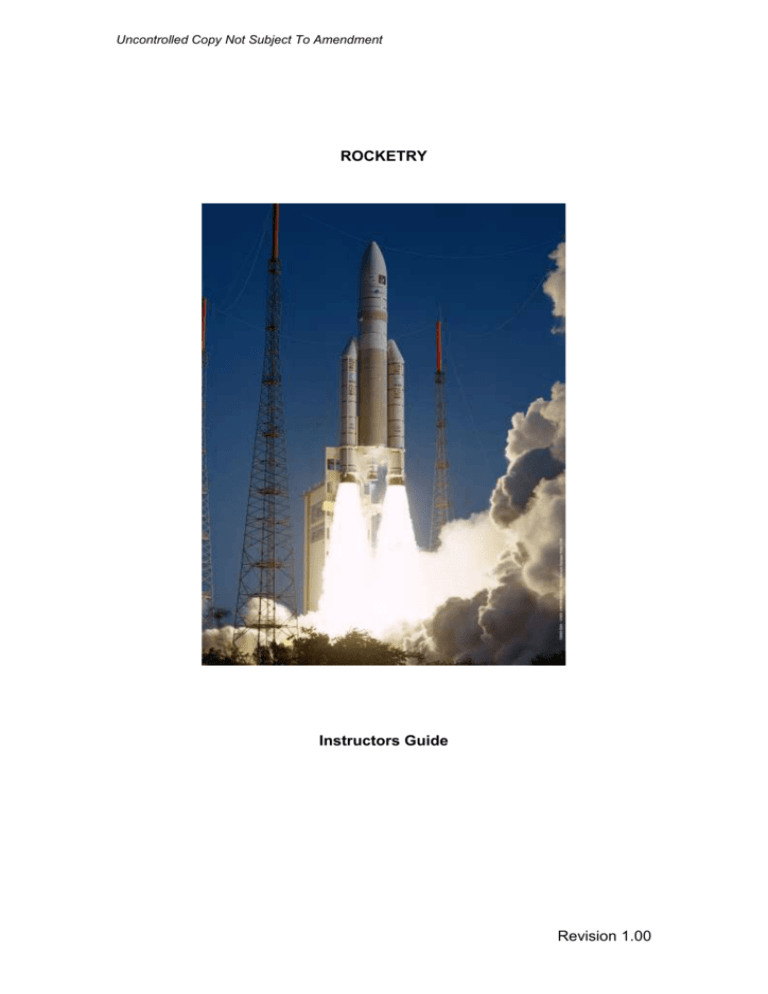

2. Applications of Rockets - No.2473 (Highlands & Southgate

advertisement