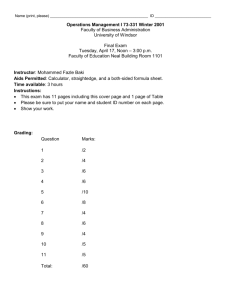

final02 - University of Toronto

advertisement

UNIVERSITY OF TORONTO

FACULTY OF APPLIED SCIENCE AND ENGINEERING

FINAL EXAMINATION, APRIL 2002

MIE363H1S - RESOURCE AND PRODUCTION MODELING

Exam Type: B

Examiner: D.M. Frances

A sheet of Formulas is provided.

20

1. A regional automotive parts wholesaler purchases catalytic converters from the

manufacturer for distribution to regional dealers and automotive repair shops. Annual

demand is constant at 100,000 units, carrying cost is $30 per unit per year, ordering cost

is $250 per order, orders are delivered without delay and backorders are not allowed.

The purchase cost is $200 per converter. For orders of at least 1,000 units the price is

reduced by 2%, for orders of at least 5,000 units the price is reduced by 3% and for orders

of at least 10,000 units the price is reduced by 3.5%. All reductions apply to the per-unit

cost of $200. Determine the ordering policy which minimizes the total cost per year.

20

2. The Gotham City Hospital (GCH) is in the process of studying the inventory policies of

its blood bank. Most of the time the daily blood demand is fairly steady at 440 units, but

for 21% of the days it jumps to 460 units, and for 15% of the days it dips to 420 units.

The carrying cost of blood is estimated at $2.25 per unit per year. Ordering is estimated at

$63 per order, and it takes 2 days before the order arrives. If GCH incurs a temporary

blood shortage it can receive “express” delivery at a cost of $1.50 per unit; these units are

then subtracted from the next order. How low should GCH allow its inventories to drop

before it reorders, and how much should it reorder?

20

3. Six chapters must be typed and proofed as soon as possible. Jack does the typing; Jill

does the proofing and correcting. Generally the typing takes longer than the proofing, but

some chapters are easier to type than to proof. The estimated time, in minutes, for each

activity is as follows:

Chapter

Typing

Proofing/Correcting

1

30

20

2

90

25

3

60

15

4

45

30

5

75

60

6

20

30

In what order should the chapters be processed? When can they expect to finish?

4. The Bill Deplant Company is planning an expansion program over the next 4 years. At

the beginning of period 1, the firm has a capacity of 100 units. The company estimates

that it should have at least a capacity of 120 units in year 2, 150 units in year 3, and 190

units in year 4. It takes a full year to construct the capacity expansion. During the

construction period only the existing production is accessible. The expansion costs in

2002 dollars are given in the table below:

From

100

120

150

120

1000

-

To

150

1800

1500

-

190

3000

3000

2000

The operating costs in 2002 dollars associated with running a plant of a given capacity at

a given level of demand are as follows:

Capacity

100

120

150

190

100

500

1200

1700

2500

Demand

120

150

1000

1600

1500

2400

2200

190

2000

Use Dynamic Programming to determine the optimal expansion plan.

5. The Yeasty Brewing Company produces a popular local beer known as Iron Stomach.

Beer sales are somewhat seasonal, and Yeasty is planning its production and manpower

levels on March 31st for the next six months. The demand forecasts are

Month

April

May

June

July

August

September

Production

Days

11

22

20

23

16

20

Forecast Demand

(in hundreds of cases)

85

93

122

176

140

63

As of March 31, Yeasty had 86 workers on the payroll. Over a period of 26 working days

when there were 100 workers on the payroll, Yeasty produced 12,000 cases of beer. The

cost to hire each worker is $125, and the cost of laying-off each worker is $300. Holding

costs amount to 75 cents per case per month. As of March 31st, Yeasty expects to have

4,500 cases of beer in stock, and it wants to maintain a minimum buffer inventory of

1,000 cases each month. It plans to start October with 3,000 cases in hand. Formulate the

linear program that minimizes Yeasty’s costs.

Formulas*

[D

Demand Variability

E(D)] 2

n

E(D)

i

For the backlog case, where x is the demand during the lead time (L) period:

r* Min{r | Pr(x r)

hq *

}

c B E(D)

For the lost sale case, where x is the demand during the lead time (L) period:

r* Min{r | Pr(x r)

hq *

}

hq * c LS E(D)

For the backlog case, where x is the demand during the period L+R, where L is the lead time and

R is the time between inventory reviews:

S* Min{S | Pr(x S)

Rh

}

cB

For the lost sale case, where x is the demand during the period L+R:

S* Min{S | Pr(x S )

Rh

}

Rh c LS

If D is a normally distributed demand in a period of length T, with mean D and variance D2,

then the demand over a period kT will be normally distributed with mean kD and variance kD2.

*Note: Not all formulas are relevant to the questions on the exam.