Document

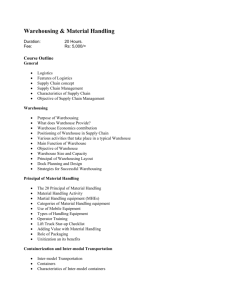

advertisement

Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland Developing Free Zone Warehouse for Business Competitiveness in Thailand: A Work-In-Progress Feasibility Study by Asst. Prof. Dr. Ungul Laptaned Department of Logistics Engineering, School of Engineering, University of the Thai Chamber of Commerce, Bangkok, Thailand Tel: 662-697-6707, Fax: 662-275-4892 Email: epxull@yahoo.com, ungul_lap@utcc.ac.th ABSTRACT JWD InfoLogistics Co. Ltd. was established to offer services in integrated logistics solution, warehousing, distribution, freight forwarding, and value added services worldwide. JWD operates as either a Lead Logistics Provider or as the provider of individual or multiplecomponents of our clients' supply chain service needs from taking responsibility for inbound/outbound transportation, customs clearance, inventory and warehouse management, the provision of a full range of ancillary and co-packing services, and distribution to customers both overseas and throughout Thailand and Indo-China, all to the highest standards of service at the lowest cost possible. Owing to the rapid increase in shipping movements through the seaport (i.e., Laem Chabang seaport, Chonburi, Thailand), the expansion of industrial activities has placed increasing demands on the development of free zone warehouse for dangerous goods. JWD entered into an agreement with the Port Authority of Thailand to have the exclusive right to operate, maintain, and carry out dangerous goods storage located at Laem Chabang seaport for a given number of years. To take advantage of hazardous segregation and classified cargo consolidation both imported and exported dangerous goods, JWD planned to develop its free zone warehouse for dangerous goods to gain business competitiveness. Free zone or free economic zones is designated areas where companies are taxed very lightly or not at all to encourage development. Therefore, this study highlighted the feasibility of the project using logistics and marketing analysis to investigate how the development would be plausible. KEYWORDS: Dangerous Goods, Free Zone, Seaport, Logistics, Marketing 1. INTRODUCTION JWD - a subsidiary of JVK Holdings Company Limited is a Thailand and Indo-China based high-technology integrated logistics solutions provider that enables clients to take full advantage of the benefits that accrue from the outsourcing of logistics activities. Our focus is upon meeting the unique and ever changing supply chain requirements of our clients on an ongoing basis and enhancing that evolution with innovative solutions that facilitate a competitive advantage for our clients in their markets. There by JWD operates as either a Lead Logistics Provider (LLP) or as the provider of individual or multiple-components of our clients' supply chain service needs from taking responsibility for inbound/outbound transportation, customs clearance, inventory and warehouse management, the provision of a full range of ancillary and co-packing services, and distribution to customers both overseas and throughout Thailand and Indo-China, all to the highest standards of service at the lowest cost possible. JWD as lead logistics provider integrates your requirements with reliable and experienced UTCC Engineering Research Papers 2010 279 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland service providers whilst managing the resources, technologies, and processes. JWD provides individual or multiple-components of our clients’ supply chain service needs – from warehouse rental, warehouse management, distribution, inbound/outbound transportation, customs clearance to a wide array of value added services. For warehousing services, JWD focuses on asset & labor management, which is best handled through long-term contract warehousing agreements. Its excellent locations enable to make timely pick ups and deliveries to Greater Bangkok and to destinations across Thailand. Supported by a large pool of trusted and competent carriers, JWD relies on a fleet of more than 500 vehicles ranging from motorbikes, four wheel trucks up to semi- trailers. Freight Forwarding services facilitate the JWD to offer competitive import and export pricing for ocean (FCL and LCL) and air shipments whilst providing reliable and efficient service, as well as able to assist the importing/exporting industries with customs clearance services. Nevertheless, JWDs expertise extends far beyond involving value-added services such as: Promotional assembly & kitting, Quality control, Re-packaging into various sizes, Labeling, Returns Processing, Cross Docking, Ticketing, and Shrink-wrapping. Moreover, dangerous goods logistics center (ChemLog DG Logistics Center) offers its service in warehousing and container year area for hazardous segregation by IMO, consolidation for classified cargo, basic inspection and survey, transportation service, customs clearance import & export, and permission & license & consulting on dangerous goods, and one-stop service for dangerous goods. It is the intent of a free zone program to stimulate economic growth and development in Thailand. In an expanding global marketplace there is increased competition among nations for jobs, industry, and capital. The free zone program was designed to promote competitiveness by encouraging companies to maintain and expand their operations in Thailand. This program encourages Thailand-based operations by removing certain disincentives associated with manufacturing in Thailand. The duty on a product manufactured abroad and imported into Thailand is assessed on the finished product rather than on its individual parts, materials, or components. The Thailand-based manufacturer finds itself at a disadvantage compared with its foreign competitor when it must pay a higher rate on parts, materials, or components imported for use in a manufacturing process. The program corrects this imbalance by treating products made in the zone, for the purpose of tariff assessment, as if it were manufactured abroad. At the same time, this country benefits because a zone manufacturer uses Thai labor, services, and inputs. Free zone, therefore, is a designated area for industrial or commercial operation or any other operations involving in economic growth and development. Foreign and domestic merchandise removed into free zone is eligible for tax and duty privileges as indicated by the law. Integrating the dangerous cargo warehouse in the free zone logistics center needs an identification of the problems such as unsystematic group and category of inventory, and customer list; uncertain location of inventory; free zone activity focusing on service and product’s quality rather than shortening time; and unsatisfactory key performance indicator of operations. Therefore, this study highlighted the feasibility of the project using logistics and marketing analysis to investigate how the development would be plausible. 280 UTCC Engineering Research Papers 2010 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland 2. LITERATURE REVIEW Facchini and Willmann (1999) conducted a study of the gains from duty free zones. They mentioned that duty free zones have been established in many countries and duty free shops can be found in every major international airport. This paper investigates their welfare effect, in the tradition of the Pareto gains from trade literature. Using the dual approach developed in Dixit and Norman (1980), this study shows that the introduction of a duty free zone leads to Pareto gains over autarky. Compared to free trade, its welfare impact depends on the redistribution mechanism accompanying free trade. We show that with a Dixit–Norman tax scheme free trade is Pareto-inferior to a duty free zone regime. The opposite holds true for lump sum redistribution. Queirolo et al. (2002) deals with the warehouse layout optimization problem with respect to the distance reduction and the travel time minimization. The authors also searched for a flexible tool in order to optimize layout functionally to the fluctuations in demand and inventory level. The addressed optimization problem is a constrained optimization problem on an integer domain and it is shown to be NP-hard. The wide applicability of evolutionary computation and its good performances on a variety of different optimization problems have led to a strong interest in this type of algorithm. A heuristic genetic algorithm has been developed and a system for the effective assignment of the storage area to the different class of items is presented. The system is based on the association of a genetic algorithm and a deterministic simulation model. Computational experiments are conducted to verify the effectiveness of the algorithm. They were made by applying the proposed tool to a real industrial case concerning an Italian soft drinks company. As a result, the authors intend to provide a tool for warehouse layout and operations optimization that could be attractive for operation management researchers and realistically applicable by practitioners. Vis and Roodbergen (2004) presented the paper on warehouse layout alternatives for varying demand situations. They mentioned that many supply chains strive to shorten the time between a customer’s order and the actual delivery of the ordered goods, i.e. the response time. However, a shorter response time may induce a higher volatility in goods flows. We present practical methods to determine layouts for the material handling facilities (warehouses, crossdocking centres and container terminals) which take these inherent variations into account. Advantages and disadvantages of the methods are treated. As an example, a comparative analysis of the methods is presented for the cross-docking centre of the “Royal Horticultural Company Lemkes” in the Netherlands. Chou and Hsu (2005) conducted a study on the integrated model of retailer’s inventory order decision and distributor’s product transportation in a supply chain by using single-period products. The goals of firms along a supply chain are usually contradictory with each other. In this paper, assuming a supply chain adopts a vendor-managed inventory strategy, they propose a model to integrate retailers’ inventory decisions and distributors’ transportation decisions. The decision variables in the model include inventory quantities sending from warehouses to retailing sites. This paper considers a one-period utility product, and assumes shortage as well as overage costs exist. They characterize demands faced by the retailers in the model as deterministic, stochastic, and fuzzy, respectively. To solve the model efficiently, we design a genetic algorithm (GA), which demonstrates superior ability in searching for the global optimum in a solution space with possible local optimums. Also, this paper compares profits between retailers and distributors under different settings of model parameters. Laptaned (2010) investigated transforming bonded warehouse into free zone warehouse. The study selected Kerry Logistics (KL) that was developed to provide services in warehouse and UTCC Engineering Research Papers 2010 281 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland logistics centre space worldwide. Its services range from pick-and-pack, light assembly, to distribution to retail network or end-customers. Owing to the rapid increase in shipping movements through the seaport (Siam Seaport or Laem Chabang Seaport, Chonburi, Thailand), the expansion of industrial activities has placed increasing demands on the transforming to Free Zone warehouse. In retrospect, KL developed its warehouse into 2 categories: bonded and general warehouses. Bonded warehouse is a warehouse in which imported goods on which the duties are unpaid are stored under bond and in the joint custody of the importer, or agent, and the customs officers. To take advantage of storing both imported and exported goods, KL planned to transform its bonded into free zone warehouse for gaining business competitiveness in ASEAN countries. This study highlighted the feasibility of the project using logistics and marketing analysis to investigate how the transformation would be plausible. 3. RESEARCH METHODOLOGY The research study collected data through an in-depth interview and focus group as primary data. For secondary data collection, it was done by the use of documentation from JWD InfoLogistics Co., Ltd. The respondents used for the in-depth interview were selected from supervisor and manager of 9 people in total (1 managing director, 1 business development manager, 2 warehouse managers, 1 safety manager, 1 project manager, 1 logistics analyst, and 2 chemists). The respondents were selected by identifying the person involved in the project. This study identified the feasibility of developing the free zone warehouse used for storing dangerous cargo by collecting data of layout and infrastructure planning, and logistics and marketing study. 4. RESULTS 4.1 ANALYSIS OF DANGEROUS CARGO WAREHOUSE Dangerous or hazardous cargo can be categorized into 9 classes according to hazardous areas classification found in Laem Chabang seaport. The classes define the general nature of hazardous material in the surrounding atmosphere illustrated in Table 1. Table 1 Classes of Hazardous Material Class 282 Class 1 Hazardous Material in Surrounding Atmosphere Combustible Material Class 2 Flammable Gases or Vapors Class 3 Flammable Liquids Class 4 Flammable Solids Material UTCC Engineering Research Papers 2010 Symbol Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland Class 5 Oxidized Material and Propylene Oxide Class 6 Toxic or Infectious Material Class 7 Radioactive Material Class 8 Corrosive Material Class 9 Other Hazardous Material Dangerous cargo warehouse (ChemLog DG Logistics Center) is licensed to store all categories of dangerous goods, except explosives. Normal operations include renting storage spaces to customers for dangerous goods storage and providing services for goods handling, container haulage, container loading, unloading and delivering, goods packing and labeling, chemical wastes treatment etc. Dangerous goods are sorted according to their categories before being stored in specified compartments formed by firewalls and fire retardant doors and protected by automatic system. All the facilities and equipments are spark-proof. The fire alarm signals are linked to our control room and fire station directly. Dangerous goods logistics center was the 5th logistics center, offers its service in warehousing and container year area for hazardous segregation by IMO, consolidation for classified cargo, basic inspection and survey, transportation service, customs clearance import & export, and permission & license & consulting on dangerous goods, and one-stop service for dangerous goods. Its facilities include: container yard area of 100,000 square meters, 2 warehouses, total space of warehouse A of 3,800 square meters, total space of warehouse B of 5,956 square meters, floor loading factor of max 2 ton/ square meters, stand alone office facility next to dangerous cargo warehouse, and suitable for accommodating chemical and hazardous goods including highly toxic (class storage 2-8) illustrated in Figure 1. Figure 1 JWD’s Dangerous Cargo Warehouse UTCC Engineering Research Papers 2010 283 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland 4.2 ANALYSIS OF FREE ZONE WAREHOUSE AND LOGISTICS CENTER To take advantage of establishing dangerous cargo warehouse with the free zone program, JWD has firstly developed its “Free Zone Laem Chabang Logistics Center” (see Figure 2) with advantages are as follows: Relief from Import and Internal Taxes/Duties Relief from Export Duty on Re-Exports Relief from Standard/Quality Duty Exemption on Waste, Scrap and Yield Loss Eligible for Export Tax Refund/Exemption Schemes Suitable immediately minutes from the port Sufficient surface area for future expansion (more than 100 rai/ 16 Hectares) Container Yards for FCL storage in proximity Figure 2 JWD’s Free Zone Laem Chabang Logistics Center Details of the JWD's Free Zone Warehouse and Logistics Center: Operation start : November 2006 Customs house on site Total Foot Print of LCB Site : 80,000 M2 (50 Rai) No. of Storage Facilities : 1 Unit Dimension : L 152 m x W 60 m x H 10 m Total storage area : Around 9,120 M2 No of storage facilities : 1 unit Floor loading factor : 3.5 Tons / M2 W/H Office: Stand alone, within facility Types of storage room : Ambient / Air-conditioned Storage Type : Racking system 1,800 Pallets Position & Floor area for block stack (Up-lifted by 1.4m.) Products : Suitable for most general cargo storage Equipment : 3+1 F/L for 2.5 tons and 1 Reach Truck Docking bays with hydraulic dock levelers CCTV control system : Total 8 unit Lighting System : Max 450 W High Bay Luminaire Fire extinguisher system On-site security guards (24 hours a day, 365 days a year) LAN based office Sophisticated Warehouse Management System with Barcode System 284 UTCC Engineering Research Papers 2010 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland 4.3 ANALYSIS OF DANGEROUS CARGO FREE ZONE WAREHOUSE Integrating the dangerous cargo warehouse in the free zone logistics center can be done by analyzing particular types of dangerous or hazardous cargo being stored and its layout and infrastructure. There are 4 classes of the dangerous or hazardous cargo that can be stored in the free zone warehouse: Class 2 (sub group 2.2 – non flammable and toxic material), Class 6 (toxic material), Class 8, and Class 9. For additional safety protections for dangerous cargo warehouse in free zone logistics center, the warehouse will be fully equipped with safety equipment such as fire alarms, fire hose reels, fire extinguishers, emergency eye wash, emergency shower, emergency response equipment, and first aid kits illustrated in Figure 3. Figure 3 Additional Safety Protections for Dangerous Cargo Warehouse in Free Zone Logistics Center By developing dangerous cargo free zone warehouse, it is also necessary to develop the layout for an identification of dangerous cargo free zone warehouse activities of JWD shown in Figures 4 and 5. Figure 4 JWD’s Dangerous Cargo Warehouse Layout in Free Zone Logistics Center UTCC Engineering Research Papers 2010 285 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland Figure 5 JWD’s Dangerous Cargo Warehouse Infrastructure in Free Zone Logistics Center 4.4 MARKETING STUDY 1) Amount and service usage of Free Zone warehouse and its transportation From the survey, it was found that 100% of road transportation activities have relation with free zone warehouse before shipping to Laem Chabang port. This can estimate the containers that will use dangerous cargo free zone service as follows: 1.1) Containers (Size: 20 feet) unit: container Amt per day IN 250 OUT 100 Amt per month 7500 3000 Amt per year 90000 36000 1.2) Free zone freight forwarder system should consider the followings: Amount of goods storage is estimated at 10% of the containers from dangerous cargo free zone warehouse (the weight of the container size 20 feet = 20 tons). 1.3) Condition of goods storage in the warehouse: In case of dangerous cargo, explosive cargo or flammable cargo with flash point at 61`C or 141`F or lower, exemption period is 1 day only after their unload date from vessel. 2) Potential Area of Dangerous Cargo Free Zone warehouse The JWD’s dangerous cargo free zone warehouse is an international warehouse with no limited storage time. Imported and exported goods can be kept in the free zone warehouse with value added activities and repacking, as well as can be partially withdrawn for particular use. JWD plans to integrate the warehouse with information system linkage that can track and trace dangerous cargo throughout several parties such as shipper, forwarder, agent, shipping, 286 UTCC Engineering Research Papers 2010 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland customs, port operator, Laem Chabang port, department of industrial works (Thailand), pollution control department (Thailand), and others. 5. CONCLUSION AND RECOMMENDATION The new dangerous cargo free zone warehouse service will be operated at the JWD’s Free Zone Laem Chabang Logistics Center. Featuring more than 20,000 sqm of indoor and outdoor space with fully facilities, JWD’s new dangerous cargo free zone service is as flexible as it is spacious. The advantage of location is nearby Laem Chabang seaport and manufacturing industry. The dangerous cargo free zone warehouse can offer manufacturers and processors to relief from import and internal taxes/duties. A few main benefits that account for most of the companies that use a free zone program are listed as follows: Relief from import and internal taxes/duties Relief from export duty on re-exports Relief from Standard/Quality Control Requirements Duty exemption on waste, scrap, and yield loss Eligible for export tax refund/exemption schemes. This dangerous cargo free zone warehouse will allow importers to bring dangerous goods of foreign origin into Thailand without paying customs duties and taxes, pending their eventual processing, transshipment or re-exportation. The dangerous cargo free zone warehouse facility acts as a hub and spoke that can handle things such as the processing of shipments and reassembly. REFERENCES Airports of Thailand Public Company Limited (2009). Suvarnabhumi Airport Free Zone, [Online Available] http://www.freezonethaiairport.com. Giovanni Facchini and Gerald Willmann (1999). The Gains from Duty Free Zones, Journal of International Economics, 49 (2), December 1999, pp. 403-412. Iris F.A. Vis and Kees Jan Roodbergen (2004). Warehouse Layout Alternatives for Varying Demand Situations, Vrije Universiteit Amsterdam. Lambert, D.M., Stock, J.R., and Ellram, L.M. (1998). Fundamentals of Logistics Management, Singapore: McGraw-Hill Companies. JWD InfoLogistics Co., Ltd. (2010). ChemLog DG Logistics Center, [Online Available]: http://www.jwd-logistics.com/cms/index.php?id=21. Laptaned, U. (2010). Transforming Bonded Warehouse into Free Zone Warehouse for Business Competitiveness: A Feasibility Study, In Proceedings of the Eurasia Business and Economics Society 2010 Conference, Istanbul, Turkey. Muther, R. (1973). Systematic Layout Planning. (2nd Ed.) New York, Van Nostrand Reinhold. UTCC Engineering Research Papers 2010 287 Proceedings of the 4th Biennial 2010 Academy of World Business, Marketing & Management Development Conference, 12-15 July, 2010, Scandic Hotel, Oulu, Finland Niebel, B. & Freivalds, A. (2003). Methods, Standards, and Work Design. (11th Eds.). New York, NY: McGraw-Hill, Co. Inc. Shihyu Chou and Chia-Hsuan Hsu (2005). A Study on the Integrated Model of Retailer’s Inventory Order Decision and Distributor’s Product Transportation in a Supply Chain: SinglePeriod Products, Proceedings of the 1st International Conference on Operations and Supply Chain Management, Bali, Indonesia. 288 UTCC Engineering Research Papers 2010