decomposition kinetics using TGA, TA-075

advertisement

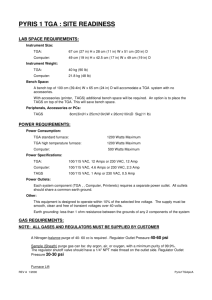

Thermal Analysis & Rheology DECOMPOSITION KINETICS USING TGA By S. Sauerbrunn & P. Gill TA Instruments 109 Lukens Drive New Castle, DE 19720 TA-075 INTRODUCTION Thermogravimetric analysis (TGA) is a thermal analysis technique which measures the amount and rate of change in the weight of a material as a function of temperature or time in a controlled atmosphere. TGA measurements are used primarily to determine the composition of materials and to predict their thermal stability up to elevated temperatures. However, with proper experimental procedures, additional information about the kinetics of decomposition and in-use lifetime predictions can be obtained. Traditionally, isothermal and constant heating rate thermogravimetric analysis have been used to obtain kinetic information with the constant heating rate method developed by Flynn and Wall [1] being preferred because it requires less experimental time. However, the Flynn and Wall method is limited to well-resolved single step decompositions and first order kinetics. High resolution TGA [2], a new approach developed and patented by TA Instruments, provides an alternative not only for improving the separation (resolution) of overlapping decompostion peaks, but also provides a means for determining the kinetic parameters for more complex decompositions. High-resolution TGA is based on varying (slowing) the heating rate during decomposition regions and consists of a collection of heating algorithms which employ both historical alogrithms namely, constant reaction rate [3,4] and stepwise isothermal [5], as well as a novel method, dynamic heating rate [2]. This paper explores the theory behind extracting kinetic parameters from each approach as well as illustrate where each approach provides maximum benefit. The specific TGA system used to conduct these experiments is shown in Figure 1. [ High resolution TGA is an optional accessory for the TGA 2950]. THEORY CONSTANT HEATING RATE TGA The constant heating rate, or conventional TGA, approach is based on the Flynn & Wall method which requires three or more determinations at different linear heating rates, usually between 0.5 and 50oC/minute (See Figure 1). The approach assumes the basic Arrhenius equation. ( ) dα n = Z exp -Ea RT (1- α ) dt where: α t Z Ea R n = = = = = = fraction of decomposition time (seconds) pre-exponential factor (1/seconds) activation energy (J/mole) gas constant (8.314 J/mole K) reaction order (dimensionless) Flynn and Wall rearranged this equation to get the following equation. -R d 1n β Ea = b d 1 T ( ) CONSTANT where: b = constant assuming n=1 β = heating rate (oC/minute) T = temperature of weight loss (oC) Using a point of equivalent weight loss (decomposition) which is beyond any initial weight loss due to volatiles evolution, a plot of 1n β vs 1/T is constructed. The slope of this straight line plot is then used to calculate activation energy (Ea), and the pre-exponential factor (Z) is calculated by the interactive method of Zsako and Zsako [3]. The results from this approach are most informative when plotted as estimated lifetime versus temperature as shown in Figure 2. [4] CONSTANT REACTION RATE TGA Constant reaction rate TGA is a high resolution approach originally developed by Rouquerol [5] and later improved by Paulik & Paulik [6]. In this approach the TGA heating rate is adjusted as required (even to the point of cooling) in order to maintain an operator selected constant rate of weight loss. Constant reaction rate TGA has proved most useful for samples which decompose reversibly. This is normally true for inorganic materials that lose ligand molecules, usually small molecules like water, carbon dioxide, etc. Figure 3, for example, shows the separation of the carbon dioxide losses from a mixture of sodium bicarbonate and potassium bicarbonate. The constant reaction rate method allows the carbon dioxide to be released from the sodium bicarbonate before the temperature increases enough for the potassium bicarbonate to begin decomposing. Taking the natural log of the Arrhenius equation yields: dα Ea n 1n = 1n Z - + 1n (1- α ) RT dt which can be rearranged to: 1n 1 (1- α ) n Ea 1 dα = - + 1n Z -1n R T dt CONSTANT The last two terms in this equation are constant during a constant reaction rate TGA experiment. Hence, the activation energy can be determined directly by plotting 1n (1/1-α) versus 1/T, assuming a reaction order of one (a reasonable assumption for many decomposing polymers). Figure 4 shows the activation energies obtained by this approach for the two weight losses which occur in polyethylene vinylacetate (EVA). Obviously, the advantages of this approach are the ability to evaluate multiple component materials and the need for only a single experiment. DYNAMIC HEATING RATE TGA Dynamic heating rate TGA is a high resolution approach (patented by TA Instruments) in which the heating rate and rate of weight loss both continuously vary during decomposition. The heating rate is decreased, however, as the rate of weight loss increases. The result is both enhanced resolution and productivity (generally faster than constant heating rate experiments). Decomposition kinetics may be obtained from dynamic heating rate TGA experiments using a derivation of the Arrhenius equation first published by Seferis and Salin (7). In their paper, Seferis and Salin take the second derivative of the Arrhenius equation versus temperature and the natural log to get: ( Hr -Ea 1n = R T2 = = n(1- α ) ) ( 1T) -1n ZR Ea n-1 Heating rate at the peak (oC/min) Temperature at the peak (K) where: Hr T assuming: α is constant dHr/dT is zero at the peak maximum d (dα/dT) / dT is zero. If the reaction order (n) is one, then the equation simplifies to: ( n) ( ) ( 1T) -1n ZR Ea Hr 1n = Ea R T2 CONSTANT Plotting 1n (Hr/T2) versus 1/T permits Ea to be determined as shown in Figure 5 for EVA. Note the excellent agreement between the activation energies determined by constant reaction rate (Figure 4) and these values. Although the dynamic heating rate approach requires at least three experiments at different maximum heating rates to obtain kinetic information, the calculation of activation energy, Ea, is independent of reaction order, a, and the reaction mechanism. STEPWISE ISOTHERMAL TGA The fourth approach for TGA kinetic analysis is the Stepwise Isothermal analysis first proposed by Sorenson (8). In this TGA method the operator defines a maximum heating rate and two weight loss per minute thresholds. A typical thermal method would look like the following: 1) 2) 3) 4) 5) Abort next segment if % /min > 5.0 Ramp 5oC/min to 1000oC Abort next segment if % /min < 0.5 Isothermal for 1000 mins Repeat from segment 1 til 1000oC In this experiment the TGA ramps at 5oC/minute until the sample starts to lose weight at 5.0% /minute or faster. When this condition is reached the Abort segment causes the method to stop segment 2 and go on to the next segment (segment 3). The TGA then holds isothermal until the sample decomposition rate falls below 0.5% /minute. At that point, the Repeat segment (segment 5) causes the whole method to be run over and over until all the transitions of the sample have been observed. Figure 6 shows a TGA plot of the typical results for a stepwise isothermal experiment. The sample is again polyethylene vinylacetate. The stepwise isothermal approach yields a kinetic treatment similar to classical isothermal TGA in which the Arrhenius equation can be arranged to: -Ea dα n Z exp RT = (1- α ) dt CONSTANT Since the last term is constant during an isothermal situation, a plot of dα/dt versus (1-α) should yield a straight line if the reaction order is one. Figures 7 and 8 show these plots for the two weight losses in EVA. The results indicate that the first decomposition has a reaction order of one, but the second decomposition does not. To determine the reaction order for the second decomposition, the previous equation needs to be modified by taking the natural log of both sides of the equation to yield: dα 1n = n 1n (1- α ) + B dt where B is a constant dα Plotting 1n versus (1-α) as shown in Figure 9 allows the reaction order to be determined from the slope of the dt resultant line. The reaction order in this case is 1.14. As seen from this illustration, the major advantage of the stepwise isothermal approach is that it permits the reaction order for each step of a multiple step decomposition to be determined from a single TGA experiment. CONCLUSIONS The addition of high resolution capability to TGA not only provides improved resolution for better interpretation of weight loss and evolved gas results, but it also provides additional flexibility for determining valuable and reliable kinetic information. Figure 10 summarizes the relative capabilities of the different approaches with regard to kinetics and should serve as a quick reference when selecting conditions for introduction of a new material. TGA KINETICS - FLYNN & WALL METHOD 2.5, 5, 10, & 20oC/minute heating rate 104 100 -1.0% -2.5% Weight (%) 96 -5.0% 92 -10.0% 88 84 -20.0% 80 76 440 460 480 500 520 540 560 Temperature (oC) Figure 1 580 600 620 640 LIFETIME PREDICTION PLOT FROM TGA RESULTS 6 10 Estimated Lifetime (hour) 105 Activation energy: Pre-exponential factor: 60 min half life temp: Conversion level: Lifetime adjustment Known lifetime: Known lifetime temp: 100 YR 289. kJ/mole 1.85E+17 1/min 512.9 oC 5.00% 10 YR 60000 hour 180.0 oC 104 1 YR 103 30 DAY 7 DAY 102 1000/Temperature (I/K) 1.9 10 260 250 240 2.0 230 220 2.1 210 200 Time (min) Figure 2 190 1 DAY 2.2 180 170 160 150 BICARBONATE MIXTURE BY HI-RES TGA 110 100 Hermetic Pan With Pinhole 133 Minutes Weight (%) 90 80 70 60 0 5 100 150 Temperature (oC) Figure 3 200 250 ENERGY ACTIVATION OF EVA USING DYNAMIC HEATING RATE 4 FIRST WEIGHT LOSS 160.6 kJ/mol [(a-l)/l]) 3 2 SECOND WEIGHT LOSS 276.kJ/mol 1 0 1.4 1.5 1.6 1.7 1000/T(k) Figure 4 1.8 1.9 300 ENERGY ACTIVATION OF EVA USING DYNAMIC HEATING RATE -10 FIRST LOSS 165 kJ/mol -11 ln(Hr/T2) -12 SECOND LOSS 270 kJ/mol -13 -14 -15 -16 1.3 1.4 1.5 1000/T(k) Figure 5 1.6 1.8 1.7 DECOMPOSITION OF EVA USING STEPWISE ISOTHERMAL ANALYSIS 120 8 10oC/min 5.0 & 0.2 %/min 100 [- - - - - - ] Weight (%) [___ ___ ___] Temperature (oC) 80 60 40 20 400 4 2 200 Deriv. Weight (%/min) 6 0 0 -2 -20 0 20 40 Time (min) Figure 6 60 80 100 DECOMPOSITION KINETICS OF EVA USING STEPWISE ISOTHERMAL ANALYSIS FIRST WEGHT LOSS 0.8 DECOMPOSITION RATE (%/min) REACTION ORDER = 1.00 0.7 0.6 74.87 7 74.63 74.4 73.8 73.63 73.46 DECOMPOSITION KINETICS OF EVA USING STEPWISE ISOTHERMAL ANALYSIS 6 DECOMPOSITION RATE (%/min) 74.19 73.99 WEIGHT PERCENT (%) Figure 7 SECOND WEIGHT LOSS 5 4 3 2 1 0 48.07 37.79 29.28 22.45 17.05 12.82 WEIGHT PERCENT (%) Figure 8 9.59 7.032 5.113 DECOMPOSITION KINETICS OF EVA USING STEPWISE ISOTHERMAL ANALYSIS 0 -0.5 In (da/dt) -1 -1.5 -2 SECOND WEIGHT LOSS -2.5 REACTION ORDER 1.14 -3 -3.5 0 1 2 In (1-a) 3 4 5 Figure 9 Kinetic Capabilities of Hi-ResTM TGA Methods TGA Method Scans Order Components Constant Heating Rate more than 2 Fixed at 1 Single Constant Reaction Rate 1 Fixed at 1 Multiple Dynamic Heating Rate more than 2 Independent Multiple Stepwise Isothermal 1 Determined Multiple Figure 10 REFERENCES 1. Flynn and Wall, Polymer Lett., 19, 323 (1966). 2. P.S. Gill, S.R. Sauerbrunn and B.S. Crowe, J. Therm. Anal., 38, 255-266 (1992). 3. Zsako and Zsako, J. Therm. Anal., 19, 33 (1980). 4. TA Instruments Application Brief TA-125. 5. J. Rouquerol, Bull. Soc. Chim., 31 (1964). 6. Paulik and Paulik, Anal. Chim. Acta., 56, 328 (1971). 7. J. Seferis and Salin, J. Appl. Poly. Sci., submitted Feb. 1992. 8. Sorensen, J. Therm. Anal., 13, 429 (1978). TA-075