ENGR 435 Lab Manual

advertisement

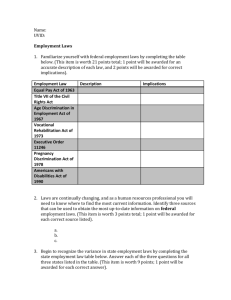

Manual for ENCH 435 PROCESS SYSTEMS LABORATORY Web site http://chem.engr.utc.edu/435 Dr. Jim Henry 425-4398 jim-henry@utc.edu College of Engineering and Computer Science University of Tennessee at Chattanooga Fall, 2001 Contents 1: 2: 3: 4: 5: Schedule Grading Objectives & Guidelines Project Information Assignments Appendices 2 3 6 8 18 25 1: SCHEDULE Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 Week 7 Week 8 Week 9 Week 10 Week 11 Week 12 Week 13 Week 14 Introduction Performance measurements, Statistics, Data acquisition software, Cleaning up Getting familiar with your system Making measurements, Analyzing data Reviewing operating instructions Giving presentations, Writing reports Getting familiar with your system Making measurements, Analyzing data Reviewing operating instructions Giving presentations, Writing reports Getting familiar with your system Making measurements, Analyzing data Reviewing and revising operating instructions Giving presentations, Writing reports Getting familiar with your system Making measurements, Analyzing data Reviewing and revising operating instructions Giving presentations, Writing reports Giving presentations, Turning in reports, Cleaning up If I treat you as you are, I will make you worse. If I treat you as though you are what you are capable of becoming, I help you become that. --Goethe Page 2 2: GRADING The grading in ENCH 435 will reflect what is observed of your understanding of process systems operation. Evidence of this understanding can be observed in your • ability to apply the principles to a physical system (performance in the laboratory and quality of results) • ability to interpret, describe and explain experimental and modeling work (reports and presentations) The weights given will be 40 points 30 points 30 points Physical laboratory (attendance, performance) Reports Presentations Lab work will be graded on this scale points for 0 points Leadership Participation Cooperation Contributions Creativity Teamwork Absent The semester grade will be determined by your point total 90-up A 80-89 B 70-79 C 65-69 D 0-64 F The following must be completed to receive a passing grade in the lab: 2 reports, 3 presentations, performance descriptions and a submitted report notebook. All work done will receive credit if it is submitted before the last scheduled lab meeting of the semester. Page 3 2. Grading Your evaluation this semester will be composed of five items as observed by the instructors and by self and peer assessments. Four different levels of assessments will be used. They are Exemplary; up to 100 points Proficient; up to 90 points Apprentice; up to 80 points Novice; up to 70 points The five items assessed by your instructors are 1. Apply knowledge of unit operations to the identification, formulation, and solution of engineering problems Exemplary will be awarded for each item if the following is true Student groups apply knowledge with virtually no conceptual or procedural errors affecting the quality of the experimental results. Proficient be awarded for each item if the following is true Student groups apply knowledge with no significant conceptual errors and only minor procedural errors. Apprentice will be awarded for each item if the following is true Student groups apply knowledge with occasional conceptual errors and only minor procedural errors. Novice will be awarded for each item if the following is true Student groups make significant conceptual and/or procedural errors affecting the quality of the experimental results. 2. Design and conduct experiments of engineering processes or systems Exemplary will be awarded for this item if the following is true Student groups design and conduct unit operations experiments with virtually no errors. Proficient will be awarded for this item if the following is true Student groups design and conduct experiment with virtually no errors. Apprentice will be awarded for this item if the following is true Student groups design and conduct experiment with no significant error. Novice will be awarded for this item if the following is true Student groups design and conduct experiments with major conceptual and/or procedural error. 3. Analyze and interpret data from engineering experiments Exemplary will be awarded for this item if the following is true Analysis and interpretation of results exceed requirements of experiment and demonstrate significant higher-order thinking ability. Proficient will be awarded for this item if the following is true Analysis and interpretation of results meet requirements of experiment and demonstrate some higher-order thinking ability. Apprentice will be awarded for this item if the following is true Results are analyzed but not interpreted; very limited evidence of higher-order thinking ability. Novice will be awarded for this item if the following is true No evidence of significant analysis and interpretation of results; fail to meet requirements of the experiment; demonstrate only lower-level thinking ability. Page 4 2. Grading 4. Demonstrate an ability to communicate effectively in oral presentations Exemplary will be awarded for this item if the following is true Presentation is virtually error-free, presents results and analysis logically, is well organized and easy to follow, contains high quality graphics, and articulates interpretation of results beyond requirements of the experiment. Proficient will be awarded for this item if the following is true Presentation presents results and analysis logically, is well organized and easy to follow, contains high quality graphics, contains few minor errors, and articulates interpretation of results which meets requirements of the experiment. Apprentice will be awarded for this item if the following is true Presentation is generally well done but contains some errors; analysis of results is mentioned but not fully developed. Novice will be awarded for this item if the following is true Presentation does not present results clearly, is poorly organized, and/or contains major errors; fails to articulate analysis of results meeting requirements of the experiment. 5. Demonstrate an ability to communicate effectively in writing Exemplary will be awarded for this item if the following is true Report is virtually error-free, presents results and analysis logically, is well organized and easy to read, contains high quality graphics, and articulates interpretation of results beyond requirements of the experiment. Proficient will be awarded for this item if the following is true Report presents results and analysis logically, is well organized and easy to read, contains high quality graphics, contains few minor grammatical and rhetorical errors, and articulates interpretation of results which meets requirements of the experiment. Apprentice will be awarded for this item if the following is true Report is generally well done but contains some grammatical, rhetorical and/or organizational errors; analysis of results is mentioned but not fully developed. Novice will be awarded for this item if the following is true Report does not present results clearly, is poorly organized, and/or contains major grammatical and rhetorical errors; fails to articulate analysis of results meeting requirements of the experiment. Credit and thanks to Dr. Ron Miller at Colorado School of Mines, for permission to use this table. It was distributed by Ron at the National ASEE Meeting, 1999, Charlotte, NC. Page 5 3: OBJECTIVES & GUIDELINES Objectives The main objectives of the laboratory experiences are to help you sharpen your skill in observing what happens to an engineering system and to accurately and completely describe what you observe. Guidelines on Safety, Cleanliness, Conservation, Citizenship We have had a number of years of experience with no lost-time injuries in this lab. Let's all do our part to make this year another one. In the event that someone is injured in the lab and is bleeding, before you help them, put on latex gloves that are available in the lab. Have someone show you where they are. These labs are not routinely cleaned by the custodial workers. We have to keep them clean ourselves. Always leave the lab cleaner when you leave than when you arrived. If the trash cans are full, set them in the hall to be emptied. If an empty trash can is outside the door, bring it into the lab. Around computer workstations, do not have food or drink. If you have food or drink elsewhere, please clean up your stuff. Recycle aluminum cans and Styrofoam containers. Rinse them first if there's grunge in them. Conserve resources and money by printing only what is necessary for effective learning. If you print something that you don't need, place the paper in the "one-side-good" recycle stack to be reused. (Put the good side up.) If you are printing a draft, please use paper from the "one-side-good" stack. Printers are not instantaneous. This lab has few printers and many users. During heavy use times, plan twice and print once. This will reduce frustrations. In the event you don't get a printout instantly, re-read this paragraph. If you have any suggestions to improve this lab, pass it on to an instructor or assistant. Page 6 3: Objectives & Guidelines Some other ways to look at course objectives from the professors' point of view: Learn to make some measurements of physical parameters Learn about errors in measurements See applications of material and energy balances Observe and quantify the performance behavior of some units See and touch some equipment parts See and hear some operating equipment Learn to operate equipment and accumulate data Apply basic principles to familiar and unfamiliar 'things' Design experiments -- objectives, data analysis, communication Communication skills development -- oral and written Group skills development Hands-on experience with unit operations Experience will emerge as a "discovery" process, based on student-generated series of questions and trial and error. The student should determine/discover how the unit works Get experience of the various measurements (temperature, pressure, flow rate, composition). Reporting orally and in writing Reviewing and editing reports Page 7 4: PROJECT INFORMATION Room 303, Administration Building Absorption column (significant, but not all, data acquisition with computer) p vs air flow & water flow Material balance Flooding behavior SO2 absorption Flow meter calibrations Design of experiments Material balance -Complete a PIT for the column Liquid in Gas out Gas in Liquid out Moist air out Drying furnace Drying rate for wet materials Design of experiments Material balance -Complete a PIT for the furnace Energy balance -Show a calculation of the heat -Estimate the heat losses -Complete a transient energy balance Adding data acquisition Drying history curve Calibration of sensors Drying Rate curve Match experiments with theory in McCabe, Smith & Harriot Express drying rates in g/min or lh/hr, flux in g/min/cm2 or lb/hr/ft2 Page 8 Heat in Dry air in 4. Project Information Page 9 Particulate studies Sieve analysis equipment Ahlstrom Filtration participation (?) Design of experiments Filtrate out Filter Press Set-up & operation Material balance -Complete a PIT for the unit Water-only operation Slurry operation Flow meter installation Flow meter calibration Design of experiments Adding data acquisition Slurry in Filter cake out 4. Project Information Flow through Packed Beds Flow rate vs. pressure drop Dispersion of concentration functions Design of experiments Adding data acquisition Calibration of sensors Material balance -Complete a PIT for the beds Page 10 Liquid in ²P Liquid out Ground-water pollution modeling (physical, scaled models) To be designed Stream model Ground transport model LUST simulator Spill simulator Elution Design of experiments 4. Project Information Page 11 Dry air out Domestic dehumidifier Performance test Material balance Energy balance Instrumentation Calibration Analysis of performance, transient & steady-state Design of experiments Adding data acquisition Measure air velocities over the exit. Make a map of the velocity distribution. Calculate the air volumetric flow rate Measure heat transfer area for the Freon evaporator coil Measure heat transfer area for the Freon condenser coil Calculate heat flux & heat transfer coefficients Report air velocities in ft/min, ft3/min Report water rates in lb/hr Report energy flows in Btu/hr Report areas in ft2 Work in Moist air in Water out 4. Project Information Page 12 Gas-Fired water heater Installation & instrumentation Performance test Steady-state operations Transient operations Emissions testing Calibrations Material balance -Complete a PIT for the combustion Energy balance -Show a calculation of the heat of reaction and heat in the flue gases -Estimate the heat losses -Complete a transient energy balance Analysis of performance Plot the time-response of the temperatures and gas analyses Design of experiments Adding data acquisition Report heat rates in Btu/hr Report flows in lb/hr Flue gases out Fuel in Air in CW in HW out Room 115, Grote Hall Distillation column (significant, but not all, data acquisition with computer) Material balance -Complete a PIT for the unit Energy balance -Show a calculation of the heat -Estimate the heat losses -Complete a transient energy balance Steady state operation, ~18% MeOH feed Transient operation, ~18% MeOH feed T-x-y plots Calibrations McCabe-Thiele plots Flooding behavior Feedback controlled operation Heat transfer theory & operation of condenser High purity product operation Medium purity product operation Design of experiments Condeser heat Tops out Feed Reboiler heat Bottoms 4. Project Information Cooling towers Laboratory, 3-ton unit (significant, but not all, data acquisition with computer) Hot, dry day operation Cool, wet day operation Material balance -Air balance -Water balance Energy balance -Air side energy balance (heat gained) -Water side energy balance (heat lost) -Estimate the heat losses -Complete a transient energy balance Steady state operation Calibrations Transient operation Design of experiments Report heat flow in Btu/hr and tons of cooling Report flows in lb/hr Report air velocities in ft/min Show air velocity distributions & averages Show impact of ambient conditions Demonstrate on a psychro-chart the calculation procedure Administration Building cooling tower Energy balance Material balance Steady state operation Design of experiments Adding data acquisition (More as above under Lab Cooling Tower) Central Energy Plant cooling tower Energy balance Material balance Steady state operation Design of experiments Adding data acquisition (More as above under Lab Cooling Tower) Page 13 Hot water in M oist air out Ambient air in Cooled water out 4. Project Information Page 14 Coffee maker Energy Balance Material Balance Transient operation Fluid flow theory & operation Heat transfer theory & operation Product concentration Grinding impact Design of experiments Adding data acquisition Room 213, Grote Hall Chemical reactor w/ spectrophotometer (significant, but not all, data acquisition with computer) Reactant NaOH Batch reactor CSTR reactor Tubular ("plug flow") reactor Steady-state and transient operation Design of experiments Reactant CV Reactor outlet 4. Project Information Page 15 Oxygen Concentrator (Pressure Swing Absorption) (significant, but not all, data acquisition with computer) Design of experiments Performance test Material balance Energy balance Instrumentation Plant visit BASF/Amnicola Velsicol W.R. Grace Alco Chemicals Bowater Paper Moccasin Bend Waste Water Treatment Plant Tennessee-American Water Treatment Plant DuPont Plant Bunge Foods 4. Project Information Page 16 Various Locations Emissions inventory ENCH 435 "Chemical Release Inventory" Distillation column Methanol Grote Hall "Chemical Release Inventory" UTC "Chemical Release Inventory" Central energy plant Natural gas Oil Freon Blowdowns from cooling towers & boiler water Chattanooga motor vehicle fueling operations Equipment performance testing Boilers in Central Energy Plant O2 analyzer Stack gas monitor Cooling towers Pitot tubes Refrigeration chillers in Central Energy Plant Energy audit of Challenger Center 4. Project Information Page 17 Computer Simulations Chemical plant simulator (ProII) Flash tank Distillation, 18% MeOH in water Design of simulation runs Air pollution monitoring & modeling Air Pollution Control Board participation (?) ALOHA & CAMEO dispersion modeling Simulated Methanol spill Design of simulation runs 5. Assignments Page 18 5: ASSIGNMENTS WEEK 1 Spend a few hours researching the information in the Library and on the Web for one of these subjects: Industrial Distillation Industrial Drying Plate and frame filtration Combustion heaters Dehumidification Packed column absorbers Chemical reactors Cooling towers Absorption chillers Cyclone dust collectors Pressure swing absorption Look for methods of operation and analysis of performance of the units. Write a report to your directors that summarizes what you find. Describe how to determine the fuel usage (miles per gallon) of your car or truck. BACKGROUND 5. Assignments On the next pages are some data for gasoline purchases. Calculate the miles per gallon for these. Calculate the average and the standard deviation. Plot the individual points versus sample number in chronological order (as much as possible). List the things that might need to be considered in describing why the results are not all the same. Comment on what you observe. Page 19 5. Assignments Page 20 Give an estimate of how long it takes for the first kernel of popcorn to pop in a microwave popcorn package. Write a procedure for an experiment that determines the average time it takes for the first kernel of popcorn to pop in a microwave popcorn package. By discussion amongst your classmates, reach agreement on a procedure and submit it to management for approval. Conduct the approved procedure and present your data and results to management. 5. Assignments Page 21 Write a procedure for an experiment that determines the weight of a sack of sawdust by using a three-arm balance. By discussion amongst your classmates, reach agreement on a procedure and submit it to management for approval. Conduct the approved procedure and present your data and results to management 5. Assignments EACH WEEK Page 22 WORK STATEMENT Each week that the lab meets, you are to submit a weekly Work Statement by noon on Friday. If you submit the statement on paper, you are to submit the statement to Dr. Henry. You may submit the statement electronically from the 435 Web Site (http://chem.engr.utc.edu/435) and no need to duplicate it. The Work Statement is to describe your activities in the lab and following the lab. It is to include the data you collected. The data must be presented clearly so that another engineer can understand it. It is to include any calculations and/or graphs that you have completed. Again, these must be presented clearly. 5. Assignments Page 23 THE UNIVERSITY OF TENNESSEE AT CHATTANOOGA Chemical and Environmental Engineering College of Engineering and Computer Science 615 McCallie Avenue Chattanooga, TN 37403-2598 MEMORANDUM To: ENCH 435 From: J. M. Henry Subject: Performance Documentation Please prepare a memo addressed to us that describes your semester in ENCH 435. The nature of this memo is similar to documentation that bosses commonly request from employees for annual performance reviews or in the process of granting them promotions or awards. Give a copy of the memo to me by 3:00 pm on 5 October 2001. In your memo, please address as many of the following as appropriate: what your participation was in the various projects what your activities were in the various weeks what contributions you made in the laboratory (background work, operating help, reporting or presentation) how you displayed leadership how you exhibited creativity when, where and how you were cooperative and worked as a member of a team Make the last paragraph a summary of the earlier parts of the memo. Your memo should deal almost exclusively with specifics. In the last paragraph, and only in the last paragraph, you may make general statements about your part in ENCH 435. Here are suggested first sentences: This memo is in response to your request. In here is a description and documentation of my part in ENCH 435 so far this semester. For each project I was involved with, I describe my participation, leadership, contributions, creativity and team work. THE UNIVERSITY OF TENNESSEE AT CHATTANOOGA Chemical and Environmental Engineering College of Engineering and Computer Science 615 McCallie Avenue Chattanooga, TN 37403-2598 MEMORANDUM To: ENCH 435 From: J. M. Henry Subject: Performance Documentation Please prepare a memo addressed to us that describes your semester in ENCH 435. The nature of this memo is similar to documentation that bosses commonly request from employees for annual performance reviews or in the process of granting them promotions or awards. Give a copy of the memo to me by 3:00 pm on 3 December 2001. In your memo, please address as many of the following as appropriate: what your participation was in the various projects what your activities were in the various weeks what contributions you made in the laboratory (background work, operating help, reporting or presentation) how you displayed leadership how you exhibited creativity when, where and how you were cooperative and worked as a member of a team Make the last paragraph a summary of the earlier parts of the memo. Your memo should deal almost exclusively with specifics. In the last paragraph, and only in the last paragraph, you may make general statements about your part in ENCH 435. Here are suggested first sentences: This memo is in response to your request. In here is a description and documentation of my part in ENCH 435 this semester. For each project I was involved with, I describe my participation, leadership, contributions, creativity and team work. Page 24 APPENDICES 1 References 2 Statistics 3 SSOC 4 Information 5 Hints on Lab Reports 6 Oral presentation format, hints and grading APPENDIX A1 REFERENCES McCabe, Smith & Harriott, Unit operations of chemical engineering CALL NO: TP155.7 M3 1976 Perry's Chemical Engineer's Handbook, 6th ed. / prepared by a staff of specialists CALL NO: TP151 P45 1984 PUBLISHER: New York: McGraw-Hill, 1984. Page 25 6. Appendices Page 26 APPENDIX A2 STATISTICS Variations in Measured Quantities (ENCH 322) Every time an experimental measurement is taken, there is some error associated with the measurement. Today you are to determine the error in measurements in your system. Do this by taking steady-state measurements of the output function, C(t), for a number of data points. Find the mean and standard deviation of the measurements you make. Report your results as mean±2x(standard deviation). This range will include the true value of the function at a confidence level of 95%. Be aware that the standard deviation may be different at different operating points. Software packages like Excel can help a lot with the statistics. The following graph shows how this statistical analysis could look. This graph is the measured output for a steady input. Output 18 Variation in Output Data 17 16 Output = 16.08 ± 0.27 15 100 105 Time 110 115 120 Output data varying with time 6. Appendices Page 27 APPENDIX A3 SSOC System Operating Curve For each value of a constant value of the input function, there will be a value of the output function; this is called the steady-state value of the output for that value of the input. A graph of the output function (on the ordinate) versus the input function (on the abscissa) is called a steady-state operating curve. An example of what steady-state operating curves look like is below. 20 Output 15 10 5 0 0 20 40 60 80 100 Input Example of Steady-State Operating Curve 6. Appendices Page 28 APPENDIX A4 INFORMATION Information Flow In the Figure below is a diagram that depicts the flow of information is the LabVIEW environment. The computer operator and the equipment transmitters provide inputs into the program. The program provides outputs to the pieces of equipment, the computer monitor and to data files on computer disks. After using LabVIEW, the controller program, the data can be read by other programs, such as spread sheet programs (Excel, for examples) or graphing programs. Excel is available on the computers at UTC. Operator Inputs LabVIEW Controller Program Outputs to Equipment Equipment inputs Outputs to Data Files Data Spread Sheet or Graphing programs Plots Information paths in laboratory experiments 6. Appendices Page 29 APPENDIX A5 HINTS ON LAB REPORT Diagrams, Graphs, & Tables: The reason for putting diagrams, graphs and tables in a report is to organize information so that it can be easily understood. However, the point that you want to convey in a diagram, graph or table may not be obvious to the reader or grader. You have to tell the reader or the grader what point you want him or her to see in the diagram, graph or table so that he or she doesn't miss that point. A good rule of thumb is to write 2 or 3 sentences for each diagram, graph or table to explain or describe the diagram, graph or table. Figures: Try to size figures so they fit upright on the page. If you have to turn them sideways, remember that the top of the figure goes to the left of the page. See the examples below. Binder: The reports submitted are to have all your group's reports included in a binder. Put the newest in the front. Include the grading sheet with each report. Separate the reports with tabbed separators that are labeled to identify the reports. "TJe": This is known as the "Thomas Jefferson Error." This is marked when you write it's when you mean its. Both words are legitimate words, but they mean different things. It's is the contraction of the two words it is; its is a possessive pronoun that refers to an object. 6. Appendices Page 30 Contents of "Theory & Background" (by Jay Ware) Brief review of system This should include a schematic diagram of your system with control elements labeled using the standard symbols in the appendix of S&C. The schematic diagram does not have to be pictorial, but is to show the functional relationships among the various components of the system. The block diagram should be included. The input and output functions should be clearly defined. Discussion of Principles behind experiment This should include the theoretical output for a given input. Discussion of theory as applied to system All variables for your system should be defined. Where you know the values of parameters (from previous measurements or reports) these are to be described in this section. Brief summary of theoretical response This should consist of an explanation of how the system should respond based on theory. In the "Discussion" section, this theoretical response should be compared with experimental and/or approximate modeling response. 6. Appendices Page 31 Informal Report REPORT CONTENTS Title Page Includes "UTC," "Engineering 435," Title, Your Name, Your partners' names, Date Introduction In the first paragraph, it tells briefly what was done and for what purpose. In the second paragraph, it tells how the report is organized. Background and Theory Describes the engineering background of the lab, including equations and schematic diagrams Procedure Describes what was done in the physical lab Results Describes what you observed, the data. Includes tables and graphs. Each table and graph must be explained. It builds on the "Procedure;" the "Procedure" section must describe how all the results in this section were obtained. It includes results of experiments: estimates of errors of the results, SSOC Discussion Tells the significance of the experiment and the results. It builds on the "Results;" the "Results" section must include all the results that are discussed in this section. "No surprises" Conclusions and Recommendations Describes what principles were demonstrated by the experimental results. It builds on the "Discussion;" the "Discussion" section must prepare the reader for all conclusions that are mentioned in this section. "No surprises" Appendices Includes raw data, references & other things that interrupt the "flow" of the report. Anything that is in an appendix (except "references") must be mentioned someplace in the report. Attachments Include a sheet for each team member that describes the contribution to the work in the laboratory. 6. Appendices Page 32 Formal Report A draft of Formal Report is due the second school day before the scheduled lab meeting. FORMAL REPORT CONTENTS Introduction Theory & Background Description & explanation of system components & connections Schematic diagram Input function(s) and output function Theory & governing equations for components and system Block diagram Modeling Equations & methods used in modeling Procedure Results Experimental results. Estimates of errors in results. Experimental and modeling results Discussion Comparison among theory, experiment & modeling Conclusions Recommendation Appendices Physical properties Modeling diagram, equations Data curves & calculations Attachments Include a sheet for each team member that describes the contribution to the work in the laboratory since last reported. 6. Appendices Page 33 ENGINEERING LAB REPORT COMMENTS & GRADING NAME:___________________________REPORT DATE: GROUP:___________________________TITLE: CONTENT (50%) Title Page -- Name and name of team members? Introduction -- Clear reason for report? Background-enough to follow report? Introduces report? Theory (diagrams, equations, calculations) Modeling (diagrams, equations) Results (tables, graphs, calculations) Discussion (follow from Results?) Conclusions (follow from Discussion?) Recommendations Appendices Evaluator's recommendations Total points (out of 50) FORM (50%) Appearance (margins, page #s) Type (size, quality, consistency) Graphs (clear, consistent) Tables (clear, consistent) Diagrams (clear, consistent) Language (word choice, significant figures) Total points (out of 50) OVERALL COMMENTS EVALUATOR_____________________________ OVERALL GRADE 6. Appendices Page 34 APPENDIX A6 ORAL PRESENTATIONS ORGANIZATION Establish Purpose: What is your objective in making presentation? Assume your audience does not know anything about your subject. Write Conclusion First Outline: Introduction Name and name of team members State reason for presentation Background-provide enough to follow talk Body Present ideas Include strengths and weaknesses Summary Summarize briefly State conclusion Questions-be prepared Select Information Based on Support of Conclusion-KISS PREPARATION Visual aids Overhead, charts etc. - approximately 1/minute of talk one idea/slide Include -title slide outline of talk conclusion Do not have complete sentences on your slides Make your letters on the overheads at least 1/4 inch high. If you can't get a printer to do that for you, do it by hand or use the copy machine to enlarge your copy. Everything on your slide must be important enough to be there. If it's not important, leave it off. If it's important, make it clear and tell your audience about it. Have a balance among the number of slides with words only, those with diagrams or graphs and those with tables Practice--to have confidence Memorize introduction and conclusions Make them strong Practice out loud to an empty room Present to other group members for critique and potential questions. DELIVERY Communicate Stay within time limit Confidence Be in control Maintain eye contact-maintain eye contact-maintain eye contact 6. Appendices Page 35 FORMAL ORAL PRESENTATION CONTENTS Brief system description, including input & output functions Review of performance curves (SSOC) Sample time response graph: Transients, steady operation Modeling approach Comparison of results of experiment & model Comparisons of experimental results and modeling results Conclusion(s) about system Conclusion(s) about approximate model 6. Appendices Page 36 ORAL PRESENTATION GRADE NAME: DATE GROUP: SUBJECT: CONTENT (50%) Introduction Name and name of team members?_______ State reason for presentation?______ Background-enough to follow talk?_______ Body Summary Summarize briefly? State conclusion? Questions? VISUAL AIDS (20%) Overhead? Include -title slide? # Text slides outline of talk? # Graphic slides conclusion? # Tabular slides DELIVERY (30%) Confidence Stay within time limit? start________end______time_____ Delivery In control/evidence of practice? Maintain eye contact? OVERALL COMMENTS EVALUATOR OVERALL GRADE 6. Appendices GRADE RECORD Page 37 STUDENT PHONE WEEK TOPIC 1 INTRO 2 3 FIRST REPORT 4 5 6 MID-TERM TOTAL POINTS GRADE A | B |C | D |F 7 8 9 10 11 12 13 SECOND REPORT ORAL REPORT #1 ORAL REPORT #2 SEMESTER TOTAL POINTS GRADE A | B |C | D |F GRADE DATE INITIALS