NR-220302-Metallurgy and Material Science

advertisement

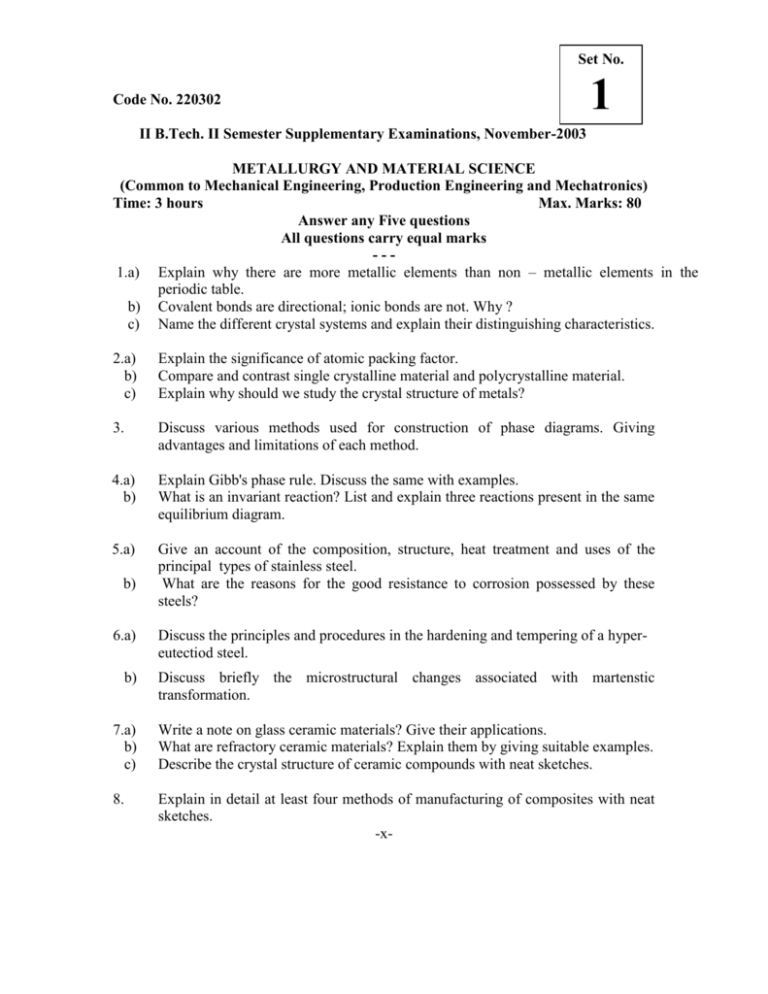

Set No. Code No. 220302 1 II B.Tech. II Semester Supplementary Examinations, November-2003 METALLURGY AND MATERIAL SCIENCE (Common to Mechanical Engineering, Production Engineering and Mechatronics) Time: 3 hours Max. Marks: 80 Answer any Five questions All questions carry equal marks --1.a) Explain why there are more metallic elements than non – metallic elements in the periodic table. b) Covalent bonds are directional; ionic bonds are not. Why ? c) Name the different crystal systems and explain their distinguishing characteristics. 2.a) b) c) Explain the significance of atomic packing factor. Compare and contrast single crystalline material and polycrystalline material. Explain why should we study the crystal structure of metals? 3. Discuss various methods used for construction of phase diagrams. Giving advantages and limitations of each method. 4.a) b) Explain Gibb's phase rule. Discuss the same with examples. What is an invariant reaction? List and explain three reactions present in the same equilibrium diagram. 5.a) Give an account of the composition, structure, heat treatment and uses of the principal types of stainless steel. What are the reasons for the good resistance to corrosion possessed by these steels? b) 6.a) Discuss the principles and procedures in the hardening and tempering of a hypereutectiod steel. b) Discuss briefly the microstructural changes associated with martenstic transformation. 7.a) b) c) Write a note on glass ceramic materials? Give their applications. What are refractory ceramic materials? Explain them by giving suitable examples. Describe the crystal structure of ceramic compounds with neat sketches. 8. Explain in detail at least four methods of manufacturing of composites with neat sketches. -x- Set No. 2 Code No. 220302 II B.Tech. II Semester Supplementary Examinations, November-2003 METALLURGY AND MATERIAL SCIENCE (Common to Mechanical Engineering, Production Engineering and Mechatronics) Time: 3 hours Max. Marks: 80 Answer any Five questions All questions carry equal marks --Distinguish between the following: a) Phase and micro-constituent. b) Primitive cell and unit cell. c) Close packed plane and close packed directions. d) Crystalline and amorphous materials. 1. 2.a) b) c) Discuss the characteristics of the unit cells of simple cubic and tetragonal type . Explain the Schottky defects fully with the help of a neat sketch. Explain the term ‘MOTIF’. 3.a) b) Write an explanatory notes on solidification of metals. Discuss various methods used for production of fine-grained materials. 4.a) State and explain Hume-Rothery rules for formation of substitutional solid solutions. What is lever rule? Explain how it is useful. b) 5. Discuss the purpose of adding the following alloying elements to steels: (a) nickel (b) chromium (c) manganese. Give the composition and engineering applications of three alloy steels (one example from each of the above alloy types). 6. a) b) c) Discuss the properties and applications of beryllium bronzes. Give an account of the red brasses. What are the typical applications of titanium and its alloys? 7. Describe (i) Dielectric ceramics (ii) Ferro-electric ceramics (iii) Piezo-electric ceramics and (iv) Semi-conductor ceramics. 8.a) Write briefly about the ways of occurrence of the cohesion between the matrix and the reinforcement . Explain the principle of reinforced composite materials by illustrating the crack propagation with neat sketches. What is rule of mixtures? How is it useful in analyzing the strength of the composite? -x- b) c) Set No. Code No. 220302 3 II B.Tech. II Semester Supplementary Examinations, November-2003 METALLURGY AND MATERIAL SCIENCE (Common to Mechanical Engineering, Production Engineering and Mechatronics) Time: 3 hours Max. Marks:80 Answer any Five questions All questions carry equal marks --1.a) Name various types of inter atomic bonds by giving two examples for each one of them. b) Give axial and angular relationships of the various crystal structures. c) Calculate the radius of an atom of a crystal with a body centered cubic structure and a lattice constant of 4 A.U. 2. Write short notes on the following (a) Tetrahedral void (b) Octahedral void (c) Frenkel defect (d) Partial dislocations. 3.a) Briefly explain the classification of phase diagrams based on the solubility in liquid and solid states. What is monotectic reaction? Explain with an example. b) 4.a) b) 5.a) b) Briefly explain why, upon solidification, an alloy of eutectic composition forms a micro structure consisting of alternating layers of the tow solid phases. Differentiate between interstitial solid solution and substitutional solid solution. What is meant by hardenability of steels? Explain one important technique to determine the same. How do process annealing, stress relief annealing and spheroid zing differ from full annealing? 6.a) b) c) Discuss the properties and applications of pure copper. Compare red-brasses with yellow brasses. Discuss in brief, the properties and applications of aluminium alloys. 7.a) What are ceramic magnets? What are its characteristics? What is their composition? Explain the steps involved in the manufacture of ceramic magnets? Give the classification of ceramic magnetic materials and give their applications. b) 8.a) b) c) Explain the terms: Matrix, Reinforcement and Interface. Write their respective functions. Distinguish between natural composites and man-made composites. Classify the composites according to (i) the geometry of the load-bearing components. (ii) the materials used i.e., type of reinforcement and type of matrix. -x- Set No. Code No. 220302 4 II B.Tech. II Semester Supplementary Examinations November, 2003 METALLURGY AND MATERIAL SCIENCE (Common to Mechanical Engineering, Production Engineering and Mechatronics) Time: 3 hours Max. Marks:80 Answer any Five questions All questions carry equal marks --1.a) Describe with the aid of sketches about the mechanism of crystallization of pure metals. b) Draw the cooling curve for a long freezing range alloy and explain the salient points in it. 2.a) b) 3.a) b) Sketch the unit cells of the following (i) Body Centred Cubic (ii) Base centred Ortho Rhombic (iii) Simple triclinic . Give their unit cell specifications. How does the length of the bond affects the physical and mechanical properties of materials ? Explain with specific examples. Explain the meaning of the term 'cored dendritic structure' as applied to solid solution alloys. Describe how the cored structure is formed when such an alloy is cooled. What are the disadvantages, if any, of this type of structure? Outline the methods used to eliminate dendritic coring. 4.a) b) Discuss the effect of the amount of free carbon on the properties of gray cast iron. Differentiate, in microstructure, gray cast iron, malleable iron, and nodular iron. 5.a) b) Name the important properties of titanium. Give the composition, special properties, and one application of the following iron-nickel alloys: Invar, Kovar, Platinite , and Elinvar. 6. Give comparative accounts on the following: (a) Austempering and martempering (b) Isothermal and continuous cooling T-T-T diagrams (c) Full annealing and process annealing (d) Stages of tempering. 7.a) b) c) List out and explain the properties of ceramic magnetic materials. What factors affect the properties of ceramic materials? Explain. Write a short note on Partially Stabilized Zirconia (PSZ). 8.a) b) c) d) Define composite materials. What unique properties have they over the conventional materials? How do the composite materials differ from metallic alloys? Mention some composite materials with their applications. Give their properties. -x-