Appendix 1 – Model OHS Specification and Tender Document

advertisement

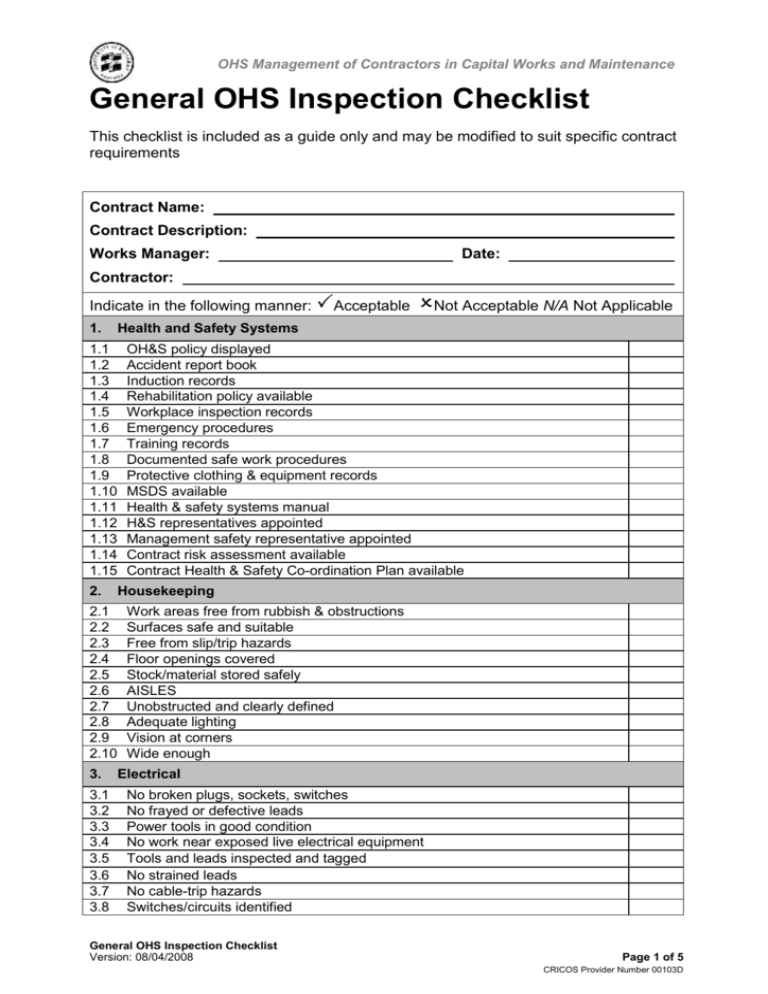

OHS Management of Contractors in Capital Works and Maintenance General OHS Inspection Checklist This checklist is included as a guide only and may be modified to suit specific contract requirements Contract Name: Contract Description: Works Manager: Date: Contractor: Indicate in the following manner: Acceptable 1. 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10 1.11 1.12 1.13 1.14 1.15 2. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 3. 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 Not Acceptable N/A Not Applicable Health and Safety Systems OH&S policy displayed Accident report book Induction records Rehabilitation policy available Workplace inspection records Emergency procedures Training records Documented safe work procedures Protective clothing & equipment records MSDS available Health & safety systems manual H&S representatives appointed Management safety representative appointed Contract risk assessment available Contract Health & Safety Co-ordination Plan available Housekeeping Work areas free from rubbish & obstructions Surfaces safe and suitable Free from slip/trip hazards Floor openings covered Stock/material stored safely AISLES Unobstructed and clearly defined Adequate lighting Vision at corners Wide enough Electrical No broken plugs, sockets, switches No frayed or defective leads Power tools in good condition No work near exposed live electrical equipment Tools and leads inspected and tagged No strained leads No cable-trip hazards Switches/circuits identified General OHS Inspection Checklist Version: 08/04/2008 Page 1 of 5 CRICOS Provider Number 00103D OHS Management of Contractors in Capital Works and Maintenance 3.9 3.10 3.11 3.12 3.13 4. 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11 5. 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 6. 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 7. 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 Lock-out procedures/danger tags in place Earth leakage systems used Start/stop switches clearly identified Switchboards secured Appropriate fire fighting equipment Mobile Plant and Equipment Plant and equipment in good condition Daily safety inspection procedures/checklists Fault reporting/rectification system used Operators trained and licensed Warning and instructions displayed Warning lights operational Reversing alarm operational Satisfactory operating practices Fire extinguisher Tyres satisfactory SWL of lifting or carrying equipment displayed Machinery and Workbenches Adequate work space Clean and tidy Free from excess oil and grease Adequately guarded Warnings or instructions displayed Emergency stops appropriately placed and clearly identifiable Operated safely and correctly Workbenches clear of rubbish Tools in proper place Duckboards or floor mats provided Hazardous Substances Stored appropriately Containers labelled correctly Adequate ventilation/exhaust systems Protective clothing/equipment available/used Personal hygiene - dermatitis control Waste disposal procedures Material safety data sheets available Chemical handling procedures followed Chemical register developed Appropriate emergency/first aid equipment - shower, eye bath, extinguishers Hazchem signing displayed Welding Gas bottles securely fixed to trolley Welding fumes well ventilated Fire extinguisher near work area Only flint guns used to light torch Flash back spark arresters fitted Vision screens used for electric welding LPG bottles within year stamp PPE provided and worn General OHS Inspection Checklist Version: 08/04/2008 Page 2 of 5 CRICOS Provider Number 00103D OHS Management of Contractors in Capital Works and Maintenance 7.9 8. 8.1 8.2 8.3 8.4 8.5 8.6 8.7 9. 9.1 9.2 9.3 9.4 9.5 Hot Work permit system used Excavations Shoring in place and in sound condition Excavation well secured Signage displayed Banks battered correctly and spoil away from edge Clear and safe access around excavation Separate access and egress points from excavation Safe work procedure in place Prevention of Falls All work platforms have secure handrails, guarding or fence panels Harness and lanyard or belts provided All floor penetrations covered or barricaded Unsafe areas signposted and fenced Safe work procedure in place 10. Stairs, steps and landings 10.1 10.2 10.3 10.4 10.5 10.6 10.7 10.8 10.9 No worn or broken steps Handrails in good repair Clear of obstructions Adequate lighting Emergency lighting Non-slip treatments/treads in good condition Kick plates where required Clear of debris and spills Used correctly 11. Ladders 11.1 11.2 11.3 11.4 11.5 11.6 Ladders in good condition Ladders not used to support planks for working platforms Correct angle to structure : Extended metre above top landing Straight or extension ladders securely fixed at top Metal ladders not used near live exposed electrical equipment 12. Personal Protection 12.1 12.2 12.3 12.4 Employees provided with PPE PPE being worn by employees Suncream and sunglasses provided Correct signage at access points 13. Manual Handling 13.1 13.2 13.3 13.4 Mechanical aids provided and used Safe work procedures in place Manual handling risk assessment performed Manual handling controls implemented 14. Workplace Ergonomics 14.1 14.2 14.3 14.4 Workstation and seating design acceptable Ergonomic factors considered in work layout and task design Use of excessive force and repetitive movements minimised Appropriate training provided General OHS Inspection Checklist Version: 08/04/2008 Page 3 of 5 CRICOS Provider Number 00103D OHS Management of Contractors in Capital Works and Maintenance 15. Material Storage 15.1 Stacks stable 15.2 Heights correct 15.3 Sufficient space for moving stock 15.4 Material stored in racks/bins 15.5 Shelves free of rubbish 15.6 Floors around stacks and racks clear 15.7 Drums checked 15.8 Pallets in good repair 15.9 Heavier items stored low 15.10 No danger of falling objects 15.11 No sharp edges 15.12 Safe means of accessing high shelves 15.13 Racks clear of lights/sprinklers 16. Confined Spaces 16.1 16.2 16.3 16.4 16.5 Risk assessment undertaken Communication and rescue plan in place Safety equipment in good working condition Suitable training provided to employees Confined Space permit used 17. Lasers 17.1 Operator has laser operator licence 17.2 Signage displayed 17.3 Laser not used in a manner to endanger other persons 18. Demolition 18.1 18.2 18.3 18.4 18.5 Risk assessment undertaken in advance Access prevented to demolition area Overhead protection in place Protection of general public Safe work procedure in place 19. Public Protection 19.1 19.2 19.3 19.4 19.5 19.6 19.7 19.8 Appropriate barricades, fencing, hoarding, gantry secure and in place Signage in place Suitable lighting for public access Footpaths clean and free from debris Dust and noise controls in place Site access controlled Traffic control procedures in place Public complaints actioned 20. Amenities 20.1 20.2 20.3 20.4 20.5 Washrooms clean Toilets clean Lockers clean Meal rooms clean and tidy Rubbish bins available - covered 21. First Aid 21.1 Cabinets and contents clean and orderly 21.2 Stocks meet requirements General OHS Inspection Checklist Version: 08/04/2008 Page 4 of 5 CRICOS Provider Number 00103D OHS Management of Contractors in Capital Works and Maintenance 21.3 21.4 21.5 21.6 First aiders names displayed First aiders location and phone numbers Qualified first aider(s) Record of treatment and of supplies dispensed 22. Lighting 22.1 22.2 22.3 22.4 22.5 Adequate and free from glare Lighting clean and efficient Windows clean No flickering or inoperable lights Emergency lighting system 23. Fire Control 23.1 Extinguishers in place 23.2 Fire fighting equipment serviced/tagged 23.3 Appropriate signing of extinguishers 23.4 Extinguishers appropriate to hazard 23.5 Emergency exit signage 23.6 Exit doors easily opened from inside 23.7 Exit path ways clear of obstruction 23.8 Alarm/communication system - adequate 23.9 Smoking/naked flame restrictions observed 23.10 Minimum quantities of flammables at workstation 23.11 Flammable storage procedures 23.12 Emergency personnel identified and trained 23.13 Emergency procedures documented - issued 23.14 Emergency telephone numbers displayed 23.15 Alarms tested 23.16 Trial evacuations conducted 23.17 Personnel trained in use of fire fighting equipment General OHS Inspection Checklist Version: 08/04/2008 Page 5 of 5 CRICOS Provider Number 00103D