The Fifth International Conference on Condition Monitoring

advertisement

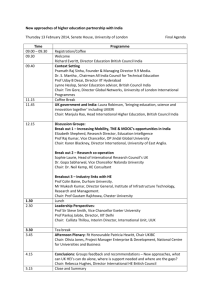

CM2008 / MFPT2008 CONFERENCE PROGRAMME Tuesday 15th July 12:00 – 18:30 Registration A 14:00-16:00 WORKSHOP: Acoustic emission for condition monitoring: an introduction Dr T Holroyd, Holroyd Instruments Chair: Dr S King, Rolls-Royce 16:00-18:00 WORKSHOP: Condition monitoring 3rd party certification -your best option Dr S Roe, PCN/BINDT Chair: Prof L Kuravsky, Russian Aviation Co. B WORKSHOP: Data management for condition monitoring Dr M Provost1, Mr C Mott2, Dr M Jessop3, Bombardier Transportation1, nCode2, University of York3 Chair: Mr J McAvoy, Cybula WORKSHOP: Mathematical modelling and computer simulation for supporting gear diagnostic inference Prof W Bartelmus, Wroclaw University of Technology Chair: Prof S Radkowski, Warsaw University of Technology C WORKSHOP: Revisiting prediction methods and the prognosis of remaining useful life Dr C Byington, Impact Technologies Chair: Prof L Kuravsky, Russian Aviation Co. OPEN SESSION: Impact Technologies’ activities Dr C Byington, Impact Technologies Chair: Prof L Kuravsky 18:30 – 19:30 Welcome reception for CM2008/MFPT2008 Committee members and cash sponsors – by invitation only 19:30 CM2008 / MFPT2008 Welcome buffet Wednesday 16th July 08:00 08:30 08:50 09:25 10:00 Registration Opening ceremony Plenary keynote lecture: [184] The significance of assets condition monitoring in the development of engineering asset management, Prof J Mathew, Dr F Stapelberg, Australia Chair: Mr R Lyon, President - BINDT Plenary invited distinguished lecture: Wavelength diversity super-resolution for condition based maintenance, HRB Prof N Bose, USA Chair: Mr R Lyon, President - BINDT Tea, coffee & exhibition 1A 1B 1C 1D 1E 1F Multidimensional diagnostics of complex mechanical systems CHAIR: Prof S Radkowski, Warsaw University of Technology [1] Vibro-acoustic diagnostics of low-energy stage of failures evolution S Radkowski, Warsaw University of Technology Advanced signal processing for condition monitoring (1) CHAIR: Dr N Martin, Gipsalab NDE and health monitoring of complex structures CHAIR: Prof L Fradkin, London South Bank University [14] Special Presentation: The role of acoustic emission in monitoring machines, processes and structures CHAIRS: Prof K Holford, Dr R Pullin, Cardiff University [19] The role of acoustic emission in monitoring machines and structures R Reuben, Heriot Watt University Trained structures and statistical methods for condition monitoring (1) CHAIRS: Prof L Kuravsky, Dr S Baranov, Russian Aviation Co. [29] Development of the wavelet-based confirmatory factor analysis for monitoring of system factors L Kuravsky, S Baranov, Russian Aviation Co. Experimental and virtual models for machines and plant diagnostics CHAIR: Prof A Lucifredi, University of Genova Diagnostics of gas turbine engines CHAIR: Dr Y Li, Cranfield University [35] On the development of virtual models, interfaced to hardware and software instruments, to support the experimental activity for diagnostic applications A Lucifredi, P Silvestri, University of Genova [40] Model based diagnosis technique for the cogeneration system (effect of operational condition on characteristics of turbine and compressor) T Kawai1, Y Kamada2, Osaka City University1, Nissan Motor Co. Ltd2 10:50 [2] Usage of symbolic analysis in condition monitoring A Galezia, S Radkowski, Warsaw University of Technology [8] Space vector analysis for the diagnosis of high frequency amplitude and phase modulations in induction motor stator current M Chabert, B Trajin, J Regnier, J Faucher, ENSEEIHT [20] Development and application of higher functionality acoustic emission (AE) sensors T Holroyd, Holroyd Instruments [34] Reliability-based design of a slat track fatigue life using mesh morphing technology R d’Ippolito1, S Donders1, M Hack1, N Tzannetakis2, G Van der Linden3, LMS1, NOESIS Solutions2, ASCO Industries3 [41] Gas path prognostic analysis for an industrial gas turbine Y Li1, P Nilkitsaranont2, Cranfield University1, Chevron Thailand Exploration and Production2 11:10 [3] Dynamic of ships shaft line A Grzadziela, Naval University of Gdynia [9] Complex-valued signal processing for condition monitoring P Granjon, GIPSA-lab [27] A new method of localisation of vibration sources and operational defects in complex constructions based on the time reversal and the finite element model of system (part 1: theoretical researches) P Artelny, P Korotin, A Suvorov, Institute of Applied Physics RAS [28] A new method of localization of vibration sources and operational defects in complex constructions based on the time reversal and the finite element model of system (Part 2. Experimental works) P Artelny, P Korotin, A Suvorov, Institute of Applied Physics RAS [33] Vibration analysis of virtual damaged gears C Carmignani, P Forte, G Melani, University of Pisa [42] A comprehensive approach for measurement validation and health state determination of gas turbines: methodology and field application M Venturini, R Bettocchi, M Pinelli, P Spina, University of Ferrara 10:25 [7] Frequency and amplitude tracking for short non stationary and nonlinear signals N Martin, M Vieira, Gipsalab Non-destructive testing as a tool in the space shuttle Columbia accident investigation S McDanels, NASA [18] Automatic NDT method for crack detection T Merazi, A University of Sciences & Technology [21] A Framework for detecting fatigue fractures using acoustic emission J Hensman, K Worden, R Pullin, K Holford, M Eaton, S Evans, Cardiff University 1G 11:30 11:50 12:10 12:30 12:50 13:35 14:10 [4] Use of the principal components analysis in the diesel engine diagnostics based on the spectrum of the vibroacoustic signal M Jasinski, G Boruta, Warminsko-Mazurski University [5] Support Vector machines and cluster analysis for fault detection and classification of rotating equipment K Gryllias, C Yiakopoulas, I Antoniadis, National Technical University of Athens [10] Comparison between the frequency spectrogram and polynomial modelling in the characterisation of cross-modulated vibration components F Leonard, Institut de Recherche d’Hydro-Quebec [11] Analysing MBN signals of different materials by time-frequency methods L Padovese1, N Martin2, University of Sao Paulo1, GIPSA-lab2 [16] Modelling propagation of ultrasonic guided waves in the layered steel/grout/steel structures L Fradkin1, V Zernov1, P Mudge2, London South Bank University1, The Welding Institute2 [17] Recent advances in simulation of NDT configurations P Calmon, CEA LIST [22] Acoustic emission for corrosion detection P Cole, J Watson, Physical Acoustics [26] Diagnosis and monitoring complex industrial processes based on self-organising maps C Frey, Fraunhofer Institute [193] Virtual experimental modal analysis: an application of simulation models to diagnostics A Lucifredi, P Silvestri University of Genova [43] Turbomachinery performance diagnostics – a practical approach using gas path analysis P Escher1, J Zumbrunn1, J Tan2, EscherTec1, Mariterm SA2 [23] An attempt to correlate gas void fraction with acoustic emission generated from two-phase air / water flow D Mba, S Al-lababidi, A Addali, Cranfield University [37] Using model-based fault detection to simplify predictive maintenance A Bates, Artesis [44] Gas path analysis applied to an aero derivative gas turbine used for power generation E Tsoutsanis1, Y Li1, P Pildis1, M Newby2, Cranfield University2, Manx Electricity Authority2 [6] The application of condition monitoring methodologies for certification of reliability in electric landing gear actuators P Phillips1, D Diston1, J Payne2, S Pandya2, A Starr1, University of Manchester1, Messier Dowty2, University of Hertfordshire3 [179] Calibration free, optical measurements of gas composition for industrial process control in harsh environments W Johnstone, A McGettrick, K Duffin, G Stewart, University of Strathclyde [12] Handling systems condition monitoring using vibrations and motor current S Sieg-Zieba, E Tructin, L Jaubert, CETIM Application of ultrasonic guided waves for monitoring components in service P Mudge, TWI [24] Flight test of acoustic emission damage detection system on a military jet I Read, P Foote, D Tunnicliffe, J McFeat, Y MacPheat, BAE Systems [30] Studying influence of manoeuvring loads occurrences and climatic conditions of basing on aircraft damage accumulation rate with the aid of trained structures S Baranov, L Kuravsky, N Baranov, Russian Aviation Co. [31] Psychological training on the base of a neuronet technology L Kuravsky, A Margolis, G Yuriev, Moscow State University of Psychology and Education [38] Role of support vector classifiers in optimal model selection fault detection of rolling element bearings Z Hameed, Y Hong, Y Cho, C Song, Seoul National University [45] Detection of blades rubs and looseness in gas turbines – operational field experience and laboratory study S Leong, L Hee, Malaysian University of Technology [13] A method for distinguishing between complex transient signals in condition monitoring applications T Pinpart, G West, S Galloway, M Judd, University of Strathclyde [187] A de-convolution technique used for NDT in x-ray & CT K Chui1, A Wride1, D Stanfield1, S Chui1, Image Enhancement Technology1 Ltd, Worcester Acute Hospital2 [25] Modelling and quantification of acoustic emission testing P Wilcox, J Scholey, M Wisnom, M Friswell, University of Bristol [32] Cepstral and statistical analysis to determine the fatigue crack depth in a rotor system T Malysheva, A Zakhezin, South-Ural State University [39] A new method of damage detection by using the reciprocal and timereversal properties of elastic waves H Go, Inha University [46] Random and regular modes of monitoring V Giniotis1, M Rybokas1, A Hope2, Vilnius Gediminas Technical University1, Southampton Solent University2 Lunch & exhibition Plenary keynote lecture: [190] Optical diagnostics for developing and testing clean combustion technologies, Prof D Greenhalgh, UK Chair: Prof K Holmberg, VTT Plenary invited distinguished lecture: Vibro-acoustic diagnostics of low energy faults, Prof S Radkowski, Poland Chair: Prof K Holmberg, VTT 14:45 Tea, coffee exhibition 15:00 Britannia visit, dinner and guided Edinburgh tour Thursday 17th July 08:00 08:30 09:05 09:40 Registration Plenary keynote lecture: [106] Advanced signal processing in mechanical fault diagnosis, Prof S Lahdelma, Dr E Juuso, Finland Chair: Prof L Gelman, Cranfield University Plenary keynote lecture: [185] Condition monitoring and diagnostics as tools for maintenance, Prof J Vizintin, Slovenia Chair: Mr R Lyon, President - BINDT Tea, Coffee & Exhibition 2A 2B 2C 2D 2E 2F 2G Integrated vehicle health management (IVHM) – advancements in CM, sensor technology and IVHM integration frameworks and service interfaces CHAIR: Dr S Roe, PCN/BINDT [80] Integrated vehicle health management (IVHM) the next evolution within condition monitoring S Roe, PCN/BINDT Incipient and developing fault detection and monitoring (1) CHAIRS: Dr F Balitsky, Dr A Sokolova, Machinery Engineering Research Institute, Russian Academy of Science [89] Condition monitoring of the equipment in real-timetechnology of safe-save maintenance of the 21st century V Kostyukov, SPC Dynamics [75] A resources based engineering asset management model A Haider,University of South Australia [81] Knowledge representation framework for railway rolling stock maintenance processes D Lane1, E Miguelanez1, K Brown1, A Roselli2, HeriotWatt University1, MERMEC2 [82] Advanced rotorcraft oil debris monitoring for the 21st century S Greenfield, Eaton Aerospace [76] Hidden markov models for condition monitoring of bearing damage E Karatoprak, Istanbul Technical University [188] A review, and challenges in the application of AE to machinery monitoring D Mba, Cranfield University Damage detection and diagnosis CHAIR: Prof L Gelman, Cranfield University Diagnostics through pattern recognition and novelty detection (1) CHAIR: Dr S King, Rolls Royce Pipeline and underground asset condition monitoring CHAIR: Prof K Horoshenkov, University of Bradford E-maintenance CHAIR: Prof K Holmberg, VTT Trained structures and statistical methods for condition monitoring (2) CHAIRS: Prof L Kuravsky, Dr S Baranov, Russian Aviation Co. 10:10 [47] Novel higher order spectra for damage detection in transient conditions L Gelman, E Lapena, Cranfield University [53] Pilot evaluation of GRID technology for EHM applications S King, Rolls Royce [60] The effect of roughness on the attenuation of eigen-modes in water pipes K Horoshenkov, G Maximov, E Podjachev, E Ortega, University of Bradford [66] Actors and roles in emaintenance E Jantunen1, A Adgar2, A Arnaiz3, VTT1, University of Sunderland2, Fundacion Tekniker3 10:35 [48] Quality assessment of a laser cut based on captured acoustic emission signals J Grum, T Kek, The University of Ljubljana [54] Incipient failure prediction in aero engines via empirical mode decomposition A Bird, Rolls Royce [61] Sonic characterisation of change in pipes K Horoshenkov, A Tolstoy, T Bin Ali, University of Bradford [67] The complexity of RFID in reality – a Volvo case S Apel, A Stromdahl, Volvo [73] Fiber bragg gratings for detection of planetary gear damage in helicopter transmissions J Coker1, D Pines1, P Samuel1, J Kiddy2, C Baldwin2, University of Maryland1, Aither Engineering2 [74] Statistical techniques for condition monitoring of manufacturing processes D Clifton, Oxford University 10:55 [49] Condition monitoring in reality-widening horizons beyond the machine: Part 1 K Innes, R Parchewsky, Shell [55] Constructing and retraining models for condition monitoring in jet engines P Bannister, D Clifton, L Tarassenko Oxford University [62] Using acoustic reflectometry to detect blockages in natural gas pipe lines B Lennox, K Papadopoulou, X Wang, J Turner, K Lewis, University of Manchester [68] Semantic web services for a distributed emaintenance framework E Gilabert, S Ferreiro, A Arnaiz, Fundacion Tekniker 11:15 [49] Condition monitoring in reality-widening horizons beyond the machine: Part 2 K Innes, R Parchewsky, Shell [56] Gaussian process latent variable models and isomap for fault detection within engine health monitoring context L Ecizola1, D King1, C Fairbrother1, M Walters1, D Ault1, I Sever1, S King1, V Kadirkamanathan2, Rolls Royce1, The University of Sheffield2 [63] Rotating optical geometry sensor for pipe inspection C Frey, Fraunhofer Institute IITB [69] Wireless sensing strategies for plant monitoring in DYNAMITE project S Mekid, R Pietruszkiewicz, The University of Manchester [90] Incipient fault detection as an obligatory component of condition monitoring for up-to-date predictive maintenance A Sokolova, F Balitsky, MERI RAS [135] Vibration condition monitoring as a means of service life management of IBR-2 movable-reflector modulator V Sizarev, N Dollezhal, Research and Development Institute of Power Engineering [88] Rolling bearing field fault detection and diagnostics technique to employ for gas turbine unit casing vibration A Sokolova, F Balitsky, MERI RAS 11:35 [50] Vibration damage detection in a aircraft engine gearbox F Combet1, L Gelman1, P Anuzis2, R Slater2, Cranfield University1, RollsRoyce2 [58] Overview of wireless sensor research at the Rolls-Royce control and systems university technology centre H Thompson, Rolls Royce Diagnosis and monitoring of complex industrial processes based on selforganising maps C Frey, Fraunhofer Institute, IITB [70] A system for mobile maintenance decision support J Campos1, E Jantunen2, O Prakash1, Vaxjo University1, VTT1 11:55 [52] Damage detection through nonlinear excitation and system identification M Hajj, G Bordonaro, Virginia Polytechnic Institute and State University [142] In-service fatigue prediction in turbomachinery L Gelman, T Noble, Cranfield University [59] High dimensional visualisation for novelty detection D Clifton, Oxford University [64] Modelling wear damage accumulation in slurry pipeline systems M Lipsett, University of Alberta [101] Engine health monitoring and high dimensional data M Alkarouri, A Hills, V Kadirkamanathan, The University of Sheffield [65] The development of online wear debris analysis sensor using pseudo 3D images of particles and flow control R Matdan, M Khan, D Cooper, A Starr,The University of Manchester [71] Vibrodiagnostic service of compressor units of the main line stations at the level of gas-transport conpany V Zasetskij, A Tikhvinskij, VNIIGAZ [72] Investigation of uncertainty in rotating machinery vibration monitoring and reliability of diagnostics M Eidukeviciute, Kaunas University of Technology 12:15 12:35 13:50 14:25 15:00 [77] A validated model for the prediction of combustion related faults in medium-speed diesel engines using crankshaft torsional vibration P Charles, University of Manchester [79] Sensor fusion in CM applications T Bradshaw, Physical Acoustics [83] Monitoring of diesel fuel injection using acoustic emission (AE) W Abdou, C Hunter, M Shehadeh, J Steel, R Reuben, Heriot-Watt University [134] Formation of orthogonal diagnostic attributes for vibrodiagnostic purposes V Kostjukov, SPC Dynamics [84] Automated decision support system for lubricant evaluation M Timusk, G Dalton, Laurentian University [192] Dynamic behaviour of a de-laminated composite beam I Ullah, J Sinha, University of Manchester [183] Mastering predictive maintenance: static and dynamic motor testing as part of a predictive maintenance program T Thomas, Baker Instrument Company [85] Advanced acoustic methods for on-stream inspection P Cole, Physical Acoustics Ltd [169] Diagnosis of incipient gear failure using optimal frequencies selection method L Castillo, UNED Lunch & Exhibition Plenary keynote lecture: [191] Predictive modelling of damage progression for reinforced composite materials, Prof A Long, UK Chair: Prof K Holmberg, VTT Plenary invited distinguished lecture: 5 steps to heaven: a Rolls-Royce perspective, Prof I Jennions, UK Chair: Prof L Gelman, Cranfield University Tea, coffee exhibition 3F 3G Gear and bearing condition monitoring and diagnostics (1) CHAIR: Prof W Bartelmus, Wroclaw University of Technology 3A Optical sensors for condition monitoring of key plants CHAIR: Dr P Niewczas, University of Strathclyde 3B Advanced signal processing for condition monitoring (2) CHAIR: Prof S Lahdelma, University of Oulu 3C Ultrasonic guided waves CHAIR: Dr T Gan, The Welding Institute 3D Prognostics CHAIR: Mr V Fox, BAE Systems 3E Education and training in maintenance CHAIR: Dr C Emmanouilidis, CETI Institute 15:25 [96] External load yielding statistical characteristics as measures of machine condition W Bartelmus, R Zimroz, Wroclaw University of Technology [182] Optical sensors for condition monitoring of key plants in energy production P Niewczas, University of Strathclyde Advanced signal processing in fault diagnosis S Lahdelma, E Juuso, University of Oulu [113] Long range inspection of engineering assets using guided ultrasonic waves C Ennaceur, P Mudge, T Gan, The Welding Institute [120] Application of RAM-T case for machinery failure prevention V Fox, BAE Systems 15:50 [97] Gearbox fault diagnosis using Hilbert transform and segmented regression M Hoseini, M Mandal, M Zuo, G Mani, University of Alberta [180] Distributed optical fibre sensing of temperature using timecorrelated two-photon excited fluorescence C Dalzell, I Ruddock, T Han, University of Strathclyde [107] New time domain method for the detection of roller bearing defects T Doguer, J Strackeljan, Otto-von-GuerickeUniversität Magdeburg [114] Modelling of guided ultrasonic waves in aircraft wiring Y Gharaibeh1, 2, S Soua1, S Chan1, T Gan1, G Edwards1, The Welding Institute2, Brunel University2 [121] Revisiting prediction methods and the prognosis of remaining useful life C Byington, M Roemer, G Vachtsevanos, Impact Technologies [127] Current trends in etraining and m-training and prospects for maintenance vocational training C Emmanouilidis, N Papathanassiou, A Papakonstantinou, CETI Institute [128] Next generation maintenance systems (NGMS): emerging educational and training needs to support an adaptive approach to maintenance planning and improve decision support A Labib, University of Portsmouth Incipient and developing fault detection and monitoring (2) CHAIRS: Dr A Sokolva, Dr F Balitsky, Machinery Engineering Research Institute, Russian Academy of Science [137] Classification of the state monitoring systems S Boichenko, SPC Dynamics [138] Correcting amplitude and phase measurement of accelerometer in frequency domain A Badri, K Sinha, University of Manchester 16:10 [92] Application of signals separation / extraction techniques for diagnostics of driving units in mining machines R Zimroz, Wroclaw University of Technology [181] In-fibre point sensing of magnetic field strength using novel photonic sensor configurations P Orr1, P Niewczas1, J McDonald1, M Walsh2, W Morris2, University of Strathclyde1, EURATOM/UKAEA2 [108] Radio frequency measurements of bearing currents in an induction motor V Särkimäki, J Ahola, T Lindh, R Tiainen, Lappeenranta University of Technology [115] Long term monitoring of offshore installations using ultrasonic guided waves P Mudge, M Kayous, S Chan, The Welding Institute [122] High frequency vibration monitoring system for incipient fault detection and isolations of gears, bearings and shafts/couplings C Byington, M Watson, J Sheldon, H Lee, S Amin, Impact Technologies [129] An analysis of maintenance education and training needs in European SME’s and an IT platform enriching maintenance curricula with industrial expertise Y Bakouros, S Panagiotidou, University of Western Macedonia+ 16:30 [93] Examination of the condition of gear wheels affected by the complex cases of gear transmission damage T Figlus, Silesian University of Technology [109] Design considerations of energy harvesting wireless sensors for condition monitoring of electric motors J Ahola, V Särkimäki, T Ahonen, A Kosonen, R Tiainen, T Lindh, Lappeenranta University of Technology [116] Modelling of long range ultrasonic waves in complex structures S Soua, S Chan, T Gan, The Welding Institute [123] Power converter prognostics L Casey, M Prestero, G Davis, F Flynn, J Perkinson, SatCon [130] Some European initiatives in requirements within the maintenance function J Franlund, UTEK 16:50 [95] Analytical description and numerical simulation of the dynamic behaviour of a gear transmission with a broken tooth F Chaari, National School of Engineers of Sfax, Tunisia [98] Instantaneous power as a diagnostic symptom of bearing damage A Dzwonkowski1, L Swedrowski1, J Rusek2, Gdansk University of Technology1, University of Mining and Metallurgy2 [94] A study upon vibroactivity of the transmission housing with the addition of ribs T Figlus, Silesian University of Technology [178] Concept level evaluation of a full-scale deployment of fibre bragg grating sensors for measuring forces in JET during plasma disruption events P Niewczas1, G Fusiek1, C Lescure2, M Johnson2, E Ivings2, A West2, P Crolla1, M Walsh2, University of Strathclyde1, EURATOM/UKAEA2 [176] Wavelet analysis for the investigation of misaligned geophone features E Tshitshonu1, S Heyns2, Vaal University of Technology1, University of Pretoria2 [157] Condition monitoring using thin film ultrasonic sensors J Elgoyhen, J Hood, D Hutson, K Kirk, University of the West of Scotland [154] Case-based condition monitoring in large scale systems T Ahola1, E Juuso2, Outokumpu Tornio Works1, University of Oulu2 [117] Development of a permanent installation tool for structural health monitoring M Kayous, G Penney, I Daniel, P Jackson, Plant Integrity Ltd [124] Predictive wear debris characteristics for prognosis of scuffing under lubricated reciprocated sliding T Itoh, Oita Technical College [131] Analysis of the skills gap and training requirements within the maintenance function A Adgar, D Baglee, University of Sunderland [139] High energy x-ray diffraction as a method of strain analysis S Zhang1, A Korsunsky2, ISIS Facility1, University of Oxford [110] Acoustic emissions from oil lubricated metal on metal sliding contacts L Wang, R Wood, J Sun, University of Southampton [118] Training and certification in long range ultrasonic testing M Spicer, C Ennaceur, P Mudge, The Welding Institute [125] Motor condition monitoring: efficiency does matter T Thomas, Baker Instrument Company [132] Integrated equipment effectiveness (IEE) F Anvari1, R Edwards1, A Starr2, The University of Manchester1, The University of Hertfordshire2 [87] Problems of technical diagnostics of machines and equipment A Lukiyanov, S Eliseev, A Khomenko, Irkutsk State University of Railway Engineering [102] An artificial intelligence approach for measurement and monitoring of pressure at the residual limb/socket interface P Sewell1, S Noroozi1, J Vinney1, R Amali2, S Andrews3, Bournemouth University1, University of the West of England2, Southmead Hospital3 [111] Monitoring bending fatigue failure in helical gears using acoustic emission, vibration and online oil debris analysis: a comparative study A Onsy1, R Bicker1, B Shaw1, C Rowland2, T Kent3, Newcastle University1, University of Southampton2, Kittiwake3 [119] Monitoring of hydrogen assisted cracking in high strength bolts using leave-in-place ultrasonic sensors D Xiang1, G Zhao1, R Bayles2, Intelligent Automation Inc1, Naval Research Laboratory2 [126] A preliminary study for the efficiency of the wear debris analysis and thermography as independent or integrated fault diagnosis methods in tool wear monitoring P Botsaris, I Tsanakas, I Siouris, Demokritos University of Thrace 17:10 17:30 18:00 18:00 – 18:45 19:45 for 20:00 Exhibition close International Scientific Advisory Committee meeting (Session room B) Conference Dinner [133] Carbon nanotube thread for multifunctional structures M Schulz1, N Mallik1, C Jayasinghe1, P Salunke1, G Li, D Hurd1, W Cho1, E Head1, V Shanov1, X Zhu1, T Wang1, M Abu-Ali1, B Walker1, J Lee1, M Kumar1, S Yarmolenko2, J Sankar2 University of Cincinnati1, North Carolina Agricultural and Technical State University2 [158] Acoustic emission techniques applied to steam wastage estimation and fault detection in an industrial process heating application S Ramadas, University of Southampton [86] A new approach to machinery vibration analysis A Prygunov, Murmansk State Technical University Friday 18th July 08:00 09:00 09:35 10:10 10:30 11:05 Registration Plenary keynote lecture: [189] The role of IVHM in delivering competitive strategies, Prof T Baines, UK Chair: Prof L Gelman, Cranfield University Plenary invited distinguished lecture: Multi-agent approaches for IVHM architectures, Dr A Tsourdos, UK Chair: Prof L Gelman, Cranfield University Tea & coffee Plenary invited distinguished lecture: Health monitoring and reliability, Mr P Anuzis, UK Chair: Prof L Gelman, Cranfield University Panel Session: Future directions in condition monitoring and failure prevention 4C 4D 4E 4F 4G Damage detection, diagnosis and prognosis CHAIR: Dr W Matta, Vitrociset 4A Diagnostics through pattern recognition and novelty detection (2) CHAIR: Dr S King, Rolls Royce Advanced reasoning and diagnosis in condition monitoring CHAIR: Dr E Juuso, University of Oulu Condition based monitoring – how to make it a friend CHAIR: Dr T Lago, Acticut International Integrated techniques for diagnostics CHAIR: Prof J Vizintin, University of Ljubljana 12:20 Key example of integrated logistics support A Bucaioni, Vitrociset [100] A data mining approach to reveal patterns in aircraft engine and operational data S Sundaram, Oxford BioSignals [152] Intelligent condition indices in fault diagnosis E Juuso, S Lahdelma, University of Oulu [159] Condition based monitoring – how to make it a friend T Lago, Acticut International Advanced prognostic technologies and reliability of structures CHAIR: Prof S Fu, Shanghai Jiao Tong University [146] A probabilistic “design allowable” method of composite laminates H Fan, X Chen, H Wang, Shanghai Jiao Tong University 12:45 Vitrociset activities in the area of health management W Matta, Vitrociset [103] Condition monitoring of electric motor based on parameter identification using genetic algorithm J Treetrong1, J Sinha1, F Gu2, A Ball2, The University of Manchester1, The University of Huddersfield2 [160] Classification of production line data, a challenging task? A Brandt, T Lago, Acticut International [140] Asset management, maintenance and condition monitoring techniques explained to the layman D Manning-Ohren, ERIKS [99] Model based fault diagnosis in a rotor-bearing system N Vyas, N Ramakrishna, Indian Institute of Technology [172] A method for generalized prognostics of a component using paris law and kalman filter Eric Bechhoefer1, W Wang2, Goodrich Sensors and Integrated Systems1, Defence Science and Technology Organisation2 [173] Localised fault diagnosis in rolling element bearings in gearboxes N Sawalhi, R Randall, The University of New South Wales [147] In-plane elastic constants FEM prediction of stitched composite sandwich structure with foam core H Yang, X Zhang, H Wang, Shanghai Jiao Tong University 13:05 [153] Artificial immune system approach for the fault detection in rotating machinery J Strackeljan1, K Leiviska2,Otto-vonGuericke-Universitat Magdeburg1, University of Oulu2 [156] Wear debris basic shapes classification by using fuzzy logic M A Khan1, D Cooper1, R Matdan1, A Starr2, University of Manchester1, University of Hertfordshire2 [164] Development of an intelligent rotating machinery diagnostics programme B Suhac1, J Vizintin1, B Krzn1, U Benko2, D Juricic2, University of Ljubljana2, Jozef Stefan Institute2 [165] Pitting detection of operating gears using cyclostationary vibration analysis P Boskoski1 , D Juricic1, J Vizintin, Jozef Stefan Institute1, University of Ljubljana2 Gear and bearing condition monitoring and diagnostics (2) CHAIR: Dr W Wang, Defence Science and Technology Organisation [171] Autoregressive model based diagnostics for gears and bearings W Wang, Defence Science and Technology Organisation 13:25 Lunch 4B [161] Classification of metal cutting vibrations, is it all chatter? L Hakansson, T Lago, Acticut International [166] Assessing the quality of electrical motors by means of integrated diagnostic techniques D Juricic, J Petrovcic, B Musizza, U Benko, G Dolanc, Jozef Stefan Institute [150] Experimental study of flaws detection at the transition zone of sucker rod using guided waves based on magnetostritive effect J Xu, X Wu, L Wang, C Huang, Y Kang, Huazhong University of Science and Technology 14:05 [141] Bayesian data fusion: ignoring and mitigating the constraint of feature independence N Sedgwick, Cambridge Algorithmica [136] High temperature thin film transducers for condition monitoring J Hood, J Elgoyhen D Hutson, K Kirk, University of the West of Scotland [155] Tuning of linguistic equations for failure mode identification using genetic algorithms O Yahyaoui1, S Gebus2, E Juuso2, M Ruusunen2, ESSTIN1, University of Oulu2 14:25 [144] Optimal filtering of gear signals for early damage detection based on the spectral kurtosis F Combet, L Gelman, Cranfield University [177] Oil film measurement in rolling bearing using thin film ultrasonic transducer K Kirk1, J Elgoyhen1, J Zhang2, B Drinkwater2, R Dwyer-Joyce3, University of the West of Scotland1, University of Bristol2, University of Sheffield3 [145] Optimisation of damage detection in transient case L Gelman, I Petrunin, Cranfield University 14:45 Conference close [162] Condition monitoring application for the production line of compressors P Potocnik1, P Muzic1, E Govekar1, V Dragos2, T Strmec2, University of Ljubljana1, Danfoss Compressors2 [105] Instantaneous angular speed monitoring of a reciprocating compressor model A Sasi1, A Ball2, The High Institute of Industry1, The University of Huddersfield2 [167] On-line wear and lubrication condition monitoring B Krzan, J Vizintin, University of Ljubljana [174] Fault detection in gear boxes using a non-contact rotational position sensor M Taylor1, C Mechefske1, M Timusk2, Queen’s University1, Laurentian University2 [149] Stochastic responses of energy absorption mechanism of composite cylinder in thermal environment Y Yan, Q Tian, X Wang, J Xu, Shanghai Jiao Tong University [168] System of forecasting and non-destructive control over operational frictionalwear parameters of machines’ frictional knots V Khovanaskiy, Institute of Tribology [175] Intelligent gearing system – solution to understand and correct operational conditions that reduce the fatigue life of a girth gear D Dyk, David Brown Gear Industries Ltd [170] Noise cancellation in sonic non-destructive testing A Joghatae, Foam i