9. equality impact statement - Portsmouth Hospitals NHS Trust

advertisement

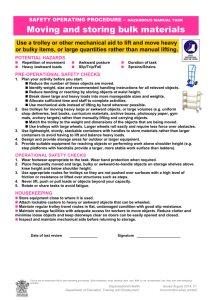

MANUAL HANDLING OPERATIONS OF INANIMATE LOADS POLICY Version 9 Name of responsible (ratifying) committee Health and Safety Committee Date ratified 08 May 2013 Document Manager (job title) Lead Back Care Advisor Date issued 22 May 2013 Review date May 2015 (unless requirements change) Electronic location Health and Safety Policies Related Procedural Documents See Page 7 Paragraph 8. Key Words (to aid with searching) Load; Inanimate; Pushing, Pulling; Manual Handling operations; Inanimate loads; Materials handling; Safe handling; Occupational hazards; Risk management; Working environment; Training; Musculoskeletal disorders; Risk assessment; Equipment; Occupational health and safety; Work related injuries; In the case of hard copies of this policy the content can only be assured to be accurate on the date of issue marked on the document. For assurance that the most up to date policy is being used, staff should refer to the version held on the intranet Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 1 of 19 CONTENTS QUICK REFERENCE GUIDE ............................................................................................................. 3 1. INTRODUCTION.......................................................................................................................... 3 2. PURPOSE ................................................................................................................................... 3 3. SCOPE ........................................................................................................................................ 4 4. DEFINITIONS .............................................................................................................................. 4 5. DUTIES AND RESPONSIBILITIES ............................................................................................. 4 6. PROCESS ................................................................................................................................... 6 7. TRAINING REQUIREMENTS ...................................................................................................... 7 8. REFERENCES AND ASSOCIATED DOCUMENTATION ........................................................... 7 9. EQUALITY IMPACT STATEMENT .............................................................................................. 8 10. MONITORING COMPLIANCE ..................................................................................................... 9 Appendix A: Assessment help checklist....................................................................................... 10 Appendix B: Example Assessment ............................................................................................... 12 Appendix C: Principles of Manual Handling Inanimate Loads…………………………………..…..13 Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 2 of 19 QUICK REFERENCE GUIDE For quick reference the guide below is a summary of actions required. This does not negate the need for the document author and others involved in the process to be aware of and follow the detail of this policy. 1. All managers are responsible for ensuring that hazardous manual handling activities are clearly identified through the process of risk assessment. They must ensure that where significant risks are identified, appropriate action is taken to reduce the risk to the lowest level reasonably practicable. Hazard Identified 2. Process. Risk Assess T.I.L.E (Appendix A) Can it be avoided? Yes No Can it be mechanised No Develop safe system of work Information given to staff Yes Train staff on equipment Record Actions Review if risk changes 1. INTRODUCTION The Trust recognises and accepts its duties and responsibilities as an employer to provide, so far as is reasonably practicable, a healthy and safe environment to enable its staff to undertake manual handling safely. All employees are required to accept responsibility for the implementation of this policy and work proactively to reduce the risks that cause musculoskeletal disorders. The Trust will ensure that reasonable resources will be made available so that the requirements of this policy can be effectively implemented. The Manual Handling Operations Regulations (as amended) 1992 impose a duty on the Trust to avoid the need for employees to undertake hazardous manual handling so far as is reasonably practicable. The regulations identify a hierarchy of duties to which the Trust must adhere. Avoid hazardous manual handling operations so far as is reasonably practicable. Assess any hazardous manual handling operations that cannot be avoided, and Reduce the risk of injury to the lowest level so far as is reasonably practicable. Indicate where practicable the weight of the load and its centre of gravity. 2. PURPOSE This policy describes how the Trust will comply and maintain compliance with the regulations. It will ensure that the Trust actively reduces the risk of injury from manual handling and thereby reduces the incidence of musculoskeletal disorders within the staff population of the Trust. Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 3 of 19 3. SCOPE This policy applies to all employees within the Trust who carry out manual handling activities including agency, bank and volunteers. ‘In the event of an infection outbreak, flu pandemic or major incident, the Trust recognises that it may not be possible to adhere to all aspects of this document. In such circumstances, staff should take advice from their manager and all possible action must be taken to maintain ongoing patient and staff safety’ 4. DEFINITIONS Health and Safety at Work Etc. Act 1974: the act and its regulations impose a duty on every employer to “ensure, so far as is reasonably practicable, the health, safety and welfare of all his employees” Manual Handling Operations Regulations 1992: supplements the general duties upon employers concerning the moving of loads. It imposes a hierarchy of measures to avoid the hazardous manual handling tasks so far as is reasonably practicable; assess those tasks which cannot be avoided and to reduce the risk to the lowest level reasonably practicable Manual Handling: lifting/lowering, carrying, pushing /pulling, transporting a load or supporting a load in a static posture by hand or bodily force. Inanimate Load: a discrete, moveable object. T.I. L. E: initials of the risk factors to be assessed; Task, Individual, Load, Environment Hazardous Manual Handling: risk to the individual of being injured when undertaking the manual handling. Musculoskeletal Disorder (MSD): disorders of the muscles, and their associated ligaments and other connective tissue, and of bones and cartilage viewed collectively. 5. DUTIES AND RESPONSIBILITIES Lead Back Care Adviser is the competent person who advises the Trust in respect of the manual handling of loads including the formulation and development of policy. In addition to carrying out these duties the Advisor will: Provide advice on the manual handling of loads Provide statutory manual handling training for the Trust in line with the Trust’s essential training matrix. Provide support to the Learning and Development Dept to underpin the Essential Skills Handbook for all staff. Organise audits of manual handling practice Provide advice to promote musculoskeletal health Provide a resource to managers to ensure compliance with the Manual Handling Operations Regulations Be an active member of the Health and Safety Committee on all matters relating to manual handling and musculoskeletal health. Design, facilitate and evaluate all manual handling training and education. Provide support to managers to enable them to review and investigate accidents and incidents related to manual handling. Provide support to managers to undertake complex risk assessments. Provide support on the purchase, use and maintenance, of manual handling equipment within the Trust. Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 4 of 19 Ensure all identified relevant issues are communicated to the Health & Safety Advisor for inclusion in the 6-monthly report to the Governance and Quality Committee. Manage the outsourcing contract to provide some essential manual handling training. Monitor incident trends and provide appropriate manual handling advice to managers. Back Care Advisers are delegated duties by the Lead Back Care Adviser. They will: Advise staff on all aspects of the moving and handling of inanimate loads. Support managers in the Investigation of accidents and incidents relating to manual handling. Support managers to undertake complex risk assessment Support managers to instigate manual handling advice following any trends identified in reported incidents Undertake the manual handling training Undertake audits of manual handling practice in the workplace Identify individual(s) who are unable to safely perform the practical elements of manual handling during training Complete the relevant documentation to provide a record of manual handling training Act as role model for staff Provide manual handling training/workshops in the workplace when requested by managers and deemed appropriate through risk assessment, Maintain the practical manual handling training room in a safe manner Provide support and advice on the use of manual handling equipment Work with a member of staff in the workplace who has been identified as encountering problems when manual handling loads. This may be by self, Occupational Health or Manager’s referral Work with and support the outsourced training provider to provide some essential manual handling training. Provide feedback to the Lead Back Care Adviser on all of the above Health & Safety Advisor will provide the Governance and Quality Committee with a 6-monthly report on all matters of health and safety, including those relating to the manual handling of loads. The Health & Safety Advisor will also ensure that any identified risks are presented to the Risk Assurance Committee for potential inclusion on the Trust’s Risk Register or Assurance Framework. Senior Managers (Clinical Service Centre (CSC) Management Team and Operational Managers) are responsible for ensuring that their line managers undertake appropriate risk assessments and that the production of information, training or supervision through local policy and procedures (safe systems of work) is provided. Managers are responsible for bringing to the attention of staff actions required to reduce the risk. All staff have the duty to work to instructions given or to use any equipment provided, which is designed to reduce the risk. Line Managers will ensure that: Safer moving and handling practice is promoted at all times and the importance of looking after the musculoskeletal health of all staff, whilst at work, is positively reinforced. They undertake moving and handling risk assessments in their area of managerial responsibility. Refer to appendix A for guidance When risk assessments identify hazardous manual handling that appropriate action is taken to reduce the risk, so far as is reasonably practicable, through the implementation of safer systems of work. Moving and handling risks and associated safe systems of work are communicated effectively to all employees they manage. Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 5 of 19 Staff they identify through risk assessment as requiring additional update training to that provided by the Essential Skills Handbook for All Staff and the accompanying E assessment receive it. There is sufficient and adequate manual handling equipment available to manage the manual handling tasks being undertaken. These may include lifting hoists, sack trolleys and height adjustable trolleys. Staff receive the appropriate instruction in how to use the equipment in accordance with manufacturer’s instructions, in line with their current duties. All equipment in their charge is fit for the purpose of use, has undergone the appropriate inspection and maintenance and relevant legislation is adhered to such as The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) and the Provision and Use of Work Equipment Regulations 1998 (PUWER). All lifting devices in their charge are notified to Carillion service so that appropriate inspection, maintenance and repair can be carried out. Requests to Carillion service for maintenance and/or repair of defective equipment is recorded. Matters relating to manual handling that are raised on the Adverse Incident Reporting System are investigated. Employees are required to take reasonable care for their own health and safety and that of their colleagues and others by the way they work. They should: Avoid any manual handling that may cause harm to themselves or others. Use handling equipment in accordance with instructions given, Report and/or label unsafe activities or faulty equipment to their Line Manager; Report all adverse incidents or near misses using the Trust’s incident reporting system. Health and Safety Committee Will receive bi-monthly updates on current issues relating to the manual handling of loads and the recommendations to be implemented or proposed to reduce the risk, as directed by the Lead Back Care Advisor, to ensure that proposed actions are appropriate and, if necessary, brought to the attention of the Trust Board via the Governance and Quality committee. 6. PROCESS Hazard Identified Risk Assess T.I.L.E (Appendix A) Can it be avoided? Yes No Can it be mechanised No Develop safe system of work Yes Train staff on equipment Information given to staff Record Actions Yes Review if risk changes Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 6 of 19 The process is designed to: a) Avoid hazardous manual handling operations, so far as is reasonably practicable. b) Assess the risk of any hazardous manual handling operations that cannot be avoided. c) Reduce the risk of injury, so far as is reasonably practicable. Access to Specialist Advisors Specialist advice can be obtained from the: Moving and Handling Advisory Team (MHAT) Occupational Health Building, Queen Alexandra Hospital Telephone 023 9228 3642 (7700) 3642 7. TRAINING REQUIREMENTS 7.1 Training forms part of the Trust’s Essential Skills and Training Requirements; as identified in the Training Needs Analysis/Matrix. 7.2 Staff read the Essential Skills Handbook for All Staff and undertake the e-Assessment annually. For information on the principles of the manual handling of inanimate loads that underpin training, please refer to Appendix C. 7.3 Managers can request the MHAT to provide manual handling training for staff that they have identified as requiring more than that at 7.2. This need will be met either through centrally provided courses and workshops or through department/locally delivered training. 7.4 All training is recorded on the Electronic Staff Record (ESR) from which the Learning and Development Team provide a monthly heat map to each CSC, to enable monitoring of compliance 7.5 Compliance is further monitored through the CSC performance reviews with the Executive Team 7.6 In addition to compliance with the training as prescribed in the Training Needs Analysis, awareness of manual handling issues is also raised through: Workshops and events guided and/ or undertaken by the Moving and Handling Advisory Team. Moving and Handling Advisory Team webpage on the intranet Articles in the Trust magazine “Link” Displays and information bulletins using the Trust intranet system Posters displayed in ward areas Participating in the National Back Care week Articles in the Health and Safety Quarterly newsletter 8. REFERENCES AND ASSOCIATED DOCUMENTATION External The Manual Handling Operations Regulations (as amended) (1992) The Lifting Operations and Lifting Equipment Regulations (1998) The Provision and Use of Work Equipment Requlations (1992) Getting to Grips with Manual Handling. A short guide (03/04) Management of Health and Safety at Work Regulations 1999 Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 7 of 19 Internal Health and Safety Policy Risk Assessment Policy and Protocol Policy for the Management of Adverse Incidents and Near Misses Inanimate Load Training Pack 9. EQUALITY IMPACT STATEMENT Portsmouth Hospitals NHS Trust is committed to ensuring that, as far as is reasonably practicable, the way we provide services to the public and the way we treat our staff reflects their individual needs and does not discriminate against individuals or groups on any grounds. This policy has been assessed accordingly Manual Handling (Inanimate Loads) Issue 9 22.05.2013 (Review date: May 2015 unless requirements change) Page 8 of 19 10. MONITORING COMPLIANCE As a minimum the following elements will be monitored to ensure compliance Element to be monitored Lead Tool Frequency of Report Reporting arrangements Manual handling of inanimate loads practice in the workplace Moving and Handling Advisory Team Workplace observation and audits (samples) Annually Health and Safety Committee CSC Managers Health & Safety Leads Manual Handling Incident trends Lead Back Care Adviser Datix 6 monthly Health and Safety Committee CSC Managers Health & Safety Leads Manual handling of inanimate loads workplace risk assessments Lead Back Care Adviser Review of manual handling of inanimate loads risks on CSC Risk Registers Annually Health and Safety Committee CSC Managers Health and Safety Leads Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 9 of 19 Lead(s) for acting on recommendations Appendix A: Assessment help checklist Problems to look for when Making an assessment Ways of reducing the risk of injury The tasks: do they involve: Can you: Holding loads away from the body? Twisting, stooping or reaching upwards? Large vertical movement? Long carrying distances? Strenuous pushing or pulling? Repetitive handling? Insufficient rest or recovery time? A work rate imposed by a process? The loads: are they: Heavy, bulky or unwieldy? Difficult to grasp? Unstable or likely to move unpredictably (like animals)? Harmful? e.g. sharp or hot Awkwardly stacked? Too large for the handler to see over? Can you make the load: Constraints on posture? Bumpy, obstructed or slippery floors> Variations in levels? Hot/cold/humid conditions? Gusts of wind or other strong air movements? Poor lighting conditions> Restrictions on movements or posture from clothes or personal protective equipment (PPE)? Lighter or less bulky? Easier to grasp? More stable? Less damaging to hold? If the load comes in from elsewhere, have you asked the supplier to help, e.g. provide handles or smaller packages? The working environment: are there: Use a lifting aid? Improve workplace layout to improve efficiency? Reduce the amount of twisting and stooping? Avoid lifting from floor level or above shoulder height, especially heavy loads? Reduce carrying distances? Avoid repetitive handling? Vary the work, allowing one set of muscles to rest while another is used? Push rather than pull? Can you: Remove obstructions to free movement? Provide better flooring? Avoid steps and steep ramps? Prevent extremes of hot and cold? Improve lighting? Provide protective clothing or PPE that is less restrictive? Ensure your employees’ clothing and footwear is suitable for their work? Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 10 of 19 Problems to look for when making an assessment Ways of reducing the risk of injury Individual capacity: does the job: Can you: Require unusual capability, eg aboveaverage strength or agility? Endanger those with a health problem or learning/physical disability? Endanger pregnant women? Call for special information or training? Handling aids and equipment: Is the device the correct type for the job? Is it well maintained? Are the wheels on the device suited to the floor? Do the wheels run freely? Is the handle height between the waist and shoulders? Are the handle grips in good order and comfortable? Are there any brakes? If so, do they work? Work organization factors: Is the work repetitive or boring? Is work machine or system-paced? Do workers feel the demands of the work are excessive? Have workers little control of the work and working methods? Is there poor communication between managers and employees? Pay particular attention to those who have a physical weakness? Take extra care of pregnant workers? Give your employees more information, e.g. about the range of tasks they are likely to face? Provide more training (see ‘What about training?’) Can you: Provide equipment that is more suitable for the task? Carry out planned preventive maintenance to prevent problems? Change the wheels, tyres and/or flooring so that equipment moves easily? Provide better handles and handle grips? Make the brakes easier to use, reliable and effective? Can you: Change tasks to reduce the monotony? Make more use of workers’ skills? Make workloads and deadlines more achievable? Encourage good communication and teamwork? Involve workers in decisions? Provide better training and information? Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 11 of 19 Appendix B: Example Assessment PORTSMOUTH HOSPITALS NHS TRUST RISK ASSESSMENT AND ACTION PLAN KEY colour coding used to identify risks Existing Risks New Risks TYPE (may be more than one type) C = Clinical H&S = Health & Safety L = Legal Risk scores are calculated by Consequence (C) x Likelihood using the 5 x 5 matrix QAH Clinical Services Centre C20a C, H&S, L, SD Anytime A Person Managing patient notes which are delivered in blue boxes. Average weight of a box of notes is 30kgs and these need to be lifted up onto desk to be sorted. IMPACT Delayed clinics. Workplace injury sustaining sickness absence, from musculoskeletal disorders of more than 3 days duration. Any specific measures currently in place to control the risk. Two persons to lift the box or One person to decant notes from box. Manual Handling (Inanimate Loads) Issue 9 08.05. 2013 (Review date: May 2015 unless requirements change) 12 3x4 4 2X2 FURTHER ACTIONS REQUIRED TO CONTROL THE RISK Boxes not to be over packed by records staff. Storage surface to be installed where the boxes are delivered so that they are situated at a height where the boxes are more easily lifted from. Page 12 of 19 ASSURANCE MECHANISM / MONITORING (how are you going to monitor whether your controls are working) Review of any manual handling injuries to ensure none related to the moving and handling of boxes of patient notes. RESPONSIBLE LEAD / COMMITTEE An Area KEY CONTROLS RISK / HAZARD DESCRIPTION SD = Service Delivery INITIAL TARGET DATE / REVISED TARGET DATE A Place R = Reputation Assessor: PREDICTED RESIDUAL RISK RATING (C x L) DATE OPENED ID / CQC Ref TYPE / SOURCE Dir/Dept/Specialty/Ward Q&P = Quality / Performance Date: INITIAL RISK RATING (C x L) Hospital Site F = Financial Risk reduced / recommended for local monitoring APPENDIX C Principles of Manual Handling Inanimate Loads This Appendix provides information which builds on the Trust’s ‘Essential Skills Handbook’ and forms the content of ‘face-to-face’ classroom-based learning. Training for managing inanimate loads in PHT comprises of the following: Staff read the Essential Skills Handbook for All Staff and undertake the e-Assessment annually. Information on the principles of the manual handling of inanimate loads, that underpin training, is contained in this Appendix. Managers can request the Moving and Handling Advisory Team to provide manual handling training for staff that they have identified as requiring more than that which is described above. This need will be met either through centrally provided courses and workshops or through department/locally delivered training. Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 13 of 19 Legislation The two key pieces of legislation which underpin manual handling practice at work are: 1. The Health and Safety at Work Etc Act 1974 This states that: Employers: ‘must, as far as is reasonably practicable, safeguard the health safety and welfare of employees’ And that: Employees: ‘must take reasonable care of their own health and safety and that of others who may be affected by their acts or omissions’ 2. The Manual Handling Operations Regulations (as amended) 1992 Define manual handling as: “Any transporting or supporting of a load (including the lifting, lowering, pulling, pushing, carrying or moving thereof) by hand or bodily force” And impose a hierarchy on employers, for manual handling risk assessment, where reasonably practicable, to: Avoid hazardous manual handling; Assess the tasks which are undertaken; to Reduce the risk Risk Assessment The risk assessment process under this legislation is often given the acronym ‘TILE’ Consideration of the manual handling tasks must be made under the following headings (some examples are shown but more detail is given in Appendix A): TASK - what is to be done? How long will it take? Will it be done frequently? Is it repetitious? Is equipment required? Is the equipment suitable and sufficient; and fit for the purpose? INDIVIDUAL– this is you. Are you fit and healthy enough? Do you have enough skills and knowledge? Can you apply the safer biomechanical principles? Do you need help? LOAD – this is what you are moving. Do you know its weight? Is it heavy? Large? Unwieldy? Difficult to grasp? Have handholds? Do you know where its centre of gravity is? ENVIRONMENT – is it spacious enough? Free from obstacles? Are there slopes, stairs or doors to negotiate? Does this need to be written down? A written risk assessment (or ‘safe system of work’ or ‘Standard Operating Procedure’) will need to be available for those tasks which are deemed hazardous or not easily passed verbally from one person to another. The manager is responsible for writing this but all staff members should have input into it and have access to it. The risk assessment(s) should be reviewed at least annually, or when the situation changes. Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 14 of 19 Musculoskeletal System ‘Musculoskeletal’ is defined as: The muscles, and their associated ligaments and other connective tissue, and of the bones and cartilage viewed collectively. To manage loads safely you need to understand where your centre of gravity (COG) is and where the COG of a load is. The COG of an object is described as: ‘an imaginary point in the centre of its mass’. If the object is uniform in shape and density then its COG will be exactly in the geometric centre. In humans the COG will alter dependant on a change in posture and in movement. However, for a stationary person standing upright, with their arms at their sides, it is generally described as being just in front of the 2nd sacral vertebra (inside your abdomen, at about the level of your navel). To remain healthy and safe at work, when you are handling a load, you need to think about how you use your body most effectively and efficiently to maintain your musculoskeletal health. This can, generally, be described as ‘using the safer biomechanical principles’, which are: 1. Adopt a wide base of support (feet apart, in a ‘walking stance’, if possible) 2. Keep your knees soft (to enable balance and to get down to a lower load) 3. Keep your spine in an upright, neutral position (avoiding bending, twisting or over-reaching) 4. Keep close to the load (its COG close to yours) 5. Keep your head up (to balance the weight of your head on the top of your spine) It may not always be possible to apply all these principles to every task so you must undertake personal risk assessment to determine if it is safe to proceed with an adaptation of the principles. This approach may work, in the short term, if the load is reasonably easy to manage. However, any such adaptation should act as a trigger to re-assess the process. Musculoskeletal (MSK) Health The following are the common causes of MSK disorders: Cumulative build up of strain from poor postures and repetition Trauma (injury) from a sudden shock to the musculoskeletal system Degeneration of discs from repetitiously bending, stooping and over-reaching Static postures (remaining in one position too long, including sitting) Rarely MSK disorders can arise due to a: Disease process Most cases of back pain resolve within a few weeks without treatment, provided that you carry on with your life as normally as possible and remain relatively active. The key ways to maintaining musculoskeletal health are self awareness, fitness (particularly core stability), active movement from one posture to another and a balanced diet. However, if you have any of the following ‘red flag’ symptoms of back pain: pain down both legs numbness or tingling, particularly in the ‘saddle area’ of your pelvis (the bit that you sit on) incontinence Then you must seek medical attention immediately. Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 15 of 19 If you have a MSK disorder, Occupational Health, or your manager, can refer you to ‘Fit4Work’ at Oasis, if exercise will be of benefit; or to us to review the manual handling that you undertake at work. Remember, also, that applying these principles when you are at home can help protect your MSK health whilst you are shopping, gardening, lifting young children, loading the washing machine, using a laptop, undertaking DIY, doing housework, etc. Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 16 of 19 Principles of Safe Lifting PLAN Stop and think Assess the weight of the load and where it is going PREPARE Give yourself a stable base with the feet apart Have your leading leg as far forward as is comfortable POSITION Bend your knees, and take a firm grip of the load Try to keep your back straight and maintain its natural curves PERFORM Using your leg muscles to aid lifting, come up to standing keeping the load as close to the body as possible Ensure that when the load is put down that the same principles of safe lifting are applied Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 17 of 19 Falling/Fallen Persons Staff members who manage inanimate loads only are unlikely to be responsible for the management of a falling or fallen person. However, all staff may find a person (or patient, or colleague) who has fallen and the following is generic moving and handling advice. The risk of falling can generally be reduced by preventing the occurrence in the first place and risk assessment is the key to successful management. We all have a responsibility to report any obstructions that someone may trip over, or a wet floor which is unmarked. If the preventative measures are not sufficient, or if the fall happens unexpectedly to a person, then the following is general guidance if you are quite near to the person as they fall: Do not catch and hold the person up. There is good evidence to show that the forces exerted on the ‘catcher’s’ body are very high You might be able to cushion their head by getting your hand between their head and the floor; or you might be able to quickly move an obstacle out of the way so that there is no impact with it Once the person is on the floor, or you find them there having not witnessed it, then your responsibility, from a moving and handling perspective, is to call for help If you have a clinical role, or you are a nominated first-aider, then you may have additional responsibilities. For further information and advice please contact us: Moving & Handling Advisory Team (7700) 3642 023 92 283642 Rosie Lake (Lead Back Care Advisor) Pam Phipps (Back Care Advisor) Sue Hanson (Back Care Advisor) Email addresses: Rosemarie.Lake@porthosp.nhs.uk Pamela.Phipps@porthosp.nhs.uk Susan.Hanson@porthosp.nhs.uk Address: Moving & Handling Advisory Team Occupational Health Building Queen Alexandra Hospital PO6 3LY Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 18 of 19 Manual Handling (Inanimate Loads) Issue 9 08.05.2013 (Review date: May 2015 unless requirements change) Page 19 of 19