LOCATION PLANNING

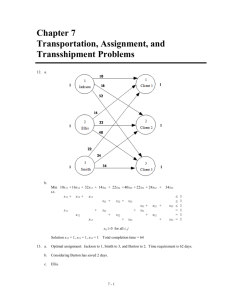

advertisement

LOCATION PLANNING Plant or warehouse location is a long term planning issue that requires a careful analysis of several factors that affect location decisions. These factors are listed below. Regional Factors Raw Materials Markets Labor Taxes Climate (for some industries) Other factors Community Related Factors Service Facilities Community Attitude Community Size Utilities Environmental Regulations Taxes Others Site Related Factors Land Transportation Legal restrictions In choosing a proper location for a plant, first regional factors are analyzed and a suitable region is chosen. Then, a suitable community within the chosen region is selected; the final step is narrowing down on the specific site within that community where the plant will be built. Some of the Techniques Used in Location Planning Factor Rating Locational Break-even Analysis Grid Method Linear Integer Programming Factor Rating We talked about the various factors that affect location decisions. These factors can be weighed and scored to yield results that are helpful in choosing a proper location. Example: Suppose we are evaluating two locations. All the factors and conditions are the same except the factors specified below. Choose the best location if only the following factors are relevant. SCORES (OUT OF 100) FACTOR WEIGHTED SCORES WEIGHT SITE 1 SITE 2 SITE 1 SITE 2 Nearness to raw materials 0.3 100 50 30 15 Labor Cost 0.1 80 90 8 9 Electricity Cost 0.4 70 80 28 32 Land Cost 0.2 40 80 8 16 74 72 1.0 On the basis of factor rating analysis we choose Site 1 because it has the highest weighted score. Locational Break-even Analysis This technique compares the total cost curves of the potential sites and chooses the site with the minimum total cost curve. Suppose the following graph depicts the total cost (TC) curves for two potential sites. Cost Total Cost Curve for Site A Total Cost Curve for Site B 5000 Quantity According to these graphs, the two alternatives break even when the production quantity is 5,000. If the plant's production capacity is going to be less than 5,000 we choose Site A as the TC curve for Site A is under that of site B for quantities below 5,000. If the plant capacity is going to be more than 5,000 we choose Site B. Grid Method A central location is determined by superimposing a grid on the relevant geographical region on the map, measuring the distances of the demand centers, multiplying these distances by the corresponding weights (proportions or percentages) of demands, and then summing the weighted distances. Example: Market Demand Proportional Demand (p) Horizontal Distance (x) Vertical Distance (y) Weighted Horizontal Distance (px) Weighted Vertical Distance (py) A 80 80/200=0.40 8 9 8(0.40)=3.2 9(0.40)=3.6 B 40 40/200=0.20 6 6 6(0.20)=1.2 6(0.20)=1.2 C 20 20/200=0.10 5 9 5(0.10)=0.5 9(0.10)=0.9 D 20 20/200=0.10 3 8 3(0.10)=0.3 8(0.10)=0.8 E 10 10/200=0.05 4 5 4(0.05)=0.2 5(0.05)=0.25 F 30 30/200=0.15 8 6 8(0.15)=1.2 6(0.15)=0.9 200 1.0 6.6 7.65 Proportional demands are computed by dividing the demand of each market by the total demand. For example, the proportional demand for Market A is given by 80 / 200 = 0.4. The sum of the weighted horizontal distances add up to 6.6 and the sum of the vertical distances add up to 7.65 = 7.7 approximately; hence, the center of demand has the coordinates of (6.6 , 7.7). This is the point where the plant or warehouse should be located to be able to serve the markets in question centrally. The coordinates of center of demand can be marked on the actual map to indicate the actual location to be chosen. Linear Integer Programming This technique uses a linear integer programming model that deals with the decisions that must be made about the trade-offs between transportation costs and costs for locating or operating facilities. The decisions concern the selection of facilities to locate or operate and the quantity to ship from each location to any demand center. The following example in table form below shows a situation where there are three warehouses with supplies of 3,000, 4,000, and 3,000 and three markets with demands of 1,000, 2,000, and 3,000. The numbers in the small inner squares show the unit transportation costs. For example, the cost of shipping one unit from W1 (Warehouse 1) to M1 (Market 1) is $5. The basic question is: "Which warehouses should be operated and how much should be shipped from each warehouse to each market in order to minimize the total transportation and warehouse operation costs?" M1 M2 5 M3 6 Supply 7 W1 3000 1 2 2 W2 4000 8 9 9 W3 Demand 3000 1000 2000 3000 Preparing a new table by placing the variables in the empty cells of the previous table will facilitate the linear programming formulation; the new table follows. M1 M2 5 W1 x11 6 x12 1 W2 x21 Demand 1000 2 2000 4000 x23 9 x32 3000 x13 x22 x31 Supply 7 2 8 W3 M3 9 x33 3000 3000 The x variables are the transportation variables. For example, x12 = number of units to be shipped from Warehouse 1 to Market 2. If we add the x variables row wise we get the supply constraints and if we add them column wise we get the demand constraints for the linear program of the transportation problem as follows. Linear Program For The Transportation Problem Min 5x11 +6x12 +7x13 +x21 +2x22 +2x23 +8x31 +9x32 +9x33 st x11 +x12 +x13 3000 x21 +x22 +x23 4000 x31 +x32 +x33 3000 SUPPLY CONSTRAINTS x11 +x21 +x31 = 1000 x12 +x22 +x32 = 2000 x13 +x23 +x33 = 3000 DEMAND CONSTRAINTS All variables 0 NON-NEGATIVITY CONSTRAINTS Solution to this transportation problem provides the answers to how much we should ship from each warehouse to each market but does not answer which warehouses should be operated. This linear programming model can be extended to provide the optimal answers to both which warehouses should be operated and how much to ship from each warehouse to each market by incorporating the binary location variables (yi) as shown below. If we are talking about nonexisting warehouses then the question "Which warehouse(s) should be operated?" would be "At which site(s) should we locate or build the warehouse(s)?" Suppose that the fixed warehouse operating costs are as follows: Warehouse Location Fixed Warehouse Operating Costs W1 $ 1000 W2 $ 3000 y2 = 1 or 0 W3 $ 500 y3 = 1 or 0 y1 = 1 or 0 We associate "y" variables with each warehouse; y1 corresponds to W1, y2 corresponds to W2 and y3 corresponds to W3. The y variables are binary, i.e., either 1 or 0 type of variables. If y = 1, it means "locate or operate the warehouse" and if it is 0 it means "don't locate or operate the warehouse". Now, the linear program for the transportation problem can be extended to include location problem as well as illustrated below: Linear Integer Program For The Location Problem Min 5x11 + 6x12 + 7x13 + x21 + 2x22 + 2x23 + 8x31 + 9x32 + 9x33 + 1000y1 + 3,000y2 + 500y3 st x11 + x12 + x13 3,000y1 x11 + x12 + x13 - 3,000y1 0 x21 + x22 + x23 4,000y2 x21 + x22 + x23 - 4,000y2 0 x31 + x32 + x33 3,000y3 x31 + x32 + x33 - 3,000y3 0 x11 + x21 + x31 = 1,000 x12 + x22 + x32 = 2,000 x13 + x23 + x33 = 3,000 xij 0 i = 1,2,3 and j = 1,2,3 yi = 1 or 0, i = 1,2,3 The solution to this problem can be obtained by using a very user friendly software like LINDO (Linear Interactive Discrete Optimizer). If LINDO is used, the model for the location problem would be typed virtually exactly as it appears followed by a "GO" command to get the answers; it is as simple as this. The summary of the LINDO solution for this problem is: Min Z = $ 23000 y1 = 1 y2 = 1 y3 = 0 x11 =0 x21 =1000 x31 =0 x12 =2000 x22 =0 x32 =0 x13 =0 x23 =3000 x33 =0 The values of the location variables at optimality indicate that we should operate warehouses at Site 1 and Site 2 and we should not operate a warehouse at Site 3. In case of nonexisting warehouses y1 = 1, y2 = 1, and y3 = 0 values would indicate that we should locate or build a warehouse at Site 1 and Site 2, but we should not locate or build a warehouse at Site 3. On the other hand, as mentioned earlier, the x variables are the transportation variables showing how much to ship from each warehouse to each demand center. For example, x11 = 0 shows that we would not ship anything from Warehouse 1 to Market 1 and x12 = 2,000 shows that we would ship 2,000 units from Warehouse 1 to Market 2, etc. Min Z = 23,000 is the value of the objective function that represents the minimum possible total transportation and warehouse operating costs. SUPPLEMENT This supplement provides a summary of transportation problem in simplified, easy to understand, and easy to use format. Transportation Algorithm (for minimization) 1. Get the initial solution (by Northwest Corner Method, for example) 2. Compute the raw variables, u, and column variables, v, on the basis of the occupied cells (initially set u1 = 0) where ui + vj = cij. 3. Compute the circled values, eij, on the basis of empty cells where eij = cij - ui - vj. 4. Put a (+) sign into the cell with the most negative circled value and find a feasible path by alternating the signs ((+) and (-)) and returning to the point where you started, i.e. you have to complete the loop. You can go in horizontal or vertical directions, but not diagonally. You can skip over and into the occupied cells. On the other hand, you can ship over empty cells, but you can NEVER skip into an empty cell. Make sure that there is an equal number of (+) and (-) signs in each row and each column on the feasible path so that they cancel row wise and column wise. 5. Look at the cells with (-) sign on the feasible path and choose that cell with the minimum quantity. Add this minimum quantity to the cells with (+) signs and subtract it from the cells with (-) sign. 6. Repeat the procedure until all the circled values (eij) are non-negative at which point we reach optimality.