11 GENERAL ORDERS OF A SENTRY

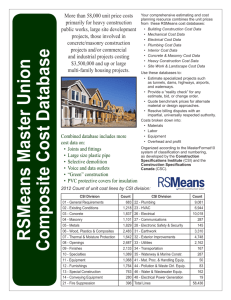

advertisement

11 GENERAL ORDERS OF A SENTRY 1. To take charge of my post, and all government property within view. 2. To walk my post in a military manner, keeping always on the alert, and observing everything within sight or hearing. 3. To report all violators of the orders that I am instructed to enforce. 4. To repeat calls from posts more distant from the guard house than my own. 5. To quit my post only when properly relieved. 5 ELEMENTS OF A DEFENSE K-key terrain features O-observation and fields of fire C-cover and concealment O-obstacles A-avenues of approach 6. (3 ESCHELONS OF DEFENSE) Security area Forward Defensive Area Reserve Area To receive, obey, and pass on to the sentry who relieves me all orders from my commanding officer, command duty officer, officer of the deck, and officers and petty officers of the watch. 7. To talk to no one except in the line of duty 8. To give the alarm in case of fire or disorder. 9. To call the officer of the deck in any case not covered by instruction. 10. To salute all officers, and all colors and standards not cased. 11. To be especially watchful at night, and during time for challenging, to challenge all persons on or near my post and to allow no one to pass without proper authority. 5 PARTS TO FIRING COMMAND A-Alert D-Direction D-Distance R-Range A-Assignment C-Command 12 STEPS TO PLANNING A PATROL S-study the mission P-plan the use of time S-study the terrain O-organize the patrol S-select men, weapons, and equipment I-issue the warning order C-coordinate M-make reconnaissance C-complete the detailed plan I-issue the Patrol Order S-supervise, inspect, rehearse, reinspect E-execute the order (4 PRIORITIES OF DEFENSE) S-surprise S-security U-unity of command M-mass 5 S’s for EPW’s Search Segregate Silence Speed Safeguard 3 Combat Positions Primary Alternate Supplementary 5 PARAGRAPH ORDER S-situation M-mission E-execution A-administration and logistics C-command and signal MAP COLORS Black – cultural / man-made features Blue – water Green – vegetation Brown – terrain features Red – main roads, special features FIGHTING – LOAD CARRYING 1. Pistol belt 2. Suspenders 3. Field pack 4. Two ammo pouches 5. Canteen cover 6. First aid cover 7. Entrenching tool and cover 8. Bayonet or K-bar scabbord BIVOUAC EQUIPMENT 1. Canteen and cup 2. First aid pack 3. Entrenching tool and cover 4. Bayonet or K-bar 5. Mess-kit 6. Poncho 7. Shelter half (1 pose, 5 pins, 1 guy line) PROTECTIVE EQUIPMENT 1. Hat and mosquito net 2. Helmet and liner 3. Camouflage cover 4. CBR Gear SPECIAL ISSUE ITEMS 1. Armor vest 2. Mountain sleeping bag 3. Sleeping mat 4. Canvas cot and Insect bar frame 5. Insect bar 6. Camouflage band RATES OF FIRE (2 minutes) 1. Rapid rate – 150 rounds/minute 2. Medium rate – 75 rounds/minute 3. Average rate – 10-20 aimed shots / minute 4. Automatic rifleman RAPID – 100 rounds/min 5. Automatic rifleman SUSTAINED – 85 rounds/min POW INFORMATION 1. Name 2. Rank 3. Social Security Number 4. Date of birth CODE OF CONDUCT ARTICLE V “When questioned, should I become a prisoner of war, I'm required to give name, rank, service number and date of birth. I will evade answering further questions to the utmost of my ability, I will make no oral or written statement disloyal to my country and its allies or harmful to their cause.” TACTICAL MESSAGES S-size A-activity L-location U-uniform T-time E-equipment MESSAGE PRIORITIES Flash (Z) – ASAP Immediate (O) – 30 min-1 hour Priority (P) – 1-3 hours Routine (R) – 3-6 hours BEADWINDOW EEFI VIOLATIONS (“Roger out”) Essential Elements of Friendly Information 01 – Position 02 – Capabilities 03 – Operations 04 – Electronic Warfare 05 – Personnel 06 – COMSEC 07 – Wrong Circuit “GINGERBREAD” (switch frequencies) COMM RELIABILITY PRECEDENCE 1. Messenger 2. Wire 3. Radio COMBAT SIGNALS 1. Whistle signals a. 1 short blast = attention to orders b. 1 long blast = cease fire c. 3 long blasts = hostile aircraft / vehicles 2. Special signals 3. Arm / Hand signals CBR SIGNS Red-yellow letters + stripe = gas mines Yellow-red letters = gas Blue-red letters = bio White-black letters = atom MOPP LEVELS 1. TROUSERS / SMOCK 2. BOOTS 3. MASK 4. GLOVES AND HOOD 1. 2. 3. 4. Enemy capable of CBR attack Enemy willing to engage CBR attack Enemy intent (statement) CBR attack imminent CBR ACCESSORIES M-8 paper M-9 paper – liquid nerve agents G,V - blister agents H, L - turns RED Mk 1 NAAK – atropine - 2 pam chloride M258A1 kit – personal decon kit M291 kit – personal decon powder kit MCU-2 Chemical Protective Mask AN/PDR-27 – radiacmeter (gamma, beta) M12 – Vehicle decon kit PERSONNEL / EQUIPMENT DECON 1. Individual 2. Hasty 3. Complete PERSONNEL DECONTAM STATIONS 1. Gross contamination removal 2. Overboots (shuffle pit) 3. Overgarmet removal 4. Overboots and gloves 5. Monitoring 6. Mask removal 7. Mask decontamination 8. Reissue point 13 PERSONNEL REQUIRED… 5 troops to set up and run PDS 5 detailed troops 1 company CBR Officer 1 medic 1 supply person M8A1 CHEMICAL ALARM 1. M43A1 detector 2. M42 alarm M8A1 DISTANCES No more than 150M upwind (farthest pos) No more than 400M from alarm unit 300M in between detectors (Check wire every 6 hours for cuts/breaks) CBR RECON TEAM MISSION 1. CBR agents present 2. Type 3. Location and time of 1st detection 4. Boundaries of contam. Area 5. Clean route through area (use M256 kits) TYPES OF CBR SURVEYS 1. Route 2. Point 3. Area 6 ESSENTIAL CONVOY PERS/POSITIONS 1. Convoy commander 2. Serial “ 3. Advance “ 4. Unit “ 5. Maintenance “ 6. Vehicle “ 3 ECHELONS (repair war damage construct urgent projects) 1. Air Det a. 89 pers. b. Deploy w/in 48 hours c. 30 days self suff. d. 34 pieces CESE e. 250-300 short tons air cargo 2. Air Echelon a. 648 pers. b. Deploy 6-10 days c. 90 days self suff. d. 103 pieces CESE e. 1200-1250 short tons air cargo 3. Sea Echelon a. 25 pers. (incl. 1 officer) b. Brings remaining TOA c. Arrive w/in 30 days d. Enables 90 day self sufficiency. MOCC 1. Controls, coord., monitors movement of all pers, supplies, and equip. to a staging area. 2. XO directs 3. MOCC is COC during embark EMBARK 1. 1 Embark CPX during homeport/deploymnt 2. Static load training 3. Emergency deployment readiness exercise ACL – Allowable cabin load ALCE – Air Lift Control Element (USAF) (limited support functions – camp) MARSHALLING – move to temp camps nearby AACG – Arrival Airfield Control Group DACG – Departure Airfield Control Group 3 CATEGORIES EQUIPMENT/CARGO 1. Vehicles 2. Bulk Cargo 3. Unitized Cargo 463L PALLET 1. 88” x 108” x 2 ¼” aluminum 2. (84” x 104” usable) 3. 290 lbs (straps 65 lbs) 4. 10,000 lbs max (netted load) 5. 7,500 lbs optimum WOOD PALLET 1. 40” x 48” 2. 2000 lbs supplies / 3000 lbs ammo 3. Not to exceed 40” in height 4. Banded 5. Hard to identify TYPES OF AIRCRAFT 1. C-130 Hercules - ACL 25K lbs 2. C-141 Starlifter - ACL 50K lbs 3. C-17 Globemaster III - ACL 90K lbs 4. C-5 Galaxy - ACL 150K lbs AIRCRAFT LOADING LIMITS 1. C-130 Hercules – (6) 463L pallets 2. C-141 Starlifter – (13) 463L 3. C-17 Globemaster – (18) 463L 4. C-5 Galaxy – (36) 463L 4 TYPES OF SHORING 1. Rolling – tracked vehicles, etc. 2. Parking – stays under wheels, tracks, etc 3. Sleeper – under balloon tires / axles 4. Special – 2 types a. Dunnage – all pallets required b. Approach – change angle of ramp. CONVOY PERSONNEL POSITIONS (3 divisions) 1. March columns – 60 vehicles 2. Serial columns – 20 vehicles 3. Unit column – 10 vehicles MAIN FUNCTIONAL PARTS CONVOY 1. Pacesetter 2. Mainbody 3. Trail CONVOY CRITICAL PERSONNEL 1. Convoy commander – LT/LTJG a. Resp. for convoy b. Initiates march orders c. Supervises 2. Serial commander – ENS/MC a. Same as above 3. Advance Officer a. Usually a MC/SC b. Takes point (tactical) c. Records route (non-tactical) d. Notifies of approach of convoy 4. Unit Commander a. PO1 b. Assigned when detached from serial column 5. Maintenance Officer a. E7/E8/PO1 b. Rides in rear c. At halts check vehicles/makes repairs 6. Guides a. Only used in non-tactical convoys 7. Escorts a. Military police (non-tactical) b. Armed guards, aircraft, infantry, whatever it takes (tactical) 8. Vehicle Commander a. Petty officer b. One assigned per vehicle/troops. ROUTE COLORS 1. Green – safe 2. Yellow – Limited hostile activity 3. Red – Hostile activity imminent ENROUTE PROCEDURES 1. 30 MPH on open road 2. Determined by slowest vehicle 3. 100 yard intervals 4. 50 yard intervals (villiages) 5. keep same convoy order 6. 100ft intervals when halted 7. Defensive positions when halted 8. Leave vehicles running until ordered to shut down by CONVOY COMMANDER 9. Remain on road 10. Inspect vehicles at stops AMMUNITION COLORS M-16A3 Unpainted – M16A1 ball Unpainted w/ green tip – M16A2 ball Aluminum – Armor piercing incendiary Black – Armor piercing Blue – Incendiary Red/Yellow/Brown – Tracer Blue w/ red tip – Incendiary tracer AMMO COLORS 40MM GRENADE Yellow body gold ogive – HE Blue body, silver ogive – practice Grey w/ red band – Riot control agent Grey w/ green band – toxic agent Grey w/ broken grn band – nerve agent Grey w/ violet band – Incapacitating agent Light green – Screening / marking smoke Unpainted w/ holes in case – dummy AMMO COLORS MORTARS Body / Nose – Type White / Grey – Illuminating Bronze / Bronze – Dummy Blue w/Lght grn stripe/ Grey – pract, spotting Blue / Blue – Practice OD Grn w/yellow stripe / Grey – H.E. OD Grn w/white diamond stripe / none flechette Light green / grey – smoke OD Grn-grey stripe / gray – chaff, leaflet HOT GUN M60E3 – 200 rounds in 2 minutes M2HB – 150 rounds in 2 minutes 3 TYPES EMPLACEMENTS 1. Dug in 2. Prefabricated fighting hole 3. Fighting bunker 5 TYPES OF DUG IN EMPLACEMENTS 1. Skirmishers trench 2. Camouflaged fighting hole 3. Cut timber revetment 4. 1 and 2 man fighting hole 5. Prone emplacement M60E3 GUN TEAM Team leader- M16/100 rounds/tripod/spots,reloads Gunner-shooter/9mm/100rounds Ammo Carrier- M16/200 rounds M2HB SERVICING 1. Headspace a. Headspace gauge (Go, No Go) b. Unscrew / screw in barrel to fit c. When gun is assembled, serviced 2. Timing a. “No Fire” gauge inserted b. Screw timing nut c. Prevents barrel contact with trunion block upon recoil while firing M224 MORTAR FIRING 1. Conventional a. M7 baseplate b. M64 sight unit c. M170 bipod 2. Hand held a. M8 baseplate alone b. Offensive use only M224 MORTAR TEAM 1. Team leader – fires w/ sight , responsible 2. A-gunner – loads mortar 3. Ammo bearer – carry ammo – charge rounds 4. Ammo bearer – carry ammo – charge rounds 5 AMMO TYPES M224 MORTAR 1. High-explosive 2. White phosphorus 3. Illuminating 4. Training/practice (spotting charge) 5. Training (inert) 20’ flatrack – 20’ x 8’ x 8’ open top/sides 20’ half height – 20’ x 8’ x 4’-4” one end opens, open top SIXCON – 6.5’ x 8’ x 4’h Pumping units (not cargo) TEU – Twenty foot equivalent unit 20’ x 8’ x 8’ 5 TYPES OF GRENADES 1. M 67 / M 26 Fragmentation 2. MK1 Illuminating (25 seconds) 3. Chemical a. ABC-M25A2 riot control b. M34 or M15 white phosphorus c. M18 colored smoke 1. red 2. green 3. yellow 4. blue 5. white 4. AN-M14 TH Incendiary 5. Practice / Training 4 STEPS IN MOVING TO NEW AREA 1. S-security 2. A-automatic weapons 3. F-fields of fire 4. E-entrenchment PRIORITIES OF DEFENSE S-security A-automatic weapons F-fields of fire E-entrenchment F-fire support I-install wire L-lay and bury comm cable M-make other obstacles A-alternate positions S-supplementary positions FREQUENCY RANGES HF – 3-30 mHz VHF – 30-300 mHz UHF – 300-3000 mHz SHF – 3000-30,000 mHz SHIPPING CONTAINERS Mount out box – 48” x 20” 6 per pallet Tricon – 6.5’ x 8’ x 8’ BULK ISO CONTAINER Configured Tricon – w/cabinetry Bulk standard 20 20’ x 8’ x 8’ TYPES OF TIE DOWNS MB-1 = 10K MB-2 = 25K CGU-1 = 5K 4 STEPS TO EMBARK 1. Marshaling – Assemble chalks & deliver to Alert Holding Area 2. DACG – alert holding area receives loadspreinspection 3. DACG & ALCE – joint inspection / discrepancy corrections / call forward 4. ALCE – ready line / loading ramp: Briefings and inspections, loading and restraining MANUALS GOVERNING HAZ CARGO 1. AR 55-355 – explosives (Army) 2. NAVSUP PUB 505 – airlift requirements 3. DD-1387-2 – Special handling cert. Form 4. NCB INST 3120 – Brigade Embark List 5. 49 CFR – DOT regulates in CONUS 4 STAGES OF EMBARK 1. Marshalling – initial prep assembly 2. Alert Holding – final assembly into change 3. Call Forward – joint inspection / minor fixes / reinspect 4. Ready line – loading MINOR PROPERTY $300-5000 $5000 or greater if life expect less than 2 years PLANT PROPERTY – 2 TYPES (all Navy owned property >$5000.) Class 3 - $5000 or more, more than 2 years Class 4 – Industrial plant equipment COSAL IDENTIFIERS UL# NAVSUP Modifier NAVSUP MODIFIERS MOD 98 – parts peculiar – spec. make/model MOD 97 – Parts common – general RRR items MOD 96 – small version of MOD 97 – air det 3 PARTS TO COSAL 1. Equipment Indices 2. Allowance Parts List (APL) 3. Stock # Sequence Listing (SNSL) SUPPLY DOCUMENTS DD1348 – Tracer action on shipments - Requisition follow up / CANX - Milstrip requisitioning form DD1149 – Requisition invoice/ shipping doc. - Container surface shipment / unaccompanied baggage - Requisition of services - Matl procurement not MILSTRIP MLN – Management List – Navy - History of NSN #’s - History of NIIN – Natl Item ID No. ASG – Afloat Shopping Guide - Lists NSN frequently requested items NSN – National Stock Number COG – Cognizance Symbols – 2 character alfanumeric code; prefixed to NSN to ID cognizant inventory manager APL – all repair parts for TOA maint. AEL – all equip. not covered by supply (Dept’s) NC – Not carried (no records kept of item) NIS – Not in stock (not on shelf at time) SIM – Selected Item Management – attention on small % of items w/majority of requests ROD SF 364 – Item came in damaged, Expired shelf life, Cost of correction is > $50 Line item worth > $100 QDR SF 368 – Item damaged, which is dangerous to life, equip, unsafe MLSR – missing lost stolen report TYPES OF CESE 1. Automotive equip 2. Mechanical construction equip 3. WHE 4. Railroad equip 5. PW, Public Utility, Waterfront equip + matl 6. Decon Equip 6. Industrial Equip CESE MANUALS NAVFAC P-300 -Management of Transportation Equip (admin, ops, maint, + trans equip.) NAVFAC P-404 -Equipment Management Manual -(criteria, policies, procedures) COMSECOND/THIRDCBINST 11200.1 -Red Book -Policies + Procedures for CESE CASEMIS -Const. Automotive Special Equip. Management Info. System -Computer prog. For management of CESE- maintained by CESE - List of equip @ ea. Deploy. Site NAVFAC P-306 -Testing and Licensing of all equip. NAVFAC P-307 -Manag. Of WHE Maint + Certification 49CFR 173.2 – regulates hazmat handling 40CFR 261 – regulates hazwaste CESE FORMS OF-346 – govt drivers license SF91 – Accident Report Form (Crash package) DD1970 – Trip ticket NAVFAC 11240/13 – Hard Card DD 518 – Accident ID Card (Hit & Run Card) NAVFAC 11240/10 – License app. Auto+MHE NAVFAC 11260/1 – License app. Constr. Equip. NAVFAC 11260/2 – License – const + WHE OSHA FORM 174 – MSDS A Co. CHAIN OF COMMAND A6 – Sr. LT , traffic court, crane cert. officer A5 – Sr. Enlisted, oversees Maint. + Operations A4 – Sr. CM, runs PM’s, oversees all deadlined A3 – All operators insp, projects, crane tst dir. RSS EQUIPMENT SPECIALIST – -Readiness Support Site Equip. Spec. -Performs manag. Control while A6 is absent - Advises A6 on readiness support allowance Equipment matters PM & COST CONTROL CLERK - Controls PM Program for A4 - Maintains PM boards, ERO’s DIRECT TURNOVER CLERK (DTO) - Liaison between Supply and Shop - Maintains RPR parts & acct. records 3 CESE MAINTENANCE CATEGORIES 1. Organizational- operator responsibility 2. Intermediate – maint. Shop responsibilty 3. Depot – “like new” resoration 3 TYPES OF INSPECTIONS A – every 40 days B – per manuf. Recommendation C – annual safety inspection LIVE STORAGE - no operational need for 80 days - typically TOA PHIBCB’S 450 personnel engineering support to Naval Beach Group maintain CESE assigned to group BEEP CONDITIONS A3 – great shape A4 – good A5 – worse A6 – junk it PHIBCB MISSION: - mil. & amphibious const. Support - move troops/equip. from ship to shore - tanker to shore bulk fuel deliv. Systems - develop and improve beach facilities OPPLAN Plan for future missioin (SMEAC) PHIBCB CHAIN OF COMMAND CINCPACFLT SURFPAC COMPHIBGRU3 NAVAL BEACH GRU 1 ACU / PHIBCB1 / BMU OPORDER Puts OPPLAN into effect (oral or written) WARNING ORDER Gives heads up (90 days out) EXECUTION ORDER (75 days out) -authority to initiate admin & supply procedures CINCLANTFLT SURFLANT COMPHIBGRU1 NAVAL BEACH GRU 2 ACU / PHIBCB2 / BMU ROC 1. CCC – command control communications 2. CON – construction 3. NSW – naval special warfare 4. MOB – mobility CBU Flt. Hospital support / augment NMCB Secondary 1. NCO – non-combat ops (disaster recovery) 2. FSO – fleet support ops UCT Survey sea bottom to select sites Construct, maintain, repair underwater facilities MAGTF 4 ELEMENTS 1. Ground Combat Element 2. Air Combat Element 3. Combat Service Support Element 4. Command Element NCFSU Support 4 NMCB’s Long haul trans. Equip. Plant ops & maint. Rock crusher, asphalt plants, concrete, Specialized repair or overhaul Inventory management of construction materials MAGTF 3 TYPES 1. MEU – O-6, 1000-5000, air det (or heavy) 2. MEF (Forward) – O7, 15K-60K, 1-2 NMCB 3. MEF – O8/09, 40K-100K, NCR supported CHAIN OF COMMAND SECDEF (COHEN) SECNAV (DALTON) CNO (JOHNSON) CINCPACFLT/CINCLANTFLT (CLEMENS) 3RDNCB (JOHNSON? ) 31ST NCR (30TH NCR TACT.) (HAMBROCK) CO (CDR COWELL) XO (LCDR KELLEY) S3 (LCDR HELINSKI) ME CBMU Maintain and operate advance bases NAVY ENLISTED PERF. EVAL MANUAL BUPERSINST 1616.9 EVAL FORM BUPERSINST 1610 CNO DUTIES WRT NCF UNITS Commissions NCF units Assigns units to fleet Approves Deployments, CESE, Det sites, TOA Defines general mission CINCLANTFLT / CINCPACFLT -Ensure NMCB deployments & projects follow CNO policies -OPCON of NCF units NCF CHIEF (KING BEE) RADM Nash Technical advisor to CNO Head of NAVFAC ENLISTED SERVICE RECORDS (LEFT) Awards Birth Certificate Contract Evals Fingerprints Security Clearance Travel ENLISTED SERVICE RECORDS (RIGHT) SGLI pg.1 Dependents pg.2 ASVAB pg.3 Quals pg.4 History assgmnts pg.5 UA’s pg.6 NJP Evals Admin remarks MPF–MARITIME PREPOS. FORCE Transports containerized cargo, vehicles, bulk fuel/water transfer systems, const. Material -Versitile barge ferry system from naval and contract merchant ships. Ferry carried by sideload or well deck method. RRR – CRATER REPAIR METHODS 1. FRP mats (fiberglass reinforced polyester) 2. High early strength concrete (cretemobile) 3. Compact crushed stone (quick, easy) 4. Precast concrete slabs (labor, equip intensv) 5. AM-2 matting ELCAS 140 steel piers driven jack causeway sections 3000’ pier complete within 7 days SLWT – SIDE LOADING WARPING TUG -Causeway size w/ 2 450hp diesel waterjets CSP Causeway section – powered -SLWT without winch and frame OFFLOAD TIME OF MPS SHIPS 5 days (using SLWT and CSP) METHODS TO CARRYING PONTOONS Side carry method: LST (4) Takes no deck space - difficult Well deck method: LSD, Amphib assault ship, or amphib transport dock Fast, takes up valuble space, easier in rough sea LASH: Lighter Aboard Ship (30) Commercial ship, complements LST Can self load and launch 30 sections On board cranes, quick loading BARGE FERRY CSP + 2 non-powered sections AABFS Amphibious Assault Bulk Fuel System 5000’ of 6” bouyant fuel hose Deployed from LCU (Landing Craft Utility) 6000lb Stato anchor at seaward end Landing forces or shore installations are responsible for ashore continuation of hose 700 gallons of diesel fuel / minute TOTAL FLOAT = late start-early start = late finish – early finish OPDS Offshore Petroleum Discharge System / Facility -UCT divers install SALM on seafloor (Single anchor leg mooring) -1.2 million gallons of fuel/day EARLY FINISH + LAG = EARLY START (between activity) RRDF (RO-RO DISCHARGE FACILITY) -Six causeway sections -floating parking lot – use ships ramp WIP CALCULATION Total MD Remaining Total MD Estimate x 100 FREE FLOAT = early start – lag - early finish (next) FORWARD PASS CALCULATIONS EARLY START + DURATION = EARLY FIN (within activity) Early finish = late finish for last activity Late finish – duration = late start (within activity) Late start – lag = late finish (btwn activities) MD EQUIVALENCY CALCS DURATION = MD DlxAFxME DL = DIRECT LABOR CREW SIZE AF = AVAIL. FACTOR ME = MANDAY EQUIVALENT (1.125) MD = QTY. OF WORK x MHRS per unit x DF Unit size 8 mhr/mo MC = DL x WD x MDE x AF MC=manday capability DL=direct labor WD=avail. Workdays AF=avail. Factor DELAY FACTOR / PROD. EFF. FACTOR DF = 67/PEF PEF = average based on conditions at hand/crew