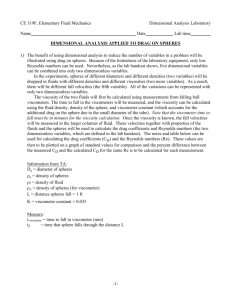

Incomplete Similitude

Dimensional Analysis & Similitude

Ref: Introduction to Fluid Mechanics, R. Fox & McDonald, A. T.

Introduction to Fluid Mechanics, S. Middleman

Introduction to Fluid Mechanics, Janna, W. S.

The development of fluid mechanics has depended heavily on experimental results, as most flow problems of practical interest cannot be solved exactly by analytical methods.

As experimental work is both time-consuming and expensive, it is natural to examine if one can gather the desired information from as few experiments as possible, while working with a suitably scaled model of the geometry of interest.

Dimensional analysis is an important tool to achieve this goal. It also exposes dimensionless groups (or parameters) which can be used to correlate the experimental data, which allows us to use the correlations across geometric scales.

Dimensional analysis also allows us to examine the exact equations of motion critically. By recasting these equations in a dimensionless form, one can recognize the relative importance of various terms in the model equations. This may allow rational simplifications of the exact equations. These simplified equations may be solved more easily, and sometimes even analytically.

The dimensional analysis can also suggest when one may be able to do away with the differential equation model for the flow, and “accept” simple macroscopic balance solutions

Nature of Dimensional Analysis

Let us first consider the problem of designing suitably scaled experimental systems and correlating the data. Dimensional analysis performed for these specific goals does not require as a starting point the differential equations we just derived in the course.

Instead, we simply need to remember that any equation (correlation) we derive must be dimensionally homogeneous.

We will now discuss an organized procedure for doing dimensional analysis and selecting dimensionless groups. Buckingham Pi theorem , which is the foundation for dimensional analysis, can be stated as follows.

Given a physical problem in which the dependent parameter q

1 is a function of n

1 independent parameters, q

1

2

,

3

,..., q n

,

2 3

,..., q n

, we expect

(83) or equivalently

76

,

1 2

,..., q n

0 (84)

If m is the minimum number of independent dimensions (mass. length, time, temperature, electric charge, etc.) required to specify the dimensions of all the parameters, the number of independent dimensionless ratios, ,

P n m

If M is the rank of the dimensional matrix, described below, then the rank of the dimensional matrix is less than or equal to . m .

P n M

.

That is,

Denoting the P dimensionless ratios as

2

,...,

p

, we write Eqs. (83) & (84) as

1

G

1

2

, ,...,

3

p

(85) or

G

2

,...,

p

0 (86)

Buckingham Pi theorem does not predict the functional form of G or G

1

and these must be found experimentally.

Dimensional Matrix

Independent Dimensions List of Parameters

q

1 q

2

...

3 q n

Mass (m)

Length (L)

Time (t)

Temperature char ge

a b c d

1 e

1

1

1

1 a b

2

2 a b c d n e n n n n

Here a b c i

, , , i i etc. denote the exponents, i.e. The dimension of q is given by

1 q

1 a b m L t c

1 ...

77

The matrix

a

1 b

1 a n b n

is known as the dimensional matrix and M is the rank of this matrix.

Example 1: Consider uniform streaming of a fluid past a smooth, stationary sphere. We seek to express the drag force F acting on the sphere in terms of the density

and viscosity

of the fluid, diameter of the sphere

and the fluid velocity

.

i.e.

F

f

, , ,

we have n

5 parameters

F

V D

The primary dimensions are , , .

The dimensional matrix can be constructed as follows:

F

V D

m

L t

1 1 0 0 1

1

3 1 1

1

2 0

1 0

1

As none of the rows can be expressed as a linear combination of the other two, we conclude that the rank of the dimensional matrix is 3. Therefore there are

5 3 2 independent dimensionless parameters for this problem.

It is convenient to select from the list of parameters a number of “ repeating parameters

” equal to the rank of the dimensional matrix, and including all the primary dimensions. For example, in this problem, we can choose

, and .

Note that we have picked three repeating parameters (consistent with the fact that we have three primary dimensions) and that none of the repeating parameters can be expressed in terms of other two.

We are now left with two other parameters, F

We seek a dimensional parameter by expressing F in terms of

, & .

78

1

0 0 0

F V D m L t mL t

2

m

L

3

L t

0 0 0

L m L t

1 0

-2-

0

1,

2,

2

1

F

2 2

V D m

Similarly, we set

2

a b c

V D and find

2

VD

We expect

1

F

2 2

V D

f

2

VD

The functional form of f must be found experimentally.

Example 2 : The pressure drop

for steady, incompressible viscous flow through a straight horizontal pipe depends on the pipe length

, the average velocity

, the fluid viscosity

, the pipe diameter

, the fluid density

and wall roughness.

The roughness is characterized by an average “roughness” height

.

A set of dimensionless parameters which can be used to correlate the data is deduced as follows:

f

k

n , the # of dimensional parameters

7 . The dimensional matrix is as follows: m

L t

p

U D L

k

1 1 0 0 0 1 0

1

3 1 1 1

1 1

2 0

1 0 0

1 0

79

The rank of this matrix is 3. Therefore, there are 7 – 3 = 4 dimensionless parameters in this problem.

Choosing

, U and D as repeating parameters, we express the other four in terms of these repeating parameters. This yields the following:

1

p

U

2

,

2

UD

,

3

L

D

,

4

k

D and

1

f

,

3

,

4

Example 3 : Capillary rise

When a small tube is dipped into a pool of liquid, surface tension causes a meniscus to form at the free surface, which is elevated or depressed depending on the contact angle

at the gas-liquid-solid contact line. It has been found experimentally that the magnitude of this capillary rise,

h , is a function of tube diameter weight tension

g

g

, liquid specific

surface

of the gas-liquid interface and .

Determine the numbers of independent

parameters.

The number of parameters

5. The dimensional matrix is as follows:

h D

m

L t

0 0 1 1 0

1 1

2 0 0

0 0

2

2 0

Clearly, the third row is trivially obtained from the first row. Thus, the rank is only 2. It then follows that there are 5 2 3 independent dimensionless parameters.

We then look for two repeating parameters which involve all three primary dimensions and do not have identical dimensions. Let us say, we choose three dimensionless parameters by relating

h

D and

, and to and

.

.

We form the

1 h D a

1

h

D

80

Similarly,

2

h

D

D

2

;

3

D

2

,

(87)

In this example, we considered

as a variable to illustrate that the rank of the dimensional matrix need not be the same as the number of primary dimensions. Had we chosen

and g as separate parameters (instead of

), we would have 6 parameters in this problem; however, we would have also found that the rank of the dimensional matrix is 3, so that we still have only three dimensionless parameters. The final expression relating the dimensionless parameters is still the same as Eq. (87).

Dimensionless Groups of Significance in Fluid Mechanics

Although a large number of dimensionless parameters (groups) has been identified in the literature, the following set of dimensionless groups holds a special importance in fluid mechanics. It is best to present these groups as ratios of stresses arising in the flows problems. [We can also view them as ratios of forces, but we’ll talk in terms of stresses.]

Inertial stress

V

2

Viscous stress =

V

L

Gravitational stress

gL

Interfacial stress

L

The Reynolds number, Re , is a ratio of the inertial and viscous stresses,

Re

inertial viscous

VL

The Froude number, Fr is taken to be the inertial and gravitational stresses.

Fr

inertial gravitational

V

2

gL

[In some books and papers, Fr is taken to be

V

2 gL

1/ 2

, so it is prudent to check the definition employed carefully.]

81

The interfacial stress is also referred to as capillary stress. The Weber number, We , is a ratio of the inertial and interfacial stresses.

We

inertial interfacial

2

V L

The capillary number, Ca , is a ratio of the viscous and capillary (interfacial) stresses.

Ca

viscous capillary

V

The Bond number, Bo , is a ratio of the gravitational and interfacial stresses.

Bo

gravitational

interfacial

gL

2

In some problems such as bubbles rising in a liquid, one refers to an

Eötvos number,

Eo , which is a ratio of the buoyancy stress to interfacial stress.

Eo

buoyancy interfacial

gL

2

.

So, Eo appears to be very similar to Bond number.

It is important to recognize that in a given problem all these dimensionless groups are not independent. Clearly

We

Re Ca

Fr Bo

As the dimensionless groups mentioned above appear as ratios of relevant stresses, an inspection of their magnitudes gives us clues on the relative importance of terms in the momentum balance equations, and allows us to seek rational simplification of the balance equations. Familiarity with these dimensionless groups allows us to recognize dimensionless parameters suggested by dimensional analysis.

(a) Returning to the problem of force on a sphere immersed in a flowing fluid, we can now recognize

2

1

as Re .

(b) The same is the case in the pipe flow problem (example 2).

(c) In the capillary rise problem,

2

is simply Bo

1

.

82

Flow similarity and Model studies

Before building large-scale units (prototypes), it is desirable to perform a carefully planned sequence of experiments on a suitably scaled down model and gather data which can be extended to the prototype. Clearly, for this exercise to be useful, the flows encountered with the prototype and model units must be similar. What constitutes similarity?

Geometric Similarity requires that the model and prototype be the same shape, and that all linear dimensions of the model be related to the corresponding dimensions of the prototype by a constant scale factor.

Kinematic Similarity between two flows requires that the velocities at corresponding points are in the same direction and related in magnitude by an appropriate scale factor.

For this to be the case, the regimes of flow must be the same for both model and prototype.

Dynamic Similarity requires that the two flows have force distributions such that identical types of forces are parallel and are related in magnitude by an appropriate scale factor at all corresponding points. The flows must be geometrically and kinematically similar for them to be dynamically similar.

The Buckingham Pi theorem can be used to identify conditions required for dynamic similarity.

Let us return to the first example where we were interested in determining the force

(F) on a sphere of diameter D immersed in a flowing field. Let us suppose that we want to determine this force by performing experiments in a model system.

Prototype Model sphere sphere

Fluid velocity,

From Buckingham Pi theorem analysis we saw that

F

2 2

V D

VD

Diameter, D m

m

m

V m

F m

83

Therefore we should achieve identical values for

VD

in both units.

Re

VD

V D m m m

m

When this is achieved, we expect that

F

2 2

V D

F m

2 2

V D m m m

The geometric scale factor

(88)

(89)

D m

/ D

can be chosen without any constraints in this problem as we need to match only a single dimensionless group for this problem. We can also use the same fluid as in the prototype problem and achieve Eq. (88) by suitably choosing V m

.

We can also choose a different fluid to perform the model experiments and select V m

to satisfy Eq. (88). Having done this, we find F experimentally, and use Eq. m

(89) to find F for the prototype system.

/

In the second example, for similitude, we should match the Reynolds number, k d When this is achieved,

p /

U

2

will be the same for both the original and model systems. In pipe flow problems, one is often concerned about flow characteristics in the so-called fully-developed region where the pressure drop is simply proportional to L .

In this regime, we then expect

L

P

D

U

2

f Re

UD k

,

D

so that we only need to match Re and / .

Incomplete Similitude

In some problems, it may not be physically possible to match all the relevant dimensionless parameters of the prototype and model systems, except for the trivial case when the prototype and model systems are identical. In such cases we try to match the most critical dimensionless parameters and estimate the influence of the unmatched parameters. It is often prudent to perform experiments with more than one model (each having a different size), where all the critical dimensionless parameters are matched between the models and the prototype. The unmatched dimensionless parameters will be different for the models and therefore one can assess the importance of the unmatched parameters by comparing results obtained with the various models.

84

Dimensional Analysis for multiple dependent variables

In the examples we discussed thus far, we were concerned with a single dependent variable whose value was determined by a set of independent variables. In some problems, there can be more than one dependent variable of interest. For example, in the first example we discussed (namely, flow past an object immersed in a fluid), the flow will become unstable for sufficiently large Re values and a time-periodic vortex shedding pattern will set it. The period of this vortex shedding is often of interest, as the object will experience a time-periodic lateral (lift) force as a result of this vortex shedding. This periodic lift force (whose mean value is zero) causes vibrations of the immersed object.

In this regime of vortex shedding, the dependent variables of interest include average drag force, period of vortex shedding, rms value of the lift force, etc. We can correlate each of these in terms of the same set of independent variables.

The most important point to keep in mind is that we should clearly separate dependent and independent variables to take maximum advantage of the dimensional analysis.

Commonly Employed Correlations

I. Fully developed flow of a Newtonian fluid through a straight pipe of circular cross section: a) Smooth pipe: We have already shown through dimensional analysis that

For fully developed flow, we expect

P

P

U

2

g Re

UD L

,

D

to be proportional to ,

i.e. we expect

P

D

L U

2

L g Re ,

D

L

We also expect that for >>1,

D

L

the right hand side will become independent of ,

D

so that

P

D

L U

2

(90)

85

Experimental data on pressure gradient

P

in fully-developed flows are usually

L

expressed in terms of a friction factor, f , defined as: f

L

P

1

2

U

2

From Eqs. (90) and (91), we conclude that f

(91)

Figure 1 shows experimental data on friction factor for smooth pipes. For Re

2100, f

16

Re which, in dimensional form, is

Q

2

D U

4

P

D

L

4

128

where Q is the volumetric flow rate. We will see later in the course that this expression, known as the Hagen-Poiseuille equation , can be deduced as the steady, fully-developed laminar flow solution.

When Re

2100, the flow is turbulent. Figure 1 shows two correlations for friction factor in the turbulent regime.

Blasius equation f

0.079 / Re

1/ 4

Von Karman – Nikuradse equation

1

4log

10

Re f

0.4

f

86

Figure 1: Friction factor for fluid flow through a smooth pipe b) Rough pipes: As discussed earlier, the roughness adds another dimensionless group,

/ , where k is the height of roughness. Figure 2 shows friction factor data obtained in pipes with various / values. Note that the roughness ratio

/

has no perceptible effect on the friction factor in the laminar flow regime. In contrast, it has a profound effect in the turbulent flow regime. A correlation known as the

Colebrook equation

1 f

4log

10 k

D

4.67

Re 7

2.28

is frequently employed to account for the effect of roughness on the friction factor in the turbulent regime.

87

Figure 2: Friction factor for flow through rough pipes

II.

Flow past a spherical object

Earlier, we discussed the problem of correlating the force acting on a sphere immersed in a flowing fluid. We now return to this problem and discuss specific expressions for this force, commonly referred to as the drag force. Recall that the dimensional analysis suggested a correlation of the form:

F

2 2

V D

VD

The left hand side of this equation can be viewed as a ratio of the drag and inertial forces.

In the literature, the drag force is usually correlated in terms of a drag coefficient,

C

D

, which is very similar to the left hand side of the above equation.

C

D

F

1

2

2

V A

P

88

where A is the area of the object in a plane perpendicular to the flow direction. For a

P sphere, it is always

D

2

/ 4, while for non-spherical objects A will depend on the

P particle orientation relative to flow.

Figure 3 shows the variation of C

D

with Re for spherical particles. For low Reynolds number flows,

Re

1, C

D

24

Re which is equivalent to saying that

F

3

DV

(92)

For 10

3

Re

5

commonly referred to as

Newton’s resistance regime,

C

D

0.44

(93) so that

F

0.055

V D 2

Eq. (92) is typically used for Re

0.1.

The data for Re

1000 is well correlated by

C

D

24

Re

Re

0.687

for Re

1000

(94)

Figure 3: Drag coefficient for flow past a sphere

89

A simple example of the application of drag force correlations involves calculation of the terminal settling velocity

of a spherical particle in a quiescent fluid. This is the steady velocity which the particle will attain when it falls in a quiescent fluid under the action of gravity. [Here, it is implicitly understood that the particle density,

is larger s

, than that of the fluid,

.

The rise velocities of light particles can be computed following the same procedure. I leave it as an exercise to the students to see how the analysis should be revised for hollow spheres.]

Downward force due to the weight of the particle

D

3

6

s g

The upward buoyancy force

D

3

6

g

Upward drag force

F

At steady state,

D

3

6

s g

D

3

6

g

F (95)

But

F

1

2

V t

2

D 2

4

C

D

, (96) where C

D

C

D

and Re t

.

One can rewrite Eq. (96) as

F C Re

D t

2

8

which upon substitution into Eq. (95) leads to

C Re

2 t

4

s

3

2

gD

3

N

D

(97)

Here N is referred to as the Galileo number , which can be readily computed once the

D fluid properties and, particle size and density are known. Eq. (97) is solved iteratively, where we guess Re t

, calculate C

D

from a correlation, and check if Eq. (97) is satisfied.

90

In the low Reynolds number regime and in Newton’s regime, Eq. (97) can be solved explicitly.

Re t

1, Re t

10

3

Re t

5

2 10 , Re t

1

24

N

D

N

D

0.44

Expressing these relations in dimensional form, one can see that, for Re t

1, the terminal settling velocity is proportional to D

2

.

However, in the Newton’s resistance regime, this dependence declines to D

1.5

.

In the intermediate region, one can expect the exponent to be between 1.5 and 2.0.

91