Heat Exchanger Procedure

advertisement

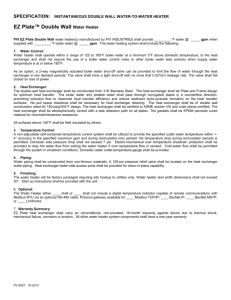

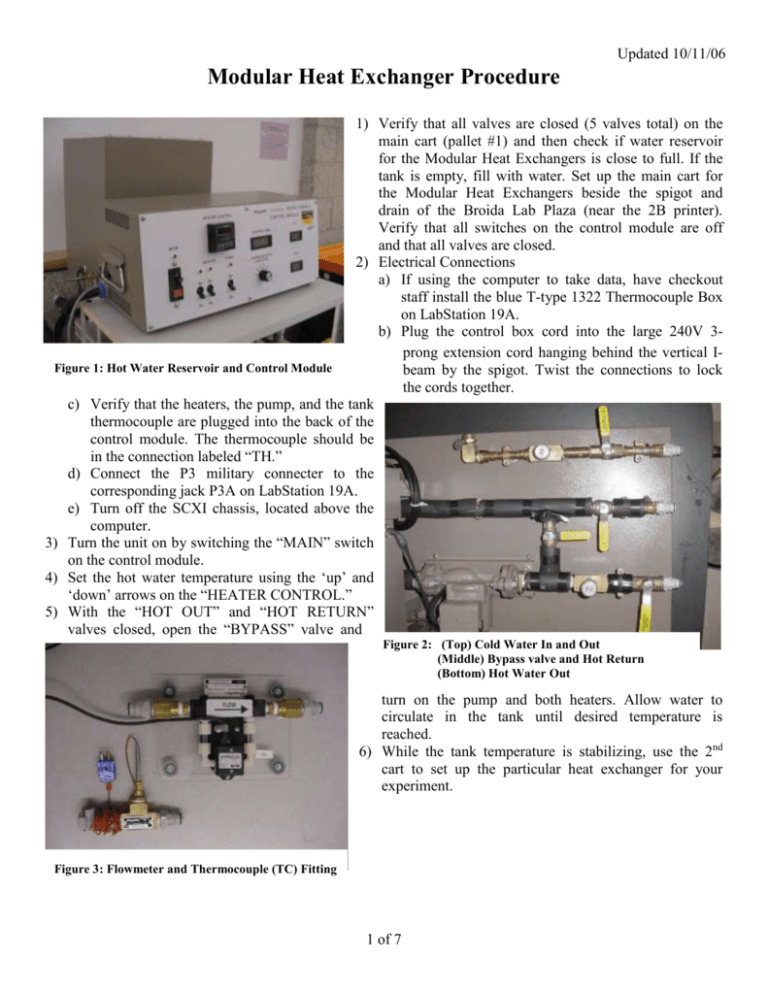

Updated 10/11/06 Modular Heat Exchanger Procedure 1) Verify that all valves are closed (5 valves total) on the main cart (pallet #1) and then check if water reservoir for the Modular Heat Exchangers is close to full. If the tank is empty, fill with water. Set up the main cart for the Modular Heat Exchangers beside the spigot and drain of the Broida Lab Plaza (near the 2B printer). Verify that all switches on the control module are off and that all valves are closed. 2) Electrical Connections a) If using the computer to take data, have checkout staff install the blue T-type 1322 Thermocouple Box on LabStation 19A. b) Plug the control box cord into the large 240V 3prong extension cord hanging behind the vertical IFigure 1: Hot Water Reservoir and Control Module beam by the spigot. Twist the connections to lock the cords together. c) Verify that the heaters, the pump, and the tank thermocouple are plugged into the back of the control module. The thermocouple should be in the connection labeled “TH.” d) Connect the P3 military connecter to the corresponding jack P3A on LabStation 19A. e) Turn off the SCXI chassis, located above the computer. 3) Turn the unit on by switching the “MAIN” switch on the control module. 4) Set the hot water temperature using the ‘up’ and ‘down’ arrows on the “HEATER CONTROL.” 5) With the “HOT OUT” and “HOT RETURN” valves closed, open the “BYPASS” valve and Figure 2: (Top) Cold Water In and Out (Middle) Bypass valve and Hot Return (Bottom) Hot Water Out turn on the pump and both heaters. Allow water to circulate in the tank until desired temperature is reached. 6) While the tank temperature is stabilizing, use the 2nd cart to set up the particular heat exchanger for your experiment. Figure 3: Flowmeter and Thermocouple (TC) Fitting 1 of 7 Updated 10/11/06 Figure 4: Heat Exchanger Connections General Comments on making fluid connections: Temperature readings should be made as close to the heat exchanger as possible. Therefore, always connect the thermocouple (TC) fittings directly to the heat exchanger entrance or exit and do not have any tubing between the exchanger and TC fitting. The flowmeters have a large arrow indicating the direction of flow. To avoid damage to the flowmeter, make sure the flow through the meter is in the proper direction. The flowmeters have a temperature limit of 122F (50C). In order to minimize exposure to higher temperatures, the flowmeter should be placed downstream of the heat exchanger on the hot stream and upstream of the exchanger on the cold stream. The flowmeters work better when oriented vertically. That is, the two plumbing connections are higher than the flowmeter itself. You can use the two white brackets located in the yellow tub to support the flow meters. Connection diagrams for individual heat exchangers are located at the end of this document, including simple procedure for switching heat exchangers. a) Cold water connections (DON’T turn the cold water on yet): i) Connect the hose from the spigot to the “COLD IN” port on the main cart. ii) Connect the “COLD OUT” port to the inlet of the COLD flowmeter. iii) Connect the exit of the flowmeter to a TC fitting and then directly to the cold water inlet on the heat exchanger. iv) Connect the cold water exit of the heat exchanger directly to a second TC fitting. v) Connect the exit of that TC fitting to another tube and return to floor drain. Lengthen with other pieces of tubing if needed. 2 of 7 Updated 10/11/06 b) Hot water connections: i) Connect the “HOT OUT” port to a TC fitting and connect the TC fitting directly to the hot water inlet on the heat exchanger. ii) Connect a second TC fitting to the hot water exit of the heat exchanger and then to the inlet of the “HOT” flowmeter. iii) Connect the exit of the flowmeter to the “HOT RETURN” port. c) Flowmeter and thermocouple connections: i) Plug the flowmeter cables into FT1 and FT2 on the back of the control box. ii) If using the computer to take data, connect the thermocouple leads into consecutive channels starting with 0 on the blue T-type thermocouple block attached to the LabStation. iii) If making manual measurements, plug the thermocouple connectors into the back of the control box. iv) Make sure to record which channel corresponds to which thermocouple / flowmeter in your notes. v) Refer to the schematic above to ensure setup is correct. 7) Preparing the LabVIEW program: a) Turn SCXI chassis located above computer on. b) The LabVIEW program can be found in “H:\ITLL Documentation\ITLL Modules\Modular Heat Exchangers\Modular Heat Exchanger.vi”. c) Enter the channels of the thermocouples you are using in the box labeled Channel(s). For example, 0:5 for channels 0 through 5. d) For Filters, select Use “MAX Setting”, which essentially means no hardware filtering. e) Before starting the program, you must select both your sample interval and the units of temperature to be displayed (located above the charts). If you need to change either of these options or the thermocouple channels after the program has been started, you will need to stop the program, change the values, and restart the program. 8) Begin your experiment: a) Start the .vi by pressing the Arrow button in the top left hand corner of the LabVIEW window. b) Close the regulators located near the “HOT OUT” and “COLD OUT” to start with a low flow rate that will not max out the flowmeters. Turn until only the green and gold bands are visible. Note: This is especially important for the COLD water regulator since the spigot can easily exceed 10 L/min. The HOT water will max out at 4.5 L/min because of pump limitations. c) Start the water flowing. Turn on the cold water just a little bit (NO MORE than a ¼ turn – this maxes the flowmeter at 10 L/min). Close the “BYPASS” valve. Use the regulators to start with a low flow rate and verify there are no leaks or loose connections in the system before increasing the flow rate. Open the “COLD OUT” valve, the “HOT OUT” valve, and the “HOT RETURN” valves on the main cart. Do not exceed the maximum flowmeter rating of 10 L/min. d) Check that the two flowmeters and all temperature measurements are visible. i) If a flowmeter reading is absent, check that all connections are secure and water is flowing through the meter. ii) If a temperature reading is absent (1) Try auto scaling the Y-axis by Right Clicking on the chart, Select Y Scale, then auto scale Y. If the signals are now displaying, you can turn auto scaling back off and enter in your desired scale axis by clicking on the max or min number and typing in the new value. (2) Otherwise, check that the proper channel numbers have been entered into the program and that the thermocouples are plugged into the proper connectors on the cable. 9) After a while, it is possible the tank heaters will not be able to keep up with the cooling capability of the exchanger. If this happens, circulate the water in the tank until temperature stabilizes (see Step 5). 3 of 7 Updated 10/11/06 10) Adjust your flow rates and temperatures to collect the desired data. 11) Cleanup Procedure: a) Disconnect all wires and tubing (except heaters, pump, tank TC). Wrap thermocouple and flowmeter cables neatly around the object to prevent them from tangling. Turn off heaters, pump, and main switch. b) Drain each piece of tubing, the flowmeters, and the TC fittings by connecting blank inserts to each end. Do this over the floor drain or sink. c) Drain each side of the exchanger by connecting blank inserts to each end and emptying into floor drain. d) Clean up any water on the floor or on the module cart. e) Thanks! Flow Diagrams for Individual Heat Exchangers Connecting/Changing Heat Exchangers Using the setup described above (Step 6), hook up the heat exchanger you will be testing as it is shown in the following diagrams. The greatest amount of heat transfer will be yielded with the counter-current arrangements. However, parallel flow arrangements have also been included for some modules. Thermocouples should be attached directly to the heat exchangers for the best readings. To switch configurations, or switch to a different heat exchanger: First, close the “COLD OUT”, “HOT OUT” and “HOT RETURN” valves. Open the “BYPASS” valve to allow water to circulate while the pump is on. Switch inputs and outputs by detaching the thermocouple fitting from the heat exchanger and reattaching at the new input/output. If the connectors are properly attached and the valves are off, the thermocouple fittings shouldn’t leak. If done correctly, thermocouples will still be reading the same inputs and outputs (i.e. the thermocouple that was reading the temperature of “hot water in” should still be reading “hot water in”). Double check that flow direction is still in the right direction for flowmeters and that the HOT flowmeter is still on the HOT OUT end of the exchanger and that the COLD flowmeter is on the COLD IN side of the heat exchanger. Close the “BYPASS” valve, and reopen the other valves. 4 of 7 Updated 10/11/06 Shell and Tube Heat Exchanger 5 of 7 Updated 10/11/06 Concentric Tube Heat Exchanger 6 of 7 Updated 10/11/06 Plate Heat Exchanger 7 of 7