R - Harvard University

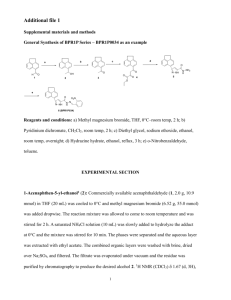

advertisement