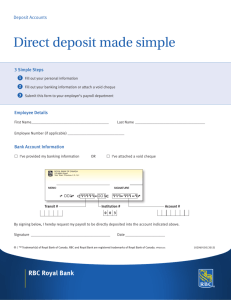

RCER-2010

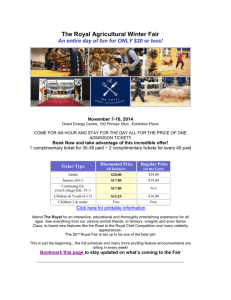

advertisement