Worcester Polytechnic Institute

advertisement

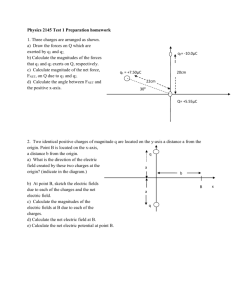

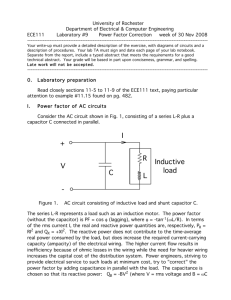

ECE2019 Sensors, Circuits, and Systems A 2013 Lab #3: Capacitive Sensing Introduction This lab involves construction of capacitors and measurement of behavior when capacitance is used as a “touch” sensor. Materials you will need from TA (to be returned at end of lab period): Insulating FR-4 material Copper foil tape Clear insulating tape 1 Prelab All of your prelab work is to be done in your laboratory notebook and will be checked by a lab TA prior to the start of lab. Parallel Plate Capacitor Figure 1. Parallel plate capacitor P1. Calculate the capacitance in pF you would expect to see from the parallel plate capacitor in Figure 1 with dimensions W = L = 1 inch and dielectric thickness d = 0.1 mm. Assume a dielectric with r = 1 so = 0 = 8.85E-12 F/m. (Caution: be sure to use consistent units!) 2 Measuring Capacitance One way to measure capacitance is to apply a voltage step to an RC circuit with a known resistance R and observe the step response in the time domain. Figure 2a shows one approach using a lowpass RC circuit; the delay tD from the VSTEP transition to the 50% point of the vC waveform can be used to determine the capacitance if R is known. Figure 2b shows another approach using a highpass RC circuit; in this case the pulse width tW at the 50% point of the vR waveform can be used to determine the capacitance if R is known. Figure 2a. Step response of RC lowpass. Figure 2b. Step response of RC highpass. P2. For the circuit of Figure 2a, find an equation providing C, given R and tD. For the circuit of Figure 2b, find an equation providing C, given R and t W. In each case, for R = 10kΩ and C = 100pF, find the value you would expect for tD and tW. 3 Lab L1. Parallel Plate Capacitance To construct a parallel plate capacitor, use copper foil as the plate and insulating clear plastic tape as the dielectric as shown in Figure 3. As a supporting mechanical substrate, use a small piece of insulating FR-4 material. (The copper foil, clear tape, and FR-4 material will be available from the lab TAs) Be sure when constructing the capacitor that the clear tape completely covers the area where the plates overlap, so that the plates are not shorted together. Figure 3a. Parallel Plate Capacitor: Perspective View 4 Figure 3b. Parallel Plate Capacitor: Top View TO R, VSTEP Using the procedure from prelab part P2, measure the capacitance of this parallel plate capacitor. Use both highpass and lowpass techniques. Compare the results to the estimate from prelab part P1. If there is a disagreement, think of as many reasons as you can that might explain the discrepancy. Note that amplitude of the VSTEP waveform does not appear your equations from prelab part P2. In theory, this means you could use any amplitude waveform to make your measurements. Try your procedure with a 5V amplitude and a 50mV amplitude for VSTEP. In practice, how does the VSTEP amplitude affect measurement accuracy? 5 L2. Response for Sinusoidal Signals In the circuits of Figures 2a and 2b, change the input signal to a sine wave. Then the output will also be a sine wave of the same frequency, but scaled in amplitude and shifted in time. Figure 4a. Sine wave response of RC lowpass. AN EXTREMELY IMPORTANT PROPERTY OF A LINEAR SYSTEM IS THAT A SINE WAVE INPUT GIVES YOU A SINE WAVE OUTPUT AT THE SAME FREQUENCY, SCALED IN AMPLITUDE AND SHIFTED IN TIME. To describe the amplitude scaling, we will look at the ratio of the output amplitude over the input amplitude; this is called the magnitude response. To describe the time shift, we will represent the time delay from input to output in degrees as a fraction of the 360° full period of the sine wave; this is called the phase response. The variation in magnitude and phase response as a function of frequency is described by the TRANSFER FUNCTION which is a very important way of describing the frequency domain behavior of a linear system. It turns out the frequency domain behavior is related to the time domain behavior as you have already measured in the step response – but more about that in class and later labs. 6 Lowpass magnitude and phase Measure the magnitude and phase response for the RC lowpass shown in Figure 4a. Space the measurement frequencies logarithmically (that is, in a 1:3:10 ratio, or maybe 1:2:5:10 near interesting frequencies). Use the table format shown below (you will need more rows!) and cover a frequency range of at least 100Hz to 10MHz. Figure 4a. Sine wave response of RC lowpass. MEASURED FREQ AMPLITUDE CALCULATED DELAY MAGNITUDE MAGNITUDE PERIOD PHASE (dB) f vin vout td v out v in v 20 log out v in 7 T 1 f t 360 d T Highpass magnitude and phase Measure the magnitude and phase response for the RC highpass shown in Figure 4b. Again, space the measurement frequencies logarithmically (that is, in a 1:3:10 ratio, or maybe 1:2:5:10 near interesting frequencies). Use the table format shown below (you will need more rows!) and cover a frequency range of at least 100Hz to 10MHz. Figure 4b. Sine wave response of RC highpass. MEASURED FREQ AMPLITUDE CALCULATED DELAY MAGNITUDE MAGNITUDE PERIOD PHASE (dB) f vin vout td v out v in v 20 log out v in 8 T 1 f t 360 d T Optional: Try some different configurations for the foil-tape-foil arrangement. For example, place the foil on opposite sides of the FR-4 (increase plate separation d) or increase the overlapping area A. Go back to the step response technique, measure the capacitance, and see if it changes the way you expect. Try to build your intuition toward larger and closer areas corresponding to stronger electric field coupling and increased capacitance. L3. Capacitive Touch Sensor Carefully disassemble your parallel plate capacitor and reconfigure the copper foil as shown in Figure 5 below. Figure 5. Capacitor for Touch Sensor Side View Top View TO R, VSTEP In this case the capacitor plates are still parallel, but now are adjacent to each other rather than overlapping. As a result you should measure a lower capacitance when you use the step response procedure of prelab P2. 9 The principle of the touch sensor is shown in Figure 6. Figure 6a shows the electric field lines for the two plates with no fingertip present. Since the plates do not overlap, we can’t use the C=A/d equation. Instead, some fields math is required, but the form of the equation that results is similar: the distance of the field lines between the plates is in denominator of the equation. So, in figure 6a, the effective distance between the plates is relatively large and the capacitance (let’s call it Cp) is lower. When a fingertip is present, as shown in Figure 6b, the low internal resistance of the body effectively acts as a new capacitor plate, and we have a series connection of two parallel plate capacitors C1 and C2, which are approximately equal. More importantly both C1 and C2 are much greater than Cp. The total capacitance of C1 and C2, represented by CT is greater than Cp. Measuring the difference gives an indication that contact is being made. Figure 6. Principle of Capacitive Touch Sensor (a) (b) Try measuring the capacitance change in both the high-pass and low-pass methods. 10 Lab Writeup W1. Capacitance Measurement Present your calculations from parts P1 and P2, as well as your measured results from part L1. Comment on any interesting aspects of the measured data. In particular, comment on the effect of VSTEP amplitude on measurement accuracy. W2. Sinusoidal Response Measurement Present your frequency response measurements for the lowpass and highpass circuits. Comment on any interesting aspects of the measured data. In particular, comment on the measured performance relative to the expected performance from the transfer function for the RC lowpass and highpass, as well as the relationship between the time domain and frequency domain responses. W3. Capacitive Touch Sensor Present your measured results from part L2. Comment on any interesting aspects of the measured data, in particular the change in capacitance from the no-contact to contact conditions. How big a change is this? How easy is it to detect? How sensitive to detection was pressure on the fingertip, or accuracy of fingertip position? Do you prefer the high-pass or low-pass method of measurement – is there an advantage to one or the other? 11