LEARNING AT WORK IN TRADITIONAL MANUFACTURING

advertisement

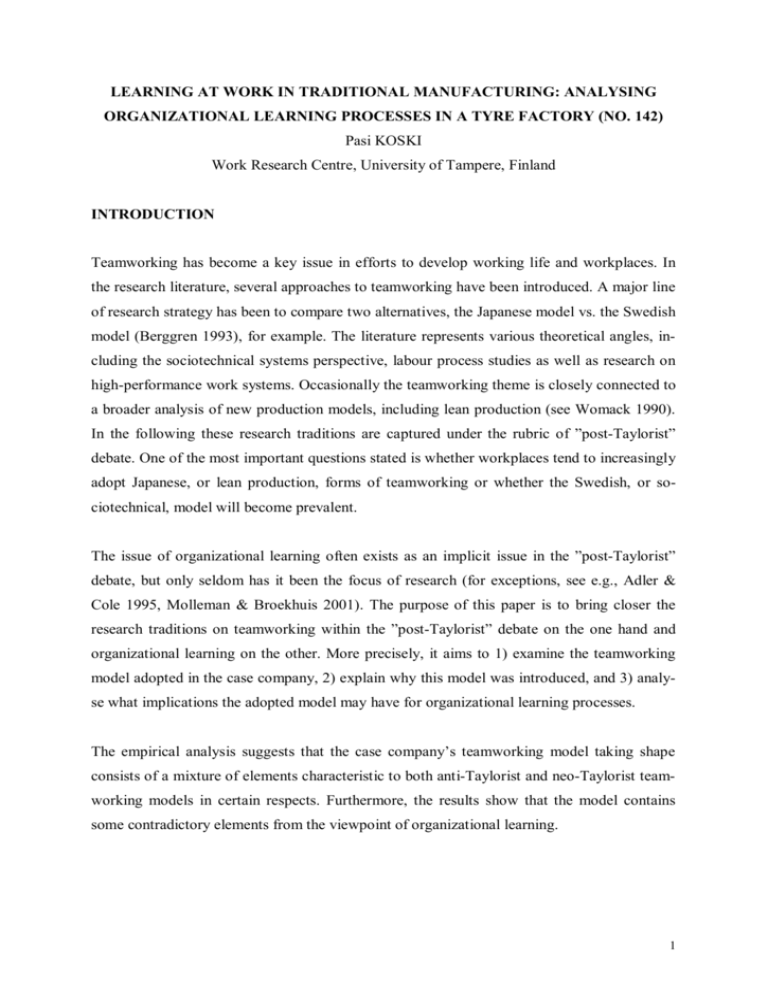

LEARNING AT WORK IN TRADITIONAL MANUFACTURING: ANALYSING ORGANIZATIONAL LEARNING PROCESSES IN A TYRE FACTORY (NO. 142) Pasi KOSKI Work Research Centre, University of Tampere, Finland INTRODUCTION Teamworking has become a key issue in efforts to develop working life and workplaces. In the research literature, several approaches to teamworking have been introduced. A major line of research strategy has been to compare two alternatives, the Japanese model vs. the Swedish model (Berggren 1993), for example. The literature represents various theoretical angles, including the sociotechnical systems perspective, labour process studies as well as research on high-performance work systems. Occasionally the teamworking theme is closely connected to a broader analysis of new production models, including lean production (see Womack 1990). In the following these research traditions are captured under the rubric of ”post-Taylorist” debate. One of the most important questions stated is whether workplaces tend to increasingly adopt Japanese, or lean production, forms of teamworking or whether the Swedish, or sociotechnical, model will become prevalent. The issue of organizational learning often exists as an implicit issue in the ”post-Taylorist” debate, but only seldom has it been the focus of research (for exceptions, see e.g., Adler & Cole 1995, Molleman & Broekhuis 2001). The purpose of this paper is to bring closer the research traditions on teamworking within the ”post-Taylorist” debate on the one hand and organizational learning on the other. More precisely, it aims to 1) examine the teamworking model adopted in the case company, 2) explain why this model was introduced, and 3) analyse what implications the adopted model may have for organizational learning processes. The empirical analysis suggests that the case company’s teamworking model taking shape consists of a mixture of elements characteristic to both anti-Taylorist and neo-Taylorist teamworking models in certain respects. Furthermore, the results show that the model contains some contradictory elements from the viewpoint of organizational learning. 1 RESEARCH METHODS The research material was collected during a two-year development programme implemented in the case company in 2000-2002. The sources of research material were observation, interviews, questionnaires, memos, other written documents and reports as well as economic and production-related performance indicators. MODELS OF TEAMWORKING Research work on teamworking has produced various dichotomical teamworking models that resemble each other to a great degree. To mention some examples, these include Japanese – Swedish (Berggren 1993), Scandinavian–Toyota/lean production (Fröhlich and Pekruhl (1996), structurally conservative–structurally innovative (Schumann 1998), sociotechnical– lean production (Niepce & Molleman 1998), and finally, anti-Taylorist–neo-Taylorist (Pruijt 2003) teamworking (or job design) models. As Pruijt (2003) argues, most of these dichotomies have been constructed against the backdrop of Taylorism – expicitly or implicitly. Thus, the focus has been on such questions as to whether teamworking brings with it some integration of planning and execution and whether the workers will have more autonomy to decide when they work and what working methods they use. Depending on the respective approach, researchers have nevertheless arrived at somewhat divergent conclusions. Classical Taylorism as a starting point, and drawing on a number of case studies, Pruijt (2003) produces a framework juxtapositing two alternative teamworking models, anti-Tayloristic and neo-Tayloristic models (see Table 1). Although Pruijt’s original focus is primarily on the autonomy and intensification of work dimensions of teamworking, the framework serves as an analytical instrument in articulating a few central teamworking dimensions from the learning perspective as well. This is because autonomy is considered to be a central prerequisite for organizational learning to occur (Nonaka & Takeuchi 1995). Here this framework is supplemented with two elements crucial to learning processes: 1) the role of feedback information and 2) the openness of team boundaries. According to Niepce & Molleman (1998), the lean 2 production team (neo-Taylorist) and the sociotechnical team (anti-Taylorist) also differ remarkably in these respects. Table 1. Classical Taylorism vs. Anti-Tayloristic and Neo-Tayloristic Teamworking. Source: Adapted from Pruijt 2003 and Niepce & Molleman 1998. Classical Taylorism Technical and logis- Technical discipline, tical context e.g. short-cycled work on the assembly line. Division of labour Relatively strict. Supervision No integration of production and management at all. Decision-making Managers decide. Standardization Power balance Relentlessly pursued. Conflicts and games. Wage system The variable part of the wage is in a predictable, bureaucratically regulated way related to performance. Team boundaries Feedback information Anti-Tayloristic Teamworking Tendency to alleviate technical discipline, e.g. to find alternatives for the assembly line. Buffers. Less strict. Jobs larger, less demarcation. No supervisor inside team. Some management functions distributed among team members. All team members can participate in decisionmaking. Not relentlessly pursued. Management accepts some measure of worker control. Pay on the basis of proven skill level. No group bonuses. Neo-Tayloristic Teamworking Technical discipline, e.g. short-cycled work on the assembly line is not seen as a problem. No buffers. Less strict. Jobs larger, less demarcation. Supervisor present in team as team leader. At most, only team leader can participate in decisionmaking. Relentlessly pursued. Nearly unlimited management prerogatives. Individual bonuses based on assessments how deeply a worker cooperates in the system. Group bonuses Stresses team boundaries. Stresses organization as a whole. Enhances autonomy. Aims at transparency, used for control. ORGANIZATIONAL LEARNING As Bontis & Crossan and Hulland (2002) note, research on organizational learning has a legacy that spans over 30 years, with more recent exponential growth. A number of approaches and perspectives have been introduced within various disciplines. Because of the somewhat exploratory nature of this paper, the definition of organizational learning or learning at work is left rather open. The concept of organizational learning is interpreted to comprise such features as the creation, diffusion and using of information on different organizational levels (individual, team, organization). The information processed may be explicit or implicit, indivi- 3 dual or collective. Indicators of learning include individual workers’ new knowledge and skills as well as new modes of operation of teams and of the whole organization. Instead of the actual learning processes, emphasis is rather on illustrating the learning potential inherent in the teamworking model adopted in the case company. THE COMPANY The company develops and manufactures summer and winter tyres for cars and bicycles as well as tyres for a range of heavy machinery. The company's product development, administration and marketing functions as well as the majority of production are located in a single facility in Finland. In 2001, the company booked a net sales of EUR 423.4 million and employed some 2,664 people. Its passenger car production unit – the site of the research project employs more than seven hundred people working in 55 production teams and produces more than 5 million tyres per year. Teamworking was first introduced in 1994 as a pilot project and it was extended to the whole organization in 1997 and 1998. However, recent discussions among management to prepare further improvement stages revealed several major shortcomings in the teamworking practices. These included, for example, unclear areas of responsibility, teams’ heteregenous modes of operation, team-internal tensions, lack of sufficient commitment to teamworking and an undefined task repertoire of team leaders. Furthermore, the factory’s new customer-oriented business strategy challenged its traditionally functional organizational structure. Instead of this traditional structure, there was a need for a process-based organization, whose focus is on the end product and in which a smooth flow of materials and components along the production chain exists. In 2000, as a result of the need for renewal, the company launched a new development programme aiming at fostering teamworking and increasing co-operation between production stages and departments. For the first time development activities were carried out in crosssectional improvement groups. 4 The teamworking model of the case company In the following the above-presented framework (Table 1) is exploited to assess the various aspects of the teamworking model introduced in the production site. The analysis is relative in nature, which means that there exists heterogenous practices among the teams. Technological and logistical context. The tyre manufacturing process consist of the following phases: compound mixing, component manufacturing, tyre building, curing and finally inspection. Basically this process can be characterized as a pull system, in which the bottleneck stage of the process (curing) orders materials it needs from the preceding production stage, which again orders the materials required from the preceding stage. Buffer stocks exist to keep the bottleneck stage loaded. Division of labour. The skills of workers are highly specialized and fragmented, and closely related to the running and maintaining of a certain machine. In certain teams job rotation is in regular use, whereas in some teams operators run their ”own” machines from year after year. The principle is that the application of job rotation lies at each team’s own discretion. Attempts towars job enlargening horizontally or vertically have been rare so far, although management increasingly encourages the workers to become multiskilled. Concerning the separation between direct production tasks and other functions, the suggestion system of the factory represents a striking exception. The number of improvement initiatives made yearly by the workers have exceeded 13 000 from 1995 onwards. Another, an even more important observation worth mentioning is that forums for continuous improvement are increasingly being established. For example, in the development programme referred to here, several cross-sectional problem-solving groups were launched. Within the next few years the factory plans to establish improvement groups for different purposes. These include groups for immediate troubleshooting, long-term groups for facilitating the functioning of the production process, and information exhange networks for teamleaders. Supervision. First-level management and production is integrated in a way that teamleaders do production work as well. In most teams the leading position is held on a permanent basis but there are also teams with rotating team leadership. Workers themselves take responsibility 5 for choosing the leader. Apart from the leader position, there is no other organized way involving more than one team member in managerial activities. Decision-making. The team leader is provided with the authority to organize daily working arrangements and to represent the team as a spokesperson in team-external relations. In contrast to traditional supervisors, the relationship between team members and the team leader is one of negotiation and commitment. Other practices to involve team in decision making include team meetings in order to foster mutual coordination and to solve operational as well as social problems. However, in practice, team meeting arrangements vary a lot in their regularity, for example. Standardization. Standardization refers to the degree of autonomy of the workers to perform tasks according to their own knowledge and experience. In the case company day-to-day working is basically connected to the running of machines. The operators are tightly bound to their working stations, which for them means minimal opportunities to walk around and communicate, for example. Also, because of fixed operation of machines, workers’ possibilities to choose their working methods or to make experimentations appear to be few. Power balance. From the late 1990s the idea of teams as self-organising units has guided the development activities of the production unit. At least in principle, teams are allowed to work autonomously within the limits of production targets and by following the general rules of the workplace. Intervention from management takes place only when serious problems in quality or in the flow of process occur or the teams themselves ask for help. Power balance is supported by the participative industrial relations system, which means, for example, that each major development effort is carefully negotiated in advance with industrial relations partners’ representatives within the factory. Wage system. Aligned with the introduction of teamworking, there has taken place an extending shift from the traditional piece-rate system to collective wage systems. The collective wage normally consists of 1) a fixed part based on how demanding the work is; 2) a changing part based on the results produced by the department or team; and 3) an individually determined fixed part, which takes into consideration the experience and skills of the person working in the team in question. 6 Feedback information. In team meetings workers receive information on the production parameters. The role of this feedback is firstly to inform workers of the extent to which their performance deviates from fixed criteria and secondly to give them a possibility to monitor the effectiveness of their working efforts and thus to suggest corrections. However, getting any major corrections done is a demanding task because of the relatively highly standardized and interconnected production process. Team boundaries. In the absence of foremen, teams have become somewhat inwardly oriented. Information flow between teams, sections and departments is considered to be one of the most difficult problems in the production process. However, as mentioned earlier, improving communication among teams is a core issue in the factory’s future development efforts. Implications for organizational learning The teamworking model of the case company seems to include elements that both hinder and further learning processes. The strict vertical and horizontal division of labour, technical discipline with machine-paced work and with restrictions on the freedom of movement and communication as well as the authoritarive position of the team leader do not offer many individual, team or organizational learning opportunities. On the other hand, the model adopted contains elements that promote learning processes. The workers’ involvement in immediate problem-solving and long-term continuous improvement activities lay a promising basis for cumulative learning processes. Furthermore, training sessions for teams enable them to understand the process as a whole and cross-team meetings aim at mutual adjustment, which gives the workers involved opportunities to create shared meanings. Pay on the basis of skill improvement is also an important element in enhancing individual learning. From the learning perspective, the prospective breaking of team boundaries is twofold. On the one hand, strict team boundaries decrease interdependence between teams and contributes to their autonomous decision-making processes. This may facilitate teams’ ability to organize among other things their daily working practices, information channels and training activities in a way that supports skills formation and learning processes within a team. On the other hand, high boundaries make it difficult to communicate across boundaries thus inhibiting 7 flows of information. The result is that the production process as a whole remains unknown for workers and new ways of operations invented in teams will not spread to other teams (Niepce & Molleman 1998). From the learning perspective, standardization may be regarded as an another contradictory factor. It inhibits the possibilities to change working methods and make experimentations and thus restrains learning and innovation. Contrary to this, Adler and Cole (1995) maintain that standardization is essential for organizational learning because it captures best practices and facilitates the diffusion of improvement ideas throughout the organization. CONCLUSIONS This paper has provided an analysis of the introduction of teamworking and its implications for organizational learning processes. The aim of the paper was to 1) examine the emerging teamworking model in the case company, 2) explain why this model was introduced and 3) analyse what implications the model had for organizational learning processes. The research material was collected during a two-year development programme in the case company. The results showed that the teamworking model introduced in the case company was characterized by both anti-Taylorist and neo-Taylorist models. The latter is indicated by such elements as a relatively strict division of labour, a strong position of the team leader, the pursuit to standardization, technical discipline and the need to cross team boundaries, whereas the teams’ decision-making procedures, power balance between management and workers as well as the wage system all represent the anti-Taylorist principles. At the present development stage the traditional organizational structure and production process accompanied by a participatory type of industrial relations provide the basis for the adopted mixed model. However, aspects closely related to the introduction of a new business strategy seeking customer orientation and better co-operation between production stages strongly determine the future development activities. The model adopted seemed to include elements that both hinder and further learning processes. The strict vertical and horizontal division on labour, technical discipline with machinepaced work and with restrictions for the freedom of movement and communication as well as 8 the authoritarive position of the team leader do not offer much individual, team or organizational learning opportunities. Instead, elements promoting organizational learning were the involvement of the workers in immediate problem-solving and long-term continuous improvement activities, training for workers to understand the process as well as pay on the basis of skills improvement DISCUSSION This case study has demonstrated that, from the standpoint of teamworking dichotomies, the generally prevailing model may be a mixture of anti-Taylorist and neo-Taylorist models. It is nevertheless justifiable to assume that within the mixed model there exists considerable intramodel variance. Thus, there is a need for empirical contributions to identify various mixed models as well as to explain reasons for adopting a certain model. In other words, the identification of different models is not sufficient to fully understand the prospective shift towards teamworking; the core question is the connection between the characteristics of teamworking model adopted and factors accounting it. One may expect that this to some extent questions the somewhat positive views on the possibilities to introduce organizational learning practices, since there may occur cases in which the preconditions or even the need for learning are missing. This holds true, for example for production sites that introduce teamworking but basically continue to operate according to the principles and strategies typical to mass production. This study has identified some ambivalent elements in the introduction of teamworking models from the standpoint of organizational learning. There may emerge situations in which the adopted model inhibits learning processes on the organizational level, while opening opportunities to learning processes within teams. On the conceptual level this refers to the possibility to identify several other contradictory factors not represented in the framework applied in this paper. Thus, it might be worthwhile to further elaborate research frameworks to identify the most essential factors and to analyse the mutual coherence of these factors. The study was exploratory in nature and aimed to bring closer the research traditions on teamworking within the ”post-Taylorist” debate, on the one hand, and organizational learning generally on the other. A useful line of research might be to create theoretically grounded analytical frameworks from the organizational learning perspective in terms of the sociotech9 nical systems tradition, for example. This refers to a need to create novel coherent research frameworks, in which different levels and actual processess of learning are explicitly examined in the context of various principles of teamworking on the workplace level. References Adler, P.S. & Cole, R.E. (1995), ”Designed for Learning: A Tale of Two Auto Plants”, pp. 157-177, in A. Sandberg (ed.) Enriching Production: Perspective on Volvo’s Uddevalla Plan as an Alternative to Lean Production, Aldershot, Avebury. Berggren, C. (1993), The Volvo experience. Alternatives to Lean Production in the Swedish Auto Industry, Macmillan, London. Bontis, N. & Crossan M. M. & Hulland, J. (2002), ”Managing an Organizational Learning System by Aligning Stocks and Flows, Journal of Management Studies, Vol. 39, No 4, pp. 437–469. Fröhlich, D. & Pekruhl, U. (1996), Direct Participation and Organisational Change: Fashionable But Misunderstood? European Foundation for the Improvement of Living and Working Conditions, Dublin. Molleman, E. & Broekhuis, M. (2001), ”Sociotechnical systems: towards an organizational learning approach”, Journal of Engineering and Technology Management, Vol 18, pp. 271– 294. Niepce, W. & Molleman, E. (1998), ”Work design issues in Lean Production from a Sociotechnical Systems Perspective: Neo-Taylorism or the Next Step in Sociotechnical Design”. Human Relations, Vol. 51, No. 3, pp.259–287. Nonaka, I. & Takeuchi, H. (1995), The Knowledge-Creating Company. How Japanese Companies Create the Dynamics of Innovation, Oxford University Press, New York and Oxford. Pruijt, H. (2003), ”Teams between Neo-Taylorism and Anti-Taylorism”, Economic and Industrial Democracy, Vol. 24, No 1, pp. 77–101. Schumann, M. (1998): New Concepts of Production and Productivity. Economic and Industrial Democracy, 19 (1), 17–32. Womack, J. P. & Jones, D. T. (1990), The Machine that Changed the World, Macmillan, New York. 10