02002_0101_r01m

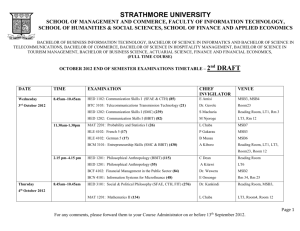

advertisement