Bulletin 71.4:630R

December 2011

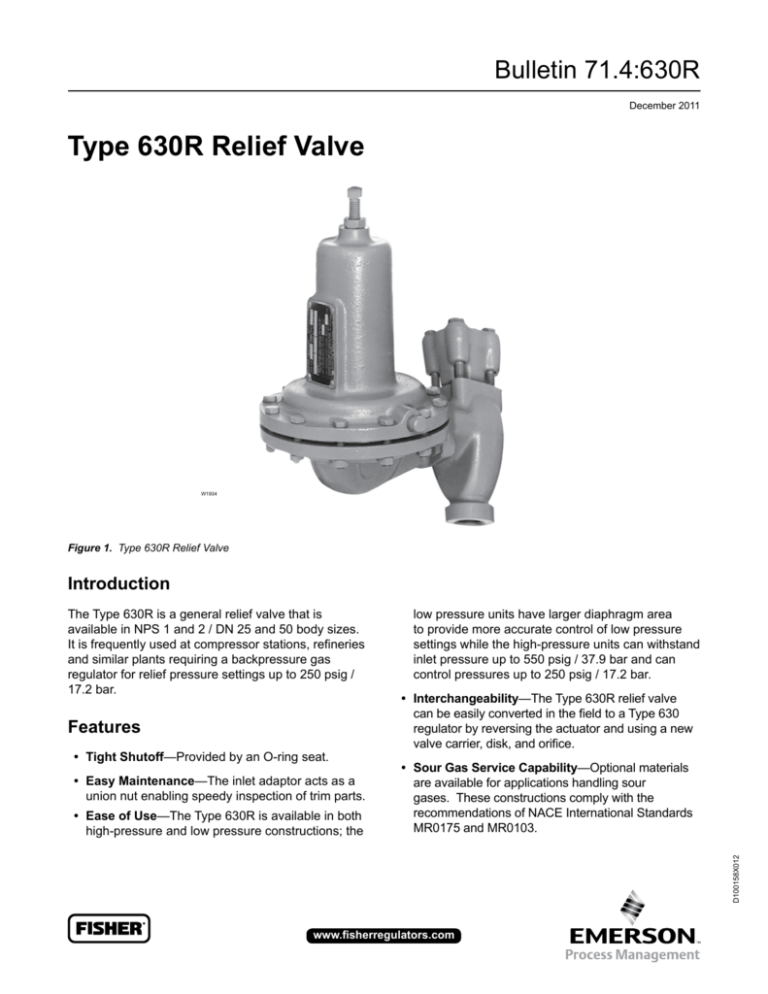

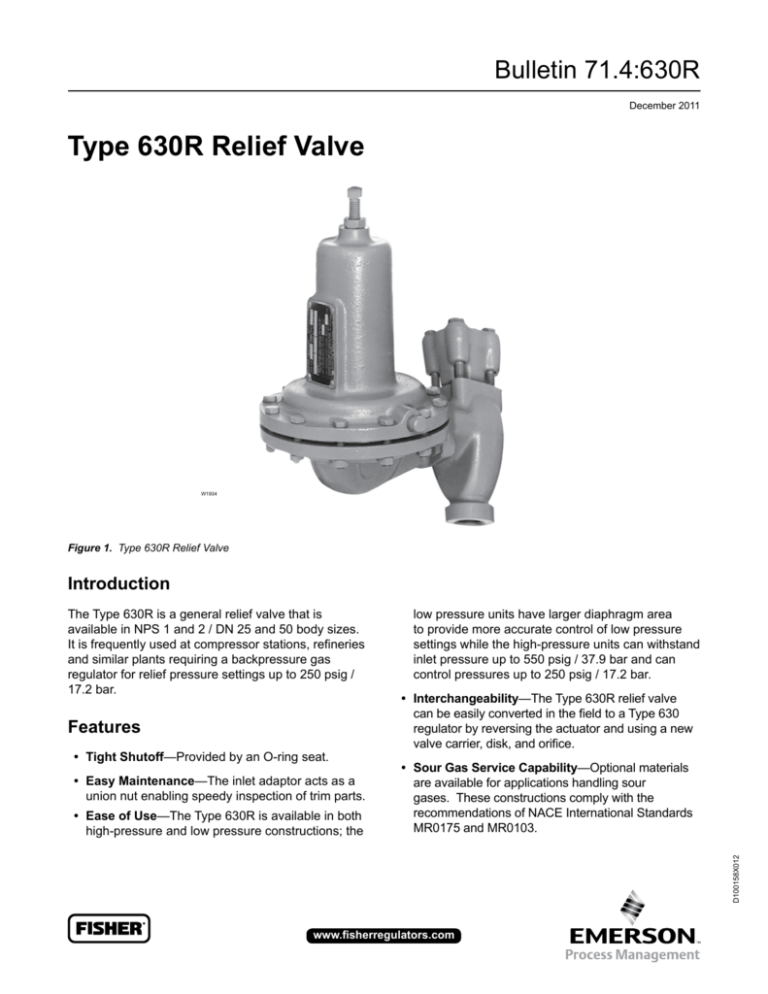

type 630r relief Valve

W1934

Figure 1. Type 630R Relief Valve

Introduction

The Type 630R is a general relief valve that is

available in NPS 1 and 2 / DN 25 and 50 body sizes.

It is frequently used at compressor stations, refi neries and similar plants requiring a backpressure gas

regulator for relief pressure settings up to 250 psig /

17.2 bar.

Features

• Tight Shutoff—Provided by an O-ring seat.

• Easy Maintenance—The inlet adaptor acts as a

union nut enabling speedy inspection of trim parts.

• Interchangeability—The Type 630R relief valve

can be easily converted in the fi eld to a Type 630 regulator by reversing the actuator and using a new

valve carrier, disk, and orifi ce. • Sour Gas Service Capability—Optional materials

are available for applications handling sour

gases. These constructions comply with the

recommendations of NACE International Standards

MR0175 and MR0103.

D100158X012

• Ease of Use—The Type 630R is available in both

high-pressure and low pressure constructions; the

low pressure units have larger diaphragm area

to provide more accurate control of low pressure

settings while the high-pressure units can withstand

inlet pressure up to 550 psig / 37.9 bar and can

control pressures up to 250 psig / 17.2 bar.

www.fisherregulators.com

Bulletin 71.4:630R

Specifications

Regulator Construction

• Low-Pressure

• High-Pressure

Body Sizes

NPS 1 and 2 / DN 25 and 50

End Connection Style

NPT, CL150 RF, CL300 RF, or CL600 RF

Maximum Inlet Pressure(1)

Low-Pressure Construction: 66 psig / 4.6 bar

High-Pressure Construction: 550 psig / 37.9 bar

Maximum Inlet Pressure Build-up above Setpoint

(Internal Damage)

Low-Pressure Construction: 25 psig / 1.7 bar

High-Pressure Construction: 250 psig / 17.2 bar

Maximum Outlet Pressure(1)

See Table 1

Pressure Registration

Internal

Orifice Size

1/2-inch / 13 mm

Flow Coefficients

Wide-open Cg: 216.0

Wide-open Cv: 8.18

C1: 26.4

IEC Sizing Coefficients

Fd: 0.50

Fl: 0.89

Xt: 0.441

Temperature Capabilities(1)

Nitrile (NBR), Nylon (PA), and Neoprene (CR): -20° to 180°F / -29° to 82°C

Fluorocarbon (FKM) and

Polytetrafluoroethylene (PTFE):

0° to 300°F / -18° to 149°C

Construction Materials

Body: Cast iron or steel

Spring Case and Diaphragm Adaptor:

Cast iron or steel

Orifice: Brass or Stainless steel

O-ring Holder: Brass or Stainless steel

Valve Carrier: Brass or Stainless steel

Diaphragm: Neoprene (CR) or Fluorocarbon (FKM)

Diaphragm Head: Zinc-plated steel

Pitot Tube: Stainless steel

Regulator Spring: Plated steel

Adjusting Screw: Steel

Inlet Body Gaskets: Copper with Brass trim or Stainless steel with Stainless steel trim

All Other Gaskets: Composition

Upper Spring Seat: Zinc-plated steel

Lower Spring Seat: Aluminum (low-pressure) or Zinc (high-pressure)

Spring Case Vent

1/4 NPT

Option

• Polytetrafluoroethylene (PTFE)

diaphragm protector

1. The pressure/temperature in this Bulletin and any applicable standard or code limitation should not be exceeded.

Principle of Operation

Refer to Figure 2. Inlet pressure registers beneath the

diaphragm. As long as the inlet pressure is less than

the set pressure, spring force causes the lever to hold

the valve closed. When the inlet pressure exceeds

the set pressure, the diaphragm moves to compress

the spring and the lever opens the valve allowing

inlet pressure to bleed into the downstream line or to

atmosphere until the inlet pressure returns to

set pressure.

Installation

The Type 630R relief valve may be installed in any

position. However, the outlet connection and vents

2

must be protected against the entrance of rain, snow,

insects, or any other foreign material that may plug the

outlet or affect the opening and closing of the valve.

If it is necessary to pipe away the outlet, remove the

outlet screen (if one is present).

Flow through the valve must be as indicated by the

flow direction arrow on the body. For dimensional

information see Figure 3.

Fisher® provides an instruction manual with every

valves shipped. Refer to this for complete installation,

operation and maintenance instructions. Included is a

complete listing of individual parts and recommended

spare parts.

Bulletin 71.4:630R

spring case

lever

diaphragm

body

orifice

diaphragm

connector

O-ring holder

valve carrier

diaphragm

adaptor

A6674

inlet pressure

OUTLET (EXHAUST) PRESSURE

atmospheric pressure

Figure 2. Type 630R Relief Valve Operational Schematic

Table 1. Relief Set Pressure Ranges

REGULAR CONSTRUCTION

Low-Pressure

High-Pressure

Relief Set PRESSURE

RANGE

Spring Part

Number

Spring

Color Code

SPRING WIRE DIAMETER

psig

bar

Inches

mm

3 to 8

0.21 to 0.55

0W019227022

Red

0.225

5.71

6 to 17

0.41 to 1.2

0W019127022

Olive Drab

0.281

7.14

15 to 22

1.0 to 1.5

0W019027022

Unpainted

0.337

8.56

20 to 35

1.4 to 2.4

0Y066427022

Green Stripe

0.363

9.22

35 to 50

2.4 to 3.4

1J146927142

Blue Stripe

0.375

9.52

30 to 70

2.1 to 4.8

0W019127022

Olive Drab

0.281

7.14

50 to 95

3.4 to 6.6

0W019027022

Unpainted

0.337

8.56

75 to 175

5.2 to 12.1

0Y066427022

Green Stripe

0.363

9.22

150 to 250

10.3 to 17.2

1J146927142

Blue Stripe

0.375

9.52

SPRING FREE LENGTH

Inches

mm

6

152

6.19

157

6

152

6.19

157

3

Bulletin 71.4:630R

Universal NACE Compliance

Optional materials are available for applications

handling sour gases. These constructions comply

with the recommendations of NACE International sour

service standards.

The manufacturing processes and materials used

by Emerson assure that all products specified

for sour gas service comply with the chemical,

physical, and metallurgical requirements of

NACE MR0175 and/or NACE MR0103. Customers

have the responsibility to specify correct materials.

Environmental limitations may apply and shall be

determined by the user.

the factors in the preceding paragraph

if necessary:

Q = (P1 + build-up)absCg

1. To determine capacities at set pressures or

build-ups not given in Table 2, use one of

the following formulas, and convert according to

GT

2. For pressure drops lower than critical (absolute

outlet pressure greater than one-half of absolute

inlet pressure), use the following formula:

Q=

Capacity Information

Table 2 gives relief capacities at selected set

pressures for the Type 630R relief valve. Flows

are in SCFH (60°F and 14.7 psia) and Nm³/h (0°C

and 1.01325 bar) of 0.6 specific gravity natural gas. To determine equivalent capacities for air, propane,

butane, or nitrogen, multiply the Table 2 capacity

by the following appropriate conversion factor:

0.775 for air, 0.625 for propane, 0.547 for butane,

or 0.789 for nitrogen. For gases of other specific

gravities, multiply the given capacity by 0.775,

and divide by the square root of the appropriate

specific gravity.

520

3417

520

Cg (P1 + build-up)abs SIN

C1

GT

P

P1

Deg.

where,

Q = flow capacity in SCFH

G = specific gravity of gas

T = abosolute temperature of gas at inlet in

°Rankine (°Rankine = °Fahrenheit + 460)

Cg = sizing coefficient (See

Specifications section)

P1abs = absolute inlet pressure in psig

(P1 gauge + 14.7)

C1 = Cg/Cv (See Specifications section)

P = pressure drop across the valve in psig

Table 2. Capacities in SCFH / Nm3/h of 0.6 Specific Gravity Natural Gas at 14.7 psia and 60°F / 1.01325 bar and 0°C

LOW-PRESSURE CONSTRUCTION

HIGH-PRESSURE CONSTRUCTION

Capacities, SCFH / Nm3/h

Relief Pressure Setting

10% Build-up

20% Build-up

Capacities, SCFH / Nm3/h

psig

bar

psig

bar

5

10

15

0.34

0.69

1.0

640

1420

2000

17.2

38.1

53.6

2710

2900

4200

72.6

77.7

113

50

75

100

3.4

5.2

6.9

2900

2700

3260

77.7

72.4

87.4

7100

7480

9670

190

200

259

20

35

50

1.4

2.4

3.4

2130

3030

4900

57.1

81.2

131

4450

7230

14,000

119

194

375

125

175

250

8.6

12.1

17.2

5500

5480

13,500

147

147

362

14,200

19,000

48,000

381

509

1286

Note: Maximum Working Pressure Above Setting is 25 psig / 1.7 bar.

4

Relief Pressure Setting

10% Build-up

20% Build-up

Note: Maximum Working Pressure Above Setting is 250 psig / 17.2 bar.

Bulletin 71.4:630R

L

D

d

A

B

F

AA7679

NPT

or

SWE

G

Type 630R with NPT body

Figure 3. NPT Dimensions

Table 3. NPT Dimensions

NPT DIMENSIONS, inches / mm

Body Size, NPS

1

2

Low-Pressure Assembly

a

B

D

F

G

L

7.38 / 187

7.88 / 200

3.69 / 94

3.94 / 100

7.12 / 181

7.12 / 181

10.31 / 262

10.94 / 278

1.38 / 35

2.00 / 51

15.88 / 403

16.38 / 416

1.38 / 35

2.00 / 51

15.88 / 403

16.38 / 416

Body Size, NPS

1

2

High-Pressure Assembly

7.38 / 187

7.88 / 200

3.69 / 94

3.94 / 100

4.62 / 117

4.62 / 117

7.81 / 198

8.44 / 214

5

Bulletin 71.4:630R

E

F

D

A

C

A/2

B

16A7430

Type 630R with Flanged body

Figure 4. Flange Dimensions

Table 4. Flange Dimensions

FLANGED DIMENSIONS, inches / mm

Low-Pressure Assembly

Body Size,

NPS / DN

a

CL150

CL300

CL150

CL300

1 / 25

19.59 / 498

9.80 / 249

2 / 50

21.9 / 556

10.95 / 278

Body Size,

NPS / DN

6

A/2

CL600

CL600

B

C

D

E

F

8.97 /

228

7.19 /

183

7.12 /

181

11.69 /

297

1.75 /

44

6.44 /

163

4.69 /

119

4.62 /

117

12.19 /

310

1.38 /

35

High-Pressure Assembly

1 / 25

19.59 / 498

9.80 / 249

2 / 50

17.6 / 447

8.8 / 223

Bulletin 71.4:630R

Ordering Information

When ordering, specify the following information:

1. Complete Type number

2. Body Size

3. Relief Setting

4. Body Material

5. Trim

Ordering Guide

Regulator Construction (Select One)

Low-Pressure

High-Pressure

Trim Material (Select One)

Brass***

Stainless steel**

Valve Carrier and Holder (Select One)

Brass***

Stainless steel**

Orifice (Select One)

Brass***

Stainless steel**

Relief Set Pressure Range (Select One)

Body Size (Select One)

NPS 1 / DN 25**

NPS 2 / DN 50**

Low-Pressure

3 to 8 psig / 0.21 to 0.55 bar***

6 to 17 psig / 0.41 to 1.2 bar***

15 to 22 psig / 1.0 to 1.5 bar***

20 to 35 psig / 1.4 to 2.4 bar***

35 to 50 psig / 2.4 to 3.4 bar***

Body and End Connection Style (Select One)

NPT**

CL150 RF**

CL300 RF**

CL600 RF**

High-Pressure

30 to 70 psig / 2.1 to 4.8 bar***

50 to 95 psig / 3.4 to 6.6 bar***

75 to 175 psig / 5.2 to 12.1 bar***

150 to 250 psig / 10.3 to 17.2 bar***

Diaphragm (Select One)

Neoprene (CR)***

Fluorocarbon (FKM)**

Replacement Parts Kit (Optional)

Yes, send one replacement parts kit to match

this order. Specification Worksheet

Regulators Quick Order Guide

***

**

*

Application:

Specific Use

Line Size

Gas Type and Specific Gravity

Gas Temperature

Relief Valve Size:

Brand of upstream regulator? Orifice size of the upstream regulator?

Wide-open coefficient of the upstream regulator?

Pressure:

Maximum Inlet Pressure (P1max)

Minimum Inlet Pressure (P1min)

Downstream Pressure Setting(s) (P2)

Maximum Flow (Qmax)

Allow Additional Time for Shipment

Performance Required:

Accuracy Requirements?

Need for Extremely Fast Response?

Special Order, Constructed from Non-Stocked Parts.

Consult your local Sales Office for Availability.

Other Requirements:

Readily Available for Shipment

Availability of the product being ordered is determined by the component with the

longest shipping time for the requested construction.

7

Bulletin 71.4:630R

Industrial Regulators

Natural Gas Technologies

TESCOM

Emerson Process Management

Regulator Technologies, Inc.

Emerson Process Management

Regulator Technologies, Inc.

Emerson Process Management

Tescom Corporation

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Asia-Pacific

Shanghai 201206, China

Tel: +86 21 2892 9000

Asia-Pacific

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Gallardon 28320, France

Tel: +33 2 37 33 47 00

Asia-Pacific

Shanghai 201206, China

Tel: +86 21 2892 9499

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 1970, 2011; All Rights Reserved