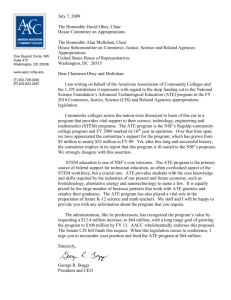

ATE Centers

advertisement