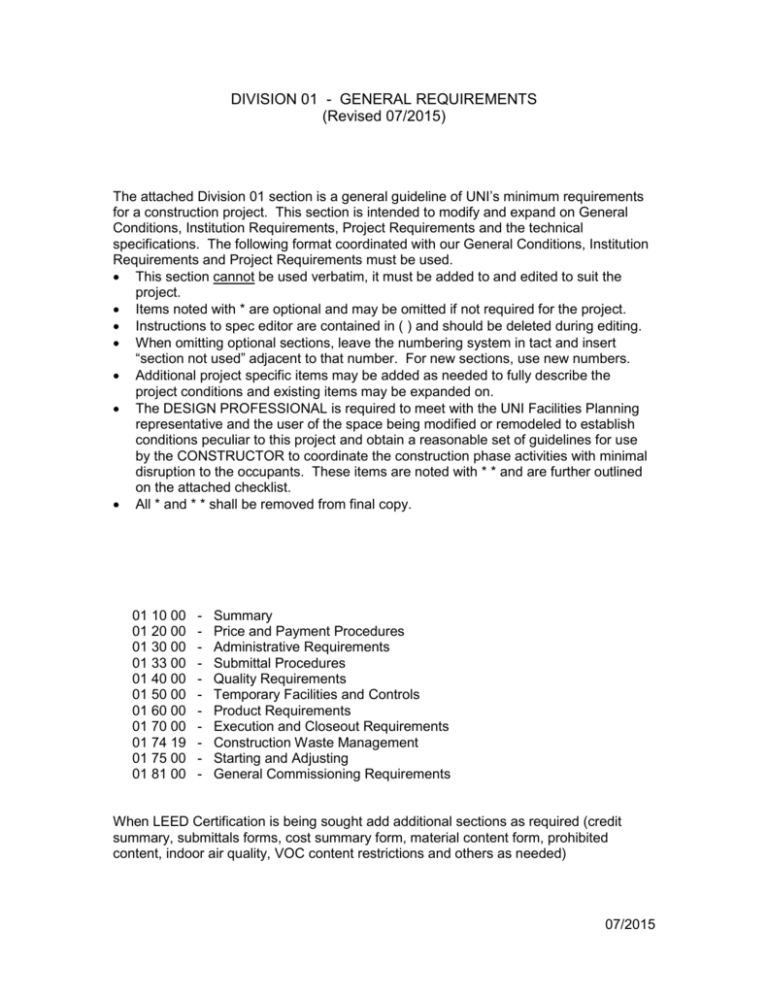

division i - general requirements - Administration and Finance website

advertisement