Supply Chain Management - TAS - HCMUT

advertisement

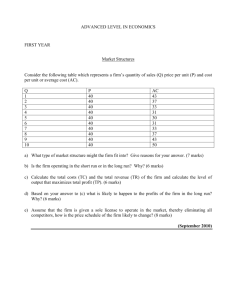

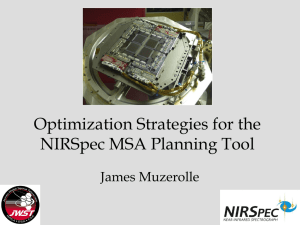

APPROVED ______________________________________________________________________________________ EXAMINATION PAPER : ACADEMIC SESSION 2003/2004 Campus Medway School Engineering Department Engineering Systems Programme MSc Engineering Suite COURSE TITLE Supply Chain Management COURSE CODE PROD 1009 LEVEL Masters Date and Duration (incl. reading time) May 2004, 2-1/2 Hours INSTRUCTIONS TO CANDIDATES The attention of the students is directed to the instructions printed on the answer book. Answer THREE of the following four Questions. All questions carry equal marks. Duration : 2-1/2 Hours. ---------- ______________________________________________________________________________________ Date & Duration of Exam: May 2004, 2-1/2 Hours Course Title: Course Code: Supply Chain Management PROD 1009 Page 1 of 5 APPROVED ______________________________________________________________________________________ Q1. (a) Explain with the aid of a diagram the Total Systems Concept which underpins the management of Supply Chains. [6 marks] (b) Describe, with the aid of diagrams, the four stages of Supply Chain Integration. Include in your answer an explanation as to why supply chain integration is difficult to achieve. [13 marks] (c) Write a detailed account of the Key Issues of Supply Chain Management. [14 marks] Q2. (a) Outline the principal factors contributing to the bullwhip effect and for each factor describe, in detail, mechanisms for its reduction or elimination. [18 marks] (b) In the past the supply chain was viewed as a set of trade-offs. Typically high inventory levels and shipping costs, and less product variation enabled manufacturers and retailers to come closer to meeting their goals. Today customers demand high variety and low cost and there is an increased pressure to control inventory and transportation costs. By considering the aspects of the supply chain detailed above, explain in detail how through the use of advanced information technology and creative network design these perceived trade-offs may now be reduced or eliminated. [15 marks] ______________________________________________________________________________________ Date & Duration of Exam: May 2004, 2-1/2 Hours Course Title: Course Code: Supply Chain Management PROD 1009 Page 2 of 5 APPROVED ______________________________________________________________________________________ Q3. (a) Discuss the application of a lean thinking approach to supply chain management and hence explain how waste associated with supply chains can be categorised. [8 marks] (b) Explain how mapping a logistics process is useful for both benchmarking and a mechanism for process improvement. [5 marks] (c) Figure Q3 represents a Value Time Profile for a simplified supply chain of an automotive product. (i) Explain the concept of the Value Time Profile. (ii) Determine the total cost of the product. (iii) Calculate the total waste associated with the supply chain. (iv) Explain how the supply chain can be improved. [12 marks] Cost/Value (Thousand £) 400 300 200 100 raw materials purchase move & store materials process parts transport assemble transport & Package & store product store product parts at product for assembly packaging plant Store finished products Time Figure Q3 - Value Time Profile of Supply Chain for Automotive Product (d) Explain the relevance of using a Balanced Scorecard approach for assessing the performance of a supply chain and briefly describe a framework for a logistics scorecard. [8 marks] ______________________________________________________________________________________ Date & Duration of Exam: May 2004, 2-1/2 Hours Course Title: Course Code: Supply Chain Management PROD 1009 Page 3 of 5 APPROVED ______________________________________________________________________________________ Q4. (a) Explain in detail how Process Reference models such as the SCOR (Supply Chain Operation Reference) methodology integrate the concepts of business process reengineering, benchmarking, and process measurement into a cross-functional framework. [12 marks] (b) Figure Q4 shows a screen capture from the animation of a simulation model of the supply chain for tubular pipes. The logistics of distributing goods from factory to end-user is represented using a macro modeling approach. Each major phase of the distribution process is shown on one level of the animation. For example, the process of transforming raw material into unfinished pipe is accomplished at the Mill level. Finishing operations are performed on each pipe at the Pipe Process level. Pipes are then shipped for distribution to the end user. Product inspection is performed at all levels. (c) (i) Explain how simulation is particularly appropriate for modeling complex system such as supply chains. (ii) Discuss the advantages of using the approach shown in Figure Q4 for modeling supply chains. (iii) With reference to the example shown in Figure Q4 discuss potential recommendations that simulation of the tubular pipes supply chain would facilitate. [12 marks] Explain how Activity Based Costing (ABC) can be used to assess the performance of a supply chain by integration into a simulation model or otherwise. [9 marks] Cont’d….. ______________________________________________________________________________________ Date & Duration of Exam: May 2004, 2-1/2 Hours Course Title: Course Code: Supply Chain Management PROD 1009 Page 4 of 5 APPROVED _____________________________________________________________________________________________________________________________ ____ Figure Q4 Simulation of Supply Chain for Tubular Pipes TAS/19.03.04 _________________________________________________________________________________________________________________________________ Date & Duration of Exam: May 2004, 2-1/2 Hours Course Title: Course Code: Supply Chain Management PROD 1009 Page 5 of 5