3 - DCU

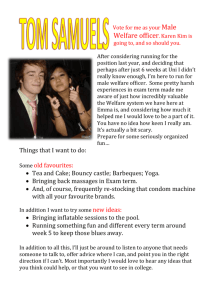

advertisement