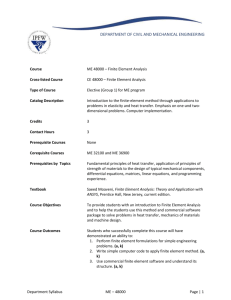

CHAPTER III

advertisement

CHAPTER III FINITE ELEMENT ANALYSIS 3.1 Introduction Finite element method has developed along with the increasing use of highspeed electronic digital computers and with the growing emphasis on numerical methods for engineering analysis. Although the method was originally developed for structural analysis, the general nature of the theory on which it is based has also made possible its successful application for solutions of problems in other fields of engineering. 3.2 Background and Applications It is not possible to obtain analytical mathematical solutions for many engineering problems. An analytical solution is a mathematical expression that gives the values of the desired unknown quantity at any location in a body, and as a consequence it is valid for an infinite number of locations in the body. Analytical solutions can be obtained only for certain simplified situations. For problems involving complex material properties and boundary conditions, engineer resorts to numerical methods that provide approximate, but acceptable solutions. In most of numerical methods, the solutions yield approximate values of the unknown quantities only at a discrete number of points in the body. The process of selecting only a certain number of discrete points in the body can be termed discretisation. One of 31 the ways to discretise a body or a structure is to divide it into an equivalent system of smaller bodies, or units. The assemblage of such units then represents the original body. Instead of solving the problem for the entire body in one operation, the solutions are formulated for each constituent unit and combined to obtain the solution for the original body or structure. This approach is known as going from part to whole. Although the analysis procedure is thereby considerably simplified, the amount of data to be handled is dependent upon the number of smaller bodies into which the original body is divided. For a large number of subdivisions it is a formidable task to handle the volume of data manually, and recourse must be made to automatic electronic computation. Many of the numerical methods developed before the era of electronic computers are now adapted for use with these machines. Perhaps the best known is the finite difference method. Other types of classical methods that have been adapted to modern computation are such residual methods as the method of least squares and such variational methods as the Ritz method. In contrast to the techniques mentioned above, finite element method is essentially a product of the electronic digital computer age. Therefore, although the approach shares many of the features common to the previous numerical approximations, it possesses certain characteristics that take advantage of the special facilities offered by the high-speed computers. In particular, the method can be systematically programmed to accommodate such complex and difficult problems as nonhomogeneous materials, nonlinear stress-strain behaviour, and complicated boundary conditions. It is difficult to accommodate these complexities in the methods mentioned above. Another favourable aspect of the finite element method is the variety of levels at which we may develop an understanding of the technique. One may take a very physical or intuitive approach to the learning and using of the method. This approach is similar to the extension of the familiar concepts of the analysis of framed structures as one-dimensional bodies to problems involving twoand three-dimensional structures. On the other hand, one may develop a rigorous mathematical interpretation of the method. In this volume we shall steer a middle course with a slant toward the intuitive or physical approach. 32 Finite element method is applicable to a wide range of boundary value problems in engineering. In a boundary value problem, a solution is sought in the region of the body, while on the boundaries (or edges) of the region the values of the dependent variables (or their derivatives) are prescribed. Since the majority of the applications of the method is in the realm of solid mechanics (including structural, soil, and rock mechanics), the descriptions in this volume are presented primarily in terms of these fields of study. Problems in these fields are usually tackled by one of three approaches: the displacement method, the equilibrium method, or the mixed method. Displacements are assumed as primary unknown quantities in the displacement method; stresses are assumed as primary unknown quantities in the equilibrium method; and some displacements and some stresses are assumed as unknown quantities in the mixed method. 3.3 General Description of the Method In brief, the basis of finite element method is the representation of a body or a structure by an assemblage of subdivisions called finite elements (Figure 3.1). These elements are considered interconnected at joints which are called nodes or nodal points. Figure 3.1: Two-dimensional region represented as an assemblage of triangular elements 33 Simple functions are chosen to approximate the distribution or variation of the actual displacements over each finite element. Such assumed functions are called displacement functions or displacement models. The unknown magnitudes or amplitudes of the displacement functions are the displacements (or the derivatives of the displacements) at the nodal points, Figure 3.2. Hence, the final solution will yield the approximate displacements at discrete locations in the body, the nodal points. A displacement model can be expressed in various simple forms, such as polynomials and trigonometric function. Since polynomials offer ease in mathematical manipulations, they have been employed commonly in finite element applications. Figure 3.2: Isometric view of triangular element with linear displacement model plotted in the third dimension 3.4 Summary of the Analysis Procedure The following six steps summarise finite element analysis procedure: 1. Discretisation of the continuum. The continuum is the physical body, structure, or solid being analysed. Discretisation may be simply described as the process in which the given body is subdivided into an equivalent system of finite elements. The finite elements may be triangles, groups of triangles, or quadrilaterals for a twodimensional continuum. For three-dimensional analysis, the finite elements may be tetrahedral, rectangular prism, or hexahedra. The effectiveness of 34 continuum analysis is depends to the number, size, and arrangement of finite elements. 2. Selection of the displacement models. The assumed displacement functions or models represent only approximately the actual or exact distribution of the displacements. Obviously, it is generally not possible to select a displacement function that can represent exactly the actual variation of displacement in the element. Hence, the basic approximation of the finite element method is introduced at this stage. 3. Derivation of the element stiffness matrix using a variational principle. The stiffness matrix consists of the coefficients of the equilibrium equations derived from the material and geometric properties of an element and obtained by use of the principle of minimum potential energy. The stiffness relates the displacements at the nodal points (the nodal displacements) to the applied forces at the nodal points (the nodal forces). The distributed forces applied to the structure are converted into equivalent concentrated forces at the nodes. The equilibrium relation between the stiffness matrix k , nodal force vector Q, and nodal displacement vector qis expressed as a set of simultaneous linear algebraic equation, k q Q 4. Assembly of the algebraic equations for the overall discretised continuum. This process includes the assembly of the overall or global stiffness matrix for the entire body from the individual element stiffness matrices, and the overall or global force or load vector from the element nodal force vectors. The most common assembly technique is known as the direct stiffness method. In general, the basis for an assembly method is that the nodal interconnections require the displacements at a node to be same for all elements adjacent to that node. The overall equilibrium relations between the total stiffness matrix K , the total load vector R, and the nodal displacement vector for the entire body rwill again be expressed as a set of simultaneous equation. K r R These equations cannot be solved until the geometric boundary conditions are taken in account by appropriate modification of the equations. A geometric 35 boundary condition arises from the fact that displacements may be prescribed at the boundaries or edges of the body or structure. 5. Solutions for the unknown displacements. The algebraic equations assembled in step 4 are solved for the unknown displacements. In linear equilibrium problems, this is a relatively straightforward application of matrix algebra techniques. However for nonlinear problems the desired solutions are obtained by a sequence of steps, each step involving the modification of the stiffness matrix and/or load vector. 6. Computation of the element strains and stresses from the nodal displacements. In certain cases the magnitudes of the primary unknowns, that is the nodal displacements, will be all that are required for an engineering solution. More often, however, other quantities derived from the primary unknowns, such as strains and/or stresses, must be computed. 3.5 Advantages of Finite Element Method Like all numerical approximations, finite element method is based on the concept of discretisation. Nevertheless, as either a variational or residual approach, the technique recognizes the multi-dimensional continuity of the body. Not only does the idealisation portray the body as, continuous, but it also requires no separate interpolation process to extend the approximate solution to every point within the continuum. Despite the fact that a solution is obtained at a finite number of discrete node points, the formulation of the field variable models inherently provides a solution at all other locations in the body. In contrast to other variational and residual approaches, the finite element method does not require trial solutions which must all apply to the entire multidimensional continuum. The use of separate subregions, or finite elements, for the separate trial solutions thus permits a greater flexibility in considering continua of complex shape. 36 Some of the most important advantages of the finite element method derive from the techniques of introducing boundary conditions. This is another area in which the method differs from other variational or residual approaches. Rather than requiring every trial solution to satisfy the boundary conditions, one prescribes the conditions after obtaining the algebraic equations for the assemblage. Since the boundary conditions do not enter into the equations for the individual finite elements, one can use the same field variable models for both internal and boundary elements. Moreover, the field variable models need not be changed when the boundary conditions change. The introduction of boundary conditions into the assembled equations is a relatively easy process. It is simplified in that only the geometric boundary conditions need be specified in a variational approach because the natural conditions are implicitly satisfied. No special techniques or artificial devices are necessary, such as the non-centred difference equations or fictitious external points often employed in the finite difference method. Finite element method not only accommodates complex geometry and boundary conditions, but it also has proven successful in representing various types of complicated material properties that are difficult to incorporate into other numerical methods. For example, formulations in solid mechanics have been devised for anisotropic, nonlinear, hysteretic, time-dependent, or temperaturedependent material behaviour. One of the most difficult problems encountered in applying numerical procedures of engineering analysis is the representation of nonhomogeneous continua. Nevertheless, the finite element method readily accounts for nonhomogeneity by the simple tactic of assigning different properties to different elements. If a refined representation of the variation of material characteristics is desired, it is even possible to vary the properties within an element according to a preselected polynomial pattern. For instance, it is possible to accommodate continuous or discontinuous variations of the constitutive parameters or of the thickness of a two-dimensional body. 37 The systematic generality of the finite element procedure makes it a powerful and versatile tool for a wide range of problems. As a result, flexible general-purpose computer programs can be constructed. Primary examples of these programs are the several structural analysis packages, which include a variety of element configurations and which can be applied to several categories of structural problems. Another indicator of the generality of the method is that programs developed for one field of engineering have been applied successfully to problems in a different field with little or no modification. Finally, an engineer may develop a concept of the finite element method at different levels. It is possible to interpret the method in physical terms. On the other hand, the method may be explained entirely in mathematical terms. The physical or intuitive nature of the procedure is particularly useful to the engineering student and practicing engineer. Nevertheless, it is significant that the method has mathematical foundations. 3.6 Limitations One limitation of finite element method is that a few complex phenomena are not accommodated adequately by the method at its current state of development. Some examples of such phenomena from the realm of solid mechanics are cracking and fracture behaviour, contact problems, bond failures of composite materials, and nonlinear material behaviour with work softening. Another example is transient, unconfined seepage problems. The numerical solution of propagation or transient problems is not satisfactory in all respects. Many of these phenomena are presently under research, and refinements of the method to accommodate these problems better can be expected. Finite element method has reached a high level of development as a solution technique; however, the method yields realistic results only if the coefficients or material parameters which describe the basic phenomena are available. Material nonlinearity in solid mechanics is a notable example of a field in which our 38 understanding of the material behaviour has lagged behind the development of the analytical tool. In order to exploit fully the power of the finite element method, significant effort must be directed toward the development of suitable constitutive laws and the evaluation of realistic coefficients and material parameters. Even the most efficient finite element computer codes require a relatively large amount of computer memory and time. Hence, use of the method is limited to those who have access to relatively large, high-speed computers. The advent of time-sharing, remote batch processing, and computer service bureaus or utilities has alleviated this restriction to some degree. In addition, the method can be applied indirectly to common engineering problems by utilizing tables, graphs, and other analysis aids that have been generated by finite element codes. The most tedious aspects of the use of the finite element method are the basic processes of subdividing the continuum and of generating error-free input data for the computer. Although these processes may be automated to a degree, they have not been totally accomplished by computer because some engineering judgment must be employed in the discretisation. Errors in the input data may go undetected and the erroneous results obtained therefrom may appear acceptable. Consequently, it is essential that the engineer/programmer provide checks to detect such errors. In addition to checks internal to the code, an auxiliary routine that reads the input data and generates a computer plot of the discretised continuum is desirable. This plot permits a rapid visual check of the input data. Finally, as for any approximate numerical method, the results of a finite element analysis must be interpreted with care. We must be aware of the assumptions employed in the formulation, the possibility of numerical difficulties, and the limitations in the material characterizations used. A large volume of solution information is generated by a finite element routine, but this data is worthwhile only when its generation and interpretation are tempered by proper engineering judgment. 39 3.7 Nonlinear Finite Element Analysis (NLFEA) Linear models provide satisfactory approximations for many problems of practical interest. However, substantial departure from linearity is common. In structural mechanics, material may yield or creep; local buckling may arise; gaps may open or close. Nonlinear problems pose the difficulty of describing phenomena by realistic mathematical and numerical models and the difficulty of solving nonlinear equations that result. Effort required of the analyst increases substantially when a problem becomes nonlinear. Computational cost may also be a concern, despite the growing capability of computers. Nevertheless, nonlinear analyses are undertaken more and more often because software has become more capable and more widely available, computational costs have declined, more demands are placed upon structures, and more understanding of manufacturing processes is required. In structural mechanics, types of nonlinearity include the following: Material nonlinearity, in which material properties are functions of the state of stress or strain. Examples include nonlinear elasticity, plasticity, and creep. Contact nonlinearity, in which a gap between adjacent parts may open or close, the contact area between parts changes as the contact force changes, or there is sliding contact with frictional forces. Geometric nonlinearity, in which deformation is large enough that equilibrium equations must be written with respect to the deformed structural geometry. Also, loads may change direction as they increase, as when pressure inflates a membrane. There are two commonly-used methods available for solving nonlinear problems which are Newton-Raphson and Modified Newton Raphson. Both methods are using different approaches to solve the problems. It is depends to one’s to determine which method is the more suitable in certain condition. There are a variety of finite element software packages (such as COSMOS/M, LUSAS, DIANA, STAAD and ABAQUS) which were developed with the material and geometrical nonlinearity capabilities for nonlinear finite element 40 analysis (NLFEA) of structural problems. The material properties of mortar and steel can be modelled nonlinearly into the software package to represent the materials behaviour. In this study, COSMOS/M has been used to analyse the models. In nonlinear finite element analysis, tensile cracking, compressive response of concrete and the yielding of the steel are the primary nonlinear characteristic studied by past researchers. The most important aspect in this NLFEA is the formation of mortar tensile crack and the stress distributions after cracking. In NLFEA of mortar, its behaviour is dominated by mortar tensile crack, followed by mortar crushing and yielding of reinforcement. The mortar crushing and yielding of steel occur in a later stage to precipitate the final collapse of the structure. In this study, four types of models have been analysed by using similar material properties from past researches. Geometrical characteristics, material response, and properties of elements are the main consideration in modelling, because this will affect the convergence of the NLFEA solution (Kadir, 2000). 3.8 Nonlinear Finite Element Analysis Procedures Generally, the NLFEA procedures of structural elements can be divided into several steps as follows: Geometric modelling into finite elements Geometric characteristics for finite element meshing Material response characteristic for element Properties assigned to finite element models Calibrating model and checking analysis at linear state Force increment modelling Numerical modelling Computational modelling 41 Termination of NLFEA NLFEA output and results interpretation 3.8.1 Finite Element Meshing for Mortar Several types of elements can be used in COSMOS/M finite element software for structural nonlinear finite element analysis. The ferrogrout I-beams were modelled in three dimensions (3D), with the steel modelled as truss element. Only 3D 8-Node Solid Element (SOLID) and 3D Truss Element (TRUSS3D) had been used to model the mortar and steel members respectively. Three translation degrees of freedom per node (3 DOF) have been considered for both types of element. Simple elements have been used with minimum nodes in each finite element models. In the models, perfect bonding between steel members and mortar are assumed by sharing the same nodes. All steel members except the wire and chicken mesh are modelled for the I-beams analyses. These analyses of I-beams are as follows: 1) Series 1 – Full model without skeletal steel and reinforcement. 2) Series 2 – Full model with skeletal steel but without reinforcement. 3) Series 3 – Full model with skeletal steel and reinforcement (2T12 at the top and bottom of beams). 4) Series 4 – Full model with skeletal steel and reinforcement (4T12 at the top and bottom of beams). 42 3.8.2 Material Response Characteristics for Element Similar material response characteristics for ferrogrout and steel elements had been developed for all the models. The material properties of ferrogrout and reinforced steels as shown below have been used. Characteristic strength of ferrogrout, fc = 40 N/mm2 Maximum tensile strength of ferrogrout, ft = 8.28 N/mm2 Modulus of elasticity of ferrogrout, Eo = 23 kN/mm2 Poisson’s ratio of ferrogrout, vf = 0.2 Characteristic strength of skeletal steel, fy’ = 485 N/mm2 Characteristic strength of reinforcement, fy = 460 N/mm2 Modulus of elasticity of steel (tension and compression), Es = 200 kN/mm2 Poisson’s ratio of steel, vs = 0.3 3.8.2.1 Ferrogrout Element Naaman (1979) declared that the design of ferrogrout for compression or tension is very simple. It is generally assumed that the ultimate tensile resistance of ferrogrout is equal to that of the mesh reinforcement in the direction of loading and that the compressive strength of the composite is about equal to that of the unreinforced mortar. Sabnis (1979) also stated compression strength of composite (ferrogrout) is generally a function of the matrix (mortar) compressive strength, while the tensile strength is a function of the mesh content and its properties. Thus, the stress-strain relationship of ferrogrout intension may show either a complete elastic behaviour (up to fracture of reinforcing mesh) or some inelasticity depending upon the yielding properties of the mesh. Basunbul et al (1984) indicated that a ferrogrout beam acts more like a steel member than reinforced concrete and hence ferrogrout is considered as a steel member than reinforced concrete (material exhibiting cracking etc.) and steel (an 43 elasto-plastic homogenous material with large ductility and resilience). Ferrogrout is considered to be the ‘missing link’ between steel and reinforced concrete. As a conclusion of efforts from past researches, the uniaxial stress-strain relationship from Omar et al (1988) was adopted in this study as shown in Figure 3.3. Figure 3.3: Typical stress-strain diagram of ferrogrout (Not to scale) The trilinear stress-strain idealisation of ferrogrout behaviour in tension was first presented by Walkus (1979) and later many investigators observed the same behaviour. Thus the ferrogrout behaviour in tension can be idealised into four distinct stages as follows: 1) Elastic stage The incremental axial stress-strain relationship in this stage is given as f Ei 44 2) Cracking stage This stage starts when the axial stress reaches f1, the tensile strength of mortar. Cracking is taken into account by altering the value of E, thus in this case f ET 3) Wire mesh yielding stage As the axial stress reaches f2, the wire-mesh starts to yield. No strain hardening is assumed and plastic flow continues until the tensile strain reaches a limiting value tu. 4) Wire-mesh rupture When the axial strain reaches tu, rupture of wire mesh is assumed to occur and ferrogrout stress is reduced to zero. Table 3.1 shows the ferrogrout materials properties adopted by Omar et al. Table 3.1: Properties of ferrogrout (Omar et al., 1988) Ferrocement Initial Tangent Cracking Yielding material modulus modulus stress stress layers Ei (N/mm2) ET (N/mm2) f1 (N/mm2) f2 (N/mm2) 2 18000 615 3.34 4.14 3 19500 900 3.42 6.21 4 23000 1100 3.53 8.28 In this study, a user-defined stress-strain curve is formulated by the stressstrain data as shown in Appendix A to represent the ferrogrout material properties. The ferrogrout material with 4 layers was chosen due to the similar condition with the I-beam cast in laboratory. The MPC TYPE and MPC commands have been used during the input data process. 3.8.2.2 Steel Element The deformation response of steel elements (skeletal steel and reinforcement) can be represented by a bilinear curve in tension and compression as shown in Figure 45 3.4. This relationship is similar to the recommendation in BS 8110: Part 1 except for the second linear curve, which has been given a slight stiffening to avoid numerical instabilities associated with zero stiffness (Kotsovos, 1984). Stress Tension Ep 0.87fy 1 Es 1 Strain 0.87fy Compression Figure 3.4: Short-term stress-strain curve for steel elements (BS8110: Part 2: 1985) The first linear curve presents the elastic properties while the second linear curve consists of post elastic behaviour. The modulus of elasticity at strain hardening of steel, Ep is taken as 2.5% of Es. Modulus of elasticity, Es and Poisson ratio used for all reinforcements is 200kN/mm2 and 0.3 respectively. In the analysis, all reinforced steels were assumed to yield at 0.87fy and failed at the ultimate yield stress, fy at a later stage. For bilinear stress-strain curve definition, material parameters input SIGYLD and ETAN are made through the use of MPROP command. The SIGYLD and ETAN parameters for bilinear stress-strain curve described the yield stress and modulus of elasticity at strain hardening of steel, Ep. For this type of material, the use of Newton-Raphson iterative method was recommended. 46 3.9 Nonlinear Finite Element Analysis for Models There were totally four types of models had been modelled. For the purpose of controlling and verifying the result of I-beams models, a control model had been developed by using the same material response characteristic for ferrogrout. In NLFEA of control model, only ferrogrout was modelled and SOLID element had been used to model ferrogrout element. The purpose of setting up this control model was to determine the behaviour of ferrogrout without supported by skeletal steel. Models 1 to 3 were modelled similar to the samples that tested in the laboratory. Table 3.2 shows the description of models using NLFEA. Table 3.2: Description of model using NLFEA Beam Description Control Model Ferrogrout I-beam Model 1 Ferrogrout I-beam with skeletal steel. Model 2 Ferrogrout I-beam with skeletal steel and two reinforcement bars T12 in the top and bottom flanges. Model 3 Ferrogrout I-beam with skeletal steel and four reinforcement bars T12 in the top and bottom flanges. 3.9.1 Control Model For Control Model, SOLID 3D element had been used to model I-beam. The properties of ferrogrout as shown in Figure 3.3 were assigned to the model. The cross section and the geometry of I-beam were shown in Figure 3.5. The beam was simply supported and two point loads are applied symmetrically. 47 Figure 3.5: Beam cross section, structural geometry, boundary and loading condition for Control Model 3.9.2 Model 1 Model 1 consisted of ferrogrout I-beam and skeletal steel. SOLID 3D element had been used to model this I-beam while TRUSS 3D used to model the skeletal steel. The diameter of skeletal steel was 8mm. The cross section and the geometry of Model 1 were similar to Control Model and shown in Figure 3.6. Figure 3.6: Beam cross section, structural geometry, boundary and loading condition for Model 1 48 3.9.3 Model 2 Model 2 consisted of ferrogrout I-beam, skeletal steel, and reinforced steel. Two reinforcement bars were located at the top and the bottom of the beam. SOLID 3D element had been used to model this I-beam. Element TRUSS 3D was used to model the skeletal and reinforced steel. The diameter of skeletal steel was 8mm and the reinforcement was 12mm. The cross section and the geometry of Model 2 were shown in Figure 3.7. Figure 3.7: Beam cross section, structural geometry, boundary and loading condition for Model 2 3.9.4 Model 3 Model 3 was similar to Model 2. The only different was four reinforcement bars located at the top and the bottom of the beam. SOLID 3D element had been used to model this I-beam. Element TRUSS 3D was used to model the skeletal and reinforced steel. The cross section and the geometry of Model 3 were shown in Figure 3.8. 49 Figure 3.8: Beam cross section, structural geometry, boundary and loading condition for Model 3 3.10 Finite Element Modelling for Ferrogrout I-Beams In the modelling of these I-beams, the transverse skeletal steel was neglected due to this element has no significant function. This action can reduce the number of elements and the running time of programme without affecting the results. The point loads were applied to the I-beam symmetrically. The location of point loads was changed. This means the distance between the support and point load, a, is different in different type of beam analysis (Figure 3.5). Each model consisted of 14 beams with different location of point loads. 3.10.1 Load Increment Modelling for NLFEA Basically, there are three increment control techniques which could be used in COSMOS/M, that is Force Control, Displacement Control and Riks Arc-Length Control provided in COSMOS/M nonlinear finite element analysis. In this research, the Riks Arc-Length Control techniques had been used for NLFEA of all models. The loads are increased step-by-step depending on the arc-length parameter and the 50 structure was analysed for each loading increment. Modified Newton-Raphson Iteration had been used as the solution method to obtain the NLFEA failure load. 3.10.2 Riks Arc-Length Control In Riks Arc-Length Control technique, a special parameter was prescribed by constraint (auxiliary) equation, which was then added to the set of governing equations of the equilibrium of the system. In this technique, the load pattern was applied loads in proportional increment (using a single load multiplier) to achieve equilibrium under the control of a specified length (arc-length) in the equilibrium path. The arc-length will be automatically re-calculated by the program, where no “time” curve is required. The analysis was terminated if either one of these controls were exceeded: i) the maximum load-pattern multiplier Value used = 1x108 ii) the maximum value of any degree of freedom (DOF) Value used = 0.5 iii) the maximum number of arc steps Value used = 500 A large value has been used for these control parameters to avoid premature termination of the analysis before achieving the ultimate stage. During the NLFEA, the NL_AUTOSTEP command was used to activate the automatic stepping option with value of each parameter as shown below: i) Minimum step increment ii) Maximum step increment adjustment for any step 51 The command NL_AUTOSTEP will cause the analysis to be terminated if: i) the number of step-increment adjustments for any step exceeded 5 trials ii) the step-increment required for convergence becomes smaller than 1x10-8 In this research, all NLFEA were terminated when the number of stepincrement adjustments for any step exceeded 5 trials in the first run. The final run of NLFEA was carried out with the maximum arc step before analysis had been terminated at the first run. The termination in the first run will show “Negative Roots for Quadratic Equations”. 3.11 NLFEA Output and Interpretation of Results There were many types of NLFEA output available after the termination of analysis. The maximum displacement at the bottom of mid-span was the most important parameter required in this research. Other parameter was the displacement of the bottom surface under the load needed if larger than the displacement of midspan.