11067 - Kendall Stage Curtains

advertisement

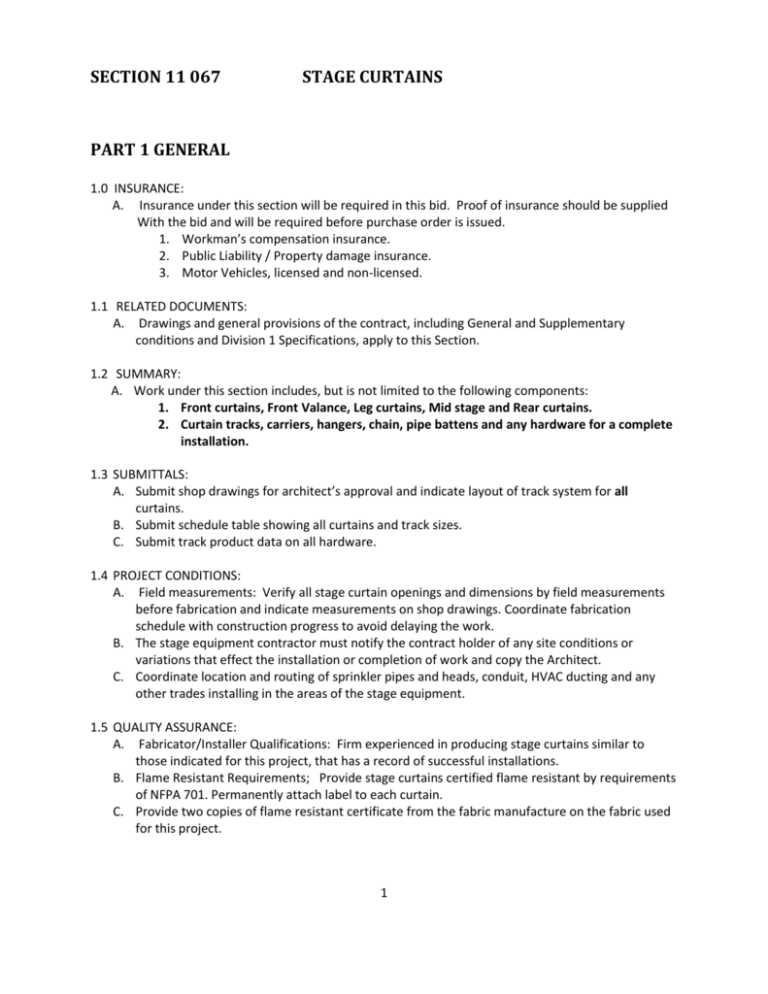

SECTION 11 067 STAGE CURTAINS PART 1 GENERAL 1.0 INSURANCE: A. Insurance under this section will be required in this bid. Proof of insurance should be supplied With the bid and will be required before purchase order is issued. 1. Workman’s compensation insurance. 2. Public Liability / Property damage insurance. 3. Motor Vehicles, licensed and non-licensed. 1.1 RELATED DOCUMENTS: A. Drawings and general provisions of the contract, including General and Supplementary conditions and Division 1 Specifications, apply to this Section. 1.2 SUMMARY: A. Work under this section includes, but is not limited to the following components: 1. Front curtains, Front Valance, Leg curtains, Mid stage and Rear curtains. 2. Curtain tracks, carriers, hangers, chain, pipe battens and any hardware for a complete installation. 1.3 SUBMITTALS: A. Submit shop drawings for architect’s approval and indicate layout of track system for all curtains. B. Submit schedule table showing all curtains and track sizes. C. Submit track product data on all hardware. 1.4 PROJECT CONDITIONS: A. Field measurements: Verify all stage curtain openings and dimensions by field measurements before fabrication and indicate measurements on shop drawings. Coordinate fabrication schedule with construction progress to avoid delaying the work. B. The stage equipment contractor must notify the contract holder of any site conditions or variations that effect the installation or completion of work and copy the Architect. C. Coordinate location and routing of sprinkler pipes and heads, conduit, HVAC ducting and any other trades installing in the areas of the stage equipment. 1.5 QUALITY ASSURANCE: A. Fabricator/Installer Qualifications: Firm experienced in producing stage curtains similar to those indicated for this project, that has a record of successful installations. B. Flame Resistant Requirements; Provide stage curtains certified flame resistant by requirements of NFPA 701. Permanently attach label to each curtain. C. Provide two copies of flame resistant certificate from the fabric manufacture on the fabric used for this project. 1 1.6 DESCRIPTION OF WORK: A. Provide all labor, Material, equipment and services required for completion of all stage curtains indicated on Drawings and specifications herein. PART 2 PRODUCTS 2.0 MANUFACTURER A. Equal to curtains as manufactured by Kendall Stage Curtains. 2.01 CURTAIN FABRICS: A. General: Provide fabrics inherently and permanently flame resistant or chemically flame resistant by immersion treatment to comply with requirements indicated. Provide fabric from the same dye lot. B. Colors, Textures, and patterns: As selected by Architect/Customer with curtain contractor. A full range of fabric colors and fabrics to be shown to Architect/Customer, prior to manufacture of curtains. 2.02 FRONT SETTING CURTAIN FABRIC: A. Materials: 1. Woven Cotton Velour: Napped fabric of 25 ounce, 100 percent cotton: 54-inch minimum width . 2. All curtains furnished with sewn 50 % fullness and box-pleated on 12-inch centers. 3. All top hems must have heavy-duty 3” poly pro webbing, black grommets to be installed in each pleat. 4. Floor length curtains shall have hems not less than 6 inches deep with a suspended inner canvas pocket containing #8 zinc plated chain weights. 5. For curtains that do not hang to the floor, provide hems not less than 3 inches. 6. 12 inch turn-back on leading edge and 6 inch on side hem. B. Fabric Manufacturers: 1. KM Fabrics 2. JB Martin Fabrics 2.03 FRONT – SETTING CURTAIN TRACKS: A. Track 1. Straight curtain tracks: Fabricate of not less than 14- gauge BLACK galvanized rollformed steel, with each half of track in one continuous piece. Equip track with adjustable, heavy duty guarded pulley as required at track ends. 2. Carriers: Provide BLACK steel ball bearing 1 ¾” solid polyethylene two wheel curtain carriers for track spaced at 12 inch on center. 3. Floor pulley: Provide a BLACK adjustable floor pulley 4. Cord: #12 BLACK stretch-resistant braided polypropylene cord. 5. Bumpers: as required between each carrier. 6. End stops, hang clamps, rope guides, trim chain etc. as required to fully operate system. B. Track Manufacturers: 1. Automatic Devices Company (ADC) 2 2.04 RIGGING: A. Installation 1. Curtain battens: Fabricate battens from BLACK galvanized 1 ¼” steel pipe with a minimum number of joints. Connect pipe with drive –fit sleeve and pin. 2. Track installation: BLACK #2/0 double loop chain secured directly to structures. Crimp all “S” hook ends. Attach other end of chain to track with a turnbuckle. Mouse all turnbuckles to prevent loosening. 3. ALL hardware not factory painted, must be painted with EPOXY BLACK PAINT. 2.05 REAR-SETTING CURTAIN FABRIC: A. Materials 1. Woven ATLAS REPP Cotton : Napped fabric , 100 percent cotton: 54-inch minimum width . 2. All curtains furnished with sewn 50 % fullness and box-pleated on 12-inch centers. 3. All top hems must have heavy-duty 3” poly pro webbing, black grommets to be installed in each pleat. 4. Floor length curtains shall have hems not less than 6 inches deep with a suspended inner canvas pocket containing #8 zinc plated chain weights. 5. For curtains that do not hang to the floor, provide hems not less than 3 inches. 6. 6 inch turn-back on leading edge and 6 inch on side hem. B. Fabric Manufacturer: 1. Fred Krieger & Company 2.06 REAR – SETTING CURTAIN TRACKS: A. Track 1. Straight curtain tracks: Fabricate of not less than 14- gauge BLACK galvanized rollformed steel, with each half of track in one continuous piece. Equip track with hardware, as required at track ends. 2. Carriers: Provide block constructed plate steel polyethylene two wheel curtain carriers for track spaced at 12 inch on center. 3. End stops, hang clamps, trim chain etc. as required to fully operate the system. 4. Fabricate sides and rear curtain tracks for walk-draw operation. A. Track Manufacturers: 1. Automatic Devices Company (ADC) 2.07 RIGGING: A. Rigging 1. Curtain battens: Fabricate battens from BLACK galvanized 1 ¼” steel pipe with a minimum number of joints. Connect pipe with drive-fit sleeve and pin. 2. Track installation: BLACK #2/0 double loop chain secured directly to structures. Crimp all “S” hook ends. Attach other end of chain to track with a turnbuckle. Mouse all turnbuckles to prevent loosening. 3. ALL hardware not factory painted, must be painted with EPOXY BLACK PAINT. END OF SECTION 3