An Improved Method of Synthesis for N- (3-acetyphenyl)

advertisement

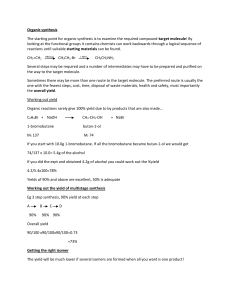

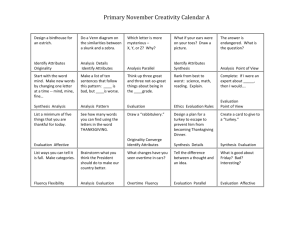

Dec. 2003 Journal of Electronic Science and Technology of China Vol.1 No.1 An Improved Method of Synthesis for N- (3-acetyphenyl) Acetamide LI Yuanxun TANG Xianzhong HE Wei (Department of Microelectronic and Solid-state Electronics, UESTC Chengdu 610054 China) Abstract 3-acetaminoacephenone is synthesized from acetophenone by nitrating, reducing and acetylating through an improved method. The designed route is reasonable and the new procedure is simple. The overall yield is 43.1%, which is about 15% higher than literature reported, and the structure of the product is identified by IR, 1HNMR, MS and elemental analysis. Key words 3-acetaminoacephenone; nitration; reduction; acetylation; synthesis 3-acetaminoacephenone has been widely founded applications in the microelectronics and drug industry [1,2] .It is an important intermediate for synthesis of Zaleplon-a novel sedative-hypnotic drug and photosensitive polyimides which is used as a ~ photoresist in the manufacture of integrated circuits[3 5] . Hence, It is regarded as a compound of potentially commercial value. A lot of chemists have focused much research on how to synthesize it easier. In the literature, many essays have reported synthetic routes and succeeded in preparing the product [6,7]. However, descriptions of the synthetic methods and procedure are complex and it’s hard to separate and pure intermediates that bring operations difficulties. Another obvious disadvantage is that the total yield rate is too low, about 30%. Here we overcome majorities of difficulties in the precious work and develop a simple, dependable and convenient way to synthesize it. 1 Theory of Synthesis This article adopts the route as following: O CH33 O CH CH33 HNO33 HNO H22SO SO44 H O Sn/HCl Sn/HCL CH CH33 NH NH22 CHCOCH NHCOCH33 Synthesis of 3-acetaminoacephenone In Fig.1, acetophenone is nitrified by HNO3/ H2SO4 at the temperature of −8ºC. Thus 3-nitroacephenone is prepared. Then Received 2003-03-19 2 Experiment 2.1 Materials and Instruments The 1H-NMR spectrum is operated at 400 MHz by using a JEOL JNM-EX 400 WB spectrometer. The infrared spectrum is recorded on a 200SXV Fourier transform spectrometer. The elemental analysis is performed on Italian CARIO ERBA1106 instrument and melting points of each substance are determined on XRC-1 apparatus. All reagents and solvents are obtained from commercial sources and used as received. 2.2 CH CH33COCL COCl C6H H6 C 6 6 NO NO22 Fig.1 O CH CH33 3-aminoacetoph-enone is synthesized by using reductant Sn/HCl. After this, the target product N(3-acetyphenyl) acetamide will be prepared by acetylating. There are two differences from other chemists have done before. One is in the procedure of preparation of 3-aminoacetophenone. The reducing agent is Sn, not Fe. The other is in the procedure of preparation of 3-acetaminoacephenone.The acetylating agent is CH3COCl, not acetic acid or acetic anhydride. These changes have done much good to operators. Preparation of 3-nitroacephenone Weigh 12 g of acetophenone into 250 ml flask, which immerse in an ice-salt bath and drop 30 ml concentrated sulfuric acid in with strong stirring. The cold acids mixture of 8.1 ml nitric acid and 12 ml concentrated sulfuric acid is added dropwise keeping the temperature below 0ºC. After this, stirrings are needed for about 30 min. Then pour the contents of flask into mixture of ice and water. A yellow product is collected by filtration. A final recrystallization from alcohol will give 9.1 g of 3-nitroacephenone[8,9]. Yield 55%. m.p75~76℃,Lit. m.p75~76℃ [10]. Preparation of 3-aminoacetophenone Weigh 1.0 g of 3-nitroacetophenone and 1.0 g of granulated tin into a 25 ml round bottom flask. Then pour 10 ml the dilute acid solution (2.5 ml concentrated hydrochloric acid with 7.5 ml water) into the flask through the condenser, stir and heat the reaction mixture until it begins to reflux. Then it will take about 30 min to dissolve the tin (a small amount of undissolved tin will do no harm). Cool the reaction solution in ice for a few minutes. Add the aqueous solution of NaOH (2.0 g of sodium hydroxide to 6 ml of water) to the reaction solution to precipitate the product. Stir the pale yellow slurry magnetically to ensure thorough mixing and cool the pale yellow suspension in ice. Then Collect the precipitate by suction filtration and wash with ice-cold water. The desired product totals 0.76 g, yield 86%, m.p93~ 94ºC,Lit. m.p95℃[11]. 2.4 benzene ring. The existence of concentrated sulfuric acid can help accelerating and completing nitration reaction. The proportion of nitric acid in total volume P affects the yield of product. Fig.2 shows the relationship between temperature and yield. We can draw a conclusion that the higher activity of nitration, the lower yield of the product will be. But if the temperature is too low, the rate of nitration will be slowed down too much. So here we control the temperature at −8℃. The yield has increased to 55%, which is 13% higher than the literature reported. Fig.3 shows the relationship between yield and proportion of nitric acid in total volume. We control the proportion at 0.675. 55 50 40 -10 3 Results and Discussion 3.1 Synthesis of 3-nitroacephenone Nitration Reaction of acetophenone using HNO3/H2SO4 is an electrophilic substitution reaction to -5 0 0 T/T/(℃) ( C) Preparation of N- (3-acetyphenyl) Acetamide Weigh 7.0 g 3-aminoacetophenone and pour 30 ml benzene and 10 ml (Et) 3N into flask. Reflux until it solves. Then drop 5.4 ml CH3COCl and reflux for 0.5 h. When the mixture cools down a little, place charcoalactivated in for 10 min. The product is got though suction filtration. A final recrystallization from alcohol and water can give 8.4 g of N- (3-acetylphenyl) acetamide, yield 91% m.p127~128ºC, Lit. m.p127~ 128ºC [12]. IR: v=3 356, 3 114, 3 062, 3 004, 1 704, 1 677, 1 546, 1 481, 1 435, 1 419, 1 357, 798, 697 cm-1.1HNMR(CDCl3): δ=2.22(s,3H), 2.63(s,3H,COCH 3), 7.43(t,1H), 7.58(br,1H), 7.68(d,1H), 7.92(d,1H), 8.0(d,1H) ppm. Anal. Calcd for C10H11NO2: C, 67.80;H, 6.21;N, 7.91. Found: C, 67.53; H, 6.23; N, 7.84. 45 Fig.2 Relationship between yield and temperature in nitration reaction 70 60 Yield/ (%) Y/(%) 2.3 91 LI Yuanxun et al: An Improved Method of Synthesis for N- (3-acetyphenyl) Acetamide Y/(%) Yield/ (%) No.1 50 40 0.4 0.5 0.6 0.7 Proportion P of nitric acid Fig.3 3.2 Relationship between yield and proportion of nitric acid in total volume Synthesis of 3-aminoacetophenone It is well known that the reducing reaction of 3-nitroacephenone use Fe/HCl as the reductive agent [13] . In such procedures, we find separation and purification of the mixture is complex andbrings operators too much trouble. The reason is that the substances are muddy. Here we change Fe/HCl to Sn/HCl. This avoids these difficulties. The improved 92 Journal of Electronic Science and Technology of China method is proved effective and the procedure has been simplified in great degree. And the yield of product is also high enough. 3.3 Synthesis of N- (3-acetyphenyl) Acetamide This reaction is a traditional Friedel-Crafts reaction. A lot of essays have reported how to acetylate it [14]. But many of the methods use expensive starting materials and need too much time. The yield of the product is also not satisfactory. We know only under conditions of existence of Lewis acid, the benzene ring will be acetylated. According to this, in our experiments, we adopt the solvent of benzene because of the differences of the solubility in benzene between the starting material 3-aminoacetophenone and the product 3-acetaminoacephenone. Adding (Et) 3N is important. From parallel experiments, we find the rate of the reaction increases with (Et) 3N and the yield is also enhanced. Time has been reduced from 90 min~ 30 min, while the yield increases from 78%~90%. Different acetylating agents also influence the reaction. Using CH3COCl or acetic anhydride has almost the same effect on the yield, which is better than acetic acid. Vol.1 Medicinal Chemistry. 2001, 11(6): 353-355(in Chinese) [4] Tang Xianzhong, Yang Bangcao, Wang Zhengyi, et al. Study of photosensitive polyimides used in MCM[J]. Mixed Microelectronics Technology, 1999, 11(1): 10-17(in Chinese) [5] Tang Xianzhong, Yang Bangcao, He Wei. Synthetic study of photosensitive diamidogen[J]. Journal of University of Electronic Science And Technology of China, 2002, 29(3): 256-259(in Chinese) [6] Huang Xuefeng, Li Yuyan, You Qidong. Synthesis of zaleplon[J]. China Pharmacist, 2002, 5(5): 265-266(in Chinese) [7] Ren Jinzhi, Wang Zhaohui. Synthesis of sedative-hypnotic zaleplon[J]. Journal of China Pharmaceutical University, 2000, 31(6): 474-476(in Chinese) [8] Icke R N, Redemann C E. Organic Synthesis[M]. New York: John Wiley & Sons, 1965. 644 [9] Corson B B, Hazen R K. Organic Synthesis[M]. New York: John Wiley, 1943. 434-438 [10] Nanjing University. Organic Synthesis[M]. Beijing: Science Press. 1964. 296-299(in Chinese) [11] Novak L, Protiva M. Mephenhydramine derivatives substituted in the p- and m- position[J]. Chem Communs, 1959:3 966-3 977 4 Conclusions N- (3-acetyphenyl) acetamide has been synthesized, and the relative procedure been developed. We discuss several factors that affect the reactions in details. The overall yield arrives 43.1%, which is about 15% higher than the literature reported and the operations are convenient. [12] Nelson J L, Samuel N B. Synthesis of aminoacetophenones and aminopropiophenones [J]. J.Org.Chem, 1946,11(4): 405-418 [13] Bredereck H, Simchen G. Darstellung and eigenschaften der amidacetale and aminalester. [J]. Chem. Ber, 1968, 101(1): 41 [14] Wen Ruan. Reaction of Drug Synthesis [M]. Beijing: Chemical Industry Press. 1988. 144(in Chinese) References [1] Feng K, Tsushima M, Matsumoto T, et al. Synthesis and Brief Introduction to Author(s) LI Yuanxun( 李 元 勋 )was born in 1979. He is now properties of novel photosensitive polyimides containing chalcone moiety in the main chain[J]. J.Polym.Sci, 1998, 36: 685-693 pursuing M.S. degree in UESTC. His research interests include: synthesis of organic electronic materials. Email: li626@163. com [2] Shen Jingshan, Li Jianfeng, Li Fei, et al. Synthesis of TANG Xianzhong(唐先忠)was born in 1963. He is now zaleplon[J]. Chinese Journal of Pharmaceuticals, 2002, 33(7): an Associate Professor. His research interests include: synthesis 313-314(in Chinese) of organic functional materials. Email: txzuestc@163.com [3] Zheng Lianyou, Wang Songqing, Li Bingchao, et al. HE Wei(何为)was born in 1957. He is now a Professor in Improvement on the synthetic technology of zaleplon as a UESTC. His research interests include: electrochemistry. Email: new sedative and hypnotic drug[J]. Chinese Journal of heweiz@uestc.edu.cn