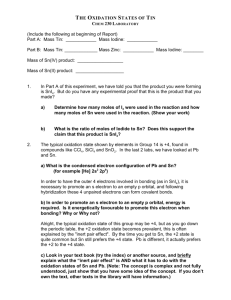

Multiple Oxidation States

advertisement

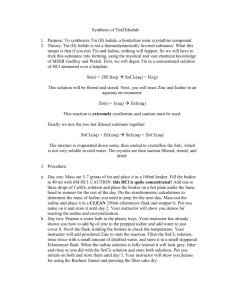

EXPERIMENT 1 Multiple Oxidation States Objective To prepare and isolate tin (IV) and tin (II) iodide. The products will be characterized by FTIR and solubility tests. Introduction Many of the non-metal main group elements, like the transition metals, exhibit multiple oxidation states. Also there is a trend toward the stability of lower oxidation states for elements moving down the group ( the primary oxidation state decreased by two). For example for the Group 14 (IVA) elements we find that carbon, silicon, and germanium are nearly always found in the IV oxidation state. Tin is equally found in either the II or IVoxidation state, whereas lead is most often found in the II oxidation state, with the IV state being fairly unstable. The trend can be rationalized by considering the valence electron configuration of the elements with respect to oxidation states. Oxidation state II: Oxidation state IV: Oxidation state II is achieved if the element retains its expected, neutral, valance electron configuration. To achieve oxidation state IV a valence electron of the neutral element must be promoted from the ns orbital to the np orbital. To decide which state is more stable, two considerations should be taken into account: 1) 2) The energy required to promote the electron (this becomes smaller and easier for elements further down the group since valence electrons are further from the nucleus). The energy gained through (or by) the bonds formed (this become smaller and decreases for elements further down the group since orbitals get bigger and, therefore, orbital overlap to form bonds becomes poorer). It is found that the cost of promoting an electron in Lead needs energy higher than the energy gained through the formation of two more bonds. The two electrons in the ns orbital, therefore, do not become involved in bonding and are known as an “inert pair” and the common oxidation state for Lead will be II. For carbon, silicon and germanium the energy gained by formation of two more bonds is larger than electron promotion, so IV is the common oxidation state. For tin, the cost and return must be equal magnitude such that both oxidation states have similar chances of occurring. In this experiment, you will synthesize tin(IV) and tin(II) iodide. Tin(IV) iodide is formed by heating metallic tin in the presence of iodine. Tin(II) iodide by reaction of metallic tin with concentrated hydrochloric acid, to first form tin(II) chloride, which then undergoes an ion exchange (metathesis) with a solution of zinc iodide. Experimental Procedure (Reactions should be run in a fume hood) A. Preparation of Tin(IV) Iodide (Stannic Iodide) 1) 2) 3) 4) In a 250 ml round bottom flask containing a boiling stone and equipped with a reflux condenser (see box to the right), add about 1.0 g (8.40 mmol) of tin followed by 2.0 g (7.87 mmol) of iodine. Add about 20-30 ml of ethyl acetate through the condenser. Gently, heat the flask and contents using a hot water bath until a mild reflux is maintained. This can be detected through a moderate dripping rate from the bottom of the condenser joint. Continue reflux until the solution turns transparent orange and there is no visible violet color of iodine vapor in the condenser throat (~30-40 min). 5) While hot, filtrate the mixture (leaving unreacted tin behind). If orange solid remains in the flask, add hot amount of ethyl acetate. Dissolve and add to the flask. 6) Place the filtrate in an ice path for about 10 minutes and then collect the orange –red crystals of tin(IV) iodide by suction filtration. 7) Wash the product with cold ethyl acetate and let dry on filter paper. Data Analysis 1) Calculate the percentage yield of the product, determine the melting point and test the solubility. 2) Collect the FTIR spectrum of the product. B. Preparation of Tin( II) Iodide (Stannous) SnCl2 1) Weigh 0.5 g (4.2 mmol) of granular tin into a small beaker. Add a small magnetic stir bar 2) Add 5-6 drops 0.1M CuSO4 solution. 3) Add about 2.0 ml of conc. HCl dropwise with a disposable pipette (no need to measure exactly). 4) Cover the beaker with a small watch glass and heat with slow stirring until it just boils (concentrated solution will boil somewhat above 100 °C). Bubbles of hydrogen gas will appear. Do not confuse gas evolution with boiling. This reaction takes a while. Get on with something else while it progresses. Check the reaction often. The volume will drop with evaporation; add drops of HCl if the volume drops more than 50%. If more than a few specks of tin metal remain, add a few more drops of HCl and heat at ~200°C a little longer. ZnI2 1) Weigh 0.30g (4.6 mmol) of zinc granules in a small beaker (10 mL if available). Add 3.0 mL deionized water and a stir bar. Begin slow stirring. 2) Add 1.00 g (3.9 mmol) of powdered iodine to the beaker. 3) Stir and heat slowly until the solution becomes a very pale yellow or clears altogether, but do not let it boil (water boils at 100 °C). 4) Filter into another small beaker or flask. Some zinc will be left over when the reaction is complete. This solid zinc must be completely removed from the solution before proceeding. Make sure that the filtered solution is perfectly clear! Repeat the filtration with a new filter pipette if necessary. SnI2 1) Slowly filter the hot SnCl2 solution through a filter pipette directly into the ZnI 2 solution so that addition proceeds dropwise. Orange crystals of SnI 2 should form immediately as the Sn(II) solution contacts the iodide solution. 2) Cool the beaker on an ice bath to complete precipitation. 3) Collect the orange crystals of product by vacuum filtration using a Hirsch funnel. Wash with a small amount of cold ethyl acetate and let dry on filter paper. 4) Collect in a weighed, labeled vial and record the final weight. Data Analysis 1) Calculate the percentage yield of the product, determine the melting point and test the solubility. 2) Collect the FTIR spectrum of the product.