3. Physical and chemical properties

advertisement

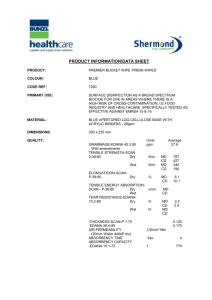

HET COLLEGE VOOR DE TOELATING VAN GEWASBESCHERMINGSMIDDELEN EN BIOCIDEN BIJLAGE II bij het besluit d.d. 8 februari 2013 tot toelating van het middel Kathon 910 SB Biocide, toelatingnummer 13967 N RISKMANAGEMENT Contents 1. 2. 3. 4. 5. 6. 7. 8. 9. Page Introduction .................................................................................................................... 2 Identity ........................................................................................................................... 2 Physical and chemical properties ................................................................................... 3 Efficacy .......................................................................................................................... 4 Human toxicology........................................................................................................... 5 Environment ................................................................................................................... 9 Conclusion ................................................................................................................... 21 Classification and labelling ........................................................................................... 21 References................................................................................................................... 22 pag. 1 van 27 1. Introduction Kathon 910 SB biocide This assessment concerns a biocidal product based on the active substance 4,5-dichloro2-octylisothiazol-3(2H)-one (DCOIT). The assessment includes the following products: Product Applicant PT Kathon 910 SB biocide 7, 9 en 10 20121122 TB Rohm and Haas Europe Trading ApS Application number The active substance DCOIT has been notified for product types 7, 8, 9, 10 en 11. DCOIT is placed on annex 1 of Directive 98/8/EC for PT8, which is not the product type for these applications. The other active substances have not been placed on annex 1 of Directive 98/8/EC yet. 2. Identity 2.1 Identity of the active substance 2.1.1 DCOIT General Active substance (ISO Common Name) Name in Dutch DCOIT (non-ISO) DCOIT Identity Chemical name (IUPAC) Chemical name (CA) CAS No EC No Other substance No. 4,5-Dichloro-2-octylisothiazol-3(2H)-one 4,5-Dichloro-2-octyl-3(2H)isothiazolone 64359-81-5 264-843-8 - Molecular formula Molecular mass Structural formula C11H17Cl2NOS 282.2 The active substance is not yet included in annex I of Directive 98/8/EC. A CAR of the active substance is available for PT8 (draft final, January 2010) and PT21 (first draft December 2010). RMS is Norway. pag. 2 van 27 2.2 Physical and chemical properties of the active substance 2.2.1 DCOIT Physical and chemical properties relevant to the risk assessment Appearance Off-white solid at 20°C Surface tension 70.8 mN/m Vapour pressure (Pa) 9.8x10-4 Pa at 25 °C 3 -1 Henry’s law constant (Pa m mol ) 2.20x10-1 Pa.m3.mol-1 at 20 °C and pH7 Solubility in water (g/L or mg/L) pH__5____:2.85 mg/l at 10°C 4.26 mg/l at 20°C 6.68 mg/l at 30°C pH__7____:2.26 mg/l at 10°C 3.47 mg/l at 20°C 5.67 mg/l at 30°C pH__9____: Technically not possible (hydrolysis) Partition coefficient (log POW) 2.8 (independent of pH) at 23 °C Dissociation constant No dissociation within an environmentally relevant pH range. UV/VIS absorption (max.) (if absorption > Neutral pH: λmax at 284 nm (ε 10314), 230 nm (ε 5924); 290 nm state at wavelength) Acid pH: λmax at 284 nm(ε 10618), 230 nm (ε 6100); Basic pH λmax at 227 nm (ε 13527) Hazard identification for classification and labelling Flammability Flashpoint: N/A Flammability: Not highly flammable Auto-flammability: 264 °C Oxidising properties Not oxidising Explosive properties Not explosive 2.3 Analytical methods for the technical active substance Adequate analytical methodology is available to determine the content of active substance and significant and/or relevant impurities in the technical active substance. 2.4 Overall conclusions active substance The identity, physical and chemical properties and analytical methods of the active substance are sufficiently described. 3. Physical and chemical properties 3.1 Identity of the biocidal poduct Kathon 910 SB Biocide Name Kathon 910 SB Biocide Content active substance 9.3% pure 4,5-dichloro-2-octyl-3(2H)-isothiazolone (DCOIT) Formulation type AL Packaging Fluorinated HDPE (HDPE/F): 20kg, 175kg, 900kg, 1000kg pag. 3 van 27 3.2 Physical and chemical properties of the biocidal product Kathon 910 SB Biocide Appearance Very light yellow-green liquid Explosive properties Not explosive Oxidising properties Not oxidising Auto-flammability 235 °C Flashpoint or Flammability Flashpoint: 142 °C pH 1% solution 10% in acetone/water: 4.3 Relative density D420 = 0.885 Storage stability/ Shelf life 2 years in fluorinated HDPE Physical and chemical compatibility Not applicable Viscosity 23 mm2/s at 20 °C Surface tension 67.3 mN/m at 20 °C 3.3 Analytical methods for detection and identification 3.3.1 Analytical methods for analysis of the biocidal product Kathon 910 SB Biocide Preparation (principle of method) HPLC-UV 3.3.2 Residue analytical methods Adequate residue analytical methodology is available to monitor residues of the biocide taking into account all possible exposure scenarios and the toxicity of the active substance(s). 3.4 Conclusions biocidal product Kathon 910 SB Biocide The identity, the physical and chemical properties and the analytical methods of the biocidal product are sufficiently described. 4. Efficacy Function Kathon 910 SB Biocide is an preservative for films (PT07), fibre, paper (PT09), and masonry which is added to polymeric (silicone) caulks, sealants, mastics, joining materials, and silicone building materials (PT10) in order to control bactericidal, fungal, and algal detoration in and on final products. The product is based on 4,5-dichloro-2-octyl-2H-isothiazol-3-one, hereafter referred to as DCOIT, and intended for professional use only. Mode of action DCOIT utilizes a two-step mechanism involving rapid growth inhibition leading to a loss of viability. Growth inhibition is the result of rapid disruption of the central metabolic pathways of the cell by inhibition of dehydrogenase enzymes. Key physiological activities that are rapidly inhibited in microbial cells are growth (reproduction) and respiration (oxygen consumption). These processes are critical in bacteria, algae, fungi, and invertebrates, which explains why DCOIT is such a broad spectrum biocide. Inhibition of cellular activity is rapid (within minutes), whereas, cell death (cidal activity) is observed after several hours contact. Cell death from DCOIT results from the progressive loss of protein thiols in the cell from one of multiple pathways. In general, the higher the concentration of DCOIT, the shorter the contact time required for inhibition and kill. Other isothiazolone biocides have been shown to generate free radicals within cells as metabolism is disrupted. The production of these radicals is considered a critical factor contributing to cell death and DCOIT is suspected to exhibit this same response in microbial cells. The two step mechanism of action of DCOIT results in its broad spectrum of activity, low use levels for microbial control, and difficulty in attaining resistance. pag. 4 van 27 Resistance No resistance to DCOIT is known. Considering that the authorisation is done under article 121 of the WGB this is acceptable. Conclusions Considering that the evaluation is done under article 121 of the WGB and that the product has already been on the market for some time, it can be concluded that when used in accordance with the proposed label (WG/GA), may be expected that: Kathon 910 SB Biocide is effective as a preservative in controlling bacteria, algae, and fungi in polymeric (silicone) caulks, sealants, mastics, joining materials, and silicone building materials. 5. Human toxicology DCOIT (4,5-Dichloro-2-octyl-2H-isothiazol-3-one) is an existing active substance, not included in Annex I of 98/8/EC. An application for inclusion is submitted for DCOIT for which Norway is the Rapporteur Member State. A draft final concept CA-report for DCOIT (Sept 2010) is available. 5.1 Human health effects assessment active substance Oral absorption of 4,5-dichloro-2-octyl-2H-isothiazol-3-one was estimated to be ca. 20%, as 20% of the applied does was recovered in urine (no information on biliary excretion). DCOIT is extensively metabolised. In several studies on dermal absorption rates between 17 and 70% were found related to the nature of the formulation and the concentration of DCOIT in the formulation that was tested. For risk assessment the dermal absorption is set at 24-51% for concentrations of approximately 0.25% and 22-31% for concentrations of 2% and above. Acute oral tests in rats and mice gave the following LD50 values: 1636 mg/kg bw (rat); 567 mg/kg bw (mouse). The LD50 values from dermal tests performed with formulations were > 652 mg ai/kg bw (rabbit); >500 mg ai/kg bw (rat). The inhalation LC50 was 0.26 mg /L. DCOIT is skin and eye corrosive and is a skin sensitizer in a maximization test at 0.01%. In repeated dose oral studies with rats (oral 28-day) and dogs (dietary 90 day) the lowest NOAEL (10 mg/kg bw/day) was found in the dog study based on minimal changes in body weight, feed consumption, haematology and clinical chemistry parameters. Rabbits were dermally exposed to a formulation containing DCOIT for 21 days with local effects at 0.35 mg/kg bw/day (LOAEL) and no systemic effects at the highest dose tested (1.75 mg/kg bw/day). Respiratory tract irritation and no systemic toxicity was seen at 0.63 mg/m3 in a 90-day study in rats (nose-only, 6h/d, 5/d/wk). The NOAEC from the study was 0.02 mg/m3, but as the effects in the study were largely attributed to o-xylene present in the formulation, a surrogate NOAEC of 0.25 mg/m3 was calculated from the LOAEC. DCOIT was considered not genotoxic in in vitro and in vivo assays. No effects on reproductive performance, hormone disruption or foetal development were reported in rats. The parental NOAEL is 16 mg/kg bw for effects on reproduction and 10 mg/kg bw/day for developmental effects. No data are available for carcinogenicity, but DCOIT is considered as not carcinogenic. Studies of DCOIT Technical in ethanol demonstrated that 250-350 ppm a.i. is at or near the threshold concentration for irritation and sensitization in humans. Based on the above mentioned the following AELs were derived: AELacute AELlong term 0.04 mg/kg bw/day based on 28-day oral study (safety factor 100) 0.02 mg/kg bw/day based on 90-day dietary study in dogs (safety factor 100) Local effects Studies of DCOIT Technical in ethanol demonstrated that 250-350 ppm a.i. is at or near the threshold concentration for irritation and sensitization in humans. pag. 5 van 27 The primary human health hazards associated with DCOIT are irritation of the skin, eyes, intestinal tract or lungs, as well as, allergy following repeated skin contact. There is no evidence of significant systemic toxicity at doses below those that gives significant local irritation. Therefore, acceptable exposure concentrations were determined: AECdermal AECinhalation 0.7 μg/cm2 (0.003%) based on repeated exposure human patch tests 0.005 mg/m3 based on the 13-week nose-only study (safety factor 48) Data requirements active substance No additional data requirements are identified. 5.2 Human exposure assessment active substance 5.2.1 General aspects Kathon 910 SB Biocide Kathon 910 SB Biocide is a liquid and contains 4,5-dichloro-2-octyl-2H-isothiazol-3-one as active substance (9.5%). The proposed fields of use are: PT 7: use as dry film preservative for polymeric (silicone) caulks, sealants, mastics, and joining materials PT 9 : use as preservative for polymeric (silicone) caulks, sealants, mastics, and joining materials PT10: use as masonry preservative for polymeric (silicone) caulks, sealants, mastics, and joining materials The formulation is intended for professional use only. 5.2.2 Identification of main paths of professional exposure towards active substance from its use in biocidal product An assessment of uses and exposure scenarios was made for the products. A summary of uses is given in Table T.1 below. Table T.1 Summary of uses Concentration a.s. in producta Kathon 910 SB Biocide 9.5% a Use concentration PT Application method Frequency 100-1000 ppm (0.01-0.1%) 71 Dosed to the end use fluid using automated dosing/metering system or manually Single application per batch 100-1000 ppm (0.01-0.1%) 91 Dosed to the end use fluid using automated dosing/metering system or manually Single application per batch 100-1000 ppm (0.01-0.1%) 101 Dosed to the end use fluid using automated dosing/metering system or manually Single application per batch pag. 6 van 27 Potential secondary exposure End-users (professional and nonprofessional), adults by touching, children by touching/ingesti on End-users (professional and nonprofessional), adults by touching, children by touching/ingesti on End-users (professional and nonprofessional), adults by touching, children by touching/ingesti on a Worst-case concentrations were used. Slightly lower concentrations were finally concluded in the PGB, however, differences were marginal and did not affect the outcome of the risk assessment. For Kathon 910 SB 9.5% was used instead of 9.3%. 1 Professional use Non-professional use 2 As the product is used by professionals, oral exposure is considered negligible. Respiratory and dermal exposure will be possible during (de)connection of the packages to the dosing device and when manually pouring the product into the system. In addition, during cleaning of the system professionals could be exposed. Considering the low vapour pressure of the active substance (9.8 x 10-4 Pa at 25 °C), considerable inhalation exposure is not to be expected. 5.2.3 Identification of main paths of non-professional exposure towards active substance from its use in biocidal product The products are intended for professional use only. 5.2.4 Indirect exposure as a result of use of the active substance in biocidal product During application of Kathon 910 SB Biocide in PT 7, 9 and 10 products, dermal and inhalation exposure of professional and non-professional users to DCOIT is possible. In addition, dermal exposure of the general public by touching of treated products/surfaces cannot be excluded. For children concomitant oral exposure via hand-mouth contact may be possible. 5.3 Human health effects assessment product 5.3.1 Toxicity of the formulated product Kathon 910 SB Biocide Studies with Kathon 910 SB Biocide have been submitted for acute oral and dermal toxicity as well as for skin and eye irritation. For the remaining endpoints the classification and labelling of the formulation has been prepared based on the calculation method described in Annex I of Regulation 1272/2008/EC (CLP). The formulation Kathon 910 SB Biocide does not need to be classified on the basis of its acute oral (LD50 rat >5000 mg/kg bw) and dermal toxicity (LD50 rat >5000 mg/kg bw). The formulation Kathon 910 SB Biocide needs to be classified as H332, ‘Harmful if inhaled’. The formulation Kathon 910 SB Biocide is considered irritating to skin and needs to be classified as H315, ‘Causes skin irritation’. The formulation Kathon 910 SB Biocide is considered not irritating to eyes. The formulation Kathon 910 SB Biocide needs to be classified as H317, ’May cause an allergic skin reaction’. 5.3.2 Data requirements formulated product No additional data requirements are identified. 5.4 Risk characterisation for human health Starting point for the risk assessment is the dermal AEC of 0.7 µg/cm2 (0.003%) for DCOIT. Inhalation exposure is expected to be low in view of the low vapour pressure of DCOIT. 5.4.1 Professional users For dermal exposure during pouring of the formulation manually, a calculation of exposure was made based on mixing and loading model 1 ((TNsG part 2 p 135). It is assumed that Kathon 910 SB Biocide is manually added only when in plastic pails of 20 pag. 7 van 27 kg each. As no details on the number of batches produced per day has been provided by the applicant, it is assumed workers will be exposed 4 times per day for maximum 0.5 hours per day. This would lead to a maximum dermal exposure of 150 mg/day for the formulation, i.e. 14.3 mg DCOIT/day. It is assumed that exposure of hands and underarms is possible (total surface 1980 cm2). This would lead to an exposure of 7 µg/cm2. Application of protective clothing (gloves and coverall) would lead to a reduction of the exposure to the level of the AEC dermal of 0.7 µg/cm2. Table T.2 Professional operator exposure to DCOIT and risk assessment for the use of Kathon 910 SB Biocide Estimated external exposure (mg /day) Local AEC Risk-indexa Manual pouring, no PPE Mixing/loading b Dermal 14.3 (7 µg/cm2) 0.7 µg/cm2 10 Manual pouring, with PPE Mixing/loading b Dermal 1.43 (0.7 µg/cm2) 0.7 µg/cm2 1 Route a b The risk-index is calculated by dividing the internal exposure by the AEC. Exposure is estimated with mixing and loading model 1. Inhalation exposure was not taken into account, but in view of the low vapour pressure of the substances in the formulation, this is considered negligible. On the basis of the above considerations, it can be concluded that the risk when manually loading the formulation Kathon 910 SB Biocide for the professional user is acceptable with personal protection, i.e. gloves and coverall. A risk index of 1 is considered sufficient here as especially the estimation of exposure with mixing and loading model 1 represents a very worst case estimate, all other models e.g. mixing and loading model 3 (TNsG part 2 p 137) would lead to a 10-fold lower exposure estimation. As the calculation presented above is expected to represent a worst case situation, the risk related to all other uses during (de)connection, pouring and cleaning is considered to be acceptable with personal protection, i.e. gloves and coverall. 5.4.2 Non-professional users, including the general public The product is intended for professional use only. 5.4.3 Indirect exposure as a result of use Secondary exposure of both professionals and non-professionals to products containing Kathon 910 SB Biocide cannot be excluded during application. The concentration in the products (0.01-0.1%) is above the AECdermal of 0.003% (0.7 μg/cm2). A leaching study submitted by the applicant showed that the leaching rate from sealant samples was less than 30 ng/cm2. The nominal levels of DCOIT in the sealants was 500 – 600 ppm. Products contain at maximum 1000 ppm DCOIT, therefore the leaching rate was estimated to be 60 ng/m2 (factor 2). It is proposed that 18% of the potential surface residue is transferred to the skin (data from TNsG, Part 2, p. 204 for dried fluid on various types of surface). This would lead to an exposure of 10.8 ng/cm2. As this is below the AECdermal of 0.003% (0.7 μg/cm2) it can be concluded that no adverse health effects are expected from indirect exposure to DCOIT after dermal contact with products containing DCOIT after application of Kathon 910 SB Biocide. Several sensibilisation studies with formulated products have been submitted. Some products are negative in a Buehler test, even up to concentration DCOIT of 1000 ppm (0.1%). However, other products induced sensitizing reactions, in general in products with concentrations from 500 ppm and above. The active substance is a known sensitizer, for which in the CAR the setting of lower specific concentration limit of 0.001% is suggested. DCOIT should be categorised as an extreme sensitizer based on a maximisation assay with a specific concentration of pag. 8 van 27 0.001%. Based on the above considerations all products containing Kathon 910 SB Biocide needs to be labelled with DPD11 / EUH208 ‘Contains 4,5-dichloro-2-octyl-2Hisothiazol-3-one. May produce an allergic reaction’ or in case of a positive sensitization test with R43 ‘May cause sensitisation by skin contact’ / H317 ‘May cause an allergic skin reaction’. 5.4.4 Combined exposure The product contains only one active substance and it is not described that it should be used in combination with other formulations. 5.5 Overall conclusions Kathon 910 SB Biocide For the unprotected professional operator, adverse health effects after dermal/respiratory exposure to DCOIT as a result of the application of Kathon 910 SB Biocide cannot be excluded. Correct use of personal protective equipment (gloves and cover all) will reduce the dermal exposure and results in a sufficient reduction of the exposure to DCOIT for the application of Kathon 910 SB Biocide. Considering the low vapour pressure of the active substance (9.8 x 10-4 Pa at 25°C), inhalation exposure is expected to be negligible. Based on the risk assessment, it can be concluded that adverse health effects can be excluded for the unprotected and protected professional and non-professional users after indirect exposure to DCOIT as a result of use of Kathon 910 SB Biocide. Regarding the sensitizing properties of DCOIT the products containing Kathon 910 SB Biocide must be labelled accordingly (DPD11 / EUH208 ‘Contains 4,5-dichloro-2-octyl-2H-isothiazol-3one. May produce an allergic reaction’ or depending on concentration or test results, R43 ‘May cause sensitisation by skin contact’ / H317 ‘May cause an allergic skin reaction’). 6. Environment 6.1 Introduction Kathon 910SB Biocide contain as active substance 4,5-dichloro-2-octyl-2H-isothiazol-3one (hereafter referred to as DCOIT). The intended uses are described in table E.1. Kathon 910SB Biocide concern preservative for application in product types PT7, 9 and 10. The biocide is added to end product professionally, but treated products may be used by non-professionals as well. Table E.1. Intended uses No. Intended Use 1 6.2 Kathon 910SB Biocide: Preservation of polymeric (silicone) caulks, sealants, mastics, and joining materials (PT7, 9, 10) Dosage Indoor / Professional / outdoor non professionals 1.05 kg-10.53 kg for a both one ton batch, which is equivalent to approximately 100 ppm to 1000 ppm active ingredient. Industrially added Treated product is used by Professionals and Non professionals Environmental effect assessment Risk assessment is based on predicted no-effect concentrations (PNECs) for the different compartments which are derived from ecotoxicity data and applying assessment factors. The assessment factor depends on the type of test performed (acute or chronic), the pag. 9 van 27 toxicological endpoint (effect concentrations (ECs), no-observed effect concentrations (NOECs), etc) and the number of data and is determined according to the Technical Guidance document (version 2003 chapter 3). The PNECs based on the ecotoxicological data for the active substances are presented in table E.2. The derivation of the PNECs is described in Appendix I. Table E.2. PNECs for the active substance DCOIT compartiment PNEC Lowest EC10/NOEC AF Test/species Aquatic 0.034 μg/L* 0.34 μg/L 10 Navicula pelliculosa STP 0.064 mg/L 0.64 mg/L 10 Activated sludge 0.41 mg 14C equiv./kg wwt 4.9 mg/kg dwt 10 Chironomus riparius Soil 0.062 mg/kg wwt 3.5 mg/kg dwt TWA 50 Earthworm reproduction Birds/mammals 1.55/4.49 mg/kg food 5d LC50 >4640 mg a.i./kg food / NOECmammals 404 mg a.i./kg food sediment 3000/ Bobwhite 40 quail/dogs * Additionally for intermitted release (in case of complete release of a swimming pool) a PNEC 0.34 µg/L is derived, using the lowest NOEC with an assessment factor of 1. 6.3 Environmental exposure assessment 6.3.1 Chemistry and/or metabolism In a ready biodegradation study, DCOIT was not classified as ready biodegradable. This was most likely due to inhibition of the inoculums by DCOIT where at the test concentration DCOIT was toxic to the microorganisms and thereby inhibiting biodegradation. However, in a OECD 303A simulation test radioactive labelled carbon that was found in the effluent could not be related to DCOIT, which was confirmed with DCOIT analyses. It was therefore assumed that DCOIT quickly degrades in an STP. Half-lives in the environment are short, being 0.689 day in water and 4.7 days in soil. Metabolism involves cleavage of the isothiazolone ring and subsequent oxidation. Dissipation of DCOIT in the environment comprises of biological degradation (mineralization and primary degradation) with subsequent incorporation of the breakdown products into the non-extractable residue fraction of soil and sediments. Abiotic degradation via chemical reactions may also occur. The biodegradation of DCOIT in the aquatic environment is given in Figure E.1. pag. 10 van 27 Figure E.1 Aquatic metabolic pathway for DCOIT due to biodegradation The main metabolites identified in the several abiotic and biotic degradation tests are listed in Table E.3. The fraction of parent represents the highest fraction detected in the respective environmental fate study. pag. 11 van 27 Table E.3. Metabolites of DCOIT Metabolite Max. % detected N-(n-octyl) malonamic acid 16 (NNOMA) In sediment N-(n-octyl) acetamide (NNOA) 12.4 In sediment N-(n-octyl) oxamic acid 31 (NNOOA) In water phase N-(n-octyl) oxamic acid 24.4 (NNOOA) In water phase (1-chloro-2-(n-octylcarbamoyl)(8.9) 1-ethene sulfonic acid)* 2-chloro-2-(n-octylcarbamoyl)-1- 11.8 ethene sulfonic acid In water phase (at 100 ppb) 1-chloro-2-(n-octylcarbamoyl)-1- 11 (pH7, 40°C) ethene sulfonic acid In water phase 2-chloro-2-(n-octylcarbamoyl)-1- 11 (pH7, 40°C) ethene sulfonic acid In water phase Reference endpoint Seawater-sediment aerobic biodegradation Seawater-sediment aerobic biodegradation Photolysis Estuarine water biodegradation Estuarine water biodegradation Estuarine water biodegradation Hydrolysis Hydrolysis * 1-chloro-2-(n-octylcarbamoyl)-1-ethene sulfonic acid was not formed in amounts > 10%; however, concentrations of this metabolite were increasing during the course of the test, not reaching a plateau at the end of the study. It is therefore possible that this metabolite might have passed the 10% threshold if the study had been prolonged. Moreover, 1-chloro-… and 2-chloro-… are isomers in equilibrium and it is not clear whether the ratio detected in the estuarine study would always be that only 2-chloro-… is detected in amounts > 10%. The cleavage of the isothiazolone ring results in metabolites which are less toxic than DCOIT. The metabolites are an order of magnitude of 2 to 5 less toxic than DCOIT based on acute toxicity data for aquatic organisms. Furthermore, the metabolites NNOMA and NNOA are readily biodegradable and (Q)SAR predicts NNOOA to be readily biodegradable. Therefore the risk assessment of DCOIT covers the risk assessment of its metabolites. Risk assessments for the metabolites will therefore not be calculated and presented in the product assessments. 6.3.2 Distribution in the environment Various phases in the life cycle of a product may cause emissions and environmental exposure. In the risk assessment, emissions from the polymer manufacturing, service life and waste phase of the of the treated article are considered. Emissions from active substance production are not included in the risk assessment. Table E.4 summarises the receiving environmental compartments that have been identified as potentially exposed during the use of the products for the different applications. Table E.4. Foreseeable routes of entry into the environment on the basis of the intended use relevant for all three products. Main scenario Environmental compartments and groups of organisms exposed STP Freshwat Saltwat Soil Air Birds and 1 1 2, 3 er er mammals preservation of polymers, including sealants, mastics, ++ ++ +/++ +/++ (Q) ++ + joining materials, and (Q) roofing membranes preservation of swimming ++ ++ ++ + pool liners (Q) ++ Compartment directly exposed, + Compartment indirectly exposed, (Q) Qualitative assessment, depending on application, 1 Including sediment, 2 Including groundwater, and soil invertebrates and arthropods, 3 In the Netherlands, surplus sludge of public STPs is not applied for fertilization and soil improvement of agricultural soil. Therefore, exposure of soil and groundwater via STP pag. 12 van 27 surplus sludge application is not part of the risk assessment. Due to the outdoor use of articles treated with the products leaching from the treated articles to soil and water may occur. 6.3.3 Predicted environment concentration calculations 6.3.3.1 General Predicted Environmental Calculation (PECs) were calculated according to relevant exposure scenario documents (ESDs, release to the environment), the Technical Guidance Document (distribution in the environment), and the model SimpleTreat (concentrations for micro-organisms in an STP and the STPs’ effluent) by using the default values for parameters, unless otherwise noted. Addition of the active substances to end products is usually done indoors in a controlled environment regulated by various legislations. Therefore, emission of the active substance during manufacturing of the end products is considered negligible and will not be assessed. Release of DCOIT during the waste phase is assessed either, because it is assumed that end-products to which DCOIT is added are disposed as solid waste and usually burned. 6.3.4 Preservation of polymers Emission scenario documents (ESDs) are available for PT07, PT09 and PT10. A limitation of the PT07 scenario is that it calculates exposure from paints on regional scale only based on the total tonnage of the product brought on the regional market. The available scenarios for polymers in PT09 are based on total polymer production. Therefore, predicted exposure concentrations (PEC) for PT07 and PT09 applications were calculated using the ESDs for wood preservatives (PT08) and masonry preservatives (PT10) as these provided realistic scenarios to assess exposure resulting from outdoor application of polymers applied in fences, houses claddings, bridges, jetties, and noise barriers on a local scale i.e. direct emission to soil and surface water from a single application or the emission to one STP. The following exposure routes were identified and assessed: direct release to surface water: PT08 offers a worst-case scenario for direct exposure to surface water by leaching during service life. This scenario assumes a bridge of 10 m² above a pond of 20 m³, which covers uses of treated polymers above or adjacent of surface water. Degradation of DCOIT was taken into account as water in ponds is stagnant and not refreshed; direct release to STP and indirect release to surface water: The scenario was adapted from PT10 which offers a scenario for treating masonry in cities where spills and precipitation holding the biocides (leachate) is collected and discharged via the sewer system to a STP. For this specific use it was assumed that 125 m² (TGD-default for façades and considered representative for flat roofs when polymers are applied as roofing membranes) per house is covered with DCOITenriched polymers. This scenario results in PECs for STPs directly exposed and PECs for surface water and sediment after purification of waste water. The scenario, however, estimates the release from one treated building, while 4000 houses are connected to one STP (TGD default). However, emission by leaching varies among these houses as some treated polymers are recently applied, resulting in the highest leaching rates, while leaching from other locations is remarkably lower or even negligible as the active substance is completely leached. To correct for this, the service life of polymers was set to 10 years, whereby it was assumed that all preservative in the polymers has leached within 3 year after application as data on long-term leaching was missing (see below). As the service life is 10 years, the number of houses with polymers from which the active substance is leaching was assumed to be 30%, from which a part (30/1095) the active substance is leaching fast. The daily emission is therefore the sum of fast and slow leaching. As not all roofs are covered with polymers but also other material, it was assumed that 50% of the roofs were treated with polymers. This results in 600 houses that contribute to the daily emission. Degradation was not taken into account as the active substance is eventually released into a flowing pag. 13 van 27 water body. As the significant lower surface of tarpaulins, the risk assessment for roofing membranes covers this use as well; direct release to soil: PECs for soil were calculated by applying the house scenario according to PT08. This scenario assumes that the soil (12.5 m³) adjacent of the façade (125 m²) is polluted by leaching from roofing membranes, covering the application in tarpaulins as well. PECs were calculated without and with degradation. Final PEC were calculated exclusive and inclusive degradation. Uses in pool lining have been assessed separately using the PT02 public and private swimming pool scenario. The swimming pool scenario takes into account three types of release: 1. direct emission to surface water from a one time release (complete pool volume discharged to surface water) 2. a daily discharge (chronic emission of a fraction of the swimming water) 3. daily emission of a fraction of the swimming water to the STP. It is assumed that the active is leached from the lining to the swimming water, which is released to surface water or sewer. The PEC for direct release to surface water is calculated using a dilution factor (see appendix III), concentrations in the STP and the STP’s effluent are calculated using SimpleTreat using the parameters presented in appendix II. When in use DCOIT will leach from treated surfaces. The applicant has submitted a leaching study showing a leaching rate of 10.9 mg/m²/d from polymers. However, this study was done for polymers completely submerged in water that was shaken for 24 hours. This rate is appropriate to assess environmental exposure during the 30 days after application, but because leaching may decrease in time, this value will overestimate the PEC for the longer assessment period. Moreover, this leaching rate suggest that 100% is leached in less than 150 days as the initial DCOIT concentration is 1620 mg/m² when an average polymer thickness and density of 1 mm and 1.35 L/kg, respectively, is considered. It was therefore assumed that the remaining DCOIT will leach completely in three years, resulting in a leaching rate of 1.18 mg/m²/d. For swimming pools, however, a different approach was used. Continuous release was modelled using a leaching rate of 10.9 mg/m²/d, which represents the worst-case i.e. emission from swimming pools with recently applied liners. To assess emission from swimming pool liners in pools with an annual water replacement, an average leaching rate of 1.48 mg/m²/d was used, based on 1620 mg DCOIT/m² and a service life of three years. PEC were calculated by using the default values for parameters, unless otherwise noted (Table E.4.) and the concentrations listed in Table E.1. (highest concentration only). Emission during service life was calculated over 13 years (1095 days) representing the worst-case. Input parameters including motivation, are listed in Table E.5. The input parameters applied for SimpleTreat and the swimming pool scenario’s are listed in Appendix II and III, respectively. pag. 14 van 27 Table E.5. Input parameters parameter scenarios Volume applied Density of the product Volume of soil adjacent to surface treated Cumulative quantity leached over initial period (30 days) Cumulative quantity leached over longer period (1 year) value 8.3.3.Wood preservatives: brushing house 8.3.4.Wood preservatives: brushing bridge 10.2. Masonry – In-situ brushing of a façade of a house in a city n.a. n.a. 12.5 m³ 3.27E-04 kg/m² remarks Calculations made for both application phase and service-life Polymers are manufactured elsewhere in a controlled environment. Emission to the environment during application is therefore not expected. As a result of the Technical Meeting held in June 2011, Milan, Italy, depth and width of soils adjacent of buildings is enlarged to 0.5 × 0.5 m, and depth of soils distant to buildings to 0.5 m.* see explanation in section 6.3.4. 1.29E-03 kg/m² Time for longer assessment period 1095 days Half lives in water (12°C) Half lives in sediment (12°C) Half lives in soil (12°C) 0.686 days not available 4.7 days pag. 15 van 27 Leaching was calculated over a three year period, considering as a realistic worst-cas Degradation rate constant in an STP see remarks DCOIT was not detected in an artificial STP when biodegradability was measured according to OECD 303A. The measured radioactive labelled carbon was most likely related to metabolites as chromatographic analyses did not detect DCOIT. The metabolites are an order of magnitude of 2-5 less toxic as DCOIT, as discussed previously. Therefore, it was assumed that an STP effectively removes 99% of DCOIT from the influent. PECSTP, however, was based on a degradation rate constant of 24/d (default). Polymers applied indoors may have emission to an STP during cleaning. However, Swedish data demonstrated that leaching from these products is about 0.05% per year. On basis of the tonnage data provided and the emission factor it can be concluded that emission to the local STP per day is insignificant. This route of exposure is therefore not discussed further and covers intended uses such as vinyl floor and wall covering, water beds, upholstery, boots and shoes. Mattress protection, may cause release to the sewer when washed. This will occur only occasionally at present no scenario is available. It is supposed that this type of use is covered by other uses with emission to the sewer. 6.3.5 Preservation of caulks Kathon 910SB Biocide is only added to fillers and sealants, which are applied both indoors and outdoors. Considering that the total volume of caulks is negligible compared to polymers applied as swimming pool liners and roofing membranes, risk assessment of the latter will cover environmental risks for caulks as well. No additional calculation concerning caulks are therefore made. 6.4 Risk characterisation for the environment For each relevant compartment, PECs are divided by PNECs. Risks are considered potentially unacceptable when PEC/PNEC >1. 6.4.1 Water and sediment organisms and micro-organisms in the STP Direct exposure to surface water The risk characterisation for the aquatic compartment (freshwater and sediment) receiving the active ingredients directly are presented in Table E.6. Table E.6. PEC and PEC/PNEC ratios for direct exposure to fresh water and sediments. fresh water PEC (mg/L) PEC/PNEC sediment Scenario PEC (mg/kg PEC/PNEC wwt) application in polymer above stagnant water (bridge scenario) without degradation 4762 57 after 30 days 1.62E-01 2.34E+01 pag. 16 van 27 fresh water PEC (mg/L) PEC/PNEC Scenario 23590 after 3 years 8.02E-01 with degradation 152 after 30 days 5.17E-03 17 after 3 years 5.78E-04 swimming pool (replacement of swimming water) 3.60 public 1.22E-02 58.7 private 2.00E-01 n.c. sediment PEC (mg/kg PEC/PNEC wwt) 283 1.16E+02 7.46E-01 8.36E-02 1.82 0.204 n.c. n.c. n.c. n.c. not calculated Direct emission to surface water due to leaching from polymers applied in, above, and/or adjacent of water or emptying swimming pool water directly into surface water will cause an unacceptable risk for water organisms, even when degradation is taken into account. Considering the negligible water-exposed surfaces of caulks compared to polymer bridges and swimming pool liners, the application of DCOIT as preservative in sealants and fillers will not result in unacceptable risks for the aquatic environment. Therefore, the environmental standards are met, but only for applications in fillers. Direct exposure to the STP and indirect exposure to surface water - outdoor use The risk characterisation for the aquatic compartment (freshwater and sediment) receiving the active ingredients indirectly via an STP are presented in Table E.7. Table E.7. Compound PEC and PEC/PNEC ratios for micro-organisms in the STP and freshwater and sediment indirectly exposed. STP PEC PEC/PN (mg/L) EC daily emission from 600 4.90E-03 houses in a city swimming pool (continuous release) public 2.02E-03 private 4.14E-04 fresh water PEC PEC/PN (mg/L) EC 0.077 5.37E-05 1.58 0.032 0.006 1.89E-04 3.86E-05 0.555 0.114 sediment PEC PEC/PN (mg/kg EC wwt) 7.76E-03 0.019 n.c. n.c. n.c. n.c. The addition of DCOIT to polymers that are subsequently applied outdoors on façades and roofing materials results in unacceptable risks for the aquatic environment. Note that the results are ‘best case’ as it was considered that 100% of the precipitation is discharged to an STP, while rainwater may also be directly discharged to surface water.,The risks ratio is most likely to be an overestimation considering that rainwater may be directly or indirectly discharged to soils as well, roofing materials are not applied on all roofs as other roofing materials (panes) are used as well on a large scale, and the roof surface is not proportional to the amount of houses connected to an STP (4000) as apartment building roofs are shared by several houses. Moreover, the majority of roofing membranes in The Netherlands consist in bitumen for which the application of DCOIT as preservative is unlikely as bitumen are applied by heat and DCOIT is thermally unstable (decomposition at 266°C DCOIT applied in fillers and sealants has a significant smaller amount of surface that is contacted with water. Therefore, the PECs resulting from leaching from these materials is considered < 1 and will thus not result in unacceptable risks for the aquatic environment. Also discharge of swimming pool water to an STP reduces the risks to acceptable levels (Table E.7), but risks are expected when waste water is directly discharged to surface water (Table E.6). pag. 17 van 27 Because of unacceptable risks for the environment when discharged directly to surface water, the application of DCOIT-treated polymers outdoors will be limited to applications where direct discharge to surface water does not occur. Therefore, swimming pool water containing DCOIT has to be released to the sewer connected to an STP. As discussed previously, the use of polymers indoors is considered acceptable as emission to the sewer is considered negligible. Micro-organisms in an STP For all intended uses, the standards for micro-organisms in an STP are met, as PEC/PNEC ratios are all below 1. 6.4.1.1 Surface water intended for the abstract ion of drinking water Present authorisations of DCOIT are for antifouling of seagoing vessels only, for which no emission to abstraction points for the production of drinking water is expected. There are no data available in the Pesticide Atlas regarding the presence of DCOIT in surface water. A closely related active substance Isothiazolinon (OIT) (without the two chlorine atoms) is on the recommended list of biocides to be monitored for drinking water from surface water (RIVM, 2010). DCOIT is however not transformed to OIT and the metabolites formed are different. From the general scientific knowledge collected by the Ctgb about the products and the active substance, the Ctgb concludes that there are in this case no concrete indications for concern about the consequences of this product for surface water from which drinking water is produced, when used in compliance with the directions for use. The standards for surface water destined for the production of drinking water are met. 6.4.2 Atmosphere Criteria for the examination of environmental risks to air are not specified in the form of a numerical standard. The assessment of potential impacts on air quality, yet, is aimed to minimize the risk for stratospheric ozone depletion. As there are no indications that DCOIT contributes to depletion of the ozone layer (calculated half life is below the trigger of < 2 days, DCOIT is not listed as ‘controlled substance’ listed in Annex I of Regulation (EC) No 1005/2009 of the European Parliament), the environmental risk to air is considered acceptable. 6.4.3 Terrestrial compartment The risk characterisation for soils is presented in Table E.8. Table E.8. PEC and PEC/PNEC ratios for soils Compound without degradation after 30 days after 3 years with degradation after 30 days after 3 years PEC (mg/kg wwt) PEC/PNEC 1.92 9.53 31 154 0.338 4.68E-02 5.45 0.755 Although the PEC/PNEC ratio is <1 3 years after application due to degradation of DCOIT, the concentration quickly increase and peaks after 30 days. Therefore, the PEC/PNEC-ration will be >1 for a long time, which is considered unacceptable. However, when DCOIT is applied in roofing membranes, the concentration in the leachate will decrease quickly considering the fast degradation in water (0.68 days) and photodegradation of DCOIT in water that is retained on roofs. Therefore, risks are likely be lower than showed in Table E.8. and only temporarily as DCOIT degrades in soils as well. Therefore, risks are considered acceptable and the standards for soils are met. pag. 18 van 27 6.4.3.1 Soil or ganisms and non target arthropods (including bees) The risk assessment to arthropods is considered to be similar to soil organisms due to their direct contact with soils. The standards for soil arthropods are therefore met. Because DCOIT is not systemic pesticides, secondary therefore exposure to bees through pollen is considered negligible. Also direct exposure to bees is not expected, hence, the risk for bees is considered acceptable for all intended uses. 6.4.3.2 Groundwater Assessment of the drinking water criterion defines that the concentration of the active substance and the relevant metabolites in groundwater for the preparation of drinking water needs to be < 0.1µg/L. According to the OECD ESD PT8 (Appendix 4) substances with a Koc of > 500 L/kg and a DT50 of < 21 days are not expected to leach to groundwater. DCOIT has a mean Koc of 6610 L/kg and a DT50 of 4.7 days (12°C) and thus fulfils those criteria. This was supported by a leaching study of DCOIT. Hence, the emission to groundwater is considered neglible and will be < 0.1 µg/L and thus the criteria for groundwater has been met. 6.4.3.3 Persistence in soil Regarding persistency of DCOIT the half-live based on primary degradation in soil is 4.7 days and the main metabolites are readily biodegradable. Hence, the active substance DCOIT is not persistent and the standards for persistence are met. 6.4.4 Non compartment specific effects relevant to the food chain 6.4.4.1 Bioconcentrat ion Bioconcentration in fish Based on the measured 14C residues, the steady-state BCF (whole fish) was 750 L/kg, indicating a potential for bioaccumulationTherefore a secondary poisoning risk assessment has been conducted, see 6.4.4.2 Bioconcentration in earthworms No experimental BCF value for earthworm is available. A BCF was calculated according to equation 82d of the TGD, using a default RHOearthworm of 1 kg (wwt)/L (as recommended by the TGD) and the Kow of DCOIT of 631 L/kg. The resulting calculated BCFearthworm is 8.4 L/kg, indicating a low bioaccumulation potential for terrestrial food webs. 6.4.4.2 Primary and secondary poisoning of bir ds and mammals The use in coatings and polymers is not expected to result in primary poisoning. Exposure of birds/mammals eating contaminated fish is considered relevant, see the argumentation above. The risk to birds/mammals through the aquatic food chain was 0.3, based on the worst case PECfresh_water of the direct exposure to surface water and a biomagnification water of 1. PNECoral can be found in Table E.2 . Therefore the criteria for secondary poisoning of birds and mammals are met. 6. 5 Measures to protect the environment (risk mitigation measures) Concept WG/GA and PUB have been checked. 6.6 Conclusion Environment An authorisation of a biocide in the Netherlands is only possible when the risks related to the product application are acceptable. An overview of the risks for products for which authorisation is requested is given in Table E.9. pag. 19 van 27 √ √ √ √ Overall √ Birds and mammals √ BCF √ Persistence in soil product and intended use Kathon 910SB Biocide preservatives for (silicone) caulks, sealants, mastics, and 7/10 √ joining materials Groundwater Aquatic organisms Sediment organisms Micro-organisms in STP Air Drinking water from surface water Soil organisms Non target arthropods Bees Overall conclusions Product type (PT) Table E.9. √ √ √ √ √ When used in accordance with the proposed label (WG/GA): Kathon 910SB Biocide comply with the environmental standards and will not cause unacceptable effects on the environment. pag. 20 van 27 7. Conclusion When used in accordance with the legal Instructions for Use (WG/GA), Kathon 910 SB Biocide is sufficiently effective and no unacceptable risk is expected to human health, the person who uses the product and the environment (Art. 121 jo art. 49 first paragraph Dutch 2007 Plant Protection Products and Biocides Act). Regarding the sensitizing properties of DCOIT the products containing Kathon 910 SB Biocide must be labelled accordingly (DPD11 / EUH208 ‘Contains 4,5-dichloro-2-octyl2H-isothiazol-3-one. May produce an allergic reaction’ or, depending on concentration or test results, R43 ‘May cause sensitisation by skin contact’ / H317 ‘May cause an allergic skin reaction’). 8. Classification and labelling Proposed for classification and labelling for the formulation based on Reg. (EC) 1272/2008: The identity of all substances in the mixture that contribute to the classification of the mixture *: Pictogram: GHS07 Signal word: Warning GHS09 H-statements: P-statements: H332 Harmful if inhaled H315 Causes skin irritation H317 May cause an allergic skin reaction H400 Very toxic to aquatic life P273 Avoid release to the environment. P280 P391 Wear protective gloves and protective clothing. Collect spillage. P501 Dispose contents/container to hazardous or special waste collection point. Child-resistant fastening obligatory? Tactile warning of danger obligatory? Not applicable Not applicable * according to Reg. (EC) 1272/2008, Title III, article 18, 3 (b) 1. 2. Ctgb includes only the highly recommended P-statements on the label, therefore, P261, P302+P352 and P333+P313 were not included in the label, as proposed by the applicant. Based on the ongoing discussions on bioaccumulation/biodegradation of DCOIT, P501 is added to the label. pag. 21 van 27 9. References Technical guidance document on risk assessment. Part II. European Commission Joint Research Centre, EUR 20418 EN/2, 2003, Ispra, Italy. Supplement to the methodology for risk evaluation of biocides ESD for PT10. Emission scenario document for biocides used as masonry preservatives. Institute national de l’environment industiel et des risques. INERIS report DRC-01-25582-ECOT-VMin°02DR0270, Verneuil-en-Halatte, France, November 2002. Available at http://ihcp.jrc.ec.europa.eu/ Emission Scenario Document for Wood Preservatives. OECD Series on Emission Scenario Documents. Organisation for Economic Co-operation and Development, Paris Poel, P. van der, J. Bakker. Emission scenario document for biocides. Emission scenarios for all 23 product types of the Biocidal Products Directive (EC Directive 98/8/EC). National Institute for Human Health and the Environment. RIVM report 601 450 009, Bilthoven, The Netherlands, 2002. pag. 22 van 27 Appendix I. Profile of active substance DCOIT PNEC derivation Freshwater: Acute and long-term studies are available for fish, invertebrates and algae both for freshwater and marine species. According to the TGD data from freshwater and marine species can be pooled for PNEC derivation if the difference in sensitivity between freshwater and marine species within trophic levels is not larger than a factor of 10. This is the case for DCOIT and the lowest NOEC used for PNEC derivation was the 24 hour NOErC of 0.34 μg a.i./L from the test with the freshwater alga Navicula pelliculosa. An assessment factor of 10 was applied to derive the freshwater PNEC: PNECfreshwater = 0.034 μg a.i./L Additionally for intermitted release (in case of complete release of a swimming pool) a PNEC 0.34 µg/L is derived. The PNECsediment can in principle be derived either from test results based on total radioactivity or on parent substance. Biodegradation of DCOIT in sediment and subsequent adsorption of the metabolites to organic matter in the sediment is fast. In the wood preservative risk assessment (PT 8), biodegradation in sediment is not taken into consideration and therefore the PNECsediment has been calculated from the lowest 14CNOEC available, which is 4.9 mg 14C equiv/kg dwt from the freshwater sediment test with C. riparius. The PNECsediment therefore represents DCOIT and metabolites. The TGD expresses PEC/PNEC ratios on a wet weight basis and the results have therefore to be converted from dry weight to wet weight. Not the standard conversion factor of 4.6 from EUSES was used for conversion but a factor of 1.184. This conversion factor was calculated using measured data on sediment characteristics in the study report for the C. riparius test. The NOEC based on total radioactivity becomes 4.14 14C equiv/kg wwt sediment. PNECfreshwater sediment (total radioactivity) = 0.41 mg 14C equiv./kg wwt sediment STP: An EC50 of 0.64 mg a.i./L could be established from a study on inhibition to microbial activity with activated sludge. An assessment factor of 10 was used to derive the PNECSTP: PNECSTP = 0.064 mg a.i./L Soil: Acute studies are available for microorganisms, earthworms and plants. The microorganism test can also be considered a long-term test and a chronic earthworm study is available as well. The NOEC from the plant test is the same as the NOEC from the 56 days reproduction test with earthworms (based on dry weight and nominal concentrations); however, based on the TWA approach the NOEC from the long term test with earthworms is the lowest endpoint and will be used for PNEC derivation with an assessment factor of 50. The NOEC from this test based on nominal concentrations is 4.42 mg a.i./kg wwt soil. The TWA NOEC is 3.1 mg a.i./kg wwt soil. A factor of 1.13 was used to calculate the endpoints from dry weight to wet weight. The AF cannot be lowered from 50 to 10 as plants are the most sensitive species in the acute studies. PNECsoil = 0.088 mg a.i./kg wwt soil (initial) PNECsoil = 0.062 mg a.i./kg wwt soil (TWA) pag. 23 van 27 PNECoral: For birds short two term feeding studies are available; however, no LC50 could be established. The 5d LC50 was above the highest concentration tested (4640 mg a.i./kg food) in both tests with Mallard duck and Bobwhite quail. The PNECoral for birds is derived from the LC50 with an AF of 3000. PNECoral (birds) = 1.55 mg a.i./kg food For mammals the lowest NOAEL was 10.1 mg a.i./kg bw/d from a 90-d subchronic toxicity with dogs. To derive the NOEC the NOAEL is multiplied with a conversion factor of 40. This gives a NOECmammals of 404 mg a.i./kg food. To derive the PNECoral for mammals an AF of 90 was used. PNECoral (mammals) = 4.49 mg a.i./kg food pag. 24 van 27 Appendix II. Physical-chemical properties parameter value molecular weight (g/mole) vapour pressure at test temperature (Pa) test temperature vapour pressure (°C) solubility at test temperature (mg/L) test temperature solubility (°C) octanol-water partition coefficient (L/kg) organic carbon-water partition coefficient (L/kg) 282.2 Henry constant (Pa m3 mol-1) test temperature vapour pressure (°C) rate constant for biodegradation in STP (/d) remarks 0.00098 25 4.28 20 631 6610 - No experimentally determined Henry constant available. 0 pag. 25 van 27 Not degradable in an STP Appendix III. Scenario calculations Table 1. Discharge of swimming water by public swimming pools into the sewage system for chronic situation Variable/parameter (unit) Symbol S/D/O/ acute chronic P Input: AREAswim Water surface m² D 440 440 w DEPTHswi Average depth of water m D 1.8 1.8 mw Length m D 50 50 Width m D 17.6 17.6 Volume of the swimming pool m³ Vpool O 792 792 Treated area swimming pool m² Atreat O 683.36 683.36 mg/m²/ 10.9 Leaching rate Qleach S 1.48 d Hydrolysis rate /d khydro S 0.0098 0.0098 Number of visitors per day (-) Nvisit D 400 400 0.05 Water replaced per visitor (m3) Vrepl D 0.05 Output: Leaching to pool per day Eleach = Qleach * Atreat mg/day Eleach O 1011 7449 Removal rate by replacement kremoval = /d kremoval O 0.0253 0.0253 Nvisit*(Vrepl/Vpool) Retention time R = 1/kremoval d R S 39.6 39.6 Remained in pool per day after leaching minus hydrolysis and replacement Qpool = Eleach * (1-khydromg/d Qpool O 976 7188 kremoval) Remained in pool after leaching minus hydrolysis and replacement after XX days Qpool_time = Qpool * R mg Qpool_time O 38648 284637 Concentration in swimming water Cproc = Qpool_time/Vpool mg/m³ Cproc O 48.8 359.4 Emission from the swimming pool Elocalwater_acute = Elocalwater g/d O 38.6 Cproc*Vpool _acute Elocalwater_chronic = (Nvisit Elocatwater g/d O 7.2 * Vrepl * Cproc) / 1 _chronic Table 2. Discharge of swimming water by private swimming pools into the sewage system for chronic situation Variable/parameter (unit) Symbol S/D/O/ acute chronic P Input: AREAswim Water surface m² D 72 72 w DEPTHswi Average depth of water m D 1.8 1.8 mw Length m D 12 12 Width m D 6 6 Volume of the swimming pool m³ Vpool O 129.6 129.6 pag. 26 van 27 Treated area swimming pool Leaching rate m² mg/m²/ d /d - Atreat O 136.8 Qleach S 1.48 S D D 0.0098 10 0.05 0.0098 10 0.05 O 202 1491 O 0.0039 0.0039 S 259 259 O 200 1471 O 51764 381234 O 399 2942 O 51.8 Hydrolysis rate khydro Number of visitors per day (-) Nvisit Water replaced per visitor (m3) Vrepl Output: Leaching to pool per day Eleach = Qleach * Atreat mg/day Eleach Removal rate by replacement kremoval = /d kremoval Nvisit*(Vrepl/Vpool) Retention time R = 1/kremoval d R Remained in pool per day after leaching minus hydrolysis and replacement Qpool = Eleach * (1-khydromg/d Qpool kremoval) Remained in pool after leaching minus hydrolysis and replacement after XX days Qpool_time = Qpool * R mg Qpool_time Concentration in swimming water Cproc = Qpool_time/Vpool mg/m³ Cproc Emission from the swimming pool Elocalwater_acute = Elocalwater g/d Cproc*Vpool _acute Elocalwater_chronic = (Nvisit Elocatwater g/d * Vrepl * Cproc) / 1 _chronic Table 3. O 136.8 10.9 1.5 Discharge of swimming water by public and private swimming pools into the surface water for the acute situation Variable/parameter (unit) S/D/O/ Symbol public private P Input: DILUTIO Dilution factor for (-): D 4 2 N DEPTHditc Depth of ditch (m) m D 0.3 0.3 h° Concentration in swimming water kg.m3 Cproc S 48.8E-6 399E-6 Parameters requiredfor distribution modules Fraction drift related to location and Fdrift Oc 1 1 way of application c Application interval d Tint O 1 1 Number of applications in one year Nappl O' 1 1 Output: Cwaterpest = Cproc / dilution mg/L 0.012 0.200 1) Already defined in distribution model for pesticides (symbol DEPTHditch) 2) use symbols with subscripts (Fdrift, Tinterval and Nappl respectively) pag. 27 van 27