15S - iricen

advertisement

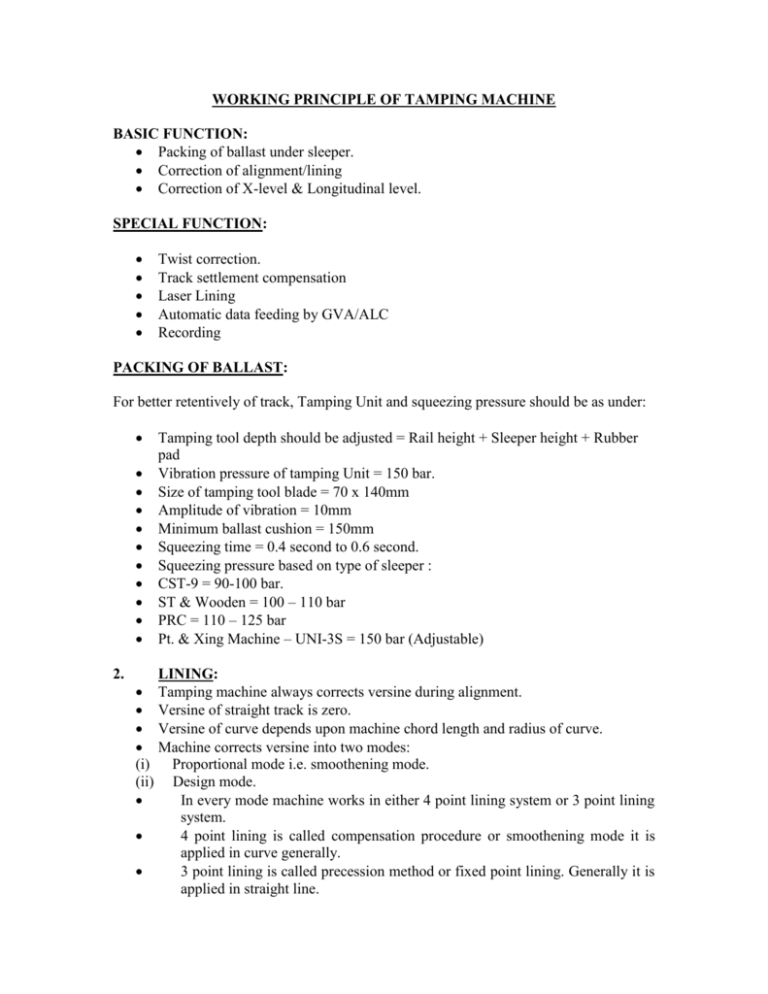

WORKING PRINCIPLE OF TAMPING MACHINE BASIC FUNCTION: Packing of ballast under sleeper. Correction of alignment/lining Correction of X-level & Longitudinal level. SPECIAL FUNCTION: Twist correction. Track settlement compensation Laser Lining Automatic data feeding by GVA/ALC Recording PACKING OF BALLAST: For better retentively of track, Tamping Unit and squeezing pressure should be as under: 2. Tamping tool depth should be adjusted = Rail height + Sleeper height + Rubber pad Vibration pressure of tamping Unit = 150 bar. Size of tamping tool blade = 70 x 140mm Amplitude of vibration = 10mm Minimum ballast cushion = 150mm Squeezing time = 0.4 second to 0.6 second. Squeezing pressure based on type of sleeper : CST-9 = 90-100 bar. ST & Wooden = 100 – 110 bar PRC = 110 – 125 bar Pt. & Xing Machine – UNI-3S = 150 bar (Adjustable) LINING: Tamping machine always corrects versine during alignment. Versine of straight track is zero. Versine of curve depends upon machine chord length and radius of curve. Machine corrects versine into two modes: (i) Proportional mode i.e. smoothening mode. (ii) Design mode. In every mode machine works in either 4 point lining system or 3 point lining system. 4 point lining is called compensation procedure or smoothening mode it is applied in curve generally. 3 point lining is called precession method or fixed point lining. Generally it is applied in straight line. 3. Tamping machine is designed to work in constant versine i.e. straight and circular curve. If half machine is in straight and half on transition. Some compensation value (Vm) is feeded to compensate the chord. LIFTING & LEVELLING: Tamping machine corrects longitudinal level and X-level. One steel rope (Chord) is used to measure straightness of longitudinal level of each rail of track. For X-level correction pendulum is used. Both rails of track are controlled separately. During lift one rail is kept base line or reference rail. Machine corrects X-level w.r.to. base line. Machine corrects the error in two mode i.e. 1. Proportional Mode. 2. Design mode In proportional mode, machine leaves some error. In design mode, a target height value is feeded to rectify 100% error. Only two tamping machines are designed for twist correction i.e. CSM and tamping express. Principle of Lining In single chord system there are two methods of lining correction. 1. 2. 4- point lining method 3- point lining method Principle of 4- point lining: In this method versines at two places are compared which is a constant for all the circles in dependent of radius a straight may be considered a curve of infinite radius from the figure given above.H1 H2 = = AC x CD 2R AB x BD 2R Versine Ratio (i) = H1 H2 = AC x CD AB x BD H1 = i x H2 In practice point B always remains on aligned track. Points C & D remain on unaligned track H2 and H1 are separately measured by measuring and lining bogies respectively by the machine. H2 is fed in PCB where it is multiplied with constant i and becomes “H2 x i. Thus H2 x i and H1 are then fed in difference amplifier and if the alignment is OK both will be equal and reading on the dial will indicate zero of alignment is not OK, the difference of the two will be indicate on the dial as well as current will flow to lining solenoids, the alignments will be corrected till both H x i and H1 are equal or the ratio H1/ H2 = i is maintained. ERROR REDUCTION: Ideal line = 1 Before lining = 2 After lining = 3 Error reducing ratio (n) = AD x BD AC x BC n = Reduction Ratio Left over error FR = FD n For 08 Machine FR = FD (n = 20 x 15 = 6 ) 6 10 x 5 Machine measure the versine H2 ( = BB1) at the measuring bogie and the versine CC2 at the lining bogie. Had the machine been on a regular curve the relationship CC 2 = 1 x H2 would have been true, but because of the changing curvature, we actually have CC2 = 1 x H2 +_ V. Therefore, even though the curvature of the transition is true the machine still experiences an “Error” V. Therefore, we have to apply some adjustment at the lining bogie to compensate for V. The procedure of applying V for the different situations is given below. The tables are applicable for the chord system in which the length of the chord is 20m the distance between the rear tightening bogies and the measuring bogie is 5m and the distance between the rear tightening bogie and the lining bogie is 10m. Straight – Transition – Curve – Transition (Write from Manual) Curve 1 to Transition – curve - 2 Say R1 & R2 are the rdil of the two curves and V1 & V2 are the corresponding ad instant for the individual curve. 1. If the R1 is bigger that R2, the net adjustment, V0 will be V0 = V2-V1 or V0m = V2m-Vm, 2. The applicable of adjustment will start as soon as the front tightening starts entering the transition. This during coco king 1/6 of the error will be left and therefore it is called smoothening lining of some procedure is available with which it is possible to give exact location of various points like beginning & end of transition and amount of fault at a particular location established with some permanent works these, by shifting front and f the chord by the amount of fault. We can achieve exact alignment. (i) (ii) But in the field it is difficult to obtain correct reference marks as such generally smoothing system is adopted which is fairly accurate for smooth running of trains. If we are tamping constructed line we can always, lay a parallel reference line from which difference can be calculated for feeding into the machine to achieve exact alignment. Alignment Correction of Track: The constant versine ratio (1) applied only to tracks with the constant curvature (Straight or circular curve). But when there is change in curvature, the constant versine ratio remains no more applicable. As on example, let us consider a case of the machine entering from straight to transition. In the position of the machine shown in the figure. LINING During alignment machine corrects versine. The versine of straight track is zero and versine on covered track depend on radius of curves. Measuring chord length and measurement method. Lining 4 Point Lining Smoothening Mode 3 point Lining Design Mode Fix point lining Design lining Laser Lining 4 POINT LINING 3 POINT LINING 4 Point Lining: 3 Point Lining: By calculation H1 = ACXCD H2 = ABXBD 2R 2R Versine Ratio (i) H1 = ACXCD H2 ABXBD For 08-Series H1 = 1.33 H2 During work H2 is corrected position The calculated versine HV = BCXCD 2R This value HV is feeded in versine potentiometer as a standard value (Required versine) and during work machine measure existing value if there is difference machine corrects versine at ‘C’. During work ‘D’ is on disturb position. Due to that machine leave some error i.e. FR = and H1 is exist position machine corrects versine at C w.r. to B. ‘D’ is disturb position due to that Machine left some error (FR) FR = FD ( n = 6 For 08 machine) n ‘C’ is corrected w. r. to ‘B’ so it is called smoothening lining. In this method required versine is not feeded. (H2 is treated as required) During work if ‘D’ is shifted on its original position then machine will correct 100% error, because FR = FD FD n- 3 For 08 machine n In straight required versine = Zero On curve required value is calculated w.r.t BC, CD i.e. (H1 = BCXCD) 2R On every point required versine is fixed at every sleeper it is called. Fix point lining. During design mode off set value is feeded as in 4 point lining in design mode. n FD = Off set value. In straight if machine will leave some error then it will again accumulate hence it will form a false curve. So it is not applied in straight. In transition the difference of versine is compensated by feeding Vm value. In this method if machine will leave some error. It will not accumulate again. Hence it is suitable for straight line. 3 POINT LINING: H1 = BC x CD 2R The versine “H2” at point “B” is not measured. The track is measured at three points. The lining versine “H1” at point “C” is specified according to the curvature. Lining commences until the THEORETICAL versine “H1” is achieved. Using the 3point system, the chord is generally fixed at point “B” which results in a reduction of the distance A-B. ERROR REDUCTION RATIO: Point “B” is on the already lined track behind the machine. The front end of the chord, point “D” is at the lining error “FD”. Point “C” is lined until “H1” corresponds with the specified Theortical versine. Specifying the Theortical versine “H1” shifts point “C” in a position which corresponds with the required radius “R”. The remaining error “FR” is a result of the ratio of the measuring point distances. Proceeding with the lining, point “B” is at the remaining error and influences therefore the next measurement. LEVELLING AND LIFTING: Levelling has two components. 1. Longitudinal level 2. Cross level. Longitudinal Level: This correction is possible only by lifting the track precise marking and required lifting is worked out by Theodolite lacking all physical constraints into consideration and marked over sleeper at suitable interval. Levelling: For longitudinal levels there are two fixed points i.e. front tower and measuring tower whereas middle feeler rod tower actuates the desired level correction. BASE RAIL: The datum rail for carrying out attentions to longitudinal profile and alignment should be selected as given below: (i) (ii) (iii) On straight & single line, higher rail will be kept as base line. On straight and double line, non cess rail is kept base line. In curve, inner rail is kept base line. Note: Direction of cant selector switch to be oppose of base line. GENERAL LIFT: 1. General lift is given to the track while tamping to cover all irregularities of longitudinal level over the base line. 2. It is given to an base line. General lift is the algebraic difference of higher and lower point of working rail + 5mm. 3. While giving the general lift, run ramp of 1:1000 & while closing the work ramp out of 1000:1 should be given to the track. So that passenger can not feel jerk. General Lift for Curve: (i) When existing SE is less than equilibrium SE. General lift will be equal to track irregularities over the base line. (Inner line + 5mm) (ii) (iii) When existing SE is more than equilibrium SE. The general lift will be the track irregularities in machine base line + Max. different in SE. (Between existing & equilibrium)) Long wave defects measured on 30m. chord & short wave defects measured on 10m chord .Machine will remove short wave defect in proportional Made. To remove long wave defect design leveling is required. Levelling of Track: 1. Proportional leveling. 2. Design Levelling Proportional Levelling: In this method, general lift over the base line is generally fixed and General lift is decided as per the track irregularities. General lift is so decided should cover the all track irregularities in machine lifting base. In this system smoothening action takes place for longitudinal level and cross-level are neet completely corrected. Only short wave defect are removed. Design Levelling: In this method, Target height are feed over the base line, instead of General lift (Target height is the differences between existing level and desired level). In this system all long wave and short wave defects are removed & X-level also corrected. FEEDING OF CANT. VALUE IN CURVE: CTP1 CTP2 TTP1 TTP2 JE/P. Way will write down cant value of curve on the sleeper near inside rail seat of outer rail. Total cant value should be distributed through out the transition length in such a way that it is Zero at TP & Max. at CTP. Generally when the tamping machine enter into the transition position, the machine operator start feeding cant value according to the value written on the sleeper. In all tamping machine except CSM there are two digital potentiometer for feeding the cant value one at front tower and other at working cabin As soon as cant value start feeding at front cabin when machine is at TTP. The lifting chord start the lifting and cant side rail will also start lifting. Lifting of Track is not required till measuring trolley reached over TTP by this hump will create. So the operator of front cabin should not feed any cant value till operator working cabin reached at TTP. At this time whatever value written on the sleeper in front of front cabin will be feeded by operator at a stretch. (at a time) Similarity when front cabin reached at CTP1 the remaining bogie is stile in transition portion i.e. working has not reached at full cant value. Similarly when machine reached at CTP2 suddenly the cant value will be reduced to the value till TTP2 as per written on the sleeper when the front tower reached at TTP2 then although the reaching of cant value digital reached at zero but reduced it in ergative till measuring bogie reached at TTP2 . No raise the cant value equal to zero. Reverse Curve: (i) With straight (ii) Without straight. Minimum straight portion between two curve 50mts initially it was 30 meter old curve are still with 30m. Straight new curve are with 50m straight. Reverse Curve with straight: In straight portion between two curve change the direction of cant selector switch cant selector switch should be opposite to base line. Don’t change the direction of cant selector switch at TTP1/TTP2. Only change direction of toggle switch to get negative super elevation. Reserve curve with zero straight laying of reverse curve. i) ii) Base line method Centre line method. Base Line Method: In this system one line is kept as base line by lowering or lifting the other line we have to provide cant. In field, how to ensure that this curve is laid by base line. Do the survey if one line is in level then it is a curve laid by base line method. Centre Line Method: From position A to C machine wise work as simple curve. When machine reached at ‘C’ and enter upto the transition portion, Decrease General lift equal to ½ of difference in cant with previous sleeper decrease General lift till complete one entered in the transition portion. Then again is raise to GL to its normal value. CTP1 CTP1 TTP1/TTP2 CTP2 CTP2 A B TTP1 TTP2 MODEL QUESTIONS FOR MARKING OF DESIGN DATA ON SLEEPERS Sl. QUESTIONS NO. ‘A’ Straight Track, Lining in Three Points or Four points. 1. A tamping machine is working in a straight track, both leveling and lining are being done in proportional mode. 1. Which data will be told verbally by P. Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. ANSWER Only Datum line (Base line) and G/Lift to be told verbally. No data is required to be written sleepers. 2. A tamping machine is working in a straight track leveling is being done in proportional mode and lining is going on in design mode. 1. Which data will be told verbally by P. Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. 3. 4. B. 5. 6. A tamping machine is working in a straight track. Leveling is being done in design mode and lining is going on in proportional mode. 1. Which data will be told verbally by P. Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. Datum line (base line) and G/Lift to be told verbally. Slews are to be written in the outer of sleeper with arrow indicating the direction of slews. No thing to be told verbally. Target heights to be written at least at every 5th sleeper inside rail seat on sleeper of datum line (Base line) A tamping machine is working in a straight track. Leveling and lining both are being done in design mode No thing to be told 1. Which data will be told verbally by P. Way staff to verbally. machine staff ? 2. Is there necessity of writing any Data on sleepers. Target levels and slews with arrow are to be return on the sleeper. Curved track with four points lining. A tamping machine working in a curve and both leveling and lining are being done in proportional mode. 1. G. lift and base line 1. Which data will be told verbally by P.Way staff to will be told verbally. machine staff ? 2. (a) Cant values will be 2. Is there necessity of writing any Data on sleepers. written on sleepers. a. If correction factor is not required. (b) In addition to above correction factor b. If correction factor is required. values will also be written. (Vm) A tamping machine is working in a curve. Leveling is being done in proportional mode and lining in design mode. 1. Which data will be told verbally by P.Way staff to 1. Base line & G Lift to be machine staff ? told verbally. 2. Is there necessity of writing any Data on sleepers. 2. (a)(i) Cant values to a. If correction factor is not required. be written. (a)(ii)Slews values b. If correction factor is required. with arrow to be written. b. In addition to above correction factor values will also be written. (Vm) 7. A tamping machine is working in a curve leveling is being done in design mode and lining in proportional mode. 1. Which data will be told verbally by P.Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. a. If correction factor is not required. b. If correction factor is required. 8. ‘C’. 9. A tamping machine is working in a curve. Both leveling and lining are being done in design mode. 1. Which data will be told verbally by P.Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. a. If correction factor is not required. b. If correction factor is required. Curves with 3 points lining. A tamping machine is working in a curve both leveling and lining are being done in proportional mode. 1. Which data will be told verbally by P.Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. 10. (1) G Lift to be told verbally. 2. a) Target height to be written on datum (base line), cant values also to be written. b) In addition to above correction factor will also be written. (Vm) (1) Nothing will be told verbally. (2)(a) Target levels on base line (Datum Line) - Cant values. Slews for design lining with arrow will be return on sleeper. In addition to above correction factor values will also be written. (Vm) (1) G. Lift and base line will be told verbally. (2) Cant values and theoretical versines will be written on sleepers. A tamping machine is working in a curve leveling is being done in proportional mode and lining in design mode 1. Which data will be told verbally by P.Way staff to (1) G. Lift and base line will be told verbally. machine staff ? 2. Is there necessity of writing any Data on sleepers. 11. 12. A tamping machine is working in a curve leveling is being done in design mode and lining in proportional mode. 1. Which data will be told verbally by P.Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. A tamping machine is working in a curve leveling and lining are being done in design mode. 1. Which data will be told verbally by P.Way staff to machine staff ? 2. Is there necessity of writing any Data on sleepers. (1) Cant, slews and theoretical versines will be written on sleepers. (1) No things will be told verbally. (2) Target levels on base line, cant values and theoretical versines will be written on sleeper. (1) No thing will be told verbally. (2) - Target levels. - Slews - Cant values. - Theoretical versines. MARKING OF DESIGN DATA ON SLEEPERS HOW TO MARK DESIGN DATA ON THE SLEEPERS. In order to feed different design values for leveling and lining system a uniform approach should be followed by different railways, which is detailed as below. NOTE: For proportional leveling (i.e. smoothening) nothing is to be written on sleepers only G. Lift as per track condition and base line (Datum line) to be told verbally. TABLE OF MARKING OF DESIGN DATA S. DESCRIPTION No. 1. Cant values in Trans. Curves. SYMBOL C 2. Target levels for design leveling. L 3. Slews for design lining. S → ← 4. Correction factor in four point lining in curves with cubic parabola transitions if required (i.e. Vm values to be computed through Vm value tables. Theoretical versine in three point lining in curves with transition for comparison with existing versine at lining bogie. To be calculated on machine lining base in three point at lining bogie from the formula. Versine = a x b/ 2R x 1000 = in mm Vm → ← 5. V FOR PLACE OF EXAMPLE WRITING. 10C To be written on sleeper in side rail seat of higher line. 20L To be written on sleeper in side rail seat of datum line (Base line) at least at every 5th sleepers. To be written in center 15S of sleeper with arrow, ← indicating the direction of slews at least at every 5th sleepers. 5Vm To be written near cant values with arrow. ← Indicating the direction of feeding. 10V To be written near cant values. NOTE: All values are to written with chalk in machine working direction and should be in MM only.