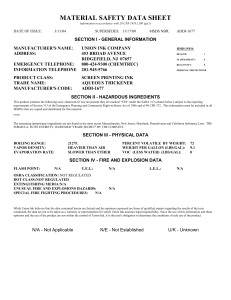

Printing Ink Problems-Causes and Remedies

PRINTING INK PROBLEMS: CAUSES AND REMEDIES.

Printing ink is a colloidal solution of a pigment in a vehicle where each pigment particle is surrounded by a film of varnish or vehicle. The ink shows characteristics of liophilic colloids. The viscosity of the ink is greater than the medium and they are stable to the addition of small amount of electrolyte.

Inks supplied to printers vary widely in formulation and properties. The variation is needed because of the wide range of surfaces being printed, the characteristics of different presses, and the various end-use requirements of printed jobs. There are inks for general commercial work that can be adjusted by the printer to suit a variety of papers. There are also inks designed especially for label printing, posters, magazine covers, greeting cards, decals, foils, plastics, metal decorating, or other purposes; these inks are usually press-ready and require little or no adjustment by the printer.

Regardless of the surface to be printed, inks can be varied in transparency, finish, rub-, scuff-, and heat-resistance, lightfastness, chemicals, and solvents.

Consequently, there are thousands of different ink formulations, each formulated for a specific paper or substrate or for a range of substrates, and for a specific set of printing conditions and enduse requirements. There is no ink that is best for all conditions. An ink that is suited for a wide range of papers and end-uses will not be best for any use. The printer must work with the ink maker to obtain the best inks

When an ink manufacturer produces ink for a specific job, he should have color copy, stock, conditions of printing, and end use requirements before formulating an ink. Properly formulated ink should perform the job well with minimum amount of difficulty or waste of printing press operation time.

Often ink is used of stock other than that for which it was formulated, may be a different press, under different operating conditions, different atmospheric condition or at different press speeds.

Even when the ink is specially formulated for the job, changes may be required. Before ink changes are made, the pressman must diagnose the difficulties exactly before applying remedies.

For example, the press must be in top operating conditions. Rollers must be scrupulously clean, free from dried ink film. Rollers and fountain should be properly set. Careful make-ready and form layout should be done prior to printing.

When printing results are below par, it is usually the ink that gets the blame. However, ink manufacturers today have rigid control specifications, which must be met before the ink is shipped, and rarely a repeat shipment of ink leaves the premises without matching the previous shipment.

Such is the thorough control of ink manufacturers these days prior to shipment.

Hence the pressman must examine other possible variables. Is the same stock being printed? An ink prints differently on different stocks. Variations in the stock's absorbency affect the appearance of the print. Is the same press being used? With heat-dry inks, is the same degree of heat being applied? Are press speeds the same? Is the volume and temperature of the circulating air in the drier the same?

Once materials have been added to the ink to adjust it, then nothing can be done to remove them.

Hence ink manipulation should be tried only after all other remedies have failed. When the stock is different and it must be used, then changes must be made to compensate for the difference. When the

press is different and the oven capacity is inadequate, the ink must be manipulated to speed drying.

When atmospheric conditions are different, ink manipulation may be needed to counteract the change.

Solving ink-related problems. Because of the many variables involved in inkmaking and lithographic printing, the web offset press operator is constantly faced with situations that require knowledge, experience, and judgement.

Experience and judgement come with practice. The inkmaker is a key source of information when troubleshooting. Usually, it is ill advised to alter inks, because uniformity is essential for the duration of the pressrun. The complexity of heatset ink formulas presents potential danger if they are altered improperly.

The following section lists the most common ink problems, their probable causes, and remedies to overcome or avoid each problem. All the ink problems can be classified under the four categories such as:

I.

Rheological problems a) Poor Trapping b) Flying or Misting c) Piling & caking d) Ink backs away from the fountain roller e) Poor binding or chalking

II.

Problems due to plate or paper selection a) Showthrough or Strike through b) Stripping of ink rollers c) Setoff d) Picking, Splitting & Tearing of paper e) Discoloration & Wearing of plates f) Scumming & Greasing

III.

Drying problems a) Poor drying b) Color fades or burns out during drying c) Crystallisation of ink during drying d) Smudging e) Sticking in the pile or web

IV.

Process problems a) Filling in or Plus up or Specking of halftones b) Ghosting c) Mottled print or poor lay d) Off color or print is off shade e) Tinting f) Counter etching in multicolor printing

g) Dot gain, Slurring or Doubling

I. a). POOR TRAPPING

The symptoms are poor quality overlays, color shades on overlays will not be true. Poor trapping ink will show up on blanket immediately as back trapping There possible causes to improper trapping in wet multicolor printings are: a) Improper tack sequence in the inks, or (b) Inks are improperly balanced as to strength, or (c) Too much water, or (d) Too much impression.

Adjust tack high to low, first to successive units. To add tack, add heavy binding varnish. To lower tack, add reducing varnish. Check water and impression. Generally, each succeeding ink should have slightly less tack than the pre-ceding ink in order to trap properly. This is very important, the more impervious the surface being printed. It is essential in the printing of metal sheets and aluminium foil. It is of little importance in printing soft, absorbent papers. Reduction of the racks of succeeding colors to the danger point, and so must not be overdone. b). FLYING or MISTING:

This results from the ink being drawn out into excessive long string or filaments when its film is split between the rotating press rollers. When these strings break off at both ends due to centrifugal force, then the ink is thrown out and floats into the atmosphere, this is more marked at higher press speeds. There are four possible causes of ink flying; a) Too Much Ink. The thicker the ink film on the press rollers, the longer the filaments formed when it is split between rollers. Sometimes substituting a stronger colored ink and running less of it will stop the flying. b) Ink Fountain Open Too Wide. Flying may result if the fountain roller carries a thick ink film and if the transmitting motion of the ratchet is a short one (sometimes called short rachet sweep). In this case, tightening the fountain balade and increasing the roller movement should stop the flying. c) Ink is too long and Tacky. A long ink draws out into long strings. By adding shortening agents such as certain wax compounds or a small amount of Soya lecithin, it is possible to stop flying.

Otherwise, a shorter ink should be substituted. Soya lecithin has the disadvantage of causing scumming with some inks. A long ink which is soft and non-tacky is less likely to fly than one that is stiff and tacky. d) Not Enough Lateral Distribution. Lateral or sidewise distribution of ink on press rollers results from the action of the vibrating drums or rollers, which is adjustable. If there is not enough lateral distribution, the ink tends to form ridges on the rollers, and these ridges produce longer strings and increase the tendency of the ink to fly. c). PILING AND CAKING

A dry accumulation or cake on the printing plate, both on solid and screen areas, is called piling or caking. To work properly, ink must have enough flow to transfer uniformity from roller to roller

roller to plate, plate to blanket and finally to the printed surface. Ink should not pile anywhere in the system. Causes of piling are: a) Ink is too short. Lack of proper flow can be due to over pigmentation, poor wetting of pigment by the varnish, too much drier, grease or wax compound too much plate moisture, or a combination of these factors. To remedy this condition add a varnish that will lengthen the ink, but always consult the ink maker. In any case reduce the dampening water to a minimum. b) Ink poorly Ground: If the ink contains undispersed pigment particles, these may separate from the vehicle and adhere to the roller, plate and blanket surface building up a cake. There is no remedy for such an ink except to send it back to the manufacturer for further grinding. c) Coarse. Heavy Ink Pigment: Coarse or heavy pigments like chrome yellow and titanium pigments require special formulations to overcome piling, however, the ink maker knows how to overcome such problems with difficult pigments. d) Paper Coating is Moisture Sensitive. Occasionally a coated paper is found that causes piling of ink on the blanket of the third or later unit of a multicolor press. Exam-ination shows a build up of putty like material on the blanket that causes the dots to slur and gives a mottled appearance to the print. The cause of this trouble is that the paper coating adhesive, due to the moisture from the blanket, begins to come off and is made sticky. This sticky coating is picked off during subsequent operations and finally works its way into, the ink. Being incompatible with the ink, it sticks and builds up on the blanket. This is a paper maker's problem and there is nothing that a printer can do much about it except wash the blankets frequently.

It may be mentioned that piling or caking can be detected by examining the print closely. Here the print shows blotchy areas outlined by a thin, non-printed line. d). INK BACKS A WAY FROM THE FOUNTAIN ROLLER

Difficulty in holding color, tendency to run light, streaky or uneven, may be due to improper ink consistency. Actually the ink sets up in the fountain thixotropically, and fails to flow and replace ink that is removed by the fountain roller. Specially certain yellows and reds are worse in this respect than others. The reason is that they are too short or too thixotropic, conditions, which result from the nature of their pigments.

The only remedy for backing away is frequent agitation of the ink in the fountain to keep it fluid and feeding properly. Ink fountain agitators are a satisfactory solution to this problem. Without agitators, agitation must be carried out by hand. Sometimes the addition of some long burnish like

No.3 or No.4 to the ink helps. Warming the fountain duct also helps. e). POOR BINDING OR CHALKING.

This difficulty should not be confused with slow drying. Chalking of ink on coated papers has no relation to the absorbency of the paper coating. Apparently, a reaction occurs between some coatings and the drier, making part of the drier inactive. As a result the ink rubs off or chalks. In most cases ultimately the ink dries but after several days and' in. some cases after a few weeks.

The root cause is insufficient binder needed to hold the pigment to the paper. The cause may be due to too Iowa binder content in the ink or the ink vehicle may have too Iowa viscosity, hence penetrates excessively into the stock, leaving unbound pigment on the surface. This difficulty can be caused by improper additions to the ink at the press, such as addition of thin oil or the wrong solvent, addition of a non penetrating, hard binding varnish can correct this defect.

The best remedy is probably the choice of a more viscous ink containing a better film forming vehicle, and possibly wax 'or a similar material to produce a hard mar proof surface.

If chalking occurs, it will not be noticed until after the expected drying time of the ink. However, the job can be usually saved by one of two methods. (i) Run the sheets through a press using a blank plate dampened with a fountain solution consisting of 60-90grams of a drying stimulator (cobalt acetate) per gallon of water. (ii) Overprint the chalking ink with a transparent tint base or an overprint varnish. This 'covers up the ink and also supplies additional drier.

II. a). SHOW-THROUGH or STRIKE THROUGH

Strike-through results when the ink vehicle penetrates and stains the sheet so that the printing is easily visible in the reverse side. This is the fault of the ink and the paper. Show-through is visibility of printing from the reverse side due to lack of opacity of the paper.

In offset printing, strike-through is rarely a problem because the ink film printed is very thin, it may occur in very lightweight or porous stocks of paper. If strike-through does take place, it is due to a strong penetrating vehicle in the ink, specially dark colored vehicle are prone to strike-through.

In such a case, order an ink with a relatively non-penetrating light colored vehicle. Sometimes a stronger ink printed with a thinner film will decrease or eliminate strike-through. If strike-through occurs, it will affect the printing on the reverse side, the ink receptivity on this side will change causing an imperfect ink lay, giving a mottled appearance. b). STRIPPING OF INK ROLLERS

Ink rollers strip and stop transferring ink if they become preferentially wet. Fountain solution that becomes emulsified in the ink is carried up into the inking system and there is always enough of it available to displace the ink from the rollers if for any reason they become desensitized too the ink. Roller stripping can be caused by:(a) glazing of the roller surface due to accumulations of dried ink and gum; (b) too much dampening water; and (c) too much acid or gum in the fountain water.

Phosphoric acid has a strong desensitizing action on steel rollers. To prevent this, the pH of the fountain solution should be preferably above 4.5. The fountain solution that is carried up into the inking system evaporates rapidly. As it does, its gum content increases and this desensitizes the rollers. The gum content of the fountain solution should never exceed 30g of 14() Baume gum arabic, per gallon or 15 g of 6% cellulose gum solution, per gallon.

Many presses now have ebonite or copper plated ink rollers, they are more ink receptive than steel and resist desensitization by phosphoric acid. Steel rollers can now be chemically copper plated by copperizing solution. Most inks these days already contain some compounds which help prevent roller stripping.

c). SETOFF

Also referred to as offset usually in litho printing. This difficulty shows up in the transfer of ink from the printed side to the under side in the delivery pile or rewind, roll. It can also cause the sheets to stick together and interfere with feeding in the second printing. Sometimes it can cause picking or rupture of the stock when the dried sheets are separated. These may be due to several causes:

Ink Not Adjusted To the Stock: The Ink must always set on the sheet before it is contacted by the following sheet in the delivery pile. To do this, its body and penetrating quality must be properly adjusted to the smoothness and absorbency of the stock. Quickest inks are formulated to avoid setoff. They are best suited for use on coated papers and boards.

Anti offset compound are effective if used properly. They speed up setting of the ink, shortening it. Those that contain wax form a protective film on the surface of the ink. If too much is used, this can prevent trapping of succeeding colors. The wax film can contaminate the backs of following sheets without being visible. Then, on printing the reverse side, the ink may not take properly, resulting in a mottle. Anti offset compound that contain magnesia prevent setoff by shortening the ink, but they tend to dull the finish of the dried ink and reduce its rub-resistance.

Cornstarch and starch compounds reduce setoff by slightly roughening the surface of the ink film. This delays intimate contact with the following sheets and allows more time for the ink to set.

The roughness reduces the ink's rub resistance. Use a minimum of starch; about 2 to 3 grams per pound of ink, too much will cause water logging and delay ink drying.

Running Too Much Ink: The thicker the ink film applied to paper or paperboard, the longer will be its setting time and greater the chances of setoff. The thinner ink films printed by offset are a decided advantage over letterpress printing in this respect. But even with offset printing, too much ink can cause setoff, specially where one ink overprints another.

A printer may run too much ink for two reasons:

(a) The ink does not have sufficient color strength; or (b) too much dampening water is being run which causes the printed ink film to appear weak and snowflakey. In both cases it appears that the plate is not well desensitized, hence requires excessive moisture to run it clean. A better plate would solve this problem. Sometimes solid prints require heavy lay of ink, and drying of such solids in the web or pile generates heat. Heat will cause softening of the ink film resulting in setoff during the drying process or can even cause sticking together of the sheets. This trouble can be prevented by winding and rewinding the web several times during the drying period or reducing the pile of the stack-ed sheets and also blow air during the stacking operation.

Embosses Sheets: When extensive solids are printed on lightweight papers, the solid areas are sometimes embossed. This is due to stretching of the paper in these areas by the tack or pull of the tack or pull of the ink when the sheets are separated from the blanket. When they fail on the delivery pile, such sheets are not properly supported on an air cushion and the embossed areas contact the following sheets too soon. When embossing occurs, reduce the tack of the ink.

Curly or Bumpy Paper: If the printed sheets are not flat, they will not remain separated by an air cushion on the delivery pile and hence there will be a tendency for set off. Besides using flat paper, anti offset spray is the only other remedy.

Piling Sheets Too High. Setoff may occur in printing heavy non-absorbent papers, paperboards, decalcomania papers, plastics and foils. Here the lack of absorbency of the stock prevents setting of the ink by penetration. Setting can take place either due to the solvent or by thixotropy. Here the sheets should not be piled too high on the delivery platform, but must be racked in lifts, to dry. The number of sheets per lift must be found by observation.

Rough Handling of Printed Sheets: Printed sheets if handled carelessly can cause setoff. Rough handling could be jarring, dumping the pile heavily instead of laying it gently, carting over rough floors etc. Careful handling is the prevention.

Printing With Gloss Inks: Gloss inks are formulated to dry with a minimum of penetration. The thicker the ink film, higher the gloss. Hence gloss inks are more prone to setoff than other types of inks. The best preventive for setoff is anti offset spray. A small amount is all that is needed. An excess will cause scratching and also give a poor rub and scuff resistance to the dried ink film. Too much spray will cause poor trapping of subsequent colors, and it can also pile on the blankets necessitating frequent wash-ups. If possible, avoid gloss inks use, instead conventional or quickset inks and obtains the desired gloss with spirit varnish, lacquer or an overprint gloss varnish.

Static Electricity: Under very dry conditions during cold weather when the print room is not humidified static electricity can cause setoff. During the passage of the paper through the press it can acquire static electricity. Ordinarily this charge is quickly dissipated by the film of moisture the paper receives from the blanket. But if the relative humidity is very low the charge remains on the sheets and causes them to be strongly attracted to the delivery pile. The air cushion is quickly squeezed out, resulting in an ink film, which does not dry quickly thus causing setoff.

Air-conditioning or at heat humidification of the print room atmosphere is the best prevention for static trouble. If this is not possible then a static eliminate or, properly mounted on the press may prevent setoff caused by static. d). PICKING, SPLITTING AND TEARING OF PAPER

This difficulty is seen in a roughening of the printed surface, the appearance of whit e specks in the solid area and even tearing of the paper surface. The paper has a definite pick resistance, which can never be altered. This ink has a definite tack, but this can be altered within certain limits. Causes of picking, splitting and tearing are as follows: a) Ink Too Tacky. The tack of an ink can vary from job to job. So it must be adjusted either by the ink maker of the printer to suit printing conditions, namely pick resistance of paper, the type, size and speed of the press. There is usually some leway in ink tack. If an ink picks the paper, its tack can be reduced to some extent without undermining print quality. But if it is reduced too far, it can cause loss of strength, finish, filling in of half tones, scumming or tinting. b) Paper Too Weak: Paper must have a certain minimum pick resistance to be printable. There are several methods of determining pick resistance of paper, the IGT is quite suitable. The Dennison

Wax Test is not a dependable measure of pick for offset papers. c) Paper is Moisture Sensitive. Most papers with sufficient pick resistance can be printed without trouble on single color presses. In multicolor work moisture resistance becomes important. Here the paper receives a thin coating of moisture from the blanket on the first printing unit. If this moisture

weakens the paper's surface, then picking will take place on succeeding units. Bear in mind that on four and five color work; moisture is cumulative on the paper, hence picking increases with each printing. Running a minimum of plate moisture and printing with minimum of pressure are the only means of combating picking on multicolor work. Unfortunately in such cases there is no test other than actual printing. A rough indication would be to rub the paper surface with a moistured finger. If the fibres are lifted or the paper surface ruptured, then the paper is likely to give trouble. d) Ink Begins To Dry On The Press. An ink with a suitable initial tack can start to dry on the press rollers, and by the time it reaches the paper it can cause picking. There may be three solutions to such a problem. i) Add a little 00 varnish to the ink to reduce its initial tack. ii) Add a little anti oxidant or slow dry compounds, consult the ink maker. iii) Let the ink maker prepare a fresh batch of. ink with less drier. In the case of quick-set and heat-set inks, drying on the rollers can be due to either solvent absorption by the roller composition rollers with low absorbency should be used. But even then trouble still persists. Trouble occurs mainly in starting the run due to increase in tack while the ink stands on the rollers during makeready. Once the run has started and the ink feed and flow established then there may not be a picking.

To prevent trouble during start-ups with quickset and heat-set inks, the following may be adopted: i) Use a special start up ink, which has the desired color but no volatile solvent; ii) If the composition rollers are new or have been standing dry for some length of time, saturate them with an ink solvent such as heat-set oil before inking them up. This prevents them from picking up solvent from the ink. iii) Soften the ink on the rollers at the start to counteract the stiffening effect due to loss of solvent by evaporation during make ready. Once the run has started and the ink flow established, then the regular ink should cause no trouble.

(iv) During press stops, spray the ink rollers with beat-set oil to keep the ink from drying. If picking of paper of board still continues, then in such a case it is best to consult the ink maker as to the proper remedy.

(v) Low Temperature: Ink works well at room temperatures around 24 to 27°C. A drop of between 3 to 50S could easily increase the tack of the ink, and this can cause picking. On such occasions it j5 best to warm up the press or slightly reduce the tack of the ink.

(vi) Excessive Pressure: Too much back cylinder pressure can cause picking of paper by quickset and heat-set inks. This happens because too much ink vehicle is forced into the paper capillaries thereby increasing the tack of the remaining ink film. Normally the pressure should be the minimum that will produce a good impression. e). DISCOLORATION AND WEARING OF PLATES:

Sometimes zinc plates during printing get discolored.

The non image areas of a plate darken or turn yellow or green. This is caused by the formation of a deposit of metallic lead or an insoluble lead compound on the plate due to the presence of a watersoluble lead salt in the dampening water.

Letterpress paste driers contain lead acetate, which is very water-soluble, this paste is used in offset inks and the lead acetate dissolves in the dampening water. This soluble lead acetate quickly reacts with the plate surface, which is made of zinc thus forming zinc acetate, and metallic lead is precipitated as a black deposit.

Litho paste driers the lead salt is oil soluble but if the fountain solution is sufficiently acid, the lead is converted into acid phosphate, which is somewhat, water-soluble. The effect on the plate can then vary depending on the conditions. The plate may turn black, gray, yellow or green. Black indicates metallic lead, gray indicates lead phosphate green or yellow deposit indicates lead chromate, which is due to the fountain solution, which may contain chromic acid or a bichromate.

Plate discoloration can be prevented by: a) Use of a litho paste drier; (b) Use cobalt drier; (c) Avoid excessive quantity of drier in inks; and (d) keep the pH of the fountain solution above 4.5.

The plate performance may vary widely depending on press condition, types of stock to be printed, how well the plate is made and the care that is given to it. If the plate image shows wear very quickly the cause may be one of the following:

Too Much Plate To Blanket Pressure: Specially with zinc and aluminium plates, blanket friction will cause wear, greater the pressure greater the wear.

Fountain solution too acidic: Strong acid fountain solutions will react with zinc and aluminium, flattening the plate grain, destroying the ink receptivity of the image areas and cause blinding.

Abrasive Pigment In The Ink: If the ink pigment is coarse or contains undispersed agglomerates, it will act as an abrasive and gradually wear away the colloid, lacquer, copper or whatever constitutes the base of the plate's printing image. The result is that the plate goes blind. But gritty pigments are hardly ever used these days by the ink maker.

Incorrect Roller Settings: Form rollers and dampeners can cause plate wear; if (a) Set too hard against the plate; (b) rollers slip during contact with the plate. Such wear usually shows up as streaks. Rollers should be set such that there is a minimum of bounce as they pass the cylinder gap.

Loose Mineral Filler of Coating Pigment on Paper: Mineral fillers and coating pigments are likely to be abrasive. If they are not well bonded to the paper, they will be picked up by the paper, they will be picked up by the non-printing areas of the offset blanket and gradually wear the plate, causing its non-image area to scum. This is a paper fault, which should be detected during trial prerun. f). SCUMMING OR GREASING

Scumming occurs when the non-image areas of the place lose their desensitization and begin to take ink. The scum begins to show on the plate and cannot be washed off with water. Following may be the causes of scumming:

Ink Too Soft. If an ink is not tacky enough at press speed Jo pull out sharp and print clean halftones and lines, the work will gradually thicken. The ink squashes and forces the moisture away from the margins of the printing image, eventually adhering and preventing dampening right up to the edges of the image. The first evidence of this will be the loss of halftones shadow detail.

The only remedy is to stiffen the ink and increase its tack by adding I to 2 ounces of body gum or water resistant varnish per pound of ink. If this weakens the ink too much, try another tackier ink. If this cause picking of paper, there is no remedy except to wash up and etch the plate or get a more pick-resistant paper.

Ink Vehicle Is too acid: If the ink vehicle contains too much of fatty acid it can destroy the desensitizing film on the non-image areas of the plate. Sometimes a fatty acid like oleic or a compound of it is added, in an attempt to counteract blinding of a plate (loss of ink receptivity in the plate's image area). This should be done with great care so as not to overdo it. Usually about half an ounce to a pound of ink is likely to cause scumming.

Too Much Ink. Running too much ink has the same effect as running it too soft. If squashed the plate image tends to thicken the work. The remedy is to use a stronger ink and run less of it.

Ink Pigment Is Coarse: This can act as an abrasive and wear the desensitizing film off the plate's non-image areas, causing scum. The remedy is to use another well-ground and well-dispersed ink,

Too Much Plate To Blanket Pressure: Too much pressure causes the ink to squash and fill in just the same as if the ink is too soft or too much ink is run. Also, the blanket scrubs then on-Image areas of the plate, wearing off the desensitizing film, this is evidenced by horizontal scum streaks. The remedy is to keep plate to blanket pressure at a minimum.

Improper Roller Settings: Plate wear and scumming can result if either the form rollers or dampening rollers are set too close to the plate. The result is the same as above, plate to blanket pressure.

Worm Or dirty Dampening Rollers: When the cotton-dampening roller covers wear-off, the base fabric becomes abrasive and wears the plate. Also if the dampeners are not sufficiently clean and contain dried ink, this presents uniform dampening and can cause plate wear. The best remedy is to keep the dampeners clean and replace: their covers when they are worm.

III. a). POOR DRYING

Inks dry in a number of different ways; Letterpress news ink dry by absorption. The vehicle drains into the sheet leaving the pigment on the paper surface. Conventional quickset inks for sheet fed offset dry by absorption and by chemical reaction (oxidation polymerization). Heat set inks dry by absorption and evaporation of the solvent but final hardening of the dry film is by chemical reaction. Web inks, whether offset, letterpress, gravure or flexo, dry mostly by evaporation. Web offset and web letterpress inks, which evaporate at high temperatures, are molten when they come out of the dryer and must be chilled to convert into solid, in order to discuss ink drying problems, it is best to discuss separately the inks that dry by chemical reaction and by evaporation.

Quickset Inks: Modern Sheet-fed inks are almost without exception, quick setting and dry by absorption and by oxidation polymerization. During the reaction, a number of small molecules, which can easily flow past each other, react to form a large, entangled molecule, which will not

flow. This is how a liquid is converted into a solid. For this reaction to proceed, the three-armed molecules found in ink varnished need oxygen. Oxygen from the air reacts extremely slowly with the varnish. To speed up the chemical reaction, driers are added: salts of lead, cobalt and manganese, when the oxygen is carried by these driers the reaction takes place rapidly. If the right amount of drier is present, the inks should dry in approximately four hours. From a purely physical viewpoint, the drying of quickset inks can be looked at as a gradual increase in viscosity.

The effectiveness of the drier is reduced by acid and by excess moisture. The effect is

"synergistic", i.e. the effect of excess moisture together with excess acid is far worse than the sum of the two effects alone. Since soft inks tend to emulsify water more readily than tacky inks, reducing the inks has the additional unfavorable effect of retarding drying.

Drying becomes very slow when the fountain solution has an acidity of pH and the relative humidity of the room is 75%. One must also note, the point often overlooked is that when fountain solution is transferred to paper and evaporates, the pH on the surface of the paper goes down and the relative humidity rises. So if the fountain solution has an original pH of 3.5 to 4.0, and if one is using a soft ink, this ink is going to emulsify a great deal of water, the conditions on the surface of paper could easily reach and acidity and moisture content which would inhibit ink drying. The above figure gives the reason why zinc plates which required low pH and large qualities of water always presented ink drying problems, but with the newer synthetic plates ink drying is not much of a problem. The more ink there is on the sheet, the more oxygen is required to dry the ink. When a form has heavy ink coverage, the printer may wind the roll of paper to provide oxygen. As the oxygen-polymerization reaction continues, heat is given off. Besides providing oxygen, winding the roll also removes heat from it. After printing it is always wise to unwind the roll, because the temperature within a very large section can rise high enough to melt the ink and cause blocking when it cools, Instances have been reported where rolls of nitrocellulose coated book covers after printing ignited due to heat generated by the drying of the ink.

Too much acid in paper can also cause ink-drying problems. Modern uncoated papers usually have pH values between 4.5 and 5.5. Retarded ink drying due to acid in the paper seldom occurs unless the pH value is below 4.5. Paper coatings vary in pH from 6.0 to 10.0 usually the higher the pH value, the faster the ink will dry. However, some high pH coatings tend to neutralize the' acid in fountain solutions, raising their pH values. If this produces a scumming tendency, the pH values of the contain solution must be lowered. Coated papers with low pH values retard ink drying more in humid weather than papers with high pH values. To counteract this effect, more dryer or a stronger dryer is needed.

Low temperature retards drying. Since ink drying is a chemical reaction its time is affected by temperature. In fact, it is cut in half by a rise of 10 to 12°C or doubled by a drop of 10 to 12°C. For the most rapid and dependable drying, the print room should be between 25 to 27°C and the paper should be at the same temperature. Since R.H. also affects drying, the ideal condition 45 + 2% R.H. at about 25 + 2°C.

To avoid ink-drying problems the following is recommended:

1. Order ink to match the paper to be printed. Paper affects drying of ink. Ink manufacturers can formulate ink more satisfactorily, if the type of paper to be printed is known.

2. Initially, check the effects of ink on paper before starting a press run. If drying characteristics are checked a day or two in advance, the printer has the opportunity to consult the ink suppliers, if drying is not adequate. A small hand proof press proves very useful for such testing.

3. Keep fountain pH above 4.5. If a lower pH is needed for a particular from the pH should be returned to normal before going on to the next form. Look forward to broader use of alkaline fountain solutions on sheet-fed press. Alkaline fountain solutions, frequently used in web offset newspaper printing help reduce ink drying problems.

4. Use very high tack ink, which will not pick the paper surface. Not only does reducing an ink usually cause it to dry slowly, but soft inks tend to enhance ink-water emulsification.

5. Run presses with the minimum water needed to prevent plate scumming. Use of isopropanolin the fountain solution reduces the amount of water reaching the paper and ultimately reduces the occurrence of drying problems.

6. Check old inks. Driers in such inks tend to dissipate, and inks that are six months old and over must be tested before use on proof press.

7. If tests show that an ink will dry slowly, it is best to approach the ink supplier and ask his opinion rather than add excess drier, because this can actually retard ink drying rather than speed up drying. In old inks some portion of the drying oil has polymerized leaving the non-drying oil as a main constituent of the vehicle and by adding an excess drier it merely gets suspended in the nondrying portion of the oil.

Heat-set ink (Web Inks) : Web inks dry mostly by evaporation although some absorption occurs when these inks are printed on paper. To increase hardness, web letterpress and web offset inks frequently contain some components that dry by oxidation-polymerization.

Web inks contain solvents that boil at such a high temperature that little evaporation takes place on the press. The printed web is dried by heating in a high temperature dryer at the end of the press.

Serious paper damage can occur, if a dryer becomes too hot. The paper temperature should not be higher than is necessary to dry the ink. Cracking, fibre puffing and blistering of paper occur when dryer temperature is too high. An optical pyrometer aimed at the web as it comes out of the dryer gives more accurate information about the dryer operation than does a thermometer or a thermocouple, which measures air temperature. The temperature of the web can change with speed whereas the temperature of the air remains unchanged. Every web printer must seriously consider installing an optical pyrometer on each dryer, and not rely upon a thermometer or the, feel by the hand.

The ink solvent for these inks must re-operate below the temperature, which causes blistering or scorching of paper. If is does not, the ink should be reformulated with a lower boiling solvent. The only control the printer has here is either to raise the temperature of the dryer or reduce the press speed but there is a limit to both of these without damage to printing.

As mentioned previously most web inks contain some drying oils and dries. If the ratio of drying oil to resin is too high, the residue left after evaporation will be soft and too easily damaged when the web is processed. This can only be remedied by reformulating the ink.

Web inks contain a thermoplastic binder dissolved in the solvent as mentioned above. When the solvent is boiled away, the vehicle remains liquid until it is coated on the chilled rollers. If for any reason these chilled rollers are not operating properly, the ink may not be properly cooled, and will remain soft and mark easily.

An inexperienced printer in this situation will try to dry the ink by raising the dryer temperature.

This of course will aggravate his problem. An optical Pyrometer aimed at the web as it comes off the

chilled rollers can provide date to the printer that will allow him to make proper corrections. At this stage it becomes more convenient and less expensive for him to feel the web with his hands and determine if it is properly chilled. In spite of proper chilling, if the resin has too Iowa melting point, the) ink film will remain tacky even though all the solvent has evaporated. This is known as "after tack". For successful results the melting point of the resin and after cooling of the printed web must be properly balanced for the press speed. Here once again, the only control the printer has is to lower the temperature of the chill rollers and if this does not help, then the ink must pre reformulated.

Some resins release their solvents faster than others. Web inks which contain resins should release their solvents quickly so as not to remain tacky. Selection of such resins is the sole responsibility of the ink maker.

With flexo and gravure inks, solvent composition is the primary cause of drying difficulties. If the inks dry too rapidly, they may dry on the press rollers. Addition of a high boiling solvent will cause the ink to dry more slowly. If the inks dry too slowly, then they may not dry on the web.

If a mixed solvent is used to prepare the inks and more of the one component has evaporated has to be added to compensate for the loss. The solvent to be used must be the one recommended by the ink maker. Some printers prefer to add the mixed solvent, because there is no simple way to determine the quantity of each component to add to bring the solvent mixture back to its original composition.

The ink maker should not use resins and binders that are touchy i.e. easily thrown out of solutions by small changes in solvent composition. As the solvent in the ink fountain evaporates, the ink pigment becomes concentrated and this is one of the few causes of ink color variation in gravure and flexography. Consequently, the printer must carefully inspect the ink fountain, replacing the solvent as required.

SUMMARY: In conclusion, close cooperation between the printer and the ink supplier is vital in securing inks that will dry properly. Inks must be formulated for the job to be printed whenever possible, and adjustments if needed should be performed by the ink maker. Ink drying problems are costly. Saving a few paisa on the price of the ink is foolish economy, because cost of the ink usually represents a small fraction of the total cost of the finished job. b). COLOUR FADES OR BURNS OUT DURING DRYING:

"Burning out" refers to a distinct change in the ink color during drying, usually in the pile. It occurs mostly in large solids or solid tints. It is caused by: a) Not enough oxygen: When inks that require oxygen from the air in order to dry, the available air is sometimes limited to that which is trapped between the sheets and in the pores. When large areas are printed, then this much amount of air is insufficient. Once drying has started, the ink vehicle is so hungry for oxygen that it starts to take it from pigments (only certain) with the result that the color is bleached or burnt out or faded. During drying, a small amount of heat is generated and this accelerates the feeding. This is very common with iron blues; mixtures of iron blues and chrome yellows, where the blue fades away. Many tints of red pigments also demonstrate this fading. To prevent fading, it may be necessary to unwind and rewind the printed sheets two or three times during the drying period, but it is always better to use pigments which do not fade.

b) Alkali Sensitive Pigments: Paper coatings vary from slightly acid to fairly alkaline. The pH of acid papers are generally 5.5 to 6.0 and those of alkali papers are 9.0 to 10.0. If an alkali sensitive color is printed on an alkali coated paper, it may appear all right at first but the color begins to fade within a few days and begins to show a marked change over the weeks. Tints may lose color while full strength prints may hardly show any change, but once the fading starts there is hardly any way of restoring the original color.

Iron blues and chrome greens show a marked change when printed on coated stocks. When using such pigments check the pH of the coated paper (coating of the paper). Most organic pigments are unaffected by the alkali in the paper coatings. c). CRYSTALIZATION OF INK ON DRYING:

When a job requires two or more printings with the ink drying in between, the dried ink sometimes fails to trap the succeeding ink properly, this is believed to be due to the non-drying oil or wax in the ink coming out or floating to its surface during drying, causing it to repel the following ink.

Crystallization can result from running too much ink too much grease or wax compound in the ink or for allowing the ink to dry too long and causing the ink film to harden appreciably before over-printing it. Too much cobalt or manganese driers can cause it because these driers cause rapid surface drying. When a job requires two or more printings, the first ink to be printed should be made without grease or wax in their formulas and no excess drier. At this stage a paste drier should be used or a bare minimum of cobalt drier used. Succeeding prints should be made as soon as the ink has dried sufficiently to permit handling of the sheets.

If an ink has crystallized, then an over-print compound added to the succeeding I ink to make it trap. Here the over-printed color may not adhere well even though the print may look all right; adhesion can be improved by heating. Usually such printed sheets are dried in an oven. Use of too much spray powder on the first printing can also cause crystallization. d). SMUDGING

If the ink does not dry it will smudge. The vehicle in an ink film may be fully oxidized and polymerized, but still the ink film may smudge. This may be due to non drying materials in the ink.

These no drying compounds could be anti offset compounds, wax compounds, cup grease, pertolatum mineral oil, tallow or any other non drying rub resistant film. These may be added by the ink maker or the printer while trying to adjust the ink. In any case, troubles like such can be avoided by proofing, drying and testing the dried ink film before using an ink on a major run. Sometimes too much drier in an ink more frequently added by a printer rather than materials in commercial driers like petroleum solvents. The best remedy would be to use a different ink. e). STICKING IN THE PILE OR WEB

This difficulty is associated with both setoff and poor drying. The cause and remedies mentioned above under these headings often apply to prevention of sticking.

IV. a). FILL IN or PLUS UP or SPECKING OF HALFTONES:

"Filling in" is a condition where a halftone starts out printing well, but gradually thickens during the run. It is first noticed in the shadow tones which becomes denser and then loses detail. It may be due to: a) Poorly Desensitized Printing Plates. When the plate is not well desensitized, the areas hardest to dampen are those at the edges of the printing image. The image therefore tends to spread and thicken. The areas first affected are halftone shadows, which fill in and lose detail. Running more water to keep them open results in snoflakiness and loss of color or density A strong or stiff ink may help fit does not pick or tear the paper. Wet washing or etching the plate may help, but the best remedy is a better plate. b) Running Too Much or Too Soft an Ink. At each point of transfer, the ink film is under pressure which makes it tend to squash or spread on 'lines or halftones. This is more marked when printing on hard, non-absorbent papers. The thicker the ink film or softer the ink, greater will be the defect. Eventually this destroys the plate's desensitization at the edges of the image, so that the thickening continually increases. To prevent this, the ink should be run as stiff and spare as possible. c) Running ink Too Tacky on Soft or Linty Paper. Uncoated papers are sometimes linty. Tacky inks pick up this lint and throw it back on to the plate and ink rollers, which become fouled. The only recourse is to reduce the tack of, the ink, but this can reduce the quality of the print if carried too far. d) The Ink is poorly Ground. If the ink is poorly ground, it contains pigment agglomerates, which may be abrasive. This causes the plate to wear gradually, causes dots and lines to thicken.

Inks can be tested for fineness of grind by means of a Hegman Gauge. e) Too Much Pressure. Excessive from roller pressure or plate to blanket impression tendons to squash the ink film and wear the desensitizing film off the plate. As a result wear usually results first in the halftones shadows, which tends to fill in and lose detail. Excessive blanket to paper pressure causes dot spread on the blanket, which in turn can cause dot spread on the plate. It can also cause slur. Printing pressures must be kept as low as possible. f) Too Much Drier or Compound in the Ink. Most driers or compounds soften the ink and reduce its tack. When too much is used, they can cause filling in of halftones. Too much drier increases the ink tendency to water log. b). GHOST IMAGES APPEAR IN SOLIDS

Occasionally a form may take all the ink off the form rollers, leaving a reverse print on the rollers. This design may be then transferred to another part of the form and shows up as a ghost or light shadow. This occurs when the metal rollers do not supply enough ink to the form rollers to

obliterate the design before it contacts the form, a second time. This can appear when the ink has more affinity for metal than for the form rollers.

The addition of a long, sticky varnish may help to prevent this complete transfer. A tight setting of the form rollers to cause a slight slippage of the roller blurs the design and makes it less apparent.

Ghosting is most prevalent on presses with relatively few from rollers. Obviously, the addition of another form roller can help obliterate ghosts. Use of form rollers of different diameters also help prevent this trouble.

Ghosting is more troublesome in solid tints than in full strength solids, usually because the ink is run spare. It is worse with transparent than with opaque colors. It can be reduced by adding No.2 varnish to give the ink better distribution qualities, running more of a less strong colored ink, or changing to an opaque ink. Excessive dampening water also aggravates ghosting and should be avoided.

STREAKS are usually caused by mechanical difficulties on the press. Cracked or slightly damaged rollers can cause streaks. In rotogravure printing, streaks may be due to defective doctor blade or to scratches on the cylinder. In some cases, accumulation of dried ink or other particles under the doctor blade interferes with proper wiping and can be the cause of streaks. c). MOTTLED PRINT AND POOR LAY

Mottling is noticed mainly in solids and dark halftones It is a spotty appearance due to variation in either ink density or finish. The following are the most likely causes: a) Ink Too Soft or Short. Mottling can be reduced or eliminated by' adding body gum or water resistant varnish provided it lengthens the ink and increases tack. In some cases a grease or wax compound or cornstarch may improve the lay. b) Non Ink Receptive Stocks. Smooth, hard uncoated papers and varnished grade coated papers can cause trouble. To improve ink lay on them, the ink should be very strong in color and run as tacky and spare as possible. Sometimes a small amount of reducing compound helps. c) Stock With a look- Through Formation: A lock through formation is the appearance of a paper when viewed through by means of transmitted light. A poorly formed paper gives a mottled or curdled appearance due to alternate opaque and transparent areas. Such papers have variable ink absorbency. On uncalendered papers, the transparent areas are usually less absorbent than the opaque areas. On calendered papers the reverse is usually true.

Solids printed on such papers vary in finish, the ink on the less absorbent areas are glossier than those on the more absorbent areas. This given the solids a galvanized appearance. To correct this, the ink should be made strong tinctorially and as non-penetrating as possible. d) Non-Uniform Paper Coatings: Sometimes paper and board coatings are non-uniform in ink absorbency. This process causes the ink to dry with an uneven finish so that the solids appear galvanized. In such cases, addition of a little gloss varnish or body gum to make the ink less penetrating helps. The K7N Ink Absorbency Test can detect non-uniformity of paper coatings.

e) Running Too Much Ink. Running too much ink on hard, poor ink receptive papers can cause mottling. If the density or color cannot be obtained without excessive ink, then a stronger ink should be used. f) Too Much Pressure: Too much back cylinder pressure tends 'to squash the ink film. It forces the ink off the high spots of the paper surface into the low spots giving the letter a thicker ink film.

Pressure should be kept to a minimum stiffening the ink may help resist squash. h) Too much Dampening Water. Too much moisture on the plate causes excessive moisture pick up by the ink. This reduces the ink's tack so that it squashes more readily. Also moisture globules on the surface of the ink film during impression moisten spots on the surface of the paper, which then rejects the ink. This produces white- spots in solids, which are minute and give a snow flaky appearance. d). OFF COLOUR or PRINT IS OFF SHADE

The ink color is off shade when it fails to match the proof. This can only be judged accurately after the ink has dried. a) Improper Match. The printed color may be clean but the shade or the strength may be wrong, this is more likely due to a poor match. This could have been caused by the matcher being furnished an inadequate copy, on which the original color had changed or the wrong stock on which to check his match. Another possibility may be improper lighting conditions.

In all such cases a rematch is required. But in all cases the color of the ink can be corrected by adding a toner of the proper hue, or an extender, or by either increasing or decreasing the ink feed.

Before finding the ink guilty, the pressman must check the thickness of his ink film because the color varies with the ink film thickness. b) Press is Dirty. If the color appears dirty, then the press may not have been completely washed or it may still carry dirty dampening rollers. To check this make a drawdown of the ink from the can and another from the ink of the press rollers. c) Ageing of Paper. Paper too may yellow on ageing and there by change the appearance of the print. e). TINTING

Tinting is the condition when a more or less uniform tint of the color being printed appears on the unprinted areas of the sheets. It is very difficult to see on the plate but can be easily removed with a sponge. It could be caused by:

Bleeding of The Ink Pigment: Some pigments are soluble enough to color the fountain solution and produce a faint tint on the blank areas of the printed sheets. This is an ink maker’s problem.

Chrome yellows are known to bleed at times in bichromate fountain solution. The bleeding usually stops if a non-bichromate fountain solution is substituted. Emulsification of Ink In the Plate

Moisture: Offset inks take up moisture on the press and form water-in-ink emulsion. But they should not break down and form ink-in-water emulsion. If they do, the blank areas of printed sheets will show an emulsification tint.

This can be easily distinguished from a bleed by the fact that it consists of myriad of fine dots that can be clearly seen under a magnifying glass. A short ink is more easily emulsified than a stiff, tacky ink. It will break down more easily if run at low speeds than at high speeds. Short and highly pigmented inks tend to break down and emulsify more easily than long, less concentrated inks.

Sensitization of the Plate's Non-Printing Areas: Some paper coatings contain water soluble protein materials that are slowly transferred to the plate's non-printing I areas. This material finally builds up on the surface of the plate and forms a partially receptive surface for ink films. When the tint first forms it can be easily washed off the plate, but if allowed to remain it eventually becomes a scum which can only be removed by wet washing and re-etching the plate. If printing is resumed on the same paper, the tint will again gradually return.

If tint of this type first appears, it could be easily overcome by using a different paper and doing away entirely with the original paper. Letterpress coated papers do not have this tinting potential, but quite a few variety of litho papers (coated) had this tinting defect. Coated papers that can cause this type of tinting can be easily identified by the following test.

Cut a 10 x 10 cm. sq. of the paper dip it in the fountain solution and squeegee it on to the nonprinting area of the plate. After a minute, remove the paper and proceed to print. If the paper is at fault, a solid or a tint will quickly appear in the are a contacted by it and will continue to do so for quite a number of impressions.

Residual Plate Coating: If the bichromated surface coating has not been completely removed from the nonprinting areas of the plate, tinting can occur. It will look like an emulsification tint, but it will be spotty and not uniform over all the white areas. It can be easily removed from the plate with a gum sponge, but comes back very quickly once the printing is resumed.

There is hardly much one can do to overcome this trouble, for best results, residual plate coating must be removed completely in plate making. f). COUNTER ETCHING IN MULTI COLOUR PRINTING:

This is a form of scumming that occurs only on multicolor presses. It always appears on the second or a later unit never on the first and is often called "secondary scumming". The blankets on the second and later units pick up ink from the wet prints from the preceding units in their nonprinting areas. This ink then comes in contact with the non-printing areas of the plate under squeeze pressure sometimes this sensitizes the plate causing it to print a scum of its color on the preceding color.

If there is a build up of ink from the preceding unit on the blanket of the unit where the scum appears, then the ink's pigments may not be well dispersed. Sometimes softening of such an ink may reduce the piling tendency but the real remedy is to get a better ink. If too much or too soft an ink is run on the previous unit, it should be replaced with a stronger or stiffer ink and run spare. Replacing the ink on the unit where the scum appears with an ink which has hardly any tendency to scum is the best solution.

Sometimes it is necessary to strengthen the fountain solution (lower the pH) on the unit where counter etching occurs. g). SLURRING, DOUBLING & DOT GAIN

Slur is caused by slippage between the offset blanket and paper during the impression. It is observed while printing a coated stock, rarely on an uncoated paper. It can be easily recognized when: (a) it causes halftone shadows to fill in and lose detail, while highlights' are unaffected (b) the back edges of solids are fringed instead of being sharp. When slur occurs it is first noticed as an increase in tone values in the darker halftones and is very often confused with dot squash or scumming. A magnifying lens is necessary to identify slur. Doubling is different from slurring as it occurs in any direction i.e., not unidirectional as in slurring.

The chief cause of slur is too much back cylinder pressure. On smooth coated papers the ink can act as a lubricant and permit slippage causing slur where there is enough ink coverage. But where there is little ink coverage as in highlights, the blanket cannot slip and the dots print sharp, on uncoated papers, the surface is usually rough to prevent slippage even when printing solids.

To prevent slur, a minimum of ink should be run. The more the ink, greater the lubricating effect and greater the tendency to slur.

The symptoms of dot gain are dots under magnification have increased their size & halftone areas fill. The probable causes are ink too soft, ink piling on blanket, improperly set rollers, improper packing on blankets & improperly made plate.

Remedies: Add long varnish to stop ink piling. Check roller pressures and blanket packing.

In some cases special printing aids or an ink fountain additives are suggested (Table 1A summarises ink problems which may be solved using ink additives, but the pressman should be aware of optional solutions).

00 8 44 220 221 230

PILING, POOR TRANSFER

Increase Tack,Increase length

X

X

CHALKING or POWDERING

Improve hold out

DRYING SLOW; POOR

GLOSS Increase drier,Polymerising extender

EMULSIFYING (TINTING)

Waterproof

FLYING, MISTING

Shorten length

PICKING, LINTING,TAIL

CURL, HICKIES

Reduce tack

SET OFF IN DELIVERY

Induce Quick set

X

X

X

X

X

X

X

X

X X

X

X

SCUFFING SCRATCHING

Increase wax and drier,Use hard surface drier X

MOTTLED SOLIDS

Improve leveling

TRAPPING POORLY

Use nonglossing drier, Adjust tack Use wax free additive

X

X

X

X

X

X

X

Table 1A - Common problems with ink and the recommended solutions.

X

X

X

X

An Ink Additive should not be considered 'a magic potion' but only as an immediate, possible remedy. Prior to using any ink additive, be sure to read the label and any technical information available on the additive you are planning to use.

X

X

X

X

X

235235232

280

805

X

X

X

00 Tack Reducer

An excellent transparent litho varnish, free flowing with excellent uniformity. It is an outstanding extender.

8 Ink Gloss

A concentrated plastic glossing resin for all inks that produces a very high gloss. It creates a scratchproof finish and helps speed drying.

44 Print Kleen

Mixes with ink to create an immediate 'set' on the sheet (though not on the press) to prevent offset. Great for use on coated stocks. It is recommended reducer for all varnishes.

220 Three Way Drier

A liquid drier that mixes easier than paste driers with all inks to give controlled overall drying. Excellent top and bottom drying qualities. It will not discolour the most delicate inks.

221 Liquid Cobalt Drier

A standard 6% cobalt naphthenate drier. It sets ink easily and rapidly. This traditional surface drier forms a hard glossy finish on the printed surface.

230 Ink Conditioner

Wax free multi purpose ink additive for all inks. Instant tack releaser. Promotes drying without hindering trapping. It maintains color quality and produces smoother solids. Eliminates hickey problems.

235 Ink Hardener

Formulated to assist drying and improve scuff resistance of printing inks when used on hard surfaced papers and boards.

280 Aquacheck

A glossy plastic resin binder. It prevents emulsification of inks and is very useful in multi colour work. Gives sharper cleaner prints. Maintains color quality.