CN213 Final Exam 11

advertisement

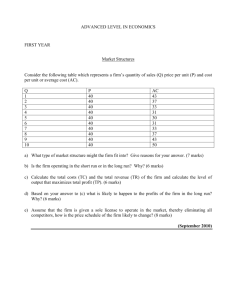

CN213 Mechanics of Materials 2 s School of Environment & Technology Semester 1 Examinations 2011-2012 CN213 MECHANICS OF MATERIALS 2 Instructions to Candidates Time allowed: TWO hours Answer ALL questions from Section A Answer TWO questions from Section B All questions carry equal marks An Aide Memorie is provided 26 January 2012, 15:00hours CN213 Strength of Materials 2 2011-12 SECTION A Answer BOTH questions from this section Question 1 (a) A hollow beam of rectangular cross section as shown in Figure 1 is subjected to a bending moment of M = 5 kNm at an angle of 25 to the vertical principal axis. (i) Find the moments My and Mz parallel to the principal axes of the beam. (2 marks) (ii) Find the neutral axis of the beam. Draw a sketch of the cross section of the beam showing the neutral axis. (5 marks) (iii) Determine the stresses in points A and B. Indicate whether these stresses are compressive or tensile. (10 marks) Figure 1 (b) Using the strain gauge rosette shown in Figure 2derive an equation from the strain transformation equation to determine the strains x, y and xy. (8 marks) y C B 45º A x Figure 2 Page 2 of 12 CN213 Strength of Materials 2 2011-12 Question 2 (a) A steel plate has a welded connection at an angle of 20˚ to the x-axis as shown in Figure 3. It is subjected to a state of stress as shown in Figure 3. (i) From the state of stress as shown in Figure 3, construct the Mohr circle of the stress situation in the steel plate. (6 marks) (ii) Use Mohr’s circle to determine the in-plane shearing stress parallel to the weld and the normal stress perpendicular to the weld. (7 marks) (iii) Draw the state of stress at the weld in a properly oriented stress element. (5 marks) Figure 3 (b) A steel plate as shown in Figure 4 is subjected to a force P = 75 kN. Determine the minimum thickness t required if the allowable stress is 200 MPa. (7 marks) Figure 4 Page 3 of 12 CN213 Strength of Materials 2 2011-12 SECTION B Answer TWO questions from this section Question 3 (a) The thin walled pipe is made up out of three steel plates that are welded together as indicated in Figure 5 below. The cross-section of the pipe is an equilateral triangle; the length of each side is 175 mm, the wall thickness is t = 5 mm. (i) Determine the maximum torque T the pipe can resist, if the maximum allowable angle of twist is allow = 0.25°. (G = 75 GPa, length L = 4 m) (4 marks) (ii) Consider that one welded seam breaks due to poor workmanship along the whole length of the beam. Determine the angle of twist (in degrees) for a torque of T = 0.25 kNm. (3 marks) (iii) Following on from (ii), assuming the thickness of one of the sides of the triangles was changed to 6mm, state if you expect the maximum shear stress in a side of thickness 5mm or 6mm and explain why. (2 marks) Figure 5 Question 3 continues on next page Page 4 of 12 CN213 Strength of Materials 2 2011-12 Question 3 (continued from previous page) (b) A cantilever beam made of channel section is subjected to a load P = 5 kN as shown in Figure 6. (i) Determine the position of the shear centre of the channel section. (4 marks) (ii) Determine the torque T applied to the section by the load P. (2 marks) (iii) Assuming that the torque T = 350 Nm, determine the maximum shear stress in the section. (10 marks) P 50 mm P 8 mm z 160 mm 12 mm 100 mm Figure 6 Page 5 of 12 CN213 Strength of Materials 2 2011-12 Question 4 (a) A wooden beam is made by gluing three 50mm × 100mm boards together to form a solid beam as shown in Figure 7. The beam is loaded symmetrically with a point load P = 1.5 kN. Ignore the weight of the beam. (i) Determine if the shear stress in the glue is going to exceed the limiting value of = 0.25 MPa. (8 marks) (ii) Determine if the tensile stress in the wood is going to exceed the limiting value of = 4.5 MPa. (8 marks) P 50 mm 50 mm 50 mm L = 3.0 m 100 mm Figure 7 (b) A steel shaft with a diameter of 43 mm has a yield strength of Y = 300 MPa. It is subjected to the axial load P = 350 kN and a torque T = 625 Nm as shown in Figure 8. Determine the factor of safety against yielding using the maximum principal stress criterion. (9 marks) Figure 8 Page 6 of 12 CN213 Strength of Materials 2 2011-12 Question 5 (a) A circular shaft as shown in Figure 9 is fixed at point C and subjected to a torque at point A. Part AB is made of steel with an allowable shear stress of steel = 100 MPa. Part BC is made of aluminium with an allowable shear stress of alu = 70 MPa. The diameter of part BC is 45 mm. Ignore any stress concentrations in the shaft. (i) Determine the largest torque T that can be applied to the shaft without exceeding the allowable stress in part BC. (4 marks) (ii) Determine the diameter of part AB that is required to withstand a torque T of 1300 Nm (4 marks) (iii) Determine the angle of twist (in degrees) at point A for the same torque as in (ii) assuming the diameter of section AB to be 40 mm. The shear moduli for the materials are: Gsteel = 78 GPa and Galu = 26 GPa. (4 marks) Figure 9 Question 5 continues on next page Page 7 of 12 CN213 Strength of Materials 2 2011-12 Question 5 (continued from previous page) (b) A H-beam is made of wood by screwing together three wooden boards as shown in Figure 8a. The beam is subjected to two point loads as shown in Figure 8b. The screws are 60mm apart along the length of the beam; the shear strength of each screw is 4 kN. Assuming that the beam will fail due to shear failure of the screws determine the maximum load P the beam can safely resist. (13 marks) P/2 140 mm P/2 20 mm 20 mm 100 mm 20 mm 1.2 m Figure 10a 1.2 m 1.2 m Figure 10b Page 8 of 12 CN213 Aide-Memoire Mechanics of Materials 2 CN213 Mechanics of Materials AIDE-MEMOIRE 2011-2012 Page 9 of 12 CN213 Aide-Memoire Mechanics of Materials 2 STRESS AND STRAIN TRANSFORMATION Stress transformation x1 y1 x y 2 x y x1y1 x y 2 x y 2 x y 2 2 cos 2 xy sin 2 1,2 tan 2p cos 2p sin 2p 2 sin 2 xy cos 2 x y max,min 2 x y 2 Principal strains 2 xy 1,2 1 2 2 x y 2 tan 2p 2 x y xy 2 2 2 xy ( x y ) 2 x y 2xy R 2 cos 2p Strain transformation x1 xy R x y xy R 2 2 Mohr’s circle for plane stress x y 2R 2 x y 2xy 2 tan 2 s max x y xy 2 2 2 xy 2 cos 2 xy sin 2 Principal stresses x y Mohr’s circle for plane strain Maximum shear stress y1 x1y1 2 x y 2 x y 2 x y 2 x y x y 2 2 sin 2p cos 2 cos 2 sin 2 xy 2 xy 2 xy 2 sin 2 sin 2 cos 2 x y 2R xy 2R Maximum shear strain 2 x y max xy 2 2 2 tan 2s x 2 y xy Page 10 of 12 CN213 Aide-Memoire Mechanics of Materials 2 CENTROIDS AND MOMENTS OF AREA TORSION Centroid Shear stress in a circular bar under torsion x A x A i y A y A i i i i i i i i i z A z A i i i zi A i Qz i i yi A i bh3 Iz 12 Parallel – axis therorem of moment of inertia I y1 I y A d2z I z1 I z A d2y Polar moment of inertia of a circle (axis through centroid) IP d 4 32 Angle of twist of a circular bar under torsion TL G Ip i Moment of inertia (axes through centroid) in z-y plane hb3 Iy 12 TR IP i First moment of area in z-y plane Qy max Shear stress in thin walled closed section under torsion aver T 2 t Am Angle of twist of thin walled closed section under torsion TL 2 4A m G tii s i Shear stress in thin walled open section under torsion max T t max J with J 1 bi t i3 3 i Angle of twist of thin walled open section under torsion TL GJ Page 11 of 12 CN213 Aide-Memoire Mechanics of Materials 2 HOOKE’S LAW SHEAR STRESS IN BEAMS x 1 x ( y z ) E y 1 y ( x z ) E z Shear stress in beams 1 z ( x y ) E V Qz Iz b Shear stress in beams with thin walled cross-sections V Qz Iz t Shear flow in beams BENDING q Normal stress due to bending x1 Mz y , Iz x2 My z Iy Normal stress due to unsymmetrical bending x Px M z y M y z A Iz Iy Orientation of the neutral axis tan I z My V Qz Iz Shear centre of channel sections V t f hb2 F 4 Iz Fh e V YIELD CRITERIA The effective stress for the maximum distortion energy criterion (von Mises) I y Mz e 1 1 2 2 2 3 2 3 1 2 2 Page 12 of 12