MECH23 - aditya institute of technology & management

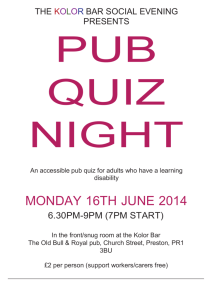

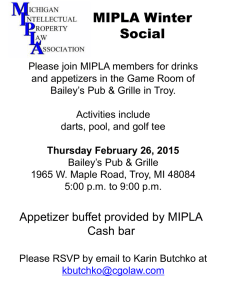

advertisement