Lab 5: Acetaminophen

advertisement

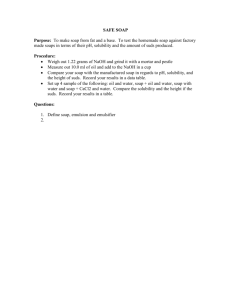

Chem1050 – Fick Chem1050 Lab 11: Preparation and Chemistry of Soap Introduction: Soaps as we know them today were virtually unknown before the first century A.D. Clothes were cleaned primarily by the abrasive action of rubbing them on rocks in water. Sometime later, it was discovered that certain types of leaves, roots, nuts, berries and barks formed soapy lathers that solubilized and removed dirt from clothes. We now know these natural materials that lather as saponins. Many saponins contain pentacyclic triterpene carboxylic acids, such as oleanolic acid or ursolic acid, chemically combined with a sugar molecule. These acids also appear in the uncombined state. Saponins were probably the first known “soaps”. They may also been an early source of pollution in that they are known to be toxic to fish. The pollution problem associated with the development of soap and detergents has been long and controversial. Soap as we know it today has probably evolved over many centuries from experimentation with crude mixtures of alkaline and fatty materials. Pliny and Elder described the manufacture of soap during the first century A.D. A modest soap factory was even built in Pompeii. During the middle ages, cleanliness of the body or clothing was not considered important. Those who could afford perfumes used them to hide their body odor. Perfumes, like fancy clothes, were a status symbol for the rich. An interest in cleanliness again emerged during the 18th century, when disease causing organisms were discovered. The process of making soap has remained practically unchanged for 2000 years. The procedure involves the basic hydrolysis (saponification) of a fat. Chemically, fats are usually referred to as triglycerides. They contain ester functional groups. Saponification involves heating fat with an alkaline solution. This alkaline solution was originally obtained by leaching wood ashes or from the evaporation of natural alkaline waters. Today, lye (sodium hyrdoxide) is used as the source of the alkali. The alkaline solution hydrolyzes the fat to its component parts, the salt of a long chain carboxylic acid (soap) and an alcohol (glycerol). When common salt is added, the soap precipitates. The soap is washed free of unreacted sodium hydroxide and molded into bars. The carboxylic acid salts of soap usually contain 12 to 18 carbons arranged in a straight chain. The carboxylic acids containing even numbers of carbon atoms predominate, and the chains may contain unsaturation. The chemical structures of fats, and the related oils, are show below and in the following charts: 2 3 The equation below shows how soap is produced from a fat. It is an idealized reaction, in which the R groups are the same. Usually, the R groups are not the same. Therefore, soap is actually a mixture of salts of carboxylic acids. A disadvantage of soap is that it is an ineffective cleanser in hard water. Hard water contains salts of magnesium, calcium and iron in solution. When soap is used in hard water, “calcium soap”, the insoluble calcium salts of the fatty acids, and other precipitates are deposited as curds or “scum”. This precipitate is referred to as bathtub ring. Although soap is a poor cleanser in hard water, it is an excellent cleanser in soft water. A diagram of soap in hard water is shown here: Water softeners are added to soaps to help remove the troublesome hard water ions so that the soap will remain effective in hard water. Sodium carbonate or trisodium phosphate will precipitate the ions as the carbonate or phosphate. Unfortunately, the precipitate may become lodged in the fabric of items being laundered, causing a grayish or streaked appearance. An important advantage of soap is that it is biodegradable. Microorganisms can consume the linear soap molecules and convert them to carbon dioxide and water. The soap is thus eliminated from the environment. 4 Dirty clothes, skin, or other surfaces have particles of dirt suspended in a layer of oil or grease. Polar water molecules cannot remove the dirt embedded in nonpolar oil or grease. One can remove the dirt with soap, however, because of its dual nature. Soap is unique in that is has a very lipophilic (lipid loving) part and an ionic end, hydrophilic (water loving) that is H2O soluble. Soap can dissolve in H2O and dissolve fats at the same time. Soap is a wonderful cleaner! Preparation of Soap In this experiment we prepare soap from animal fat (lard) or an oil of your choosing. Animal fats and vegetable oils are esters of carboxylic acids and they have a high molecular weight and contain the alcohol glycerol. Chemically, these fats and oils are called triglycerides. The principal acids in animal fats and vegetable oils can be prepared from the natural triglycerides by alkaline hydrolysis (saponification). The natural acids are rarely of a single type in any given fat or oil. In fact, a single triglyceride molecule in a fat may contain three different acid residues. (R 1COOH, R2COOH, R3COOH), and not every triglyceride in the substance will be identical. Each fat or oil, however, has the characteristic statistical distribution of the various types of acids possible. The fats and oils that are most common in soap preparations are lard and tallow from animal sources, and coconut, palm, and olive oils from vegetable sources. The length of the hydrocarbon chain and the number of double bonds in the carboxylic acid portion of the fat or oil determine the properties of the resulting soap. For example, a salt of a saturated long chain acid makes a harder, more insoluble soap. Chain length affects solubility. Tallow is the principal fatty material used in making soap. The solid fats of cattle are melted with steam, and the tallow layer formed at the top is removed. Soapmakers usually blend tallow with coconut oil and saponify this mixture. The resulting soap contains mainly the salts of palmitic, stearic, and oleic acids from the tallow, and the salts of lauric and myristic acids from the coconut oil. The coconut oil is added to produce a softer, more soluble soap. Lard from hogs differs from tallow from cattle in that the lard contains more oleic acid. Pure coconut oil yields a soap that is very soluble in water. The soap contains essentially the salt of lauric acid, with some myristic acid. It is so soft (soluble) that it will lather even in seawater. Palm oil contains mainly two acids, palmitic acid and oleic acid, in about equal amounts. Saponification of this oil yields a soap that is an important constituent of toilet soaps. Olive oil contains mainly oleic acid. It is used to prepare Castile soap, named after the region in Spain in which it was first made. Toilet soaps generally have been carefully washed free of any alkali remaining from the saponification. As much glycerol as possible is usually left in the soap, and 5 perfumes and medicinal agents are sometimes added. Floating soaps are produced by blowing air into the soap as it solidifies. Soft soaps are made by potassium hydroxide, yielding potassium salts rather than the sodium salts of the acids. They are used in shaving creams and liquid soaps. Scouring soaps have abrasives added, such as fine sand or pumice. Procedure: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Prepare a solution of 2.5 grams NaOH dissolved in a mixture of 10 mL distilled water and 10 mL ethanol. Be extremely careful with the NaOH solids and solution as it will dissolve skin and eye tissue! Rinse any affected areas immediately !! Place 5 grams of lard or equivalent amount of oil in a 250 mL beaker and add the solution to it. Heat the mixture on low heat on a hot plate for 45 minutes. Make sure you have a watchglass on top of the beaker and you place ice on the watchglass to aid in refluxing the mixture. Prepare another 20 mL of 50:50 solution ethanol and water and add it in small portions to the reaction over the 45 minute period. Prepare 25 grams of NaCl dissolved in 75 mL water in a 400 mL beaker. At the end of the 45 minutes of heating your mixture, pour the hot soap mixture into the salt mixture. Stir the mixture for several minutes. Cool the mixture in an ice-water bath. Collect the soap in a buchner funnel via vacuum filtration. Wash the soap with two portions of ice cold water. Allow the soap to dry overnight and weigh soap. Save your soap for further analysis. Analysis: 1. 2. 3. 4. 5. 6. 7. 8. 9. Setup (6) 25 x 150 mm testubes in your testube rack for analysis of your soap and Murphy’s Oil Soap. In testube 1 put 1/3 full of distilled water. In testube 2 put 1/3 full of tap water. In testube 3 put 1/3 full of “hard” water. In testube 4 put 1/3 full of distilled water. In testube 5 put 1/3 full of tap water. In testube 6 put 1/3 full of “hard” water. In testubes 1-3 put in 10-20 drops of Murphy’s Oil Soap Mixture. Count your drops for discussion. Put your thumb over each tube and shake vigorously and note what you observe. 6 10. 11. 12. Repeat in testubes 4-6 using a piece of your soap. Add one drop of acetic acid (vinegar) to your distilled tubes 1 and 4 and shake. Note any changes. Add some solution of washing soda into testubes 3 and 6. Shake again and note any changes. 7