View/Open

advertisement

Bibliography

1.

ADENDORFF, S.A. & DE WIT, P.W.C. 1997. Production and

Operations Management- A South African Perspective. 2nd ed.

Goodwood, Western Cape: International Thompson Publishing

Southern Africa (Pty) Ltd. 349 p.

2.

AHMAD, M & BENSON, R. 2000. Benchmarking in the process

industries. Trowbridge: Cromwell Press. 155 p.

3.

AUSTRALIAN MARITIME COLLEGE. 2005. Quality and Improvement.

[Web] http://www.amc.edu.au/quality/improvement/ [Date of Access:

01 September 2005].

4.

CHASE, R.B., JACOBS, F.R. & AQUILANO, N.J. 2004. Operations

Management for Competitive Advantage. 10th ed. New York: McGraw

Hill/Irwin. 765 p.

5.

COETZEE, J.L. 1997. Maintenance. Hatfield RSA: Maintenance

Publishers Pty (Ltd). 475p.

6.

HELLRIEGEL, D, JACKSON, S.E., SLOCUM Jr., J.W. 2002.

Management- A competency- based Approach. 9th ed. Canada:

South Western, a division of Thompson Learning. 561 p.

7.

HUGHES, R.L. 2000 Strategic Maintenance Management [Web:]

http://www.reliabilityweb.com/art04/strategic mm.htm [Date of access:

16 Jul. 2005].

8.

JOHNSON, B. 1996. Polarity Management: Identifying and managing

unsolvable problems. 2nd ed. Amherst, Mass.: HRD-Press. 267 p.

9.

JONES, E.K., DUPONT, E.l., ROSENTHAL, ROHM & HAAS Co. 1997.

Assessing

Maintenance

Performance.

[Web]

http://www.mt-

online.com/current/11-97mm.html [Date of access: 16 Jul. 2005].

10. KATILA, P. 2000. Applying Total Productive Maintenance (TPM)

Principles

in

the

Manufacturing

system.

[Web:]

http:l/epubl.luth.se/1402-1536/2000/23/LTU-TR-0023-SE.pdf [Date of

access: 16 Jul. 2005].

Measuring and Managing Maintenance

Page 73

11. LEDET W. P. 2004. Measuring and tracking ownership. [Web]

http://www.manufacturinggame.com/2004JulyNewsletter.pdf [Date of

access: 04 Aug 2005].

12. MIDDLE EAST TECHNICAL UNIVERSITY. 2005. A brief introduction

of total productive maintenance. [Web]

http://www.me.metu.edu.tr/me407/seminer/tpm2004A ver3.ppt#319

[Date of access: 20 Jul 2005].

13. MOUBRAY J. 1997. Reliability Centered Maintenance. 2nd ed. Oxford:

Butterworth- Heinemann. 423p.

14. PETERS, R.W. 2002. Maximizing Maintenance Operations for Profit

Optimization:

The

Journey to

Maintenance

Excellence.

[Web]

http://www.plant-maintenance.com/articles/PathForward.pdf [Date of

Access: 25 Aug 2005].

15. PETERSON, B. 2000. Reliability Solutions for Industry with a Human

Touch. SAMI Corp. [Web]

http://www.samicorp.com/PublicationsPages/Newsletters/Winter%2020

OO.pdf [Date of access: 19 Jul 2005].

16. PRODUCTIVITY

FACTORY.

2000.

OEE:

Overall

equipment

effectiveness. [Web] http://www.tpfeurope.com/EN OEEinfo.html [Date

of access: 19 Jul 2005].

17. RELIABILITY WEB. 2001. Manufacturing and Business Excellence.

[Web:]

http://www.reliabilityweb.com/excerpts/excerpts/01 Making%20Commo

n%20Sense.pdf [Date of access: 16 Jul. 2005].

18. WILD, R. 1991. Production and Operations Management. 4th ed.

Oxford: Alden Press. 792p.

Measuring and Managing Maintenance

Page 74

Appendix A-

Maintenance Strategy for a Heavy

Engineering Environment

MAINTENANCE VISION

Operational Excellence through world class maintenance

MAINTENANCE MISSION

To provide a maintenance function that adds maximum sustainable value

through the optimization of asset performance, availability and reliability

MAINTENANCE PHILOSOPHY

Preventive and predictive maintenance

SAP(CMMS)

Computerised Maintenance Management System

•

•

•

•

•

•

Preventive and predictive maintenance.

Training of production on the first line of maintenance systems & philosophy.

Integrated holistic approach regarding performance of production and maintenance.

Common basic maintenance approach for the Works, along SAP principles and system

discipline.

Adhering to basics:

• Minimum tolerance for failure repetitions.

• Minimum patch up jobs or temporary quick-fix repairs.

Continuous Improvement

• Increased condition based maintenance.

• Improving operation stability by the prevention of breakdowns.

• Annual benchmarking

Measuring and Managing Maintenance

Page 75

MAINTENANCE OBJECTIVES AND STRATEGY

STRATEGY

OBJECTIVES

•

•

•

•

Move from reactive to preventive and

predictive maintenance.

Achieve 80% planned and 20%

unplanned maintenance.

Establishment and tracking of fixed

maintenance measurements on order

to continuously evaluate the quality of

maintenance.

Establish a culture of holistic

approach within both maintenance &

production disciplines on all levels of

the organisation (know each other's

business).

•

•

•

•

•

•

•

80% of all maintenance activities are

planned well in advance on the CMMS

20% of maintenance tasks are planned after

condition monitoring and inspections.

There is zero or 0% tolerance for failures

Utilising RCM II approach to determine

maintenance phins for equipment.

Condition monitoring to ensure that no

unmanaged failures occurs.

• Structured inspection system

• Statistical process control

• Vibration measurement

• Tribology

• Thermography

Formally documented root cause analysis of

failures.

Enhanced maintenance training on all levels

of maintenance personnel.

MANAGEMENT. PROCESS MONITORING AND TRACKING

Daily

•

•

•

Weekly

•

•

•

Monthly

•

•

•

6 Monthly

Ensure proper execution of planned maintenance tasks.

Updating of system with future plans.

Root Cause Analysis on equipment failure and rectify data packs and

maintenance plans.

Ensure 80% of work planned 1 week in advance with resource balancing.

Follow up on RCA targets.

Report on maintenance process performance and disciplines together with

equipment performance.

Condition monitoring of Critical on Critical equipment.

Plant availability tracking.

Full maintenance audit to ensure compliance with stated goals according

to fixed measurements set.

Measuring and Managing Maintenance

Page 76

Appendix B-

Question set for evaluation of

Maintenance Performance Elements

Maintenance (capability assurance)

Question Type AID: Element: 1 Plant condition monitoring

Practice: 1.1 Equipment maintenance plans

Question: How is equipment maintenance plans applied to ensure the capability of equipment is assured

according to the user's needs?

Question Type AID: Element: 1 Plant condition monitoring

Practice: 1.2 Careful operations

Question: How is maintenance departments involved in setting up of operational procedures regarding

the careful operations of equipment, what is the approach and how is it deployed?

Question Type AID: Element: 1 Plant condition monitoring

Practice: 1.3 Equipment inspections

Question: How is the frequency and scope of work regarding equipment inspections determined?

Question Type AID: Element: 1 Plant condition monitoring

Practice: 1.4 Predictive maintenance

Question: How do you approach predictive maintenance and to what extent is this approach deployed?

Question Type AID: Element: 1 Plant condition monitoring

Practice: 1.5 Preventive maintenance triggers

Question: How are the principles of preventive maintenance used and utilised in order to improve the

condition of equipment and reduce losses?

Question Type R: Element: 1 Plant condition monitoring

Question: A) What principles are used to identify the areas of measure for determining the equipment's

condition?

B) Is an effective historic database of these results kept?

C) Is this data being used to determine the current condition of the equipment by comparing

the actual trend data to the baseline data of the equipment?

Measuring and Managing Maintenance

Page 77

Question Type 1: Element: 1 Plant condition monitoring

Question: What systems are in place to ensure that the use of condition monitoring of equipment .is

improved over time. How is the effective use of condition monitoring measured to ensure

reduction of losses?

Question Type AID: Element: 2 Work origination

Practice: 2.1 Information required to originate work

Question: What data is used in order to originate work, how is the quality of this data verified in order

to ensure effective work planning and execution?

Question Type AID: Element: 2 Work origination

Practice: 2.2 Work origination methodology

Question: What systems and procedures are in place to identify and automatically generate new work?

How and what data is captured for historic reference?

Question Type AID: Element: 2 Work origination

Practice: 2.3 Review and feedback

Question: Is the requestor of the work timely informed of the progress and status of the work?

Question Type 1: Element: 2 Work origination

Question: Is historically captured data on the CMMS utilised to improve the creation of routine

maintenance tasks?

Question Type R: Element: 2 Work origination

Question: A) Is work origination measured in different categories?

B) Are these categories trended and communicated?

C) Is this data effectively used to improve the reduction of losses over the long term?

Question Type AID: Element: 3 Planning

Practice: 3.1 Information required for planning

Question: What systems & structures are in place to determine the need for information required to do

effective planning?

Measuring and Managing Maintenance

Page 78

Question Type AID: Element: 3 Planning

Practice: 3.2 Planning methodology

Question: How are new jobs prioritised with respect to planning and resource scheduling?

Question Type AID: Element: 3 Planning

Practice: 3.3 Creating a standard job library

Question: Are standard jobs compiled using a scientific approach based on the OEM specifications. Are

these tasks reviewed according to the current state of the equipment's condition? ·

Question Type R: Element: 3 Planning

Question: A) Is effective planning compared to not performing planning at all in terms of actual and

potential losses?

B) Is a database of this information kept and available?

C) Is historical data being used as an input for planning new tasks?

Question Type 1: Element: 3 Planning

Question: Are post mortem meetings being held after job execution and compared to the baseline

planning in order to serve as future improvement initiatives?

Question Type AID: Element: 4 Scheduling

Practice: 4.1 Scheduling (two weekly, monthly)

Question: How are resources scheduled over the medium term (two weekly and monthly), how does

this interact with the planning process?

Question Type AID: Element: 4 Scheduling

Practice: 4.2 Scheduling (daily)

Question: What is the availability of resource for scheduling on the short term (daily)?

Question Type 1: Element: 4 Scheduling

Question: How are the systems and procedures regarding scheduling of resources reviewed and

improved?

Measuring and Managing Maintenance

Page 79

Question Type R: Element: 4 Scheduling

Question: A) How is scheduling measured?

B) Are all the parties involved in scheduling identified and is scheduling data communicated?

C) Is historical data used to improve the results obtained from scheduling?

Question Type AID: Element: 5 Work allocation and execution

Practice: 5.1 Information for allocation and execution

Question: What information is currently being used for effective work execution?

Question Type AID: Element: 5 Work allocation and execution

Practice: 5.2 Methods of allocation and execution

Question: Is the efficiency of work execution measured against the original planning?

Question Type AID: Element: 5 Work allocation and execution

Practice: 5.3 Communicating shift handover

Question: What systems are being used to communicate the information required to hand over work

from one team to another, how is this information required determined?

Question Type AID: Element: 5 Work allocation and execution

Practice: 5.4 Equipment handover

Question: Is there a system in place to hand over equipment to the user; is a checklist in place to

ensure that all the needs of the user are satisfied after work completion? Who are the parties

involved in the official handover (maintenance disciplines and customers)?

Question Type R: Element: 5 Work allocation and execution

Question: A) How is the effectiveness of work allocation and execution measured?

B) Is historical data being kept of work execution measures?

·

C) How is this data being used to explain gaps between baseline planning of work and the

actual execution of the work?

Question Type AID: Element: 6 Work Completion and recording

Practice: 6.1 Work completion and history recording methodology

Question: What approach is followed in determining what data must be recorded and captured?

Measuring and Managing Maintenance

Page 80

Question Type AID: Element: Element: 6 Work Completion and recording

Practice: 6.2 Information recorded as history at closure

Question: Is data recorded at completion of work stored in an understandable manner for easy future

reference. Are deviations recorded to ensure effective benchmarking for the future?

Question Type 1: Element: 6 Work Completion and recording

Question: Is data recorded being used to improve work completion and how is this integrated with

planning and scheduling?

Question Type R: Element: 6 Work Completion and recording

Question: A) Is the quality of work completion data being verified?

B) Is this data being used to communicate the current state of effective work completion?

C) Is the data effectively interpreted in order to understand the gaps that exist?

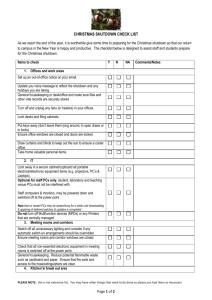

Question Type AID: Element: 7 Shutdown management

Practice: 7.1 Shutdown formulation

Question: What method is being used in order to effectively collect information required for shutdown

planning?

Question Type AID: Element: 7 Shutdown management

Practice: 7.2 Shutdown planning

Question: What tools are being used in order to plan shutdowns (e.g. Bar charts, resource planning,

process pipeline planning)?

Question Type AID: Element: 7 Shutdown management

Practice: 7.3 Shutdown execution

Question: How is shutdown execution managed especially towards scope changes, what criteria is being

used to accept scope changes?

Question Type AID: Element: Element: 7 Shutdown management

Practice: 7.4 Start up and commissioning

Question: How is commissioning managed especially from the customer and safety point of view?

Measuring and Managing Maintenance

Page 81

Question Type AID: Element: 7 Shutdown management

Practice: 7.5 Post shutdown review

Question: Is post mortem meetings being held and are all deviations (from planed time and planed

scope) of the original plan recorded with reasons in order to eliminate future losses?

Question Type R: Element: 7 Shutdown management

Question: A) Is baseline planning of downtime and the scope of work available?

B) Is the progress of work measured against the baseline and communicated?

C) Is the data being used to understand the gaps that exist?

Question Type 1: Element: 7 Shutdown management

Question: Is previous historical data being used as inputs to planning with respect to improvement?

Question Type AID: Element: 8 Facilities, equipment and tools

Practice: 8.1 Tools

Question: What criteria are being used to determine the tools required for the work (e.g. safety)?

Question Type AID: Element: 8 Facilities, equipment and tools

Practice: 8.2 Facilities and equipment

Question: How are the facilities and equipment required, determined to ensure minimum losses (e.g.

workshop location etc.)?

Question Type AID: Element: 9 Determining root cause of losses

Practice: 9.1 Determining root cause of losses

Question: To what extent is an analytical and scientific approach followed to determine areas of

improvement for RCA?

Question Type R: Element: 9 Determining root cause of losses

Question: A) Is the actions implemented from RCA processes measured to determine the loss reduction

achieved?

B) Are the actions measured against the expected completion date?

C) Are implemented RCA actions reviewed for effectiveness after implementation?

Measuring and Managing Maintenance

Page 82

Question Type 1: Element: 9 Determining root cause of losses

Question: How regular is the RCA process reviewed in order to improve it?

Question Type AID: Element: 10 Achieving improvement in Capability assurance

Practice: 10.1 Routine improvement

Question: What approach is followed to improve the capability of equipment and to reduce losses, are

losses recorded in different categories and analysed to focus improvement initiatives?

Question Type AID: Element: 10 Achieving improvement in Capability assurance

Practice: 10.2 Focused improvement

Question: Are improvement initiatives aimed at improving specific losses identified?

Question TypeR: Element: 10 Achieving improvement in Capability assurance

Question: A) Are losses and the causes thereof determined?

B) Are losses displayed in revenue lost and well communicated?

C) Is the data being used to understand the nature and cause of the loss; are actions being

implemented in order to reduce 1 eliminate these losses?

Question Type R: Maintenance (capability assurance)

Question: What are the results achieved form overall equipment capability management?

Question Type 1: Maintenance (capability assurance)

Question: What initiatives are currently being implemented in order to improve the overall equipment

efficiency management?

Measuring and Managing Maintenance

Page 83

Results from Maintenance Performance

Appendix C-

Elements Evaluation

Maintenance (capability assurance) Measurement

Ref.

0.0

Maintenance (capability assurance)

ES*

NS*

R

3.0

2.5

3.0

I

3.7

2.5

3.5

0.0

1.0

1

Equipment maintenance plans

R

2.5

3.0

3.6

I

2.0

3.0

3.0

A

2.0

3.0

3.5

3.0

3.0

1.0

1.1

1.1

Equipment maintenance plans

1.1

1.2

1.2

Careful operation

1.2

1.3

3.0

2.0

3.2

3.0

2.1

4.0

4.5

D

3.0

3.5

4.0

A

1.5

2.0

4.0

D

1.2

2.0

3.5

R

0.6

3.5

3.0

Preventive maintenance triggers

I

2.0

3.5

3.0

2.1

Information required to originate

work

A

2.5

4.0

4.5

D

3.5

3.8

3.5

2.2

Work origination methodology

A

3.5

4.0

4.0

D

2.0

3.8

3.0

A

1.5

3.5

3.0

D

1.0

3.0

3.0

R

3.5

2.5

4.0

2.3

Review and feedback

,

3

Planning

3.0

3.1

3.1

Information required for planning

3.1

3.2

3.2

Planning methodology

3.2

3.3

3.3

Creating a standard job library

3.3

4.0

4

Scheduling

4.0

4.1

4.1

Scheduling (two weekly, monthly)

4.1

5.0

5

Work allocation and execution

5.1

5.1

Information for allocation and

execution

5.1

5.2

5.2

Methods of allocation and

execution

5.2

5.3

5.3

Measuring and Managing Maintenance

3.5

D

2.2

2.3

4.0

A

2.1

2.3

2.0

Predictive maintenance

2.0

2.2

3.0

2.0

1.4

Work origination

2.1

3.0

1.2

2.0

1.5

2

2.0

D

A

1.5

2.0

A

Equipment inspections

1.4

1.5

D

1.4

1.3

1.3

1.4

WA*

QT*

Communicating shift handover

I

1.5

2.2

3.0

A

3.6

3.0

2.0

D

2.5

2.8

2.0

A

4.0

3.5

4.0

D

3.0

2.8

3.0

A

2.0

2.0

4.0

D

1.6

2.5

3.6

R

4.0

3.0

4.0

I

2.5

2.5

3.8

A

3.5

3.0

3.5

D

3.0

1.5

2.5

R

2.5

3.0

3.0

A

2.5

3.5

3.0

D

1.5

3.0

2.5

A

3.6

3.5

4.0

D

3.1

2.0

3.0

A

0.0

3.5

4.5

Page 84

5.3

5.4

5.4

Equipment handover

5.4

6.0

6

Work Completion and recording

6.0

6.1

6.1

Work completion and history

recording methodology

6.1

6.2

6.2

Information recorded as history at

closure

6.2

7.0

7

Shutdown management

7.0

7.1

7.1

Shutdown formulation

7.1

7.2

7.2

Shutdown execution

7.2

7.3

7.3

Start up and commissioning

7.3

8.1

8

Facilities, equipment and

tools

9

3.0

1.0

2.0

2.5

3.0

I

1.5

2.6

2.5

A

3.0

2.8

4.0

D

2.0

2.0

3.0

A

2.5

3.0

4.0

D

2.0

2.0

3.0

R

1.5

2.5

4.0

I

2.0

3.0

4.0

A

2.5

3.0

4.0

D

2.0

2.6

4.0

A

2.5

3.5

4.5

D

2.0

3.0

4.0

A

2.0

3.0

4.0

D

1.0

2.5

3.5

4.0

D

2.0

4.0

3.0

Facilities and equipment

A

4.0

3.5

4.0

D

3.0

3.5

4.0

Determining root cause of losses

R

3.0

2.0

4.0

I

2.0

2.2

2.5

A

3.5

2.5

3.7

D

2.0

2.0

3.6

R

3.5

2.6

3.6

10.1

Routine improvement

A

3.5

3.0

3.0

D

2.0

2.0

2.5

10.2

Focused improvement

A

3.0

3.0

5.0

D

2.0

2.0

4.0

Achieving improvement in Capability assurance

10.1

10.2

1.3

R

8.2

9.1

10

D

4.0

Determining root cause of losses

10.1

4.5

2.0

9.1

10.0

4.5

3.5

A

9.0

9.1

3.0

Tools

8.2

9.0

0.0

3.0

8.1

8.1

8.2

D

A

10.2

QT = Question Type

ES = Engineering Services

NS = North and South Plants

WA =West and Advalloy Plants

Measuring and Managing Maintenance

Page 85

aoueualU!BII'J 6u!5eueii'J pue 6upnseaii'J

IB!lU8P!JUO:)

98 a6ed

s~re

0

0

0

~

~

~

~

~

0

~

0

~

w

0

w

~

~

~

~

0

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

Information required to originate work

Work origination methodology

Review and feedback

)>

Information required for planning

"0

"0

....

g

Planning methodology

(")

::r

Creating a standard job library

m

1D

3(1)

:I

c(1)

Ill

n

0

s::::

CD

Scheduling (two weekly, monthly)

til

=.

0

Information for allocation and execution

::I

:;o

CD

Methods of allocation and execution

til

:::1.

"&

0

s::::

ur

Communicating shift handover

:I

"0

CD

....

Equipment handover

CJ)

-cs·

CD

Work completion and history recording

methodology

(")

::I

Information recorded as history at closure

Shutdown formulation

Shutdown execution

Start up and commissioning

Tools

Facilities and equipment

j~~~~ii~~~~~~~~~~~~~~~~

~.t~?:-iit:;

improvement

DeterminingRoutine

root cause

of losses

}<"'ill>: :•w;.;;;> :;;~'fill<'· ;,;:,.·;,w<

Focused improvement

'··-~

,...... ,..

. --.........,. ..

·· · ·~

a::>ueualU!BVIJ 6u!6eueVIJ pue 6upnseaVIJ

IB!lU9P!JUO:)

L9 a6ed

Srore

0

0

~

~

N

N

~

~

~

~

~

0

~

0

~

0

~

0

~

0

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

Information required to originate work

Work origination methodology

Review and feedback

c

Information required for planning

CD

"C

Planning methodology

'<

0

3

CD

::s

Creating a standard job library

m

3

eo

CD'

m

:I

0

r:::

Scheduling (two weekly, monthly)

CD

tJ)

-~·l;;~?~~i'i

a·

Information for allocation and execution

::s

c

"

'2.

tJ)

Methods of allocation and execution

:I.

c;·

""'""'" "''"'

~~~.•:.?~.'!'..~ ~-g.,-:,.;0_·!/£ r.~.!tJ.:_:,;.;~<

.''i:<.(•,_i/.(,·:-.·

·~'iY-~§;1.~ ~:.·~·:.::·

:;tl

CD

tJ)

Communicating shift handover

r:::

Equipment handover

"C

CD

Work completion and history recording

methodology

en

ct

:I

Information recorded as history at closure

Shutdown formulation

Shutdown execution

Start up and commissioning

Tools

Facilities and equipment

Determining root cause of losses

Routine improvement

Focused improvement

..,

CD

aa·

::s

$:0

<D 0

Q) :J

(/) ::!!

ca..

..., <D

- · :J

:J .....

<.0 -Q) ·

Results Question Results per Section

Q)-

4.5

:J

a_

$:

Q)

4.0

:J

Q)

<.0

5'

<.0

$:

Q)

5'

3.5

:J

3.0

co

Q)

:J

(')

<D

~

2.5

0

u

Cl)

2.0

1.5

1.0

0.5

0.0

Maintenance

(capability

assurance)

"0

Equipment

maintenance

plans

Work origination

Planning

Scheduling

Work allocation

Work

and execution Completion and

recording

Q)

<0

<D

00

00

Element Description

Shutdown

management

Determining root

Achieving

cause of losses improvement in

Capability

assurance

:5::0

<D 0

Q) ::J

en::!!

Improvement Question Results per Section

co..

~ . <D

::J ::J

co!::!:

Q)~

4.5

::J

Q_

:5::

Q)

::J

4.0

Q)

co

:r

c.o

:5::

Q)

3.5

s·

ro::J

3.0

Q)

::J

()

<D

Cll

....

2.5

0

u

en

2.0

1.5

1.0

0.5

0.0

"'U

Q)

co

<D

(X)

co

Maintenance

(capability

assurance)

Equipment

maintenance plans

Work origination

Planning

Scheduling

Element Description

Work Completion

and recording

Shutdown

management

Determining root

cause of losses

06 a6ed

0

0

0

~

~

0

~

~

a:lueualU!BV\1 Bu!BeueV\1 pue BupnseaV\1

IB!lU8P!JU08

N

0

S~re

N

W

~

0

W

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

)>

Preventive maintenance triggers

"C

"C

0

I»

0

...

Information required to originate work

m

Review and feedback

::r

Work origination methodology

a

~

Cf!.

Information required for planning

~

(t)

(t)

Planning methodology

~­

~

CQ

Creating a standard job library

en

m

CD'

3

-

(t)

~-

Scheduling (two weekly, monthly)

0

CD

::I

cCD

(t)

Information for allocation and execution

1/1

Ul

r;

Methods of allocation and execution

n

Ul

1::

::::!.

"2.

ct

Communicating shift handover

s·

::I

0

Equipment handover

0

3

Work completion and history recording

methodology

"C

I»

...

c;r

Information recorded as history at closure

0

~

cE"

Shutdown execution

0

Shutdown formulation

::I:

::r

~

<

Facilities and equipment

Qo

Start up and commissioning

r

Tools

e!.

1::

(t)

Determining root cause of losses

Ul

Routine improvement

f ++

rIm

0

-·

=EC§.

<

cCD

!!?..

(/)

<

lll

-C

CD

~6 a6ed

a::>ueualU!BV\J Bu!BeueVIJ pue BupnseaVIJ

IB!lU8P!JU08

S~re

0

0

0

~

~

0

~

~

~

0

~

~

w

0

w

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

~

Information required to originate work

"C

""'I

Work origination methodology

0

Dl

(')

~

Review and feedback

a

Information required for planning

z

0

;I.

Planning methodology

~

QO

Creating a standard job library

en

0

c

-

m

CD'

3

-

Scheduling (two weekly, monthly)

~

C1)

::::!

cC1)

"C

Information for allocation and execution

!II

-cr

::::s

Methods of allocation and execution

n

0

::::!.

"S.

0

Communicating shift handover

s·

3

"C

::::!

Dl

Equipment handover

""'I

c;;·

Work completion and history recording

methodology

0

::::s

0

Information recorded as history at closure

:I:

cE"

Shutdown formulation

~

QO

I

Shutdown execution

E"

Tools

~

<

Start up and commissioning

Dl

CD

(/1

Facilities and equipment

Determining root cause of losses

Routine improvement

Focused improvement

+ +zf

r

:::r:

~ <§:

<<

!!!.

(f)

Ill

ffi

<I>

-

c

G6 a6ed

80UBU8lU!BV\I 6U!6BUBV\I pue 6upnSB8V\I

IB!lU8P!JU08

S~re

0

0

0

~

~

0

~

~

~

0

~

~

~

0

~

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

0

Q)

Work origination methodology

~

Information required to originate work

"C

0

::T

s.

Review and feedback

:iE

-

Information required for planning

CD

t/)

Planning methodology

Q)

::s

a.

Creating a standard job library

6:

m

(;"

3

-

01

Scheduling (two weekly, monthly)

CD

:I

c

~

Information for allocation and execution

"'tl

CD

Ill

i»

::s

Methods of allocation and execution

(')

:::!.

~

0

Communicating shift handover

s·

0

:I

3

Equipment handover

"C

..,

Q)

Work completion and history recording

methodology

u;·

0

::s

Information recorded as history at closure

0

:I:

Shutdown formulation

ce·

::T

QO

I

Shutdown execution

Start up and commissioning

CD

Facilities and equipment

~

<

Tools

e!..

s:

t/)

Determining root cause of losses

Routine improvement

Focused improvement

f +f

b cg.

6

:E

~

)>

<<

!!!..

Q)

cCD cCD

£6 a6ed

aoueuelU!eV\1 5u!5eueV\I pue 5upnseeV\I

18!lU9P!JU08

S~re

0

0

0

~

~

0

~

~

N

0

N

~

~

0

~

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

c

(I)

"2.

~

3

Information required to originate work

Work origination methodology

-a

(I)

:::s

Review and feedback

ca.:::s

Planning methodology

m

Information required for planning

:::s

(I)

(I)

Creating a standard job library

:::::!.

:::s

m

iD

3

-

cc

Scheduling (two weekly, monthly)

en

CD

~

(I)

<

g"

Information for allocation and execution

0

CD

en

Methods of allocation and execution

(')

C/1

:::!.

~

Communicating shift handover

0

0

0

~

3

Equipment handover

"'C

...

I»

:::s

Information recorded as history at closure

c;r

Work completion and history recording

methodology

0

0

ca·::I::::T

Shutdown formulation

Shutdown execution

QO

r-

Start up and commissioning

~

<

I»

Tools

c

Facilities and equipment

(I)

C/1

Determining root cause of losses

Routine improvement

f ++

r ::r: m

~<§:(/)

<

<

!!1.. Ql

cCD C

CD

v6 a6ed

aoueualU!BVIJ 6u!6eueV1J pue 6upnseaVIJ

IB!luap!JU08

Score

0

0

~

~

w

w

~

~

~

o m o m o m o m o m o

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

c

(J)

'<

Work origination methodology

"tJ

Information required to originate work

0

3

(J)

z

Information required for planning

:::J

Review and feedback

a

0

;::::.

Planning methodology

m

ii'

3

-

::r

QO

1::

Scheduling (two weekly, monthly)

en

Creating a standard job library

0

::r

CD

:I

c

"'tt

Information for allocation and execution

iii

:::J

fit

CD

(II

Methods of allocation and execution

n

:I.

"S.

(")

Communicating shift handover

s·

0

:I

3

Equipment handover

"tJ

Dl

'"'I

u;·

Work completion and history recording

methodology

0

:::J

Information recorded as history at closure

S'

~

Shutdown formulation

(C

-=r

Shutdown execution

QO

r

Start up and commissioning

~

<

Tools

!!!.

1::

Facilities and equipment

(J)

til

Determining root cause of losses

Routine improvement

Focused improvement

96 aBed

aoueualU!BV\J 5u!5eueV\J pue 5upnseaV\J

IB!lU8P!JU08

Srore

0

0

0

~

~

0

~

~

N

0

N

~

W

0

W

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

c

Preventive maintenance triggers

(I)

"'2.

~

3

Information required to orig inate work

a(I)

Work origination methodology

:::s

Review and feedback

~

Information required for planning

Ul

Planning methodology

Ol

:::s

c.

Creating a standard job library

m

lD

3

-

~

~

Scheduling (two weekly, monthly)

0

CD

::I

c

,

Dr

Methods of allocation and execution

'<

Information for allocation and execution

CD

Ill

n

-

::::!.

'0

:::s

til'

Communicating shift handover

c;·

(")

::I

0

Equipment handover

3

'0

Work completion and history recording

methodology

...

Ol

(ij'

0

Information recorded as history at closure

:::s

0

Shutdown formulation

::I:

~·

::::T

Shutdown execution

~

Start up and comm issioning

r

~

<

Tools

e!..

c:

Facilities and equipment

(I)

Ul

Determining root cause of losses

Routine improvement

Focused improvement

+t +

b;;!;

~

:E<§.>

< <

Q1..

c

CD

m

~

96 a6ed

aoueualU!BVIJ 6u!5euew pue 5upnseaw

IBHU9P!JU08

Score

0

0

0

(.n

0

(.n

1\.)

0

1\.)

(/.)

0

(.n

(/.)

(.n

(.n

0

~

~

01

0

Maintenance (capability

assurance)

Equipment maintenance

plans

kt~~~~~~~;~~1ryl~~~1~~~~~~t~~t~~t~~~tr~~\%tt~~~1~~~~11~~1fJ~~~~f~&t~{~&IJ~ttra~~~

;;Q

CD

til

c

ur

Work origination L11mt1¥~~~~~. !11P:Z~~i~\~1~~~1~¥J~~nt.;U*~B~t~?~J~Nt.1~tJ~~%~~;fi:~-tN&!-~~~f~{~\~i_~~o]lkt~~~~{mJ2g

0

c

CD

til

cs·

::I

til

Planning l:,~f~i0£~~t~lf~~.~:Zf~17~~1f{$}~~~~(~f¥~;·:1:\1~\;~m¥~%i~~\~ZIIrt*M:;;itH~~t~M-~t~fZ;~l-~M~4~~m~~~k.{l

0

m

::I

co

::I

CD

CD

m

CD'

""''

Scheduling

3

,"'

-

::I

co

en

CD

::I

cCD

CD

~n

Ill

::s.

Work allocation and

execution

c;·

CD

til

I

::I

0

0

3

Work Completion and

recording

r:rjtt:;~~~~~t~&~~~fl!t~f~~~~~&~~~~~~-~~!rli~i!I~~~~'~'~i~ii

"C

I»

u;·

""''

0

::I

Shutdown management litliif~~\~Y;I~!.qir~~~;~n~~~t~~~J~~~~~~1~1&f.f.Y::Ji~1#W1f.1¥Jit~1~J~~:t;Jt~~~~~-·:t~Jt.i~~Jt.l~&~f.{~~ff~~

0

::I:

cE"

=r

QO

r-

Determ~~i~ogs~~~t cause lre~~~~~~~l~~j;~;~~t~ll114}~1t~~tiilif.ii\~i~~r~~lii~rr~l~~i1I~1l

0

:E

<

e!.

c

t·Jp;J:W~~i7.:1t.~~i1~:: ~dt0~4:1'};_~:f~~;~-:tT;Jf~l!(f::l)J~;~~~:.,.:~1,!,f~f.~ti{.~~:l~'?#?;~~f~l~~:~~~:<~~~~~:rJ.Jt~~~~~

CD

til

Achieving improvement

in Capability assurance

+ce·+en+

r

0

:I:

m

::E ::r

< <

Ol

c

(1)

Ol

E

CD

L6 a5ed

aoueualU!BVIJ 5u!5eueVIJ pue 5upnseaVIJ

IB!lU9P!JU08

Score

0

b

0

(n

b

(n

(n

b

1\.)

1\.)

(n

b

(..)

(..)

(n

b

-1>-

-1>-

0'1

b

Maintenance (capability

assurance)

Equipment maintenance

plans

~~~~~i~l~~r~j~~~~~~£?;~~~~~~~~if$~~SI¥~%.1l~~~~1?1~J:Ii~~~J1~l(~~~~~!ij\~W~l

;:u

(I)

Ul

c:

;:::;::

Ul

Work origination E~~J~~ii·~~l;~~~~~~t~~~t~~~t~i~~hl~~if~~~~?:'l:~1l~~~~t~kA~t{~~1Ar~[f:;~~J:If~{~g;~kl,:!;~~~~!l

0

c:

(I)

Ul

c;·

::::s

Planning ~~~:q;>!fii~f~:~5)J4~~17ili1M.~~~lt~~~R%tf1i(;rr.:Jr{f}b.~Rfi:~~~1t~lt~~i~).~;.lt~~~l:{f~lfi:~J.f/Jiil~l~~~fl~~~

Ul

0

z

0

;l.

;:r

m

iD

3

QO

CJ)

-

Scheduling

-

0

(D

c:

:::1

;:r

"'0

c(D

Ill

Di'

(')

::!.

"0

::::s

Work allocation and

execution

e.

0

:::1

Ul

I

(')

0

3

Work Completion and

recording

~~~i~~IJi~~~~~~~~~~~il~i\1~~~-~~~li~lll~~~ffil~~~t~l

"C

..,

I»

(ij'

0

::::s

0

shutdown manag erne nt l:i~~&j;~-r.\:l¥.~~t~~~J~;I~W~)l~~tl!t~~~~~tJ~!;l;~~at~{;~t,;~r,~~~~~~~~t~t~~~[;~l{~~fit:~~;¥-}11}1fu}?r~~~E~~~{~~~~

:I:

ce·

;:r

Qo

r-

~

<

a!.

c:

(I)

r;~:\ftl~tM~~t~~:~f~H!t~~i~!:i;f:IW~~:~\f.i~li£&b~~I~~~?f~1.~&;~\f.t~r;x;t1gf~~,~i~~~ki~Yf~fff£7.}f;f~Jt~~~~~1~tf~J

Ul

Ach ieving improvement

in Capabi lity assu rance

:::r

:E

::r:: z

r0

c3"

(/)

<

<

Ol

c cOl

(!)

(D

86 a6ed

aOUBU8lU!BV\J 6U!6BUBV\J pue 6U!JnS89V\J

IB!lU8P!JU08

Score

0

0

0

(n

0

(n

N

0

w

0

N

(n

w

(n

.t:>-

0

.t:>-

0,

<11

0

Maintenance (capability

assurance)

Equipmen;l:~ntenance l~\j~f~~~liiflr~l~~!~[~~~~\~1~!~~:~:~ l5.li1li,J!II~I~~il~~~~l,JI

:;a

(I)

Ul

c

;:::;

0

c

(I)

Work origination [a~tJ.g~~~~~1~H'§{f:¥1~1~1§~W;~~~S~f:t.~?f;~~!fl1~1}{~~}!~h{'~t~-a!~~t~?JI~£;1~~~~~ll;1f~j~!1:l

Ul

=0

:::1

-:e

Ul

0

Planning t~::.~i¥i~1~11~·l~%:tit~~~tt~r~;~~~~~X;W, t;~{~JP~ttfjllf~?~~-~tWM%~~~i,~l;{i~§~~Lf.:~!~¥-;~k.~W~~~~1~WJ~~1

(I)

Ul

Ql

:::1

Q.

m

)>

CD"

Q.

Scheduling

3

-

<

CD

~

;:)

0

-a

0

'<

CD

Ill

0

::::!.

or

:::1

Work allocation and

execution

~

0

Ul

;:)

I

(')

0

Work Completion and

recording

r~~~t~I%~J~!I~IIIIff~i~{~~lft~f.14lf~l~1t~ltil~f~t41!~~i1~1

3

"0

..,Ql

u;·

0

:::1

Shutdown manag eme nt 1:.2~lt~t~t~i%tt\1;{%1~J~¥~Mtl:~:~;*~~i;l~t?:~~M~{)~~l~ti1~.ft&~ff.~~1~~~X~l~~%;~~;¥JI~~!$.{~i\~~:~t~~tkt.~~1Ii~1

0

:I:

cE"

:::T

~

I

0

:E

<

Ql

c

(I)

Ul

Achieving improvement

in Capability assurance

++t

r

I

~ ce·

::::;

< <

c(I) cIll

(I)

~

)>

Ill

aoueJnsse Al!l!qede~ U!

jU9W9AOJdW! 6U!II9!LJO'If

U>

Cl)

::::s

ca

>

~

S9SSOI JO

asneo JOOJ 6U!U!WJ9J90

...J

~

.c:

C)

:E

.ss:::

1uawa6euew UMOpJnLJs

0

U>

·;::

ca

0.

6U!PJ009J

E

pue

0

UO!J9idWO~

)jJOM

0

U>

c

Cl)

u

·~

0

UO!Jnoaxa

pue UO!JBOOIIB )jJOM

a

·c

u

Cl)

tn

!/)

Q)

c

C)

s:::

·;::

~

Q)

Cl)

Cl)

E

Q)

·a,

s:::

w

jjj

s:::

0

.

U>

s:::

0

U>

Cl)

::::s

a

s:::

Cl)

E

~

SUBid

90UBU9JU!BW )U8Wd!nb3

0.

E

(aoueJnsse

Al!l!qedeo) aoueuaJU!BVII

l{)

ci

Confidential

Measuring and Managing Maintenance

q

0

Page 99

1/)

a:>ueJnsse Al!l!qede::> U!

JU9W9AOJdW! 6UJA9J4:l'v'

Q)

::::s

(ij

>

_.==0

SaSSO! jO

asne:> JOOJ 6uJUJWJalaa

oes

.I:

.21

:I:

0

1uawa6euew UMOpJn4S

c

0

1/)

·~

ctl

Q,

E

0

6uJpJo:>aJ

pue UOJl9idWO:)

~JOM

0

-a:

1/)

c

ctl

-

c

uo!ln:>axa

pue UO!lB:JOIIB ~JOM

0

+l

Q.

·c

u

.J:.

Ill

Cl)

c

::::s

0

c

E

Cl)

iii

tJ)

Cl)

oes

6UJtnP94:JS

-

6UJUUB1d

.J:.

....

...

0

z

0

1/)

c

0

:0:::

1/)

Q)

::::s

a

....

cQ)

E

Q)

>

0

...

Q,

E

UO!lBU!6!JO ~JOM

suetd

a:>ueua)U!BW wawd1nb3

(a:>uem sse

Al!l!qede:>) a:>ueualU!Brl

Confidential

Measuring and Managing Maintenance

Page 100

en

C1)

aoueJnsse Al!l!qede8 U!

juawaAoJdW! Bu!A9!40'V

:;,

~

~

sasso1 ~o

asneo JOOJ Bu!U!WJalaa

...J

otS

.t:

.!2'

:::c

0

JUawaBeuew uMop1n4s

c::

en

·;:

ca

0

c.

E

BulpJOoaJ

pue uona1dwo:)

0

(.)

~JOM

c

UO!Jn:>axa

pue uoneooue ~JoM

0

a

·c

u

Ill

Cl)

-

c

cCl)

E

Cl)

iii

SUeid

aoueua1u!ew 1uawd!nb3

(aoueJnsse

Al!l!qedeo) aoueuaJU!eVII

0

IJ")

Confidential

Measuring and Managing Maintenance

0

C'i

Page 101

aoueualU!BV\1 6u!6BUBV\I pue BupnseaV\1

IB!lUap!JU08

2:0~ aBed

Score

0

0

0

~

~

0

~

~

N

0

N

~

W

0

W

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

,,0

Preventive maintenance triggers

Information required to originate work

0

2-::::s

Work origination methodology

a:

<D

,

Review and feedback

Ul

...

<D

Information required for planning

en

<D

Planning methodology

~

c;·

Creating a standard job library

::::s

m

3

Scheduling (two weekly, monthly)

~

_o

a

Information for allocation and execution

iD

~

c

:X

n

Methods of allocation and execution

:I.

~

0

>0

,a_

,occ-·

... ::::s

I»

0

0-

:::r_

-::::s

Communicating shift handover

(j)

Equipment handover

9!.

Work completion and history recording

methodology

<D

:I

3

Information recorded as history at closure

DJ

::::s

g.

3

...

0.

I»

Shutdown formulation

::::s

,

cc

Shutdown execution

Start up and commissioning

Tools

Facilities and equipment

Determining root cause of losses

Routine improvement

Focused improvement

cE'

s::

m

£0~ a6ed

a::>ueualU!BV\1 6u!6BUBV11 pue 6upnseaVII

IB!lUaP!JU08

Srore

0

0

0

~

~

0

~

~

N

0

N

~

W

0

W

~

~

0

~

~

~

0

Equipment maintenance plans

Careful operation

Equipment inspections

Predictive maintenance

Preventive maintenance triggers

0

s::

:::s

Work origination methodology

"C

"C

0

Information required to originate work

::I:;:::;:

cr;·

...

Information required for planning

til

Review and feedback

-g

en

C1)

-

Planning methodology

(")

s:::s·

Creating a standard job library

m

(i'

~

-n

Scheduling (two weekly, monthly)

Co

3

-

C1)

CD

::1

...

3 0-

Methods of allocation and execution

~9:

0 :::s

Information for allocation and execution

c

'<CC

CD

Ill

n

-C1)

:::s-:::s

::1.

~

a·

::1

...

""

Communicating shift handover

(1)

:::s

!!.

Equipment handover -~'··•·'··· ··""' '·'·' ••""""·

aJ

3

Information recorded as history at closure

C1)

Work completion and history recording

methodology

:::s

(")

:::r

...AI

~

Shutdown formulation

:::s

CQ

Shutdown execution

!!

CQ

s:::

;

Start up and commissioning

til

Tools

Facilities and equipment

Determin ing root cause of losses

Routine improvement

Focused improvement

aoueJnsse Al!l!qede::> U!

jU9W9AOJdW! 6U!A9!40\;f

SaSSO! JO

asneo jOOJ 6U!U!WJ9l90

(/)

f

:::s

.2>

1uawa6euew uMop1n4s

LL

C)

s::

:;:

.....

cu

E

.c:

(.)

s::

C1)

6U!PJ009J

pue UO!l9idWO:)

~JOM

m

n;

s::

.....

--= C1)

0

c

UO!Jnoaxa

pue UO!leooue ~JOM

s::

(/)

C1)

o

(.)

"C

..

Ul

Cl)

c

C):::S

"E~

Q.

u

(/)

·-

0

;;

cCl)

E

Cl)

6u!lnP940S

jjj

(.)

<(

s::

0

:;::

(.)

C1)

C/)

6U!UUeld

.....

C1)

Q.

(/)

C1)

E

s::

:::s

UO!jeU!6!JO ~JOM

t::

0

Q.

Q.

0

sue1d aoueua1u!ew

jU9Wd!nb3

(aouemsse

Al!l!qedeo) aoueua1u!e~

Confidential

Measuring and Managing Maintenance

Page 104

SaSSO! JO

asneo 100J 6U!U!WJalaa

1uawa6euew uMop1n4s

(/)

Cl)

...::I

.2l

u..

C)

c:

::;:

...

6U!PJO:>aJ

pue UO!l9ldlUO:J

«<

E

~JOM

.c:

(,)

c:

Cl)

CD

coc:

...

Cl)

.

c:

6unnpa4os

Z'

0

c: c:

Cl)

0

E

-

Q.

·c:

u

1/)

G)

-

~~

... c.

0

cG):

·0

"'C ...

<o E

(,)_

E

G)

6U!UUeld

iii

(,)

.

...

..

c:

0

(,)

Cl)

en

Cl)

UO!jeU!61JO

c.

~JOM

(/)

Cl)

·c:::I

t:

0

c.

c.

sue1d aoueua1u!ew

1uawd!nb3

0

(aouemsse

Al!l!qedeo) aoueualU!eLAI

q

o.q

L()

N

L()

c)

0

c)

aJO!>S

Confidential

Measuring and Managing Maintenance

Page 105

Appendix D-

The ARDI Cycle for Improvement

AMC - Quality and Improvement

The ADRI cycle is similar to the Plan-Do-Act-Check model found in many quality systems. Both are designed to

prompt the user to ask simple questions that will assist in the implementation of improvement initiatives.

How to undertake a quality improvement project (using the ADRI cycle)

Quality improvement projects are best conducted as a team exercise. The people in your work-group are the best

people to understand quality issues affecting their everyday work life. Form a small team of interested people,

have a discussion on the variety of issues affecting your work and start swapping ideas on how to improve

things.

Before commencing a quality improvement project, staff members are encouraged to read through the ADRI

users guide below:-

Stage 1 - Approach

What the user should do and what questions to

ask

Useful information

1. What are the objectives of the organisation and how The AMC Strategic Plan contains the organisations'

will my quality improvement project assist with

mission, vision, goals, strategies and KPis. This will

achieving those objectives?

help you identify those projects which have the

greatest value to the organisation.

2. Are these objectives well established and accepted

by all stakeholders?

Confidential

Measuring and Managing Maintenance

The objectives in the AMC Corporate Plan should be

widely disseminated and reflected in other plans such

as Faculty Plans and polides in the Document Library.

This will help you assess the suitability of existing KPis

and whether new KPis are needed.

Page 106

3. Define the problem you are trying to resolve or the

process you are trying to improve. Is the resolution of

this problem in line with the organisations' objectives?

As above

4. Briefly define the current situation using readily

available data to establish a "base-line"

A quick review of existing KPI's will often assist you in

"setting the picture" so you can readily see

opportunities for improvement.

5. Sketch out a plan for your quality improvement

project and discuss it with others.

The Management & Projects Analyst can advise you on

planning your project and point you towards other

data sources or other people in the organisation with

similar interests. The Quality Enhancement Committee

(QEC) and its associated working parties may be able

to offer some valuable advice or support.

Stage 2 - Deployment

What the user should do and what questions to

ask

Useful information

1. How am I going to put my quality improvement

project into action?

The document AMC Principles and Approaches to

Quality & Improvement will give you some guidelines

on how to pia A a project. Likewise the Management &

Projects Analyst can also give you some advice.

2. Who will work on this project and are they suitably

trained? Do I need additional resources?

If you need assistance resourcing your project you can

approach your Program or Faculty Head and brief

them about the value of your idea. Alternatively the

QEC through the Management and Projects Analyst

can also give you some advice on suitable training

courses or resource availability.

3. What additional data will I need to measure the

success of my project?

Before deploying any plan it is wise to first think of

how you are going to measure the impact of your

initiative. You may be able to use existing KPI's or you

may need to develop entirely new measures. The

Management and Projects Analyst can give you some

direction on this topic.

4 . Analyse the data and identify some possible

solutions.

This part relies heavily on team-work. Use the

available data to brainstorm possible solutions in your

work-group. This may require gathering new data and

undertaking some root-cause analysis, or it may

involve some simple discussions. The greater the

number of ideas - the better. You may also choose to

get advise from someone outside your work-group - a

fresh set of eyes will often see different solutions.

5. Set a target and implement your quality

improvement plan.

Use the available data to set a challenging but realistic

target for your project. This may involve some

benchmarking to see how well we perform against

other like-organisations. Implement the plan.

Stage 3 - Results

What the user should do and what questions to

ask

Useful information

1. What are the results from implementing this plan?

Monitor the progress of your project by collecting data

(eg KPI's) that you had earlier decided would be a

suitable measure of success. Plot these data on a

time-series graph so you can see the improvement.

Benchmark the data against those of other

organisations.

Confidential

Measuring and Managing Maintenance

Page 107

2. Do I understand how these results were achieved?

Are the targets achievable?

The graphing of a measurable improvement over time

is a good way to show that your project has worked.

In turn this shows that you have accurately

understood the problem, defined that the project is

relevant to the organisations' strategic objectives and

implemented an effective improvement strategy. If

you have been successful, then your improvement

initiative will be repeatable and you can modify your

project to attain a realistic target.

Stage 4- Improvement

What the user should do and what questions to

ask

Useful information

1. How can I review this improvement project? How

can the results be further improved?

Ongoing monitoring of the results of your project and

further discussion of the results amongst your workgroup may produce ideas as to how you can further

improve the process or outcomes. You may also

choose to look further afield for opinions or undertake

further benchmarking to see how other institutions

perform. When you have developed a new strategy to

improve the outcomes of your project, or decide to

undertake a new project, it is time to start the ADRI

cycle again.

2. How can the rest of the organisation learn from this

quality improvement project.

If you have successfully completed the ADRI cycle and

have achieved the desired improvement, share your

findings with other work groups in the organisation.

This may be through informal discussion and staff

meetings or a formal presentation or briefing paper.

Other work-groups will be interested to hear of your

work and they may be able to apply a similar plan to

improve their areas of responsibility. The QEC and the

Management & Projects Analyst will be keen to hear of

the progress and outcomes of your project.

Quality is often described as the degree to which a set of inherent characteristics fulfils requirements. Therefore

attaining quality is the first step in the cycle.

Continuous Improvement is described as recurring activity to increase the ability to fulfillment of

requirements. Consequently improvement is the second step in the cycle.

Confidential

Measuring and Managing Maintenance

Page 108