The Overcurrent Zone -------------------------------------------------------------------------------------------------------- Introduction With the wide spread of utilization of electrical energy in industrial and domestic uses, the need arose for a reliable and simple method of protection. Wire fuses were the earliest protection device used for protection of electrical equipment against damage caused by overloading or short circuit. They were developed by, Edison as early as 1880 using lead , platinum and tungsten wires and taking different forms . The wire is capable of carrying the full load current without deterioration and if this current is exceeded by a certain value in the overcurrent zone then during the prearcing time the fuse element temperature increases until the melting point is reached somewhere along the element ( usually the midpoint). Disruption of the element then occurs and an arc is usually drawn between the molten ends of the broken element. This situation continues during the arcing time until final interruption of the circuit is achieved. The sum of the arcing and the prearcing times gives the total operating time of the fuse. However, under short circuit conditions the element melts along almost the whole of its length and in a very short time (10~20ms). The original forms are similar to the semi-enclosed fuses shown in fig. 1. These fuses suffer from the problem that the wire element is liable to oxidation which may significantly affect its fusing characteristics. In addition, terminals tightness problems and the fire risk involved if not 8 carefully protected made their use unfavorable. This led to the development of cartridge or high rupturing capacity ( H.R.C ) fuses where the fuse element is attached to plated copper connectors and caps surrounded by powder quartz which absorbs the heat generated within the element and transmits it uniformly through a ceramic or melamine glass cartridge . This cartridge is hermetically sealed to prevent oxidation of the fuse element. The different types of fuse elements of the cartridge fuse are shown in fig. 2. Procedure : 1 - Connect the circuit as shown in Fig. 3. 2- Adjust the setting of the RXIG2 (2.5-7.5A) to minimum, and adjust the resistance R to the position shown in fig.3. 3- Adjust the variac to produce an output voltage as shown in table 1. 4- Close the contactor and take the reading I1= ( Ifuse / 25) and the time required by the fuse to interrupt the circuit. 5- Repeat steps 3-4 for all voltages in the table. 6- Draw the I-t characteristics of the wire fuse and comment on the results. Table 1 Measurement Ser. No. Input Voltage (V) 1 130 2 3 4 5 6 7 8 9 10 135 140 150 160 170 180 190 200 210 Primary Current Fuse 1/25 (A) 9 Time sec. I Fuse developed by Prof. S.f. Thompion Fuse patented by Roly and Cunygham Fuse developed by Cockburn Cutaway view of cartridgc fuselink Fig. 1: Semi-enclosed and Cartridge Fuses (a) (b) Typical designs (c) of (d) enclosed (e) fuse-element Fig. 2: Fuse – elements of Cartridge Fuses 10 RXIC2 (2.5-7.5A) Fig. 3: Circuit diagram for testing wire fuse 11