Biosan Directory - Lynwood Associates

advertisement

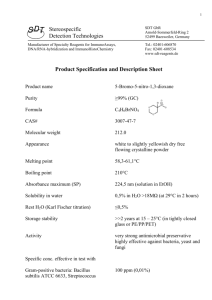

Technical Directory Introduction. Bactron is the unique antimicrobial agent used in the Biosan range of water based hygiene coatings. The purpose of this document is to explain, substantiate and where appropriate quantify the properties of Bactron; primarily but not exclusively in the context of Biosan. An overview of Bactron. Bactron is a microbiologically active liquid concentrate based on a unique (patent pending) formula that imparts exceptional bactericidal properties when incorporated into a finished product. Although initially developed for use in paint, Bactron can be added to a wide range of polymer and mineral based products including mastics, sealants, grouts, plastics and adhesives. The principal active ingredient in Bactron has been shown to be effective against a wide range of bacteria including ‘super bugs’. The technology is well understood and has proven safe over the 40 years of its use, gaining food contact approval in both the USA and EU. Importantly, scientific opinion concludes that bacteria cannot develop resistance to this technology, as they have been able to do to certain antibiotics. Traditionally the active ingredient has been dispersed into finished products as a dry white powder. The uniqueness of Bactron comes from the fact that the (patent pending) technology enables the active ingredient to be dissolved into an almost ‘water white’ solution, which is then added to the product. This has two principal benefits: It greatly simplifies the manufacturing process of a product with antimicrobial properties. Tests undertaken by an independent DEFRA approved microbiological testing laboratory, prove that the antibacterial properties of Bactron show significant improvement over the powder itself. Primarily this is because the active ingredient contained in Bactron becomes homogenously distributed and is able to migrate more effectively through the host material. Adding Bactron does not affect the finished product adversely in any way and at the levels of incorporation safety data sheets and labels need not refer to its presence. Bactron exhibits the following notable benefits: Bactron is effective against a wide range of gram positive and gram negative bacteria and viruses (see Section 1). Bactron does not contribute to the evolution of resistant strains of bacteria (see Section 2). Bactron is safe (see Section 3). Bactron lasts for the normal service life of the treated product (see Section 4). Bactron is verified by independent testing (see Section 5). Section 1 : Bactron is effective against a wide range of gram positive and gram negative bacteria and viruses. The mechanism of action:The antimicrobial agent in Bactron is incorporated into coatings at the level of 5000 parts per million. This level far exceeds the minimum inhibitory concentration (MIC) required for an inhibitory antimicrobial effect. (see appendix 1:1). Studies have shown that the active ingredient in Bactron is effective against a wide range of gram positive and gram negative bacteria (including antibiotic resistant strains) and viruses that are important in personal and public hygiene. These include opportunist, transient and pathogenic (disease causing) bacteria. Bactron kills through a variety of different mechanisms. One of the ways that Bactron kills microbes is by acting on the cytoplasmic membrane of the cells, preventing the uptake of essential amino acids. This disorganization causes leakage of the low molecular weight cellular contents, bringing about the death of the micro organism. There are a number of other documented mechanisms by which cells are killed, which explains why Bactron works even when certain enzymes are absent from the micro organism. Incorporation into coatings (Biosan):Bactron is added to the aqueous phase (liquid paint) consisting of the resin, pigment and solvent (water in the case of Biosan). The resin and pigments in the liquid paint are surrounded and partly penetrated by Bactron, which has an affinity for the polymer. Hence Bactron becomes an integral part of the continuous paint film. Bactron permeates the film and because of the (patent pending) technology, it retains sufficient mobility within the dry film to be able to diffuse to the surface or any other areas of the coating that have become depleted due to wear, tear and mechanical damage. The way in which Bactron is incorporated in the host product and its ability to ‘recharge’ challenged areas, makes it uniquely effective at controlling micro organisms (see appendix 1:2). The antimicrobial effectiveness of Bactron in Biosan can be demonstrated by two experiments undertaken by an independent DEFRA approved microbiologist:- 1/ The 24 Hour Halo Test on Staphylococcus aureus ATCC 6538 Using a Test Method Based on AATCC 90:The effectiveness of Bactron in Biosan can be shown qualitatively by the 24 hour halo test experiment. In this test, two sample disks coated in the same host paint product were placed in petri dishes containing nutrient agar inoculated with Staphylococcus aureus. Paint sample B contained Bactron, paint sample A remained as the control (benchmark). The Halo Test. Paint Sample B : Containing Bactron. Paint Sample A : The Unmodified Control After 24 hours incubation a zone free of Staphylococcus aureus growth was evident around sample B. This zone of inhibition or ‘halo’ is a qualitative representation of the antimicrobial effectiveness of Bactron when compared with sample A. The results for this experiment can be broadly quantified by measuring the halo in millimetres from the edge of the sample to the edge of the bacterial growth. The larger the halo, the more effectively the bacteria have been inhibited or controlled over the 24 hour period. 2/ The 7 day Bactericidal Activity Test on Staphylococcus aureus ATCC 6538 Using a Test Method Based on AATCC 100. In this test sample disks coated in the same host paint product were inoculated with a liquid culture containing 560,000 CFU’s of Staphylococcus aureus. Paint sample B contained Bactron, paint sample A remained as the control (benchmark). The number of CFU’s of bacteria in each case, were counted at 24 hour, 72 hour and 7 day time intervals following inoculation. The 7 Day Bactericidal Activity Test for Biosan Ultra. Product Number of CFU’s expressed linearly Number of CFU’s expressed as an index Biosan Ultra with Bactron @ 24hrs 94,000 9.4 x 104 Number of CFU’s expressed logarithmically 4.97 Unmodified Control @ 24hrs 100,000 1.0 x 105 5 Biosan Ultra with Bactron @ 72hrs 360 3.6 x 102 2.56 Unmodified Control @ 72hrs 18,000 1.8 x 104 4.26 Biosan Ultra with Bactron @ 7 days <10 <10 <1 Unmodified Control @ 7 days 7,100 7.1 x 103 3.85 The results of this experiment can be shown graphically using the logarithmic scale as per industry standards:- Biosan Ultra.: Graphical Representation of The 7 day Bactericidal Activity Test.on Staphylococcus aureus ATCC 6538 Using a Test Method Based on AATCC 100. The experiment shows that after the initial 48 hour period 99% of bacteria have been killed by the sample containing Bactron, with numbers of bacteria declining from 560,000 to approximately 5000 CFU’s. After 7 days the bacteria cannot be detected on the Bactron protected sample whereas significant numbers of potentially pathogenic bacteria are still surviving on the unprotected coating. Based on the results of this experiment it can be stated that after 7 days, Biosan Ultra containing Bactron antibacterial protection has reduced the bacteria count by greater than a log reduction of 4.75. By way of comparison, the unprotected control has reduced the bacteria count by less than a log reduction of 2. These results enable us to conclude that ‘the antimicrobial treated product (Biosan with Bactron) exhibits excellent bacteriostatic and bactericidal activity,’ as verified by a DEFRA approved microbiologist commissioned to undertake independent testing on the Biosan range (see Section 5). Section 2 : Bactron does not contribute to the evolution of resistant strains of bacteria. Bactron’s active ingredient has been widely used for almost forty years without any convincing evidence of resistant strains of bacteria being encountered in real life situations. The emergence of resistant strains of bacteria is a significant health issue that relates to the over prescription of antibiotics and the incorrect usage of disinfectants. Bactron contains an antimicrobial agent used at bactericidal concentrations; it is not an antibiotic. In fact, the active ingredient in Bactron has been used successfully in hospitals to control outbreaks of the antibiotic resistant strains of the bacteria ‘Methicillin Resistant Staphylococcus aureus (MRSA)’. Scientific opinion concludes that bacteria cannot develop resistance to Bactron for two principal reasons (see appendix 2:1:1):1/ The level of incorporation. Bactron is incorporated into coatings at a level of 5000ppm. This level far exceeds the minimum inhibitory concentrations and so kills the micro organisms outright (see appendix 1:1). If the bacteria are killed outright there is no theoretical possibility of these bacteria being able to pass on any form of resistance to a subsequent generation. 2/ The multifaceted mechanisms of action. Evidence published over a number of years shows that Bactron’s active ingredient kills bacteria in a variety of different ways. These varied mechanisms ultimately result in a breakdown or failure in the organism’s cell wall. Cell wall failure affects the bacteria’s most vital processes and ultimately causes cell death. As there is no single mechanism of action it is not possible for a specific resistance to be developed. The European Commission has asked its Scientific Steering Committee (SSC) for an opinion on whether the active ingredient in Bactron could lead to the development of resistant strains of bacteria. Their report was adopted at a meeting held in July 2002 and concluded that:‘There is no convincing evidence that the active ingredient in Bactron poses any risk to humans or to the environment by inducing or transmitting antibacterial resistance under current conditions of use.’ In 1997 the US Food & Drug Administration convened an independent panel to determine whether antimicrobial products presented any risk of promoting antibiotic resistance. This panel also concluded that there was no evidence linking the use of antimicrobial products with antibiotic resistance. Section 3 : Bactron is Safe. Bactron is not classified as harmful to humans and as the likely human exposure levels due to handling products that contain Bactron are extremely low, it is completely safe to do so. The active ingredient has an extensive safety record and is regarded as being so safe that it is widely used in personal care products such as mouthwash, toothpaste, liquid soap and deodorant. There are extensive publications relating to its toxicology and efficacy. The antimicrobial contained in Bactron conforms to the safety requirements of the United States Pharmacopeia (USP26) Antimicrobial Effectiveness Test and each batch of the ingredient is certified as pure by an independent analytical laboratory. Bactron is manufactured to our own recipe by an ISO9002 accredited company. Separate studies have shown that Bactron’s ingredients, when diluted in the environment, are biodegradable and do not accumulate because biological and photolytic processes break them down. Additionally, as Bactron forms an integral part of the coating and is only added as a tiny percentage, any concentration present in the environment is negligible. Regulatory information Bactron is recommended as an additive for paints that are intended for use as disinfectants or sterilants to control bacteria or viruses. As such Bactron does not fall within the scope of The Control of Pesticides Regulations 1986. Products modified with Bactron do fall within the remit of the Biocidal Products Directive (98/8/EC) as implemented in the UK by the Biocidal Products Regulations 2001. Under the EC Review of Existing Biocidal Active Substances : First Review Regulations (1996/2000), producers and/or formulators of biocidal active substances were required to inform the European Chemicals Bureau. This was done for the active component of Bactron in 1999. As the antimicrobial in Bactron is included in the preliminary list of the European Chemicals Bureau, it means that products containing it may be marketed in member states of the EC, subject to any existing national legislation, until a decision is made on the antimicrobials included in the list. The Directive gives 10 years for all existing antimicrobials to be reviewed and there is no reason to believe that the status of the antimicrobial in Bactron will not be confirmed following the review. Bactron is also registered with the UK National Poisons Information Service because of the biocidal activity of the product and not because of any hazards relating to its use or composition. 4. Bactron lasts for the normal service life of the host product. The resin and pigments are surrounded and partly penetrated by Bactron, which has an affinity for the polymer yet remains able to diffuse evenly throughout the coating. Bactron is only removed at the surface of the coating in negligible amounts through wear, cleaning and it’s bactericidal action. The unique property of Bactron to migrate through the coating to recharge depleted areas means that antimicrobial protection is constantly maintained (see appendix 1:2). The relatively high level of Bactron in the coating (5000ppm of the active ingredient) is far in excess of the minimum inhibitory concentrations to micro organisms and this reservoir is sufficient to recharge depleted areas for at least the normal service life of the host product (see appendix 1:1). Scientific opinion states that at the recommended level of incorporation there is sufficient Bactron present in a host product to exert a broad spectrum antimicrobial action for at least 5 years (see appendix 2:1:2). This would exceed the normal service life of a coating in a hygiene sensitive area. 5 : Bactron is verified by independent testing. All testing on Bactron in Biosan hygiene coatings has been undertaken by a DEFRA approved microbiologist: Appendix 1:1. BACTRON™ efficacy The minimum inhibitory concentrations for the active ingredient of Bactron™ are shown below for a wide range of standard strains of micro organisms that are of importance to hygiene and public health. The antimicrobial content of Bactron™ containing coatings is 5000ppm. This is the reservoir of active ingredient that gives the coating the ability to remain active throughout its service life. Gram-positive bacteria Bacillus cereus Bacillus cereus var.mycoides Bacillus megatherium Bacillus pumilus Bacillus subtilis Bacillus subtilis Bacillus subtilis Brevibacterium ammoniagenes Clostridium botulinum Clostridium tetani Corynebacterium acnes (Propionibacterium acnes) Corynebacterium diphtheriae Corynebacterium diphtheriae Corynebacterium diphtheriae Corynebacterium melassecola Corynebacterium minutissium Corynebacterium minutissium Diplococcus pneumoniae Enterococcus faecalis Enterococcus faecalis Enterococcus faecalis Enterococcus faecalis Lactobacillus arabinosus Lactobacillus arabinosus Lactobacillus fermenti Listeria monocytogenes Listeria monocytogenes Micrococcus luteus Micrococcus luteus Mycobacterium phlei Mycobacterium smegmatis Mycobacterium tuberculosis Propionibacterium acnes Sarcina lutea Sarcina ureae Strain A A A ATCC 7061 ATCC 6051 ATCC 6633 NCTC 8236 ATCC 6871 NCTC 3805 NCTC 9571 ATCC 6919 MIC ( ppm ) 3 3 3 0.3 0.1 0.3 0.1 1.0 3 3 3 A ATCC 6917 NCTC 3984 ATCC 17965 ATCC 23348 ATCC 6501 NCTC 7465 ATCC 10541 ATCC 29212 ATCC 6055 ATCC 6057 ATCC 8014 CITM 706 CITM 707 ATCC 15313 NCTC 7973 ATCC 7468 ATCC 9341 A NCTC 8152 A ATCC 6919 NCTC 196 ATCC 6473 3 3 3 3.0 3.0 5 3 3.0 4.0 5.0 3.0 33 33 33 1.0 1.0 3.0 1.0 0.3 1 100 3.0 3 0.1 Sporosarcina ureae Staphylococcus albus Staphylococcus albus Staphylococcus aureas Staphylococcus aureas Staphylococcus aureas Staphylococcus aureas Staphylococcus aureas Staphylococcus aureas Staphylococcus aureus Staphylococcus aureus Staphylococcus aureus Staphylococcus aureus Staphylococcus aureus Staphylococcus epidermidis Staphylococcus hominis Streptococcus agalactiae Streptococcus faecalis Streptococcus faecalis Streptococcus haemolyticus A Streptococcus haemolyticus A Streptococcus pyogenes Streptococcus pyogenes ATCC 6473 C NCTC 7292 ATCC 13709 ATCC 6538 NCTC 4163 NCTC 6571 NCTC 6966 NCTC 7447 ATCC 13709 ATCC 6538 ATCC 9144 NCTC 4136 NCTC 6571 ATCC 1228 ATCC 27844 NCTC 8181 ATCC 10541 NCTC 8619 A A ATCC 9342 NCTC 8322 1.0 0.03 0.1 0.01 0. 01 0.01 0.03 0.1 0.01 0.01 0.01 0.05 0.03 0.03 0.01 1.0 3 3 10 1 3 3.0 3 Gram-negative bacteria Aerobacter aerogenes Aerobacter aerogenes Alcaligenes faecalis Brucella abortus Brucella intermedia Brucella melitensis Brucella suis Cloaca cloacae Enterobacter cloacae Escherichia coli Escherichia coli Escherichia coli Escherichia coli Escherichia coli Escherichia coli Escherichia coli Escherichia coli Escherichia coli Escherichia coli Haem. ophilus influenzae Kiebsiella aerogenes Kiebsiella pneumoniae Strain CITM 413 CITM 812 A NCTC 8226 A A A NCTC 8155 ATCC 13047 A ATCC 10536 ATCC 11229 ATCC 25922 ATCC 4157 ATCC 9661 ATCC 9663 NCTC 8196 NCTC 86 NCTC 9001 A NCTC 8172 ATCC 4352 MIC ( ppm ) 1 1-3 >100 0.1 0.1 0.1 0.03 0.3 0.5 0.3 0.5 0.3 0.3 0.3 0.3 0.3 0.03 0.1 0.1 33 0.3 0.3 Gram-negative bacteria Klebsiella aerogenes Klebsiella edwardsii Klebsiella pneumoniae Klebsiella pneumoniae Legionella pneumoniae (isolate) Loefflerella mallei Loefflerella pseudomallei Moraxella duplex Moraxella glucidolytica Moraxella Iwoffi Neisseria catarrhalis Pasteurela pseudotuberculosis Pasteurella septica Proteus mirabilis Proteus mirabilis Proteus mirabilis Proteus vulgaris Proteus vulgaris Proteus vulgaris Proteus vulgaris Proteus vulgaris (Neotype) Pseudomonas aeruginosa Pseudomonas aeruginosa Pseudomonas aeruginosa Pseudomonas aeruginosa Pseudomonas aeruginosa Pseudomonas capacia Pseudomonas fluorescens Pseudomonas fluorescens Salmonella choleraesuis Salmonella enteritidis Salmonella enteritidis Salmonella paratyphi Salmonella paratyphi A Salmonella paratyphi B Salmonella paratyphi B Salmonella paratyphi B Salmonella pullorum Salmonella typhi Salmonella typhi Salmonella typhi Salmonella typhi Salmonella typhimurium Salmonella typhimurium Serratia marcescens Serratia marcescens Shigella dysenteriae Strain ATCC 13048 NCTC 7242 ATCC 10031 ATCC 4352 A NCTC 9674 NCIB 10230 A A A NCTC 3622 C NCTC 948 A ATCC 14153 NCTC 8309 ATCC 13315 ATCC 6896 NCTC 4636 NCTC 8313 NCTC 4175 ATCC 12055 ATCC 15442 ATCC 19582 NCTC 1999 NCTC 8060 C-175 ATCC 17397 NCTC 4755 ATCC 1078 A A NCTC 5704 NCTC 5322 A NCTC 3176 NCTC 5704 ATCC 9120 A ATCC 6539 NCTC 786 NCTC 8384 ATCC 13311 NCTC 5710 A ATCC 13880 NCTC 2249 MIC ( ppm ) 0.5 0.3 0.2 0.3 10 0.3 1 0.01 0.3 0.1 33 10 0.1 0.3 0.5 0.3 0.3 0.3 0.3 0.1 0.01 >1000 > 500 > 500 > 100 >1000 256 > 500 > 100 0.3 0.1 0.3 0.1 0.3 0.1 0.3 0.1 0.3 0.1 0.3 0.3 0.3 0.3 0.3 > 100 > 500 0.1 Gram-negative bacteria Shigella flexneri Shigella flexneri Shigella flexneri Shigella sonnei Vibrio cholerae Vibrio eltor Strain NCTC 8192 NCTC 8204 NCTC 8205 NCTC 7240 A NCTC 8457 MIC ( ppm ) 0.3 0.1 0.1 0.1 10 10 Moulds and yeasts Aspergillus flavus Aspergillus fumigatus Aspergillus niger Aspergillus terreus Aspergillus versicolor Candida albicans Candida albicans Candida albicans Epidermophyton floccosum Keratinomyces ajelloi Microsporum canis Microsporum gypseum Pityrosporum ovale Saccharomyces cerevisiae Trichophyton mentagrophytes Trichophyton rubrum Trichophyton rubrum Trichophyton tonsurans Strain ATCC 9643 ATCC 9197 ATCC 6275 ATCC 10690 ATCC 11730 A ATCC 10231 ATCC 10259 ATCC 10227 A ATCC 10214 ATCC 6286 ATCC 14521 ATCC 2601 ATCC 9533 A ATCC 10218 A MIC ( ppm ) 10 10 30 30 10 3 3.0 3.0 1-10 10 3.0 3. 10 10 1.0 10 3.0 10 Origin of the Strains: CITM official culture collections NCTC official culture collections ATCC official culture collections C Ciba A Bacteriological or veterinary institute Appendix 1:2 Liquid Paint. The aqueous phase contains, amongst other things:- Bactron, resin and pigment. The resin and pigments in the liquid paint are surrounded and partly penetrated by Bactron, which has an affinity for the polymer. Dry Paint Film. Bactron permeates and becomes an integral part of the dry film. Because of the (patent pending) technology, Bactron retains sufficient mobility to diffuse to the surface or any other areas of the coating that have become depleted. Consequently, Bactron is able to recharge challenged areas, making it uniquely effective at controlling bacteria. Appendix 1:3 An explanation of logarithmic scales. Scientific protocol calls for a logarithmic scale rather than a linear scale to be used when representing graphically the decline in the number of CFU’s of bacteria. This can be confusing but in essence the vertical scale of the graph can be explained as follows:Log 1 = 101 = Log 2 = 102 = Log 3 = 103 = Log 4 = 104 = Log 5 = 105 = Log 6 = 106 = 10 x 1 =10 10 x 10 = 100 10 x 10 x 10 = 1,000 10 x 10 x 10 x 10 = 10,000 10 x 10 x 10 x 10 x 10 = 100,000 10 x 10 x 10 x 10 x 10 x 10 = 1,000,000 Both the Bactron protected sample and the control were placed in perti dishes containing nutrient agar inoculated with approximately 560,000 CFU’s of Staphylococcus aureus; 560,000 transcribed onto the vertical scale of the graph falls between the points 105 and 10 6. Expressed as a logarithmic figure 560,000 equates to 5.75. Over a seven day period the sample containing Bactron reduced the number of CFU’s of bacteria to a point below 101; this equates to less than 10 when transcribed to a linear scale. Over the same seven day period the unmodified sample, largely as a result of the presence of relatively short acting ‘in can’ preservatives, reduced the number of CFU’s of bacteria to a point below 10 4; this equates to more than 7000 when transcribed to a linear scale. A log reduction takes place when the number of bacteria drops by one logarithmic value. Eg ; a log reduction of 1 takes place when the value falls from 106 to 105; a log reduction of 2 takes place when the value falls from 106 to 104 and so on. Appendix 2:1 2:1:1 ‘Bactron Solution is a broad spectrum antimicrobial preparation, effective against a wide range of bacteria and fungi. At the biocidal concentrations of Bactron used in application, the main ingredient is non specific and acts by rupturing the cell wall of the micro organism with resultant and fatal lysis of the cell contents. At sub lethal inhibitory levels, studies also suggest that the antimicrobial agent inhibits growth by blocking microbial enzymes responsible for essential fatty acid and lipid biosynthesis. As a consequence of this multi level mode of action, the development of tolerant or resistant strains is highly unlikely; as has proved to be the case under practical conditions of usage for many years in a variety of applications1.’ 2:1:2. ‘It is my considered opinion that surface coatings protected with the recommended level of Bactron will, under normal conditions of service, continue to exert a broad spectrum antimicrobial action for 5 years or the lifetime of the coating, whichever is shorter1.’ 1 Ashley Cox. MSc. C.Chem. MRSC. M.I.BIOL. Glossary of Key Terms AATCC – American Association of Textile Colour Chemists. An accepted testing protocol. ATCC – American Type Culture Collection. ATCC 6538 is the particular strain of Staphylococcus aureus tested. Algae – Members of a group of predominantly aquatic, photosynthetic organisms of the kingdom protista that can also inhabit areas such as damp walls, tree trunks and soil. Amino Acid – Organic compounds containing an amino group and a carboxylic acid group; proteins are composed of various proportions of about 20 common amino acids. Antibiotic – Chemical substances produced by living organisms such as moulds and bacteria, or synthesised in laboratories for the purpose of destroying or preventing the growth of bacteria that cause disease. Bactericidal – Capable of killing bacteria. Bacteriostatic – Arrests the growth of bacteria. Bacteria – Usually single celled spherical, spiral or rod shaped organisms lacking chlorophyll that reproduce by fission. Important as pathogens and for biochemical properties. Bactron – The unique antimicrobial additive used in Biosan. Biosan – A unique range of water based hygiene coatings containing Bactron. Cell – The basic structural and functional unit of all organisms; cells may exist as independent units of life or may form colonies or tissues in higher plants and animals. Colony Forming Unit (CFU) – An individual cell, which is able to reproduce itself into an entire colony of identical cells. Control (Benchmark) – A method in which hypothesis are tested by comparing two or more populations that are similar or identical in most respects other than that which has been identified as the independent variable. Cytoplasm – The protoplasm of the cell excluding the nucleus. Cytoplasmic membrane – The membrane that surrounds the cell’s cytoplasm separating it from the environment. It consists of a double layer of phospholipids and has proteins embedded in it. DEFRA – The Department for Environment, Food & Rural Affairs. The government body overseeing the regulation of food issues in the UK including animal welfare, safety standards and environmental issues. DNA – A nucleic acid found in the nucleus of a cell and consisting of a polymer formed from nucleotide and shaped like a double helix; associated with the transmission of genetic information; ‘DNA is the king of molecules’. Enzymes – Any of several complex proteins that are produced by cells and act as catalysts in specific biochemical reactions. Fission - Reproduction by splitting into equal parts. Gram Positive – A prokaryotic cell who’s cell wall stains purple (positive) in Gram stain. The cell wall of a gram positive bacterium consists chiefly of peptidoglycan and lacks the outer membrane of gram negative cells. Gram Negative – A prokaryotic cell who’s cell wall stains pink (negative) in Gram stain. The cell wall of a gram negative bacterium contains relatively little peptidoglycan but contains an outer membrane composed of lipopolysaccharide (LPS), lipoprotein and other complex macromolecules. Logarithmic scale – A scale on which actual distances from the origin are proportional to the logarithms of the corresponding scale numbers (see appendix 1:3). Minimum inhibitory requirement – The minimum amount of an active ingredient needed to control a particular strain of bacteria. Normally expressed in parts per million (ppm). Mould – A fungus that produces a superficial growth on various kinds of damp or decaying organic matter. Nucleus – A part of the cell containing DNA and RNA and responsible for growth and reproduction. Nutrient Agar – A nutritive culture medium that uses agar as the gelling agent. Pathogen – One of a class of virulent micro organisms or bacteria found in the tissues and fluids in infectious diseases and supposed to be the cause of the disease. Photolytic (photolysis) – The breakdown of molecules into smaller units via absorption of light. Pigment – Solids in powdered form, which are derived from chemical reactions, minerals, vegetables or animals. Pigments may be organic or inorganic. Pigments give a paint film its colour and opacity (hiding power), but may also improve the paint film’s hardness and durability. Polymer – A naturally occurring or synthetic medium consisting of large molecules made up of a series of repeated simple monomers. Prokaryotic – Essentially a simple type of cell, lacking organelles (persistent structure with specialized function). Protista – A group (kingdom) including all organisms of simple biological organization, such as algae, bacteria, fungi and protozoa. Protoplasm – The living substance of the cell including cytoplasm and nucleus. Qualitative – Involving distinctions made on quality. Quantitative – Involving distinctions based on quantity. Resin – The binder or film forming constituent of the paint. It is the adhesive that holds the pigment and other additives together. The resin contributes mainly to the durability, provides the necessary mechanical and physical properties and provides the adhesion, cohesion and flexibility of the coating. Solvent – A liquid substance capable of dissolving other substances that does not change its state in forming a solution. Water is the solvent for the Biosan range of products. Superbugs – A colloquial term applied to certain strains of bacteria that have developed resistance to some antibiotics; eg; MRSA. Virus – An ultramicroscopic infectious agent that replicates itself only within cells of living hosts; many are pathogenic; a piece of nucleic acid (DNA or RNA) wrapped in a thin coat of protein. Yeast – A single celled organism that can cause infection. Many types are of great economic importance in brewing and baking. They can also be a source of proteins and vitamins.