Sprinkler Plan Review Checklist - Woodbury, MN

advertisement

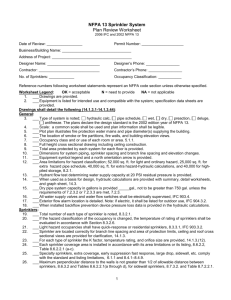

8301 Valley Creek Road • Woodbury, Minnesota 55125-3330 • www.ci.woodbury.mn.us 651/714-3500 • TDD 651/714-3568 • FAX 651/714-3501 Office of the Fire Marshal Sprinkler Plan Review Checklist This checklist should be used as a guide when submitting plans for review. Fire suppression plans submitted with incomplete information will delay the plan review process and delay the issuance of your permit. Location of work to be completed and Designer/Contractor Information □ □ □ □ Business Name where work is to be done Address where work will be completed including suite number if applicable Designer name and contact information Sprinkler contractor contact information and license number Working Plans Type of system is noted: Hydraulic Calculation Pipe Schedule Wet System Dry System Preaction System Deluge System Scale: plans are drawn to a common scale and plans are legible Plot plan showing supply piping and pipe size to the building Location of party walls and fire walls Occupancy classification of the building Provide occupancy for each room or area Classify each room or area if the hazard is different than adjacent rooms or areas Full height cross sections including ceiling construction if required for clarification Total area protected by each system per floor Dimensions for system piping and component spacing Equipment symbol legend and compass point Area limitations for hazard classification 8.2.1 Light Hazard & Ordinary Hazard – 52,000 sf Extra Hazard Pipe Schedule – 25,000 sf Hydraulically Calculated – 40,000 sf Storage – 40,000 Hydrant flow test showing water supply capacity Working Plans (cont) Hydraulic calculations are provided with summary, detail worksheets, and graph sheet, except for permissible pipe schedule systems 14.3 Scale: plans are drawn to a common scale and plans are legible Plot plan showing supply piping and pipe size to the building Location of party walls and fire walls Occupancy classification of the building Provide occupancy for each room or area Classify each room or area if the hazard is different than adjacent rooms or areas Full height cross sections including ceiling construction if required for clarification Total area protected by each system per floor Dimensions for system piping and component spacing Equipment symbol legend and compass point Area limitations for hazard classification 8.2.1 Light Hazard & Ordinary Hazard – 52,000 sf Extra Hazard Pipe Schedule – 25,000 sf Hydraulically Calculated – 40,000 sf Storage – 40,000 Hydrant flow test showing water supply capacity Hydraulic calculations are provided with summary, detail worksheets, and graph sheet, except for permissible pipe schedule systems 14.3 Sprinklers Number of each type of sprinkler is noted Ordinary temperature-rated sprinklers shall be used, see exception 8.3.2.1 Minimum temperature for ceiling sprinkler for general rack, tire, and rollpaper storage is 150 degree 8.3.2.7 General rack, tire, and rollpaper storage with required densities: 12.1.13.1 .20gpm/sf or less use standard response sprinklers w/K-factor of 5.6 or larger .20 - .34gpm/sf use standard response sprinklers w/K-factor of 8.0 or larger >.34gpm/sf use standard response sprinklers w/K-factor of 11.2 or larger (see exception which allows quick response sprinklers if listed for use 12.1.13.5) Light hazard occupancies shall use quick-response sprinklers 8.3.3.1 Sprinkler location is correct, ceiling and roof sectionals are provided for clarification 14.3 Types of sprinklers: K-factors, temperature rating, and orifice size 14.3.12 Each sprinkler coverage area is within the square footage limitations 8.6.22, Table 8.6.22.1(a-c) Specialty sprinklers, EC, ESFR,QRES, large drop, sidewall, etc. comply w/standard & listing limitations 6.1.1, and 8.4 1-9 Maximum distance to walls is not greater than ½ of the allowable distance between sprinklers 8.6.3.2 for sidewall sprinklers 8.7.3.2 Standard sprinkler spacing from vertical obstructions comply with table 8.6.5.1 Sidewalls, Table 8.7.5.2 Extended coverage up and pendent, Table 8.8.5.2 Extended coverage sidewall Table 8.9.5.2 Obstructions below large drop Table 8.10.5.1.2 Sprinklers (cont) Standard sprinkler spacing from horizontal obstructions comply with Table 8.6.5.1.2 Sidewalls Table 8.7.5.1.3 Extended coverage up and pendent Table 8.8.5.1.2 Extended coverage sidewall Table 8.9.5.1.3 Large drop Table 8.11.5.1.2 ESFR Table 8.12.5.1.1 Sprinkler coverage is provided under obstructions > 4’ wide and shielding of sprinklers is provided for under grating coverage 8.5.5.3.1 Baffles are provided for sprinklers < 6’ apart 8.6.3.4.3 Pipe Support and Hangers Type and location of hangers, sleeves, and braces are shown 14.1.3 Non-listed hangers shall meet requirements in 9.1.1.2 Steel pipe hanger spacing is not greater than: 12’ for 1” to 1 ½” 15’ for 1 ½” to 8” See table 9.2.2.1 for copper See table 9.2.2.1 for plastic Light wall steel pipe hanger spacing is not greater than: 12’ for 1” to 3” pipe table 9.2.2.1 Branch lines show one hanger per section of pipe, see exceptions 9.2.3.2 Cross mains show one hanger between each branch line, see exceptions 9.2.4 Risers in multi-story buildings show support at the lowest level, each alternate level, below offsets, and at the top 9.2.5.3 Risers have a distance between supports not greater than 25’ 9.2.5.4 If trapeze hangers are used, locations are shown and meet specifications in 9.1.1.6.1 Pipes and Valves Main drain pipe is: ¾” or greater for riser up to 2” 1 ¼” or greater for riser 2 ½” to 3 ½” 2” only for riser 4” or greater Size is shown or determined by specified valve type 8.15.2.4 Main drain to exterior or interior is specified 8.15.2.4.4 Auxiliary drain location is shown and size is per 8.15.2.5 Fire Department Connections Water flow alarm required on all sprinkler systems having more than 20 sprinklers 8.16.1.1 Flow alarm location is shown above the FDC 8.16.1.1 FDC location and check valve is shown, location will not obstruct emergency vehicle access to the building when connected IFC 912 FDC is minimum 4” pipe, supported and 18” – 48” above grade see size exceptions 8.16.2.3, 8.16.2.4 FDC is on system side of water supply check valve and located before other control valves for mulit-risers see 8.16.2.4.2 1-4 for single systems. Hydraulic Calculations Provide method used for density/area calculations 11.2.3.2 Reference points match with plans and occupancy classifications are correct 11.2.1 Use of QR sprinklers in design area meet design specifics 11.2.3.2.3 Pipe size references match plans Sloped ceiling may require 30% increase of design area 11.2.3.2.4 Sprinkler head information supplied matches the plans Water flow information is provided with static psi, and residual psi, Density and area design are provided and comply with 11.2.3.1.8 Calculations are correct: Static psi Pipe length Gpm K for drops or branch lines Elevation data Hose allowance Friction loss Equivalent pipe length 11.2.3 Minimum of 2 summary calculations provided for a grid system see exception 14.4.4.2 Legend provided for calculation abbreviations Calculations provided for EH occupancy, deluge, and exposure systems Dry pipe and double interlock preaction design areas are increased 30%, density remains the same 11.2.3.2.5 Use of high temperature sprinklers in EH occupancy may reduce design area by 25% 11.2.3.2.6 Residential Sprinklers in an NFPA 13 System Calculations for a single and for a multiple sprinkler discharge are provided 11.2.3 Calculation design is based on the 4 most demanding sprinklers at the minimum listed flow rate or .1gpm/ft 11.2.3.5.1 Hose streams and water duration requirements are for LH per table 11.2.3.1.1, 11.2.3.5.5 Special Design Special design considerations for exposure protection, water curtain, and dry systems are per 11.2.3 7-9 Wet System Relief valve not less than ¼” is detailed for gridded system An alarm connection not less than 1”, discharging to the exterior is provided to test the water flow alarm 8.16.4.2.1 Dry System (grid system not permitted 7.2) Only upright sprinklers are used see exceptions for return bends 7.2.2 System capacity is provided and is not more than 750 gallons, unless water is delivered within 60 seconds 7.2.3.2 A test trip connection with a shut-off valve and at least a 1” plug is at the furthest sprinkler pipe 8.16.4.3 Compressor capacity specification sheet is provided, restores system within 30 minutes 7.2.6 Compressor piping system: Air fill line not less than ½” Check valve shown Relief valve shown Shut off shown or noted 7.2.6.3 Location for the Quick Opening Device (QOD) for systems greater than 500 gallons is shown see exception 7.2.4 Check valve for the QOD and the anti-flooding device between the riser and the QOD are shown 7.2.4.6 Preaction or Deluge System Pressure gauge locations are above and below the preaction valve and on the air supply 7.3.1.3 Location and spacing of the detection devices are detailed 7.3.1.6 Preaction system is limited to 1000 heads, see exception 7.3.2.1 750 gallon limit per valve Preaction system is supervised when there are more than 20 sprinklers 7.3.2.3 Sprinklers used in pendant position shall be listed as dry pendants 7.3.2.4 Double interlock systems are not gridded 7.3.2.5 and valve room is heated 7.3.1.8 Combined Dry Pipe and Preaction Systems Dry pipe riser location is shown Two 6” dry pipe valves are interconnected with 1” pipe with shut off valve for simultaneous tripping 3.4.2.2 QOD is provided at the dry pipe valves 7.4.2.8 A minimum 2” exhaust valve is shown at the end of the common feed main 7.4.3 Fire area requiring greater than 275 sprinklers shall divide system into sections of 275 sprinklers or less by the use of check valves A building with multi-fire areas shall limit 600 sprinklers per check valve 7.4.4.2 Manual method of activating the detection system is within 200’ of travel 7.4.1.3 Water shall reach the farthest sprinkler within a time period not exceeding 1 minute for each 400’ of common feed main 7.4.5.1 Check valve is at/near connection to water supply, single riser’s alarm valve is considered a Control Valve 8.15.1 Control valves are provided per 8.15.1.1.4 Water supply exceeding 175 psi requires pressure reducing valve, show locations 8.15.1.2 Gauges are on inlet and outlet sides of PRV and an indicating valve is on the inlet side 8.15.1.2 Flushing instructions are on plans Refrigerated Spaces: Refer to 7.8 Storage: Refer to Chapter 12 Protection against Exposure Fire: 7.7 Commercial Cooking Equipment: 7.9 Special Occupancy Requirements: Refer to Chapter 13 J:\WP\Fire 2011\Sprinkler Plan Review Checklist.doc